Hill Helicopters HX50

To be fair, not all of those that invested are total morons.

Some of them are savvy business owners, others are pilots or engineers.

If I have to guess, some of them probably see the risks, but they think potential reward/s outweighs the risk.

Some of them are savvy business owners, others are pilots or engineers.

If I have to guess, some of them probably see the risks, but they think potential reward/s outweighs the risk.

Judging by Hargreaves posted the updated 4 days ago and looks like almost completed airframe in background, and I do wonder if manufacturing is taking place Not here in UK but in Canada .

cheers

cheers

And to build 500 a/c per annum, it will require 20 finishing bays working flat out of 50 weeks a year, if each owner has to do a 2 week self- build. Each bay will obviously need some engineers in

The following users liked this post:

I don't doubt something will get in the air by 2024. And when that happens tons more people will pile in with more investment/orders

Either way Jason Hill wins

Either way Jason Hill wins

Last edited by hargreaves99; 30th May 2023 at 13:24.

What a crazy story....

Crab, Sasless, other know what is required to design, build, test a brand new machine.

Anybody who has knowledge, experience in the helicopter industry understand what is required for a project like that.

It is amazing to see that you can drag so many people and make them believe what you want and it remind me what we have seen lately with some high profile stories in the financial world when millions were invested in "new project" who end up being a complete scam.

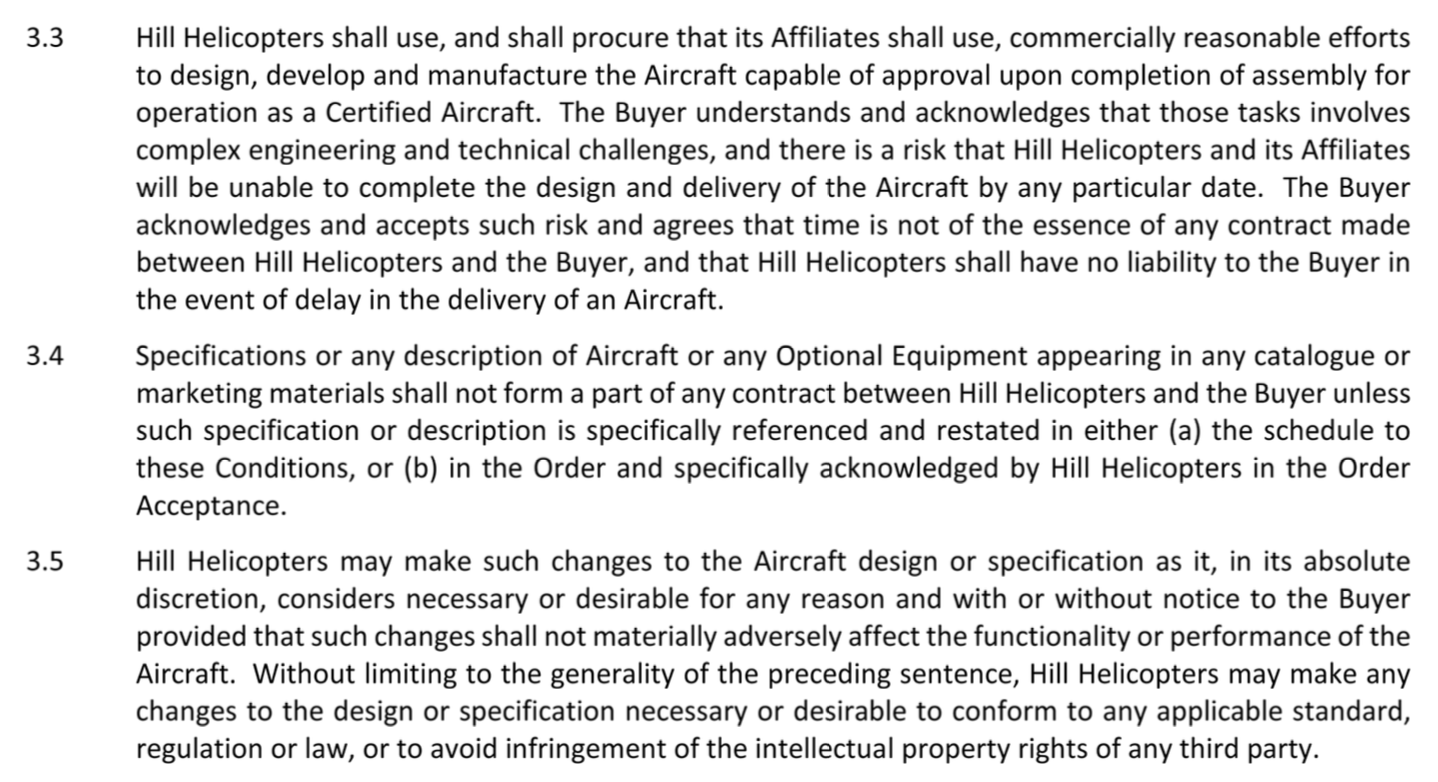

The bulk of those who decided to pre-order do not understand the enormous work and cost related to a project, who looks good on paper, but required so much time and money.

Of course, most of them do not understand or know what a company like this one can face in the coming months.

It is not a car that you can park on the side of the road....It is flying aircraft, with thousand of pieces moving around who have to be well deigned and tested to make sure you are safe.

This idea that you can make you own engine, because it will cheaper is probably the most scary one for the entire story.

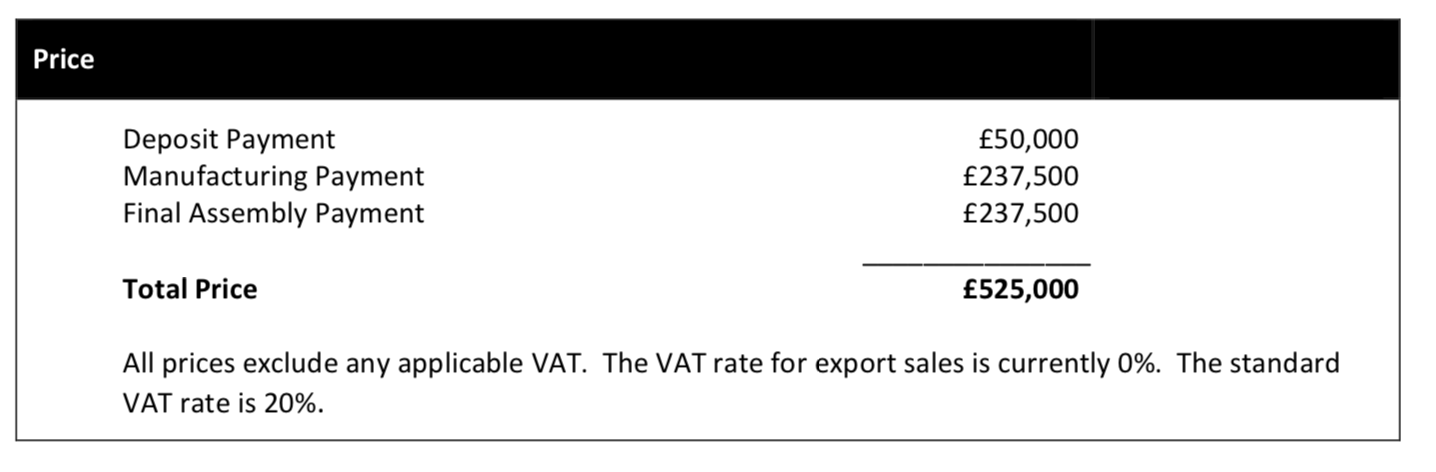

Using deposit money to start a project like that should be seen as a gigantic red flag, but, like in other stories when red flags were highly visible, it is ignored.

There is no way this machine will be delivered in 2024 and there is now way they will produce 500 a year....

How much money, outside those deposits, is available for test and development ???

What is the time frame for test flight and who will test the aircraft ??? (brave enough to do it...)

After flying so many years, there is one thing who still scare all of us, a major component failure.

It looks like all those people are not scared of anything...well, they should...

Crab, Sasless, other know what is required to design, build, test a brand new machine.

Anybody who has knowledge, experience in the helicopter industry understand what is required for a project like that.

It is amazing to see that you can drag so many people and make them believe what you want and it remind me what we have seen lately with some high profile stories in the financial world when millions were invested in "new project" who end up being a complete scam.

The bulk of those who decided to pre-order do not understand the enormous work and cost related to a project, who looks good on paper, but required so much time and money.

Of course, most of them do not understand or know what a company like this one can face in the coming months.

It is not a car that you can park on the side of the road....It is flying aircraft, with thousand of pieces moving around who have to be well deigned and tested to make sure you are safe.

This idea that you can make you own engine, because it will cheaper is probably the most scary one for the entire story.

Using deposit money to start a project like that should be seen as a gigantic red flag, but, like in other stories when red flags were highly visible, it is ignored.

There is no way this machine will be delivered in 2024 and there is now way they will produce 500 a year....

How much money, outside those deposits, is available for test and development ???

What is the time frame for test flight and who will test the aircraft ??? (brave enough to do it...)

After flying so many years, there is one thing who still scare all of us, a major component failure.

It looks like all those people are not scared of anything...well, they should...

From my past 45 years both in operations (flying and wrenching) and my long tenure with OEMs, leading 'entry into service' activities on a variety of airframe and engine developments, an old saying comes to mind concerning the HX50:

The less you know, the more you think you know and the more you know, the less you think you know.

Fly safe, Always

The following users liked this post:

Encyclo but you are stuck in the OEM way of thinking ! Remember being shown round Westlands on the EH 101 production line, it took one " engineer " over 4 hours to cable tie 2 m of loom to the aircraft !

The few early adopters that I know have a far more realistic viewpoint, which can only happen if you don’t have brown rings round your ankles.

The following users liked this post:

The idea that somehow OEM’s are bumbling and not utilizing latest technological “shortcuts” to make product more cost effectively or higher performing… it’s just another example of how Hill and it’s investors are over simplifying the challenges in developing and producing products. Westland is no longer a helicopter company and has not been state of the industry for 3 generations of design. To go from the cost effectiveness of 505 and R66 down to ~40% of the equivalent performing aircraft is just nonsense. Similarly ridiculous to imagine it will go faster and further… utter nonsense.

designing from a blank page will make that more exciting.

Have a go at reading the UKCAA CAPS - Start at 659 and go from there. Get back to us with the "gotcha's". Currently there may be a few.

Bellblade, I m sure they do but some of the costs OEM charge for putting paperwork on items is eye watering. Wasnt that long ago for instance i had 2 owners needing a new clutch on a 341. One was on the Bosnian register so clutch came from Bosnia around £ 8k. The other clutch for a G ref ac couldnt have a clutch overhauled in Bosnia, it came from your favourite helicopter manufacturer with a price tag of over £ 27 k opened the box and what a surprise the clutch came from the factory in Bosnia, nice work to just put a piece of paper on it. As owner of over 35 different helicopters over the years I could give you numerous examples of ridiculous pricing for parts that quite frankly are of **** quality and wouldn't pass basic quality control at any automotive manufacturer. ( before you ask my QM used to be a chief quality auditor at a large automotive company and was applied at the lack of quality control in our industry, eg HTC blades and a Tq inspection to stop the blades falling apart, 10 years later done nothing to change the process of blade manufacture, to cure the root cause. As my QM says that would not happen in automotive ) If Hill can bring sensible manufacturing to his machines and lets be frank he is not doing anything that radical, just bringing the best ideas from all sorts of industries he is onto a winner. Of course he will have problems , I would guess supply shortages of things like Titanium would be a killer at the moment.

Bellblade, I m sure they do but some of the costs OEM charge for putting paperwork on items is eye watering. Wasnt that long ago for instance i had 2 owners needing a new clutch on a 341. One was on the Bosnian register so clutch came from Bosnia around £ 8k. The other clutch for a G ref ac couldnt have a clutch overhauled in Bosnia, it came from your favourite helicopter manufacturer with a price tag of over £ 27 k opened the box and what a surprise the clutch came from the factory in Bosnia, nice work to just put a piece of paper on it. As owner of over 35 different helicopters over the years I could give you numerous examples of ridiculous pricing for parts that quite frankly are of **** quality and wouldn't pass basic quality control at any automotive manufacturer. ( before you ask my QM used to be a chief quality auditor at a large automotive company and was applied at the lack of quality control in our industry, eg HTC blades and a Tq inspection to stop the blades falling apart, 10 years later done nothing to change the process of blade manufacture, to cure the root cause. As my QM says that would not happen in automotive ) If Hill can bring sensible manufacturing to his machines and lets be frank he is not doing anything that radical, just bringing the best ideas from all sorts of industries he is onto a winner. Of course he will have problems , I would guess supply shortages of things like Titanium would be a killer at the moment.