MAX’s Return Delayed by FAA Reevaluation of 737 Safety Procedures

Join Date: Mar 2019

Location: French Alps

Posts: 326

Likes: 0

Received 0 Likes

on

0 Posts

The Boeing idea of resorting to the runaway procedure is obviously from non-pilot engineers or executives with no knowledge of their own systems.

The considerable delay and test flight time it took them to discover how the system works and how to - not yet - fix it is an indication of the complication of the matter, and the negligence of Boeing and the FAA

Join Date: Jun 2019

Location: VA

Posts: 210

Likes: 0

Received 0 Likes

on

0 Posts

Here's a novel idea. I doubt it has been considered by too many people, including pilots on this forum:

If you experience low oil pressure you should follow the QRH procedures for low oil pressure. If you experience an engine failure at or after V1, you should follow the QRH procedures for engine failure after V1. If you experience a runway stab trim you should follow the QRH procedures for a runaway stab trim. And so on.

Pretty radical, isn't it?

Note that the MCAS failure presents itself as a runway stab trim so that would mean that, wait for it! You should follow the QRH procedures for runway stab trim! Amazing, yes?

If you experience low oil pressure you should follow the QRH procedures for low oil pressure. If you experience an engine failure at or after V1, you should follow the QRH procedures for engine failure after V1. If you experience a runway stab trim you should follow the QRH procedures for a runaway stab trim. And so on.

Pretty radical, isn't it?

Note that the MCAS failure presents itself as a runway stab trim so that would mean that, wait for it! You should follow the QRH procedures for runway stab trim! Amazing, yes?

Boof,

I’m going to disagree with you here, but probably not for the reasons you think. One of my ongoing concerns with the current state of pilot training and management is that there has been far too much emphasis on executing written procedures and strictly complying with company policies and far too little on basic aircraft management (with and without the automation) while maintaining a “big picture” of what is going on without necessarily looking it up in a manual. Training itself has become so compressed and scripted that there is little room for critical thinking. At some airlines, pilot discretion exists in name only. In some cases, training and operational management has adopted so much of a paint-by-numbers philosophy that some pilots are no longer able to color outside the lines.

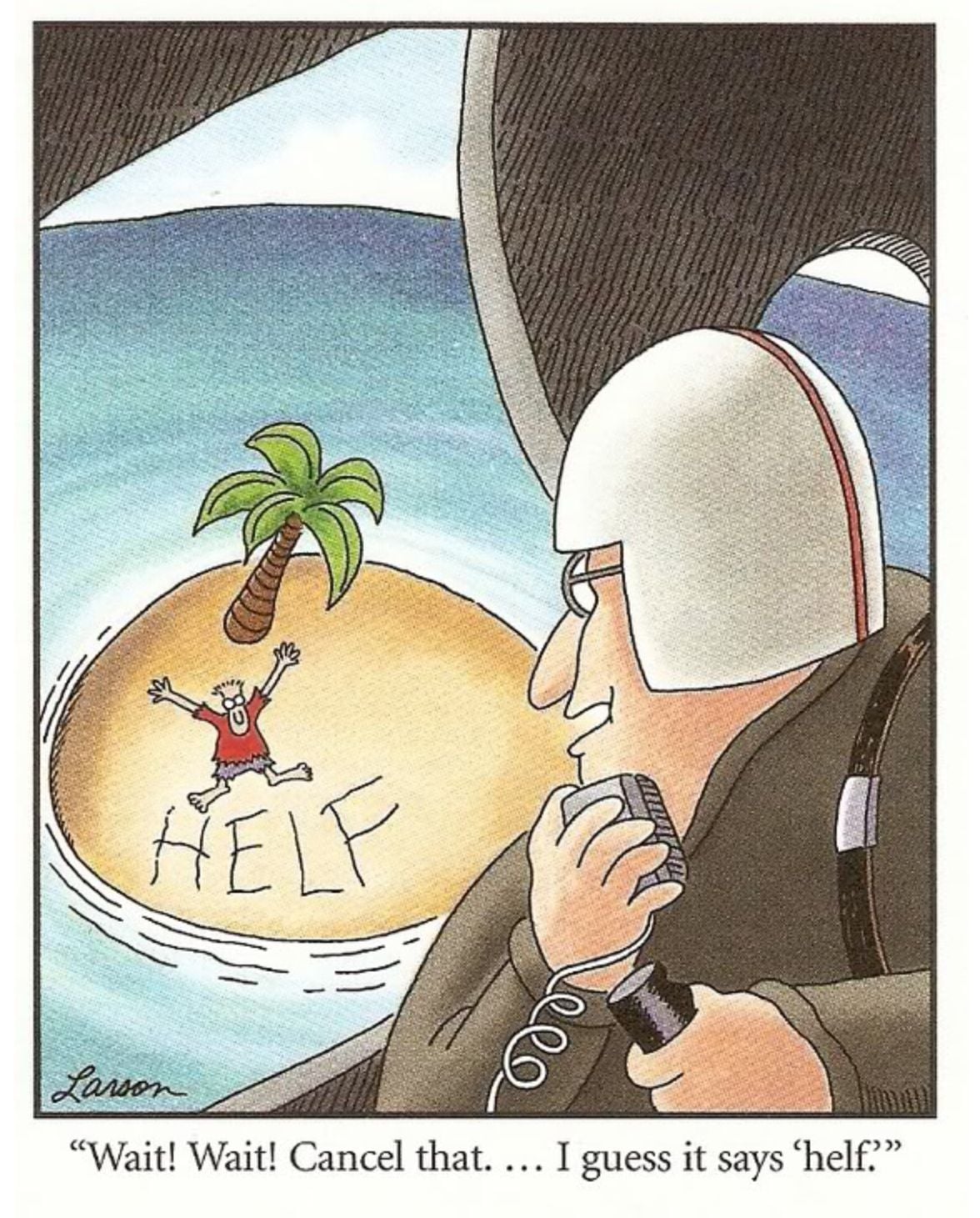

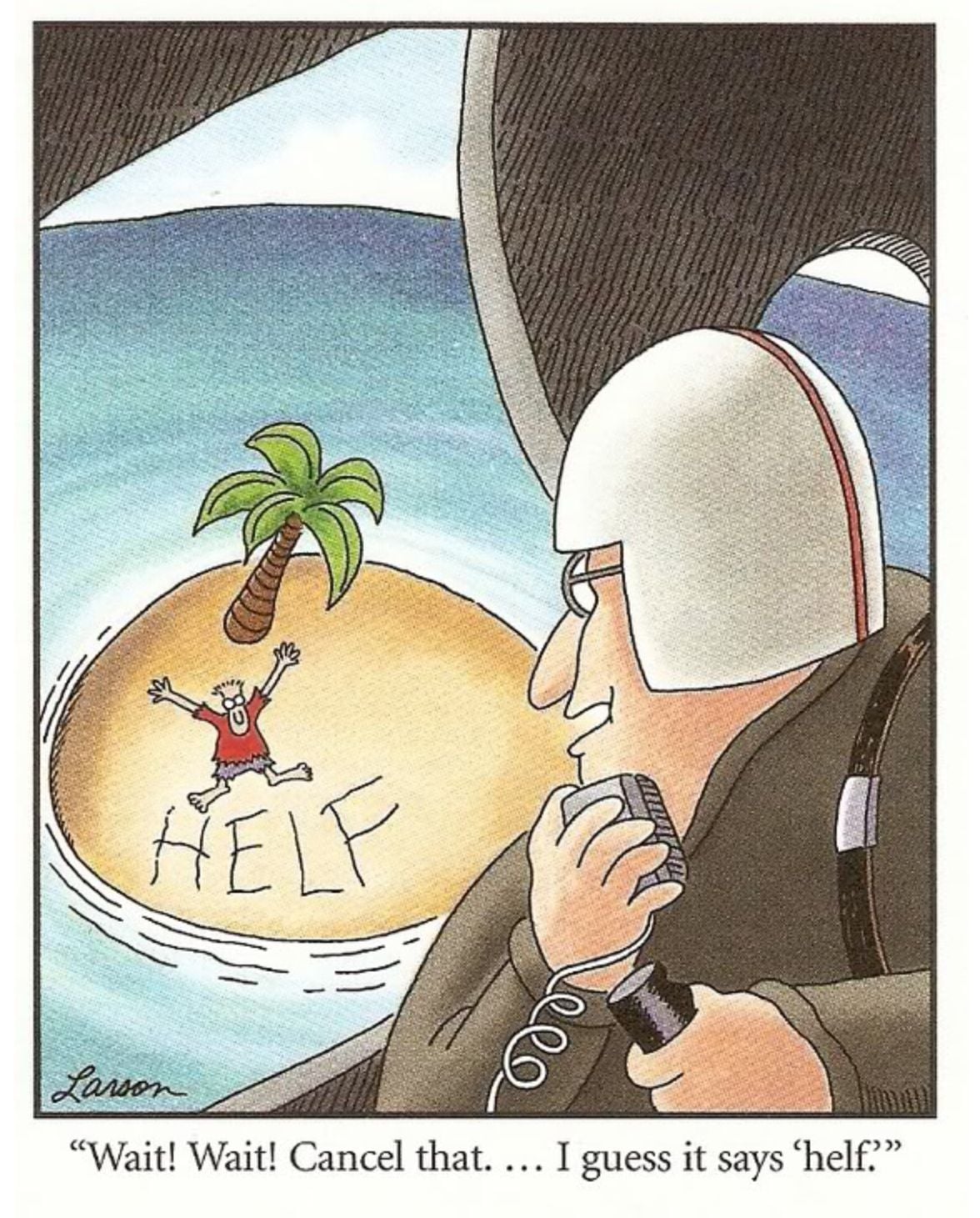

To illustrate, here is one of my favorite all-time aviation-related cartoons:

Here we have too much reliance on the literal word, not enough seeing the big picture. Funny in this context, not so much in real life.

For every airliner I have flown, somewhere in the preamble to the non-normals section (we used to call them “emergencies, and then “abnormals”, but I digress) there is a statement to the effect that while the manufacture has made a good faith attempt to create procedures for possible malfunctions, it is simply not possible to anticipate every possible failure or combination of failures in which case the pilots are expected to exercise good judgement. This is a very critical concept that is frequently disregarded in both training philosophy and overall company culture. The “good judgement” pilots are expected to exercise in unusual situations can be trained out of them by company policies that emphasize strict adherence to procedures (even when they may not apply), maximum use of automation that leads to loss of hand flying skills, and top-heavy or authoritarian management that discourages adaptive decision making.

Consider what we know of the first Lion Air accident (the ones that survived). The crew reported confusion regarding which procedure to apply because the MCAS failure did not match a classic runaway trim. Much has been made of the word “continuously” in the description section of this NNC. For my part, 9 seconds of continuous operation is “continuous” enough, but I could see how others would see it differently. However, this discussion itself has too much focus on the literal words, not enough on the big picture.

After the crew had turned off the trim and stabilized the aircraft, they then did two peculiar things. First, they did not disable the erroneous stick shaker even though the circuit breaker was in easy reach. Why would they not get rid of such an obvious distraction that increased the risk of further crew errors? Because there was no written procedure to do so. Too much literal interpretation, not enough big picture.

Next, despite having a malfunctioning AOA vane (which itself compromises a number of other aircraft systems like flight instruments, autothrottles, autopilot, etc), no electric trim, and probably quite a few distressed passengers, the crew elects to continue to the scheduled destination hundreds of miles away. Why? As the preliminary report cogently stated, neither the Airspeed Unreliable or Runaway Stab checklists direct the crew to land at the nearest suitable airport. In absence of some piece of paper that instructed them to get the aircraft on the ground now, they apparently felt they had no choice but to continue the flight - with an active stick shaker all the way.

We see strong desire to identify and execute a written procedure repeated in the second Lion Air flight. The Captain initially was able to stabilize the aircraft and flew around for several minutes while the FO looked through the QRH for an appropriate procedure. This is important. The aircraft was relatively stable and not in danger of crashing because the Captain was, quite appropriately, using aggressive electric stab trim inputs to counter MCAS despite the lack of any existing guidance that this is what he needed to do.

The First Officer stated that he could not find an appropriate procedure in the QRH. We can set aside for the moment the discussion whether either pilot should have connected the MCAS malfunction with the Runaway Stab procedure. The Captain, who so far was maintaining aircraft control, then hands the aircraft over to the First Officer so the Captain can then go look for an appropriate procedure in the QRH. Within seconds of this transfer of aircraft control, we see an immediate deterioration in the aircraft state due largely to inadequate electric stab trim inputs and the aircraft crashed within about a minute. Why the First Officer was not able to maintain aircraft control in the same manner as the Captain is an open question, but what is key to me is that this crew seemed to place such importance on finding a written procedure that precisely fit their situation that they sacrificed aircraft control in that pursuit.

Given what we know of these accidents, Boeing obviously needs to build a better aircraft and everyone in the chain needs to look at and revise the written guidance given to the air crews. However, I think the evidence also shows that there is more going on than just a need for “better” procedures and better adherence to those procedures.

Last edited by Tomaski; 18th Aug 2019 at 18:23.

What is the logic behind suddenly telling people to follow a checklist for something completely different? Just because it might have looked "similar"? We can end all the non normal procedures with an approach like that. What happened to training?

Our workplace has changed drastically latest since the elimination of the flight engineer. It's purest sarcasm while on steam planes like 747 classic, 707, 727, DC 10, Lockheed 1011 etc. with simple systems a qualified non pilot, called FE, did assist. Nowadays we have very complexe machines but are supposed to "learn" to operate them in a few weeks.... The "software" of these modern machines is often unknown even to our trainers, not to say on us, the operators. And this isn't an issue only at Airbus meanwhile....

Last edited by gearlever; 19th Aug 2019 at 09:23. Reason: Lockheed 1011 instead of MD11

Join Date: Aug 2002

Location: Castletown

Posts: 241

Likes: 0

Received 0 Likes

on

0 Posts

What happened to training?

Our workplace has changed drastically latest since the elimination of the flight engineer. It's purest sarcasm while on steam planes like 747 classic, 707, 727, DC 10, MD 11 etc. with simple systems a qualified non pilot, called FE, did assist. Nowadays we have very complexe machines but are supposed to "learn" to operate them in a few weeks.... The "software" of these modern machines is often unknown even to our trainers, not to say on us, the operators. And this isn't an issue only at Airbus meanwhile....

Our workplace has changed drastically latest since the elimination of the flight engineer. It's purest sarcasm while on steam planes like 747 classic, 707, 727, DC 10, MD 11 etc. with simple systems a qualified non pilot, called FE, did assist. Nowadays we have very complexe machines but are supposed to "learn" to operate them in a few weeks.... The "software" of these modern machines is often unknown even to our trainers, not to say on us, the operators. And this isn't an issue only at Airbus meanwhile....

Old MD-10 (no conversion) yes, the FE was still a part of the crew compliment.

Modern aircraft have an EICAS/ECAM system which goes along way in identifying the problem and giving the correct remedial action. Whilst not perfect it does reduce workload and is practically a necessity given todays standard of pilot training, as Tomaski outlined in his post.

The MAX should have been fitted with this, rather than relying on an outdated paper checklist system from a bygone era which isn't suited to the new generation of pilots and aircraft.

However that would have required a new type certificate and a new type rating.

The MAX should have been fitted with this, rather than relying on an outdated paper checklist system from a bygone era which isn't suited to the new generation of pilots and aircraft.

However that would have required a new type certificate and a new type rating.

Join Date: Feb 2000

Location: Pacific

Posts: 731

Likes: 0

Received 0 Likes

on

0 Posts

Boof,

I’m going to disagree with you here, but probably not for the reasons you think. One of my ongoing concerns with the current state of pilot training and management is that there has been far too much emphasis on executing written procedures and strictly complying with company policies and far too little on basic aircraft management (with and without the automation) while maintaining a “big picture” of what is going on without necessarily looking it up in a manual. Training itself has become so compressed and scripted that there is little room for critical thinking. At some airlines, pilot discretion exists in name only. In some cases, training and operational management has adopted so much of a paint-by-numbers philosophy that some pilots are no longer able to color outside the lines.

To illustrate, here is one of my favorite all-time aviation-related cartoons:

Here we have too much reliance on the literal word, not enough seeing the big picture. Funny in this context, not so much in real life.

For every airliner I have flown, somewhere in the preamble to the non-normals section (we used to call them “emergencies, and then “abnormals”, but I digress) there is a statement to the effect that while the manufacture has made a good faith attempt to create procedures for possible malfunctions, it is simply not possible to anticipate every possible failure or combination of failures in which case the pilots are expected to exercise good judgement. This is a very critical concept that is frequently disregarded in both training philosophy and overall company culture. The “good judgement” pilots are expected to exercise in unusual situations can be trained out of them by company policies that emphasize strict adherence to procedures (even when they may not apply), maximum use of automation that leads to loss of hand flying skills, and top-heavy or authoritarian management that discourages adaptive decision making.

Consider what we know of the first Lion Air accident (the ones that survived). The crew reported confusion regarding which procedure to apply because the MCAS failure did not match a classic runaway trim. Much has been made of the word “continuously” in the description section of this NNC. For my part, 9 seconds of continuous operation is “continuous” enough, but I could see how others would see it differently. However, this discussion itself has too much focus on the literal words, not enough on the big picture.

After the crew had turned off the trim and stabilized the aircraft, they then did two peculiar things. First, they did not disable the erroneous stick shaker even though the circuit breaker was in easy reach. Why would they not get rid of such an obvious distraction that increased the risk of further crew errors? Because there was no written procedure to do so. Too much literal interpretation, not enough big picture.

Next, despite having a malfunctioning AOA vane (which itself compromises a number of other aircraft systems like flight instruments, autothrottles, autopilot, etc), no electric trim, and probably quite a few distressed passengers, the crew elects to continue to the scheduled destination hundreds of miles away. Why? As the preliminary report cogently stated, neither the Airspeed Unreliable or Runaway Stab checklists direct the crew to land at the nearest suitable airport. In absence of some piece of paper that instructed them to get the aircraft on the ground now, they apparently felt they had no choice but to continue the flight - with an active stick shaker all the way.

We see strong desire to identify and execute a written procedure repeated in the second Lion Air flight. The Captain initially was able to stabilize the aircraft and flew around for several minutes while the FO looked through the QRH for an appropriate procedure. This is important. The aircraft was relatively stable and not in danger of crashing because the Captain was, quite appropriately, using aggressive electric stab trim inputs to counter MCAS despite the lack of any existing guidance that this is what he needed to do.

The First Officer stated that he could not find an appropriate procedure in the QRH. We can set aside for the moment the discussion whether either pilot should have connected the MCAS malfunction with the Runaway Stab procedure. The Captain, who so far was maintaining aircraft control, then hands the aircraft over to the First Officer so the Captain can then go look for an appropriate procedure in the QRH. Within seconds of this transfer of aircraft control, we see an immediate deterioration in the aircraft state due largely to inadequate electric stab trim inputs and the aircraft crashed within about a minute. Why the First Officer was not able to maintain aircraft control in the same manner as the Captain is an open question, but what is key to me is that this crew seemed to place such importance on finding a written procedure that precisely fit their situation that they sacrificed aircraft control in that pursuit.

Given what we know of these accidents, Boeing obviously needs to build a better aircraft and everyone in the chain needs to look at and revise the written guidance given to the air crews. However, I think the evidence also shows that there is more going on than just a need for “better” procedures and better adherence to those procedures.

In this case none of the pilots followed the QRH procedures for the abnormal situation they found themselves in and over 300 people paid for their lack of knowledge with their lives. Sorry to hurt your precious sensibilities but I am frustrated with the apparent need to blame Boeing and in the process to destroy the aviation industry I have known and cared about to so many years with the only result being damage to those of us who do know what we are doing and do it regularly with no fanfare or fuss. What do you guys want? For the world to embrace pilotless aircraft?

All pilots especially those who occupy the left seat, should be able and ready to follow the emergency procedures correctly when needed. Mostly those will be read and do but some, for the "killer" items such as engine failure at V1, Stall, and especially loss of control, they must be able to do so from memory. The MCAS failure presented itself as unintended stab movement and the emergency procedure to cover that was the runaway trim recovery. It is a simple procedure involving the maintenance of control and returning the stab to a more normal position. Once that has been done the QRH can be used to confirm the follow up actions such as isolating the part of the system that failed and perhaps bringing back the parts that still work but none of that can be done if the first response to the failure is not completed correctly and immediately.

The real reason for these accidents is human failure and this is what we should be concerned about..

One wonders why the plane has been grounded for so long with more than one issue to fix then. All to accommodate below average pilots I guess? You're right about human failure though but it lied in the engineering and certification process IMSLFO.

Thread Starter

Join Date: Apr 2015

Location: Under the radar, over the rainbow

Posts: 788

Likes: 0

Received 0 Likes

on

0 Posts

Tomaski has written a very good thought-provoking post , and it is worth considering the whole philosophy behind checklists, the QRH and SOPs, so, please forgive me for writing at length. In a previous life, I thought long and hard on 'the what' and 'the whys' of SOPs. What was their basis? What was their real purpose? Were they immutable? Why did we need them? Should they always be followed rigidly? Were there ever good reasons to deviate from them?

First, it is necessary, to look at the derivation and purpose of each one – some are required by law, some by the way a piece of equipment works, some are part of the aircraft manufacturer’s operating philosophy, some are part of the airline’s operating philosophy, and some are custom and practice or merely folklore.

A good example of a procedure required by law is the approach ban when the RVR is below limits. In the past it used to be that pilots were allowed to descend to the decision altitude and have a look, but after several accidents CAAs imposed an approach ban. But even this can vary in different countries.

Some items of equipment require rigid operating procedures. For example, when early INS sets were fitted to aircraft, it was necessary to go through a precise alignment process during which the aircraft could not be moved for some ten to fifteen minutes. Also, to guard against false data being entered, each crew member was required independently to check the entered positions and resulting tracks and distances.

During the design and testing of a new aircraft type, the manufacturer will determine a detailed set of normal, abnormal and emergency procedures for such things as fire warnings in engines and/or cargo holds; failure modes in hydraulic and electrical systems; flap and undercarriage malfunctions; runaway stabilsers and normal checklists for pre-start, engine start, taxiing, take-off, after take-off, before descent, landing, after landing and shut-down, etc. This is done in good faith, but cannot, with the best will in the world, cover every eventuality

Most airlines will adopt these without change, but some will modify them depending on their individual operating experiences and mixtures of aircraft types in their fleet. So long as the vital parts of the manufacturer’s checklists and procedures are respected, certain things can be changed. For example which crew member handles the thrust levers and when, which pilot flies the approach and landing and when, who reads and actions the checklists – the pilots or the flight engineer. These changes will be subject to much internal discussion within the airline and also with the CAA and manufacturer.

But some procedures are derived merely from the long established custom and practice of the airline concerned and sometimes for no good reason at all.

The most important thing is that, once established, all crew members must follow these procedures. They are the ‘glue’ that holds the operation together. They are the collective wisdom of all the actors (regulatory authorities, manufacturers, airline) on how best to operate the aircraft safely in the various environments the crew are likely to face. And, very important indeed, they enable the crew members to monitor each other and advise of any departure from the norm.

Thus it will be seen there can be many differences between individual countries – for example, the USA vv Europe; between manufacturers – Airbus vv Boeing; and between individual airlines. All these differences have their merits and demerits, but, once they have been established, all crew members on the flight deck must abide by them for the reasons stated above.

In addition, management should only make changes to the SOPs, for example following an incident or accident, after very careful consideration. And when they do so, with adequate explanation and/or training so that all parties know why the changes have been made and how to apply them.

However, despite all these considerations, it is impossible for the SOPs to cover every eventuality. There then comes the point when they are not appropriate to the situation and the captain decides to deviate from them. This is an extreme measure and should only be done when there is no other option and when the pilot has sufficient knowledge to understand fully the implications of what he is doing. I can think of several examples.

Suppose on take-off at maximum weight in a four engine aircraft (a 747 with multiple landing gears) at a hot and high airfield, birds are ingested into both engines on the same side. Then, when airborne only a few feet above the ground, and barely able to climb, the co-pilot calls positive rate of climb, but the captain elects to leave the gear down until more speed and altitude has been gained. Non-standard, but his reasoning is that the extra drag of the open doors and wheel wells will probably cause the aircraft to sink back towards the ground.

Suppose on final approach all engines suddenly stop. The captain elects to retract the flaps one notch. Non-standard, but the drag reduction is just sufficient to stretch the glide and make the airfield.

Suppose in mid-Atlantic, the underfloor cargo fire warning lights illuminate, the crew have reason to believe the warning is genuine and divert to the Azores. When they arrive the weather has deteriorated, the cross-wind has risen above limits and the cloud base has descended to below decision altitude. There is nowhere else to go and it is imperative to land. They do so successfully. All three examples were genuine events. It is not difficult to dream up other scenarios where such actions may be necessary.

And one more to ponder: the Qantas Airbus A380 at Singapore when a turbine disc exploded causing extensive damage and multiple unrelated warnings. In what order should the crew action the various procedures, which should be ignored and which have to be actioned?

My conclusion, therefore, is that normally, flight crews should always obey the SOPs, even in an emergency, yet there may still be times when circumstances may dictate otherwise. Then, and only then, is it permissible and maybe essential to deviate, but this must be done in the full knowledge of ALL the implications. SOPs are for the guidance of wise men and not necessarily to be slavishly followed.

They provide the pathway – the steps to be taken – through the minefield of possible errors so that the crew can carry out all the required actions in the correct sequence, without error and within established limits.

Next, they enable the crew to carry out a well-rehearsed sequence of actions, in much the same way as acquired skills can relieve the thinking part of the brain and so give the individual some spare capacity to think ahead, solve problems and make decisions.

Thirdly, SOPs provide predictability so that crew members can monitor each other and detect and correct errors before they develop into something more serious.

End of philosophical discussion!!

First, it is necessary, to look at the derivation and purpose of each one – some are required by law, some by the way a piece of equipment works, some are part of the aircraft manufacturer’s operating philosophy, some are part of the airline’s operating philosophy, and some are custom and practice or merely folklore.

A good example of a procedure required by law is the approach ban when the RVR is below limits. In the past it used to be that pilots were allowed to descend to the decision altitude and have a look, but after several accidents CAAs imposed an approach ban. But even this can vary in different countries.

Some items of equipment require rigid operating procedures. For example, when early INS sets were fitted to aircraft, it was necessary to go through a precise alignment process during which the aircraft could not be moved for some ten to fifteen minutes. Also, to guard against false data being entered, each crew member was required independently to check the entered positions and resulting tracks and distances.

During the design and testing of a new aircraft type, the manufacturer will determine a detailed set of normal, abnormal and emergency procedures for such things as fire warnings in engines and/or cargo holds; failure modes in hydraulic and electrical systems; flap and undercarriage malfunctions; runaway stabilsers and normal checklists for pre-start, engine start, taxiing, take-off, after take-off, before descent, landing, after landing and shut-down, etc. This is done in good faith, but cannot, with the best will in the world, cover every eventuality

Most airlines will adopt these without change, but some will modify them depending on their individual operating experiences and mixtures of aircraft types in their fleet. So long as the vital parts of the manufacturer’s checklists and procedures are respected, certain things can be changed. For example which crew member handles the thrust levers and when, which pilot flies the approach and landing and when, who reads and actions the checklists – the pilots or the flight engineer. These changes will be subject to much internal discussion within the airline and also with the CAA and manufacturer.

But some procedures are derived merely from the long established custom and practice of the airline concerned and sometimes for no good reason at all.

The most important thing is that, once established, all crew members must follow these procedures. They are the ‘glue’ that holds the operation together. They are the collective wisdom of all the actors (regulatory authorities, manufacturers, airline) on how best to operate the aircraft safely in the various environments the crew are likely to face. And, very important indeed, they enable the crew members to monitor each other and advise of any departure from the norm.

Thus it will be seen there can be many differences between individual countries – for example, the USA vv Europe; between manufacturers – Airbus vv Boeing; and between individual airlines. All these differences have their merits and demerits, but, once they have been established, all crew members on the flight deck must abide by them for the reasons stated above.

In addition, management should only make changes to the SOPs, for example following an incident or accident, after very careful consideration. And when they do so, with adequate explanation and/or training so that all parties know why the changes have been made and how to apply them.

However, despite all these considerations, it is impossible for the SOPs to cover every eventuality. There then comes the point when they are not appropriate to the situation and the captain decides to deviate from them. This is an extreme measure and should only be done when there is no other option and when the pilot has sufficient knowledge to understand fully the implications of what he is doing. I can think of several examples.

Suppose on take-off at maximum weight in a four engine aircraft (a 747 with multiple landing gears) at a hot and high airfield, birds are ingested into both engines on the same side. Then, when airborne only a few feet above the ground, and barely able to climb, the co-pilot calls positive rate of climb, but the captain elects to leave the gear down until more speed and altitude has been gained. Non-standard, but his reasoning is that the extra drag of the open doors and wheel wells will probably cause the aircraft to sink back towards the ground.

Suppose on final approach all engines suddenly stop. The captain elects to retract the flaps one notch. Non-standard, but the drag reduction is just sufficient to stretch the glide and make the airfield.

Suppose in mid-Atlantic, the underfloor cargo fire warning lights illuminate, the crew have reason to believe the warning is genuine and divert to the Azores. When they arrive the weather has deteriorated, the cross-wind has risen above limits and the cloud base has descended to below decision altitude. There is nowhere else to go and it is imperative to land. They do so successfully. All three examples were genuine events. It is not difficult to dream up other scenarios where such actions may be necessary.

And one more to ponder: the Qantas Airbus A380 at Singapore when a turbine disc exploded causing extensive damage and multiple unrelated warnings. In what order should the crew action the various procedures, which should be ignored and which have to be actioned?

My conclusion, therefore, is that normally, flight crews should always obey the SOPs, even in an emergency, yet there may still be times when circumstances may dictate otherwise. Then, and only then, is it permissible and maybe essential to deviate, but this must be done in the full knowledge of ALL the implications. SOPs are for the guidance of wise men and not necessarily to be slavishly followed.

They provide the pathway – the steps to be taken – through the minefield of possible errors so that the crew can carry out all the required actions in the correct sequence, without error and within established limits.

Next, they enable the crew to carry out a well-rehearsed sequence of actions, in much the same way as acquired skills can relieve the thinking part of the brain and so give the individual some spare capacity to think ahead, solve problems and make decisions.

Thirdly, SOPs provide predictability so that crew members can monitor each other and detect and correct errors before they develop into something more serious.

End of philosophical discussion!!

Join Date: Feb 2000

Location: Pacific

Posts: 731

Likes: 0

Received 0 Likes

on

0 Posts

I disagree that it takes an above average pilot to fly these, or most aircraft and certainly all airliners must be able to be flown by average pilots. All pilots of all skill levels should be trained and able to follow the emergency procedures for their aircraft. Does anyone disagree with that?

I would be ashamed, as a pilot, to blame my failures on the aircraft. If I could not fly the aircraft safely I would go sell insurance or houses or something more suited to my skills.

"Rules are for the guidance of wise men and the blind obedience of fools"

"There's no point following all the rules if you don't survive"

Dave,

Hear, Hear.

Hear, Hear.

The MCAS failure presented itself as unintended stab movement and the emergency procedure to cover that was the runaway trim recovery.

Salience of the stick shaker must be recognised and the cognitive processing functions that occur in order to dismiss the stick shaker as a symptom of a different failure, also have to be taken into account. This is before most humans brains will be capable of switching attention to other sensory inputs such as the feel of the yoke or the visual of a spinning trim wheel. Channeling of attention is powerful. Often people involved in rescues or intense sport won’t recognise that they are injured until after they have finished focusing on the task at hand, finished channeling their attention. Think you’re different? That’s not very likely.

(Not to mention he did not follow the ditching checklist as itemised, and decided to turn the APU on much earlier).

https://www.denverpost.com/2016/09/1...t-carried-out/

Join Date: Dec 2001

Location: Leeds, UK

Posts: 281

Likes: 0

Received 0 Likes

on

0 Posts

https://www.thetimes.co.uk/article/f...737s-x2wk9k2rx

states that 32,000 tickets are on sale on B737 Max's for later on this year at several airlines, including TUI and American Airlines

G

states that 32,000 tickets are on sale on B737 Max's for later on this year at several airlines, including TUI and American Airlines

G

Most company OPS manuals will have a paragraph to the effect that SOPS cannot cover all conceivable situations and crews are expected to exercise good judgement and airmanship in that event.