Alaska Airlines 737-900 MAX loses a door in-flight out of PDX

Even more significant was the air rush sucked the emergency SOP checklist out of the flight deck. Which presumably contained the CVR switch off command. The crew had to do it all from memory instead.

One day the CVR industry will come up with an ever so simple way to avoid this overwriting. Goodness knows how often it has occurred in incidents in the past. I know the requirement is to maintain the last 2 hours, but that didn't extend to any instruction to start overwriting at 2 hours and 1 minute.

One day the CVR industry will come up with an ever so simple way to avoid this overwriting. Goodness knows how often it has occurred in incidents in the past. I know the requirement is to maintain the last 2 hours, but that didn't extend to any instruction to start overwriting at 2 hours and 1 minute.

That's what really needs to stop.

Aircrew in the US are fortunate to work in a system where human error is almost never a criminal matter, but the flip side of that is that safety culture requires honest participation in fact finding, and of late, it hasn't been happening.

Join Date: Dec 2014

Location: Somerset

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

Follow on to my response to JamiaJoe above. I said there should not be significant loads on the quides, pins or upper lock-out bolts.

Unless of course, as I suggested yesterday, the stops were not correctly adjusted. This would put pressurisation loads on the guide / pin possibly resulting in low cycle fatique failure of the guide / pin/ bolt and loss of the plug.

I've seen no comment on this theory.

Unless of course, as I suggested yesterday, the stops were not correctly adjusted. This would put pressurisation loads on the guide / pin possibly resulting in low cycle fatique failure of the guide / pin/ bolt and loss of the plug.

I've seen no comment on this theory.

- the split pin was not present or fell out, the nut loosened and the bolt disengaged

- or

- the bolt was overtightened and damaged the guide track such that the engagement with the guide roller was not effective.

What am I seeing that looks like silver bolt heads on a properly installed one?

I think I’ve just cross posted with a similar question… so they are only locating pins??

So Dave, are you saying the stop fittings on the door, which go inside the stop pads and therefore take the outward pressure , do not have bolts through them once the plug door is located in position on the tracks ?

What am I seeing that looks like silver bolt heads on a properly installed one?

What am I seeing that looks like silver bolt heads on a properly installed one?

Join Date: Dec 2014

Location: Schiphol

Posts: 479

Likes: 0

Received 0 Likes

on

0 Posts

Some thoughts… and wondering…

Definitions are extremely important in aerospace (engineering, manufacturing, maintenance, and all their interactions over time). Not having your definitions right … costs money, costs time, and can kill (over time).

In one aircraft type a customer option type of pax door was called a drop-down door with an integral airstair, which required a specific (pressurisation) locking mechanism and motion. Another option was a pax door designed for connection to the usual terminal airbridges, that door had a horizontal opening and closing movement, and such, that when closed, cabin pressurisation pushed/held it closed, and therefore named a plug-in door.

So from that point of view the Boeing ‘panel’ (‘functionally’ speaking it is not a ‘door’, and not even a ‘hatch’) would not be called a plug-in but a drop-down.

Note that forgetting a bolt(s) in each case might move risk from airborne to ground.

Ever since the HS-748 postal flight door loss many years ago (preceded by many warning events), and subsequent cases over the years with doors, escapes, hatches, panels, skins … I am wondering about the gap between ‘aircraft structures rules’ and ‘25.1309 rules’ based design. (What if you design a ‘structures’ door like a 1309 ‘system’.)

From a program management level point of view doors are nice. Easy as an outsourcing package.

From a manufacturing point of view you would prefer the maker of the respective fuselage sections to also make the door. But in practice you should expect them to be delivered as components to your (one or more) fuselage section makers. You might prefer to deliver them to your section makers to guarantee a 2-way proper fit, and keep that structures work outside your final assembly line. Also doubles up as a (incl.weather) protection during transport of the section with doors to the final assembly line location. In a 737 case how are they put on the trains.

For practical and technical reasons after arrival in final assembly the doors will be (most likely) taken out, put in a special cart, and may well be mounted and dismounted more than once, and certainly opened and closed a few times, during final assembly stages. Wiring, isolating, interiors mounting, pressurisation testing, painting … these processes and their sequences influence this.

This means …a door or its substitute goes through various processes and may change in configuration/fitting/mounting during that time in production …

In this 737-MAX-9 case, what manufactured configuration was delivered from the assembly line is an important question. The more so if this (re low hours aircraft) substitute panel was never opened during operations and maintenance after delivery.

Boeing’s reputation on engineering and manufacturing process control, configuration control and standards of QA/QC has taken many hits. In this case you would expect the NTSB to also establish a specialist group in this investigation covering those subjects.

In one aircraft type a customer option type of pax door was called a drop-down door with an integral airstair, which required a specific (pressurisation) locking mechanism and motion. Another option was a pax door designed for connection to the usual terminal airbridges, that door had a horizontal opening and closing movement, and such, that when closed, cabin pressurisation pushed/held it closed, and therefore named a plug-in door.

So from that point of view the Boeing ‘panel’ (‘functionally’ speaking it is not a ‘door’, and not even a ‘hatch’) would not be called a plug-in but a drop-down.

Note that forgetting a bolt(s) in each case might move risk from airborne to ground.

Ever since the HS-748 postal flight door loss many years ago (preceded by many warning events), and subsequent cases over the years with doors, escapes, hatches, panels, skins … I am wondering about the gap between ‘aircraft structures rules’ and ‘25.1309 rules’ based design. (What if you design a ‘structures’ door like a 1309 ‘system’.)

From a program management level point of view doors are nice. Easy as an outsourcing package.

From a manufacturing point of view you would prefer the maker of the respective fuselage sections to also make the door. But in practice you should expect them to be delivered as components to your (one or more) fuselage section makers. You might prefer to deliver them to your section makers to guarantee a 2-way proper fit, and keep that structures work outside your final assembly line. Also doubles up as a (incl.weather) protection during transport of the section with doors to the final assembly line location. In a 737 case how are they put on the trains.

For practical and technical reasons after arrival in final assembly the doors will be (most likely) taken out, put in a special cart, and may well be mounted and dismounted more than once, and certainly opened and closed a few times, during final assembly stages. Wiring, isolating, interiors mounting, pressurisation testing, painting … these processes and their sequences influence this.

This means …a door or its substitute goes through various processes and may change in configuration/fitting/mounting during that time in production …

In this 737-MAX-9 case, what manufactured configuration was delivered from the assembly line is an important question. The more so if this (re low hours aircraft) substitute panel was never opened during operations and maintenance after delivery.

Boeing’s reputation on engineering and manufacturing process control, configuration control and standards of QA/QC has taken many hits. In this case you would expect the NTSB to also establish a specialist group in this investigation covering those subjects.

Wifi Antenna was installed by third party MRO just prior to pressurization warnings. Line of investigation continues to determine if MRO removed plug for instal of equipment

Isn't that exactly what led to the Paris DC-10 crash ? External indications appeared closed, but the mechanism, not modified to the updated drawing, was distorted underneath.

Join Date: Jan 2024

Location: UK

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

I think the proper name for the roller part is a Cam Follower and a Google search shows plenty of examples.

Last edited by DTA; 8th Jan 2024 at 11:47.

Join Date: Jul 2021

Location: FL95

Posts: 32

Likes: 0

Received 0 Likes

on

0 Posts

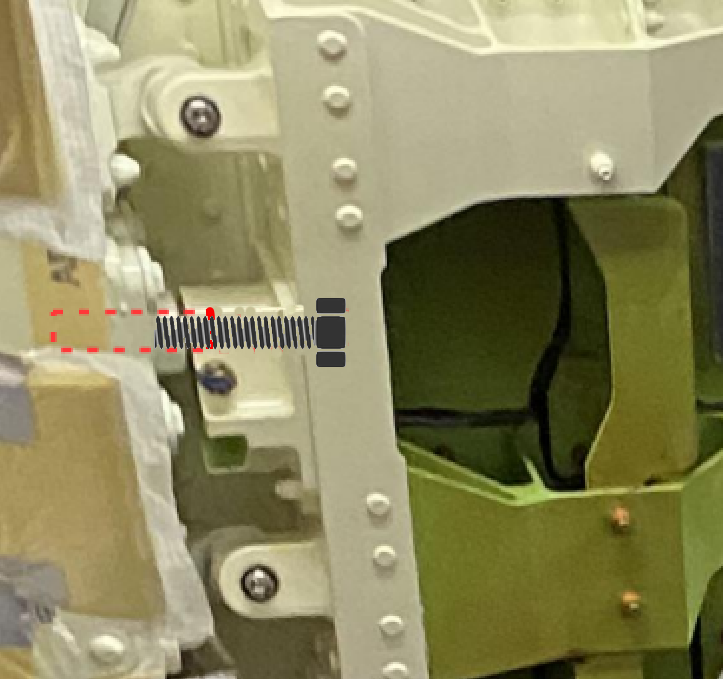

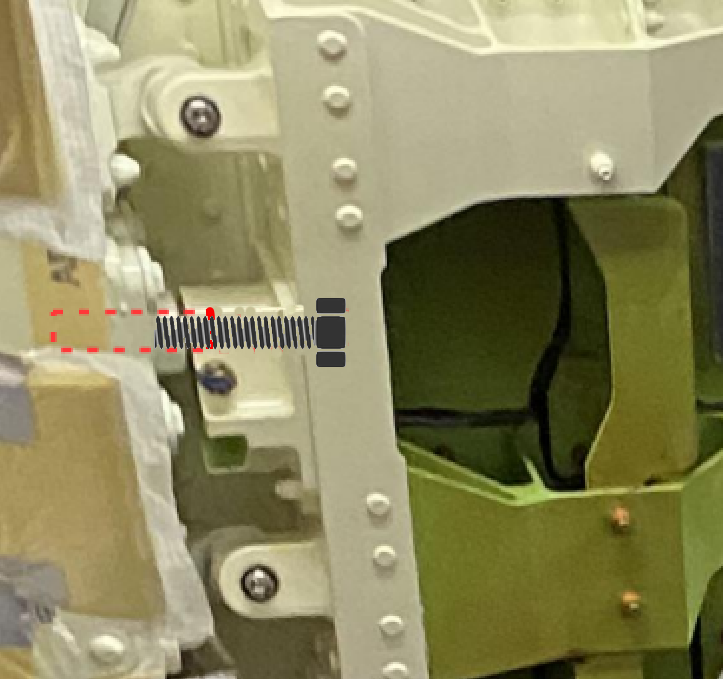

Here is what I see from an engineering viewpoint.

The first image shows the stub guide location and due to its length, guides the door up and out. This would be how it functions when the extra exit door is installed.

Where the stub guide would be

In the second photo taken from the incident aircraft, we can see the stub guide indicated by the red arrow,. The blue arrow shows it has a threaded hole in it and that is where we would expect to see a locking bolt for when a permanent plug door is in place.

Shows the stub guide in place on incident aircraft

The third image shows where and how I would see the locking bolt in situ if it were ever installed.

shown with locking bolt

,

To me it seems the locking bolts were never installed.

The first image shows the stub guide location and due to its length, guides the door up and out. This would be how it functions when the extra exit door is installed.

Where the stub guide would be

In the second photo taken from the incident aircraft, we can see the stub guide indicated by the red arrow,. The blue arrow shows it has a threaded hole in it and that is where we would expect to see a locking bolt for when a permanent plug door is in place.

Shows the stub guide in place on incident aircraft

The third image shows where and how I would see the locking bolt in situ if it were ever installed.

shown with locking bolt

,

To me it seems the locking bolts were never installed.

As said before this stub of the roller pin is rather short. I wonder if it is still blocked if wrong diameter locking bolts are used.

Even if the 4 locking bolts (with their slotted nuts and cotter pins/split pins) were missing, the lower hinge arms which are still attached to the floor bracket, have a double lock nut arrangement on the shaft end and large washer, allowing the semi plug to rise and hinge outwards, spring assist, as it is apparently designed to do; the exterior fuselage does not appear to have any buffet damage from the plug assembly which indicates to be at least that either the washer was not large enough to hold on the bracket structure and the shaft just pulled through; Or the double lock nuts and washer was not present. Accepted the lanyards are unlikely to offer little resistance to the cabin pressure acting on the large plug surface.

I do not have a good definition screen to zero in on the hinge fittings on the outside to see if there is just thread or nuts present, anyone?

I do not have a good definition screen to zero in on the hinge fittings on the outside to see if there is just thread or nuts present, anyone?

Join Date: Dec 2018

Location: Florida

Posts: 248

Likes: 0

Received 0 Likes

on

0 Posts

This particular aircraft apparently had the pressure warning light activate several times over the past week. I assume that this happens at altitude. Airline maintenance presumably looked into each episode of the warning light activation and at some point, a more thorough evaluation was planned. The decision was made to pull the aircraft off of ETOPS routes (Hawaii).

While it's not clear that these pressure light warning activations are related to the door plug "departure" from the aircraft, it does lead to some interesting operational decisions made by the carrier. They didn't trust sending the plane to Hawaii, but PDX to ONT was OK?

While it's not clear that these pressure light warning activations are related to the door plug "departure" from the aircraft, it does lead to some interesting operational decisions made by the carrier. They didn't trust sending the plane to Hawaii, but PDX to ONT was OK?

Join Date: Dec 2008

Location: PDX

Posts: 72

Likes: 0

Received 0 Likes

on

0 Posts

Can the panel be opened from outside?

Hello, I have read that this panel can be opened from outside. That must be wrong, correct?

To my comprehension, the interior paneling would need to be removed and fasteners removed from the panel before the "drop down" mechanism could be deployed.

To my comprehension, the interior paneling would need to be removed and fasteners removed from the panel before the "drop down" mechanism could be deployed.

Last edited by fotoguzzi; 8th Jan 2024 at 11:58. Reason: typo

Join Date: Jul 2021

Location: FL95

Posts: 32

Likes: 0

Received 0 Likes

on

0 Posts

It seems to me an odd arrangement that two cylindrical items are touching each other at right angles - the guide roller pin and the retaining bolt. Is this likely to cause wear if they move against each other? The retaining bolt looks a bit awkward to get in, towards you from a blind position, though that shouldn't lead to the mistake of not fitting it properly.

Join Date: Oct 2005

Location: uk

Posts: 141

Likes: 0

Received 0 Likes

on

0 Posts

There are two sorts of fatigue - low cycle and high cycle.

Low cycle fatigue is typically a material issue where the material strength is far below the requirement, such as from an improper heat treatment or incorrect alloy. It can also happen if the manufacturing process has left a fatigue initiator such as using a sharp corner end mill instead of a fillet end mill. Low cycle is found in the 5.0 -100 cycle range. This can be typified by flexing a paper clip. It is from a load near or above the yield strength.

High cycle fatigue is the more typical for manufactured goods. It is typified by a load that is far below the yield strength and is nearly independent of yield strength and can run from 100,000 cycles to well into the millions. If there is a manufacturing process problem it can be as simple as a surface texture that's a bit rougher or an internal inclusion of contamination.

At only 3 months - that is no bueno.

Low cycle fatigue is typically a material issue where the material strength is far below the requirement, such as from an improper heat treatment or incorrect alloy. It can also happen if the manufacturing process has left a fatigue initiator such as using a sharp corner end mill instead of a fillet end mill. Low cycle is found in the 5.0 -100 cycle range. This can be typified by flexing a paper clip. It is from a load near or above the yield strength.

High cycle fatigue is the more typical for manufactured goods. It is typified by a load that is far below the yield strength and is nearly independent of yield strength and can run from 100,000 cycles to well into the millions. If there is a manufacturing process problem it can be as simple as a surface texture that's a bit rougher or an internal inclusion of contamination.

At only 3 months - that is no bueno.

Join Date: Jan 2009

Location: Earth

Posts: 74

Likes: 0

Received 0 Likes

on

0 Posts

NTSB reports the flying door plug has been found in a school teacher’s backyard last night. Quite fortunate that it wasn’t found under a hole in a roof or in a schoolyard.

Amazingly, two mobile phones from the flight were also found.

https://www.reuters.com/business/aerospace-defense/no-data-captured-alaska-airlines-737-cockpit-voice-recorder-ntsb-chair-2024-01-08/

Amazingly, two mobile phones from the flight were also found.

https://www.reuters.com/business/aerospace-defense/no-data-captured-alaska-airlines-737-cockpit-voice-recorder-ntsb-chair-2024-01-08/