Hill Helicopters HX50

18 months to go, no working engine, no planning permission, no factory, no working demonstrator, 673 people out of pocket - just a big bucket of bravado and self-belief to counter that lot.

Zero to 500 a year? Really?

Zero to 500 a year? Really?

Don't forget that anyone who has placed a deposit (about £40,000) needs to make the "Manufacturing payment" a year before the "projected delivery date". ie about £200,000. Then another £200,000 three months prior to the "projected delivery date".

And in a lesson from the CRAN school of economics that's almost all profit for Hill Helicopters, as the R&D was paid for by the depositors and the materials are all really cheap...

Here we go again! Brandolini’s Law striked again:

The amount of energy needed to refute bs is an order of magnitude bigger than that needed to produce it

In the latest AMA he didn’t promise a flying proto in December. He promised at least a fully finished ground model for the public event. The end of year flying proto assumes zero schedule slippage so it was very clear that would be a bonus, but I’m personally not expecting it.

Progress is incremental. Since last time:

- Tail section composite moulds done (in production techniques) & made one tail section.

- 5th main “monolage” composite structure made, now fully complete with foams, detail, surface finish, lightning mesh, b section pillars, metal inserts. I think 6th underway? Can’t remember.

- Tail ducted fan section now quite thicker. He said it’s 20% better performance than the thin original designs

- Lighting & nose cluster

- Digital cockpit moving to target hardware and some avionics control integrated

- Windscreen bonding trials, and coatings.

- Human machine interface trials (read: validating everything in correct location, and tweaking)

- Gears now all fully made. Some being sent off for testing

- Discussed how maintenance is done mostly accessible from top section of tail

- Engine most sections designs now finalised & frozen. Only one section remains and will be put out for manufacture soon.

- All of the main rotating engine parts have been made once proving it can be done (joins, details, finish, etc). Only production blades to go.

- Explained some detail on efficiency vs cycle life switching to a slotted disk design (fewer blades is less efficient but better life & failure modes), and they managed to get efficiency up 1%.

- Bearings now all made & tested. Explained why he makes his own (cost of “helicopter” tax).

- Explained engine test schedule plan

- Flight control rapid prototypes

- Production facility delayed again; reading between the line it looks like politics, and more red tape (noise & environmental stuff). He said he isn’t commenting publicly yet, but won’t be held up by this. Which means he has several backup options but it isn’t appropriate to comment which could prejudice PlanA. Seems sensible.

- Discussion on production engineer factory plans, timelines for training, producing spares inventory first, scaling etc.

- No details on rotor yet due IP on “clever packaging”, but looks like it’s being worked on.

- Some discussions on insurance. He will do at least the hull which he can make a lot cheaper than it costs us. Wants to make GA ownership affordable again.

It’s materialising before our eyes at a rate of knots. I believe some people will be eating their hats next year.

830 orders.

Yep non-refundable deposits are booked up as revenue. I’m not seeing why this is a problem. People like me put down $70k risk to secure a $300k discount. That’s a 400% return on what I see as really only a risk in delays, not the fundamental product. I’m happy to wait.

People who want zero risk will pay full price and have to wait 2-3+ years longer. I’m not seeing the issue here; it’s an individual decision. The data on progress is all public. It’s literally an “AMA” ask anything, and he answers everything including financials, timelines, risk, schedules, and current pain points. If you don’t like risk, then just wait. It’s not your money he’s spending. It’s ours, so not sure why the crabbiness (pun intended!)

The amount of energy needed to refute bs is an order of magnitude bigger than that needed to produce it

Progress is incremental. Since last time:

- Tail section composite moulds done (in production techniques) & made one tail section.

- 5th main “monolage” composite structure made, now fully complete with foams, detail, surface finish, lightning mesh, b section pillars, metal inserts. I think 6th underway? Can’t remember.

- Tail ducted fan section now quite thicker. He said it’s 20% better performance than the thin original designs

- Lighting & nose cluster

- Digital cockpit moving to target hardware and some avionics control integrated

- Windscreen bonding trials, and coatings.

- Human machine interface trials (read: validating everything in correct location, and tweaking)

- Gears now all fully made. Some being sent off for testing

- Discussed how maintenance is done mostly accessible from top section of tail

- Engine most sections designs now finalised & frozen. Only one section remains and will be put out for manufacture soon.

- All of the main rotating engine parts have been made once proving it can be done (joins, details, finish, etc). Only production blades to go.

- Explained some detail on efficiency vs cycle life switching to a slotted disk design (fewer blades is less efficient but better life & failure modes), and they managed to get efficiency up 1%.

- Bearings now all made & tested. Explained why he makes his own (cost of “helicopter” tax).

- Explained engine test schedule plan

- Flight control rapid prototypes

- Production facility delayed again; reading between the line it looks like politics, and more red tape (noise & environmental stuff). He said he isn’t commenting publicly yet, but won’t be held up by this. Which means he has several backup options but it isn’t appropriate to comment which could prejudice PlanA. Seems sensible.

- Discussion on production engineer factory plans, timelines for training, producing spares inventory first, scaling etc.

- No details on rotor yet due IP on “clever packaging”, but looks like it’s being worked on.

- Some discussions on insurance. He will do at least the hull which he can make a lot cheaper than it costs us. Wants to make GA ownership affordable again.

It’s materialising before our eyes at a rate of knots. I believe some people will be eating their hats next year.

830 orders.

Yep non-refundable deposits are booked up as revenue. I’m not seeing why this is a problem. People like me put down $70k risk to secure a $300k discount. That’s a 400% return on what I see as really only a risk in delays, not the fundamental product. I’m happy to wait.

People who want zero risk will pay full price and have to wait 2-3+ years longer. I’m not seeing the issue here; it’s an individual decision. The data on progress is all public. It’s literally an “AMA” ask anything, and he answers everything including financials, timelines, risk, schedules, and current pain points. If you don’t like risk, then just wait. It’s not your money he’s spending. It’s ours, so not sure why the crabbiness (pun intended!)

Shagpile - I am sure that something will eventually appear from Hill that will look like a helicopter and fly like a helicopter but whether or not it will perform to his claims and be any cheaper than competitors remains to be seen and not for some while either.

Robinson build 250-300 per year.

And they don't make the engines.

errr, he previously promised the engine running by "summer 2023" and a prototype flying by "end of 2023"

https://www.hillhelicopters.com/orders

And they don't make the engines.

"In the latest AMA he didn’t promise a flying proto in December"

https://www.hillhelicopters.com/orders

Last edited by hargreaves99; 28th May 2023 at 07:26.

It has already been stated that as soon as patent application is submited IP is set. So, are we sure this is about IP or there are some problems with developing new revolutionary rotor?

I'm all for clean sheet designs building on old knowledge so Im not trying to find faults. I just want to learn more about the design.

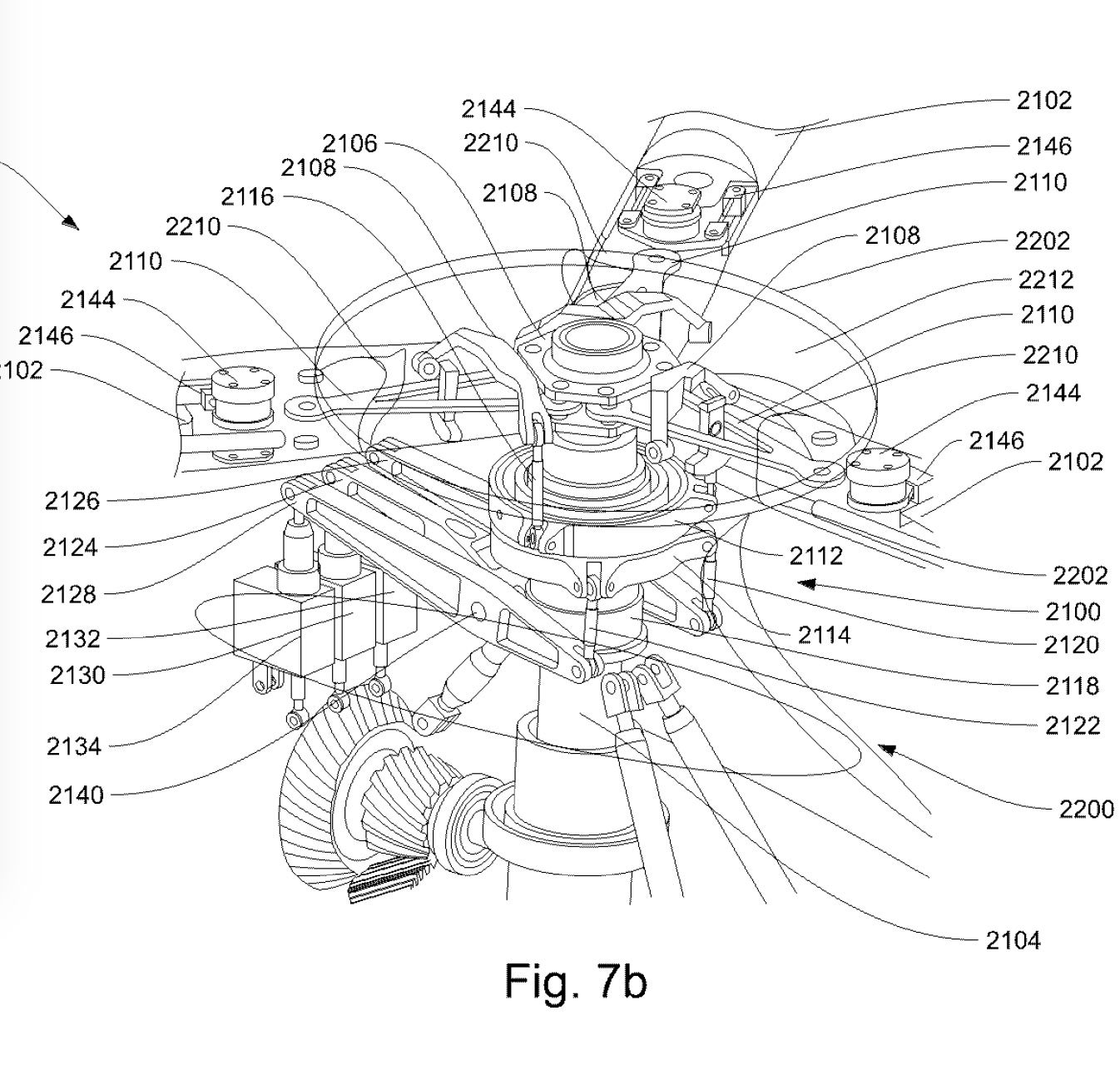

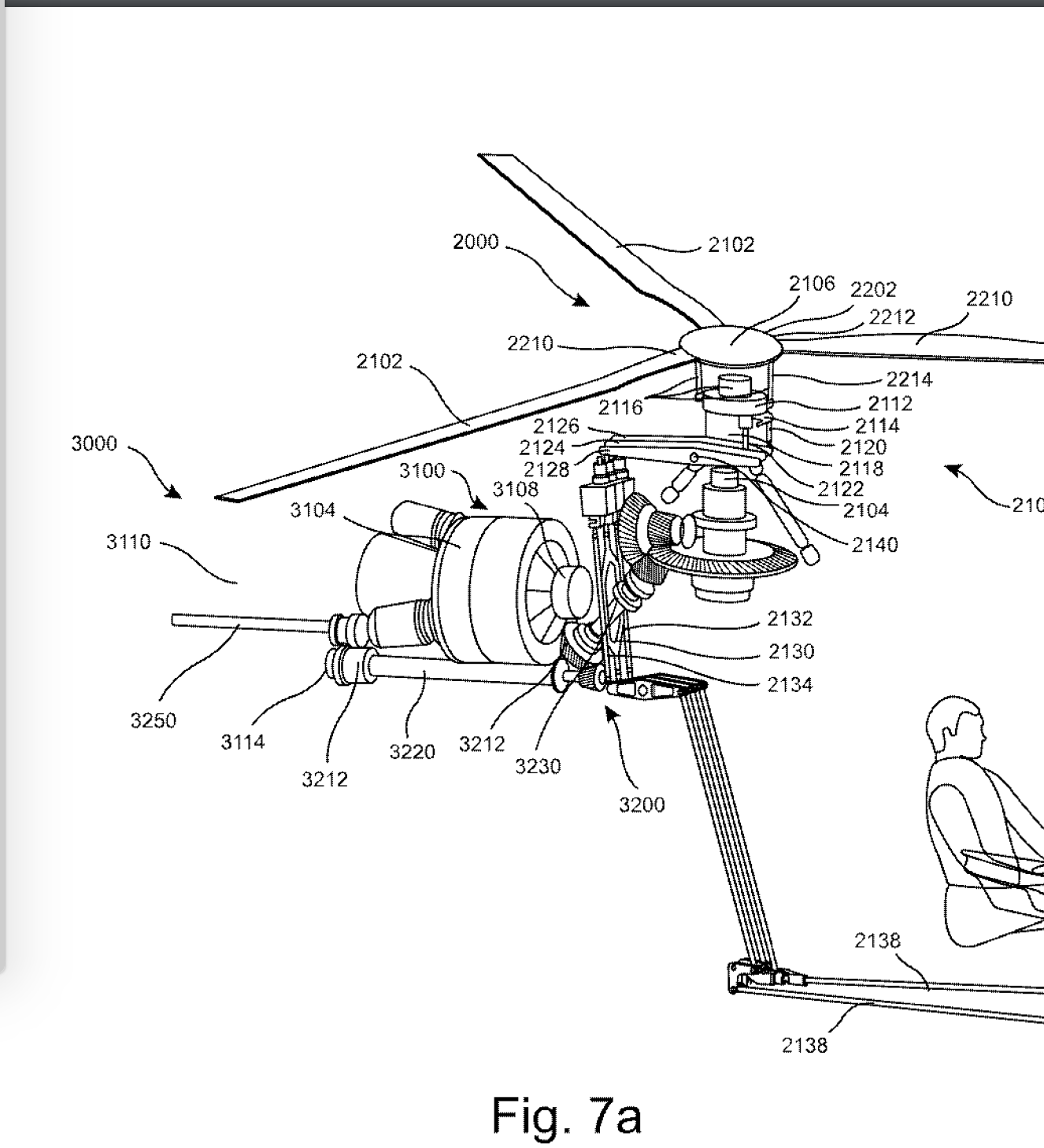

Looking at the patent application, I saw something on the diagram Fig.7a.

The center push tube splits into two paths and wraps around the engine input drive shaft before being connected to the servo.

Will there be some protection provided to the push tubes should the drive shaft split and flail about?

How is the fuselage held to the transmission and how are misalignments and expansion dealt with between the engine and transmission?

Looking at the patent application, I saw something on the diagram Fig.7a.

The center push tube splits into two paths and wraps around the engine input drive shaft before being connected to the servo.

Will there be some protection provided to the push tubes should the drive shaft split and flail about?

How is the fuselage held to the transmission and how are misalignments and expansion dealt with between the engine and transmission?

I'll admit I am not a prodigy regarding mechanics, but can someone explain what is so revolutionary about this rotor system?

It looks a lot what Airbus calls spheriflex rotor head?

It looks a lot what Airbus calls spheriflex rotor head?

Agile raises a good point.....were the drive shaft come adrift and start flailing about it does seem likely the flight control linkage could get Involved.

If you recall, a 139 had a similar problem (electrical and not mechanical as a cause) where an electrical fire compromised the Collective Linkage and caused a very serious flight control problem.

There are only so many ways to separate critical components and at times unintended consequences arise that remind us of that.

What Agile points out bears consideration.

If you recall, a 139 had a similar problem (electrical and not mechanical as a cause) where an electrical fire compromised the Collective Linkage and caused a very serious flight control problem.

There are only so many ways to separate critical components and at times unintended consequences arise that remind us of that.

What Agile points out bears consideration.

Join Date: Jun 2008

Location: Canada

Posts: 69

Likes: 0

Received 0 Likes

on

0 Posts

What a crazy story....

Crab, Sasless, other know what is required to design, build, test a brand new machine.

Anybody who has knowledge, experience in the helicopter industry understand what is required for a project like that.

It is amazing to see that you can drag so many people and make them believe what you want and it remind me what we have seen lately with some high profile stories in the financial world when millions were invested in "new project" who end up being a complete scam.

The bulk of those who decided to pre-order do not understand the enormous work and cost related to a project, who looks good on paper, but required so much time and money.

Of course, most of them do not understand or know what a company like this one can face in the coming months.

It is not a car that you can park on the side of the road....It is flying aircraft, with thousand of pieces moving around who have to be well deigned and tested to make sure you are safe.

This idea that you can make you own engine, because it will cheaper is probably the most scary one for the entire story.

Using deposit money to start a project like that should be seen as a gigantic red flag, but, like in other stories when red flags were highly visible, it is ignored.

There is no way this machine will be delivered in 2024 and there is now way they will produce 500 a year....

How much money, outside those deposits, is available for test and development ???

What is the time frame for test flight and who will test the aircraft ??? (brave enough to do it...)

After flying so many years, there is one thing who still scare all of us, a major component failure.

It looks like all those people are not scared of anything...well, they should...

Crab, Sasless, other know what is required to design, build, test a brand new machine.

Anybody who has knowledge, experience in the helicopter industry understand what is required for a project like that.

It is amazing to see that you can drag so many people and make them believe what you want and it remind me what we have seen lately with some high profile stories in the financial world when millions were invested in "new project" who end up being a complete scam.

The bulk of those who decided to pre-order do not understand the enormous work and cost related to a project, who looks good on paper, but required so much time and money.

Of course, most of them do not understand or know what a company like this one can face in the coming months.

It is not a car that you can park on the side of the road....It is flying aircraft, with thousand of pieces moving around who have to be well deigned and tested to make sure you are safe.

This idea that you can make you own engine, because it will cheaper is probably the most scary one for the entire story.

Using deposit money to start a project like that should be seen as a gigantic red flag, but, like in other stories when red flags were highly visible, it is ignored.

There is no way this machine will be delivered in 2024 and there is now way they will produce 500 a year....

How much money, outside those deposits, is available for test and development ???

What is the time frame for test flight and who will test the aircraft ??? (brave enough to do it...)

After flying so many years, there is one thing who still scare all of us, a major component failure.

It looks like all those people are not scared of anything...well, they should...