Hill Helicopters HX50

I do wish Hill success but unfortunately there are too many unanswered questions for me to really believe in it.

People have mentioned that he might have some Ex F1 composite guys on board for the fuselage. If that's the case, then tell us (and show us) rather than standing in front of the camera going through the various steps of the build entirely by yourself trying to make people believe your engineering expertise runs across rotor blade design, engine design, composite structure, gearbox design, hydraulics, electrics etc etc. Yeah sure, he's an intelligent chap, but professional engineers have expertise in one or maybe two areas, not 10. If he has a team of professional engineers with vast expertise in these areas, show and tell as it would give more credibility.

There is a reason why Bell, Agusta, Airbus, Boeing, McD, Embraer, Robinson, Sikorsky and every other aircraft manufacturer use engines designed and built by someone other than themselves. This is another question I have.

I expect he will try and make the tyres as well!!!

Yes, homebuilt fixed wing aircraft are plentiful and some are excellent, like the Vans series for example, however the stresses on a helicopter are completely different and as Crab said, when something lets go, it can often be catastrophic.

One more question, sorry. Many if not most of those that have invested into this are succesful people with some spare cash to chuck about. Would they sell there services, products or whatever there business is for a third of the price they could command? I don't think so, otherwise they wouldn't be so wealthy. If the HX50 can do everything Hill says it can do, he could sell it for three times the price.

Crab, what pie is it?

People have mentioned that he might have some Ex F1 composite guys on board for the fuselage. If that's the case, then tell us (and show us) rather than standing in front of the camera going through the various steps of the build entirely by yourself trying to make people believe your engineering expertise runs across rotor blade design, engine design, composite structure, gearbox design, hydraulics, electrics etc etc. Yeah sure, he's an intelligent chap, but professional engineers have expertise in one or maybe two areas, not 10. If he has a team of professional engineers with vast expertise in these areas, show and tell as it would give more credibility.

There is a reason why Bell, Agusta, Airbus, Boeing, McD, Embraer, Robinson, Sikorsky and every other aircraft manufacturer use engines designed and built by someone other than themselves. This is another question I have.

I expect he will try and make the tyres as well!!!

Yes, homebuilt fixed wing aircraft are plentiful and some are excellent, like the Vans series for example, however the stresses on a helicopter are completely different and as Crab said, when something lets go, it can often be catastrophic.

One more question, sorry. Many if not most of those that have invested into this are succesful people with some spare cash to chuck about. Would they sell there services, products or whatever there business is for a third of the price they could command? I don't think so, otherwise they wouldn't be so wealthy. If the HX50 can do everything Hill says it can do, he could sell it for three times the price.

Crab, what pie is it?

The following users liked this post:

There are tons of aircraft (certified) with composite monocoque bodies. This is not new. Many airplanes use carbon-fiber.

There are plenty of helicopters with composite bits, including things like tail booms, but they don't take impact damage well and are next to impossible to repair.

Jeepys - it's a hypothetical humble pie for

Does anyone know what happened to Composite Helicopters International? They had a similar design paired with a RR300 engine but had one ditching and one heavy landing after vibration issues.

Can't seem to find much more.

So Hill not the first to go down this route.

Can't seem to find much more.

So Hill not the first to go down this route.

If he has a team of professional engineers with vast expertise in these areas, show and tell as it would give more credibility

Compared to existing manufacturer's & products, this is ultra transparency. But I think it's needed when taking orders from a CAD design.

I expect he will try and make the tyres as well!!!

however the stresses on a helicopter are completely different

Would they sell there services, products or whatever there business is for a third of the price they could command? I don't think so, otherwise they wouldn't be so wealthy

He's not selling for 1/3 the price. I'm #334 and got 29% off (let's call it 2/3). Latest offers are around 10% discount +/- ... it's sliding to no discount after 1000 orders.

Sounds entirely reasonable business idea to me. Pre-sell 1 year worth of orders at cost price (assuming 30% margins normally), 2nd year onwards profitable, at full scale. That's actually epic returns for such a huge undertaking. Use the ~10% deposits for development without diluting shareholdings with capital raising or loans, in order to retain 100% control & direction. Having a massive order book allows appropriate scaling straight to big 500/year factory with minimal overproduction risk. Use HX profit and cashflow, plus HC order book deposits, to fund certification of HC. Use experience of HX50 to de-risk HC50 certification in parallel.

I predict his equity is going to be billionaire status in 10 years (assume 500 orders, 200k GBP profit ea, is 100m GBP profit per year. 10x multiplier = billionaire). Pretty good from starting with a few million in equity and grants.

I'm getting bull**** correction fatigue. See: Brandolini's Law:

"The amount of energy needed to refute bull**** is an order of magnitude bigger than that needed to produce it."

And this comic haha

Originally Posted by [email protected]

Which helicopters have composite monocoque?

The cabri G2 has two sections in carbon the cabin and the tail boom joined by a traditional tubular sub section

smarter in many ways:

- modules are small enough to fit in lower cost autoclave (no infusion)

- high stress attachment points (engine / transmission) are diffused away by the metal frame.

- another specialized company does it

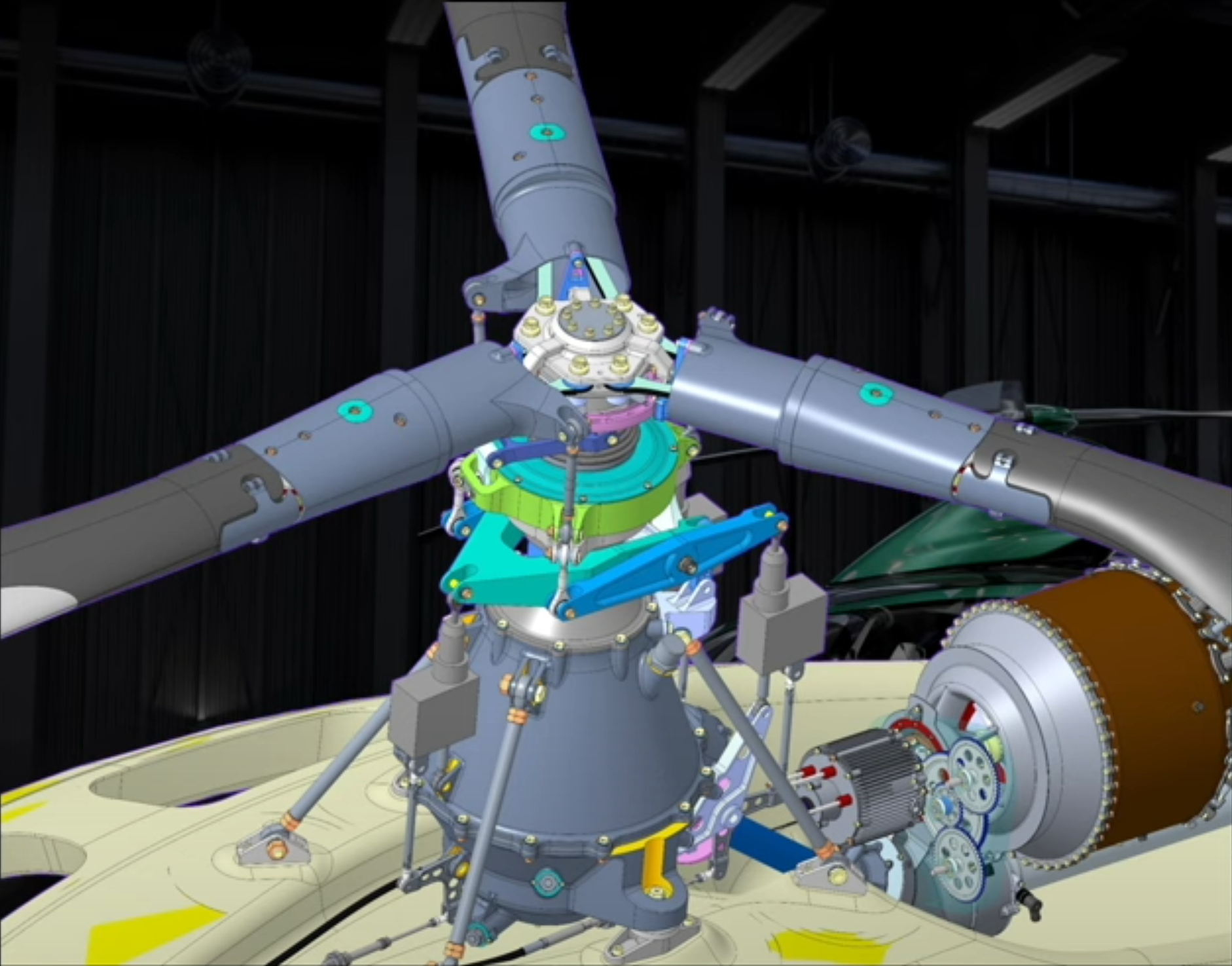

I especially worry about those lifting rod attachement points in the picture below, if they go bad, the fuselage is a write off.

Well, we are not going to know anything more about specs, timelines etc until..

a) the engine is running and tested

and

b) prototype built, flying and tested

and

c) factory built and production properly started

and

d) aircraft delivered to owners and they are flying them

Everything up to this point is plans, conjecture, mockups, predictions, theories, videos, some parts machined, a couple of shell hulls, promises, and/or BS.

a) the engine is running and tested

and

b) prototype built, flying and tested

and

c) factory built and production properly started

and

d) aircraft delivered to owners and they are flying them

Everything up to this point is plans, conjecture, mockups, predictions, theories, videos, some parts machined, a couple of shell hulls, promises, and/or BS.

Last edited by hargreaves99; 26th Sep 2023 at 09:43.

The following 2 users liked this post by hargreaves99:

Everything up to this point is plans, conjecture, mockups, predictions, theories, videos, promises, and/or BS.

Cgameprogrammerr - for you https://www.abbottaerospace.com/aa-s...onocoque-type/

I keep reading this '500 per year' rubbish. Anyone who believes this will ever happen is naive in the extreme. Given that customers must complete a 2 week build, that's 20 completion bays, running all year. All supplied with parts on a continuous basis, so there are no shortages? Ever?

And err....do you really think that the order bank will continue to grow at a continuous rate? That those very same completion bays will be required after say 5 years of production?

Let's be honest: Hill is funding his development by continually seeking more deposits. And promising undeliverable timescales on an ongoing basis. If he was honest, the deposits would dry up and the development put under threat.

To remind you, first flight was supposed to be in 2022 and first deliveries in 2023. Now first flight is 2024 (but it won't be, imho). So the important milestones have been missed by a factor of 2 and I don't believe in the new ones. And before the howls of protestation about Covid having changed the landscape and blah blah, the original announcement was in August 2020...you can find it right at the start of this thread.

And err....do you really think that the order bank will continue to grow at a continuous rate? That those very same completion bays will be required after say 5 years of production?

Let's be honest: Hill is funding his development by continually seeking more deposits. And promising undeliverable timescales on an ongoing basis. If he was honest, the deposits would dry up and the development put under threat.

To remind you, first flight was supposed to be in 2022 and first deliveries in 2023. Now first flight is 2024 (but it won't be, imho). So the important milestones have been missed by a factor of 2 and I don't believe in the new ones. And before the howls of protestation about Covid having changed the landscape and blah blah, the original announcement was in August 2020...you can find it right at the start of this thread.

Last edited by 206 jock; 26th Sep 2023 at 19:03.

The following users liked this post:

like the position lights, like the bearings, and the big one: The Engine.

The cabri G2 has two sections in carbon the cabin and the tail boom joined by a traditional tubular sub section

smarter in many ways:

FEA for composite materials is a very immature science, easy to model homogeneous materials like metal, quite another thing to predict behaviour of multi materials, especially with the variability of the infusion process.

I especially worry about those lifting rod attachement points in the picture below, if they go bad, the fuselage is a write off.

The cabri G2 has two sections in carbon the cabin and the tail boom joined by a traditional tubular sub section

smarter in many ways:

- modules are small enough to fit in lower cost autoclave (no infusion)

- high stress attachment points (engine / transmission) are diffused away by the metal frame.

- another specialized company does it

FEA for composite materials is a very immature science, easy to model homogeneous materials like metal, quite another thing to predict behaviour of multi materials, especially with the variability of the infusion process.

I especially worry about those lifting rod attachement points in the picture below, if they go bad, the fuselage is a write off.

According to my (Aerospace Phd) son, things have moved on in the last few years...

so what? Agree itís a bit misleading and JH should know better being an engineer with 20 yrs experience in aviation, and yes probably does it to enhance deposit sales which funds Development. Does that really rubbish the whole thing though? Other than timeframes do you have any other major criticisms of the hx50?

Anyone who says nothing actually exists, or it is all CGI stuff, simply doesn't know what they are talking about.

The next publicly available update is scheduled for next week. looking forward to hearing the negative comments from the famous 5 more that the update!

That leave Boeing and Airbus, that kind of tech they have I am not sure is within reach of Hill.

Yes the A350 is carbon wound and I am sure they did not guess it to be a good design, but they use prepreg composite that gives a very controlable fiber to resin ratio, while Hill infusion process is still sorting out to avoid resin dry areas.

And otherwise?

- The made up price point The £495k initial price was chosen to sound like it's similar to a supercar. It just cannot be done.

- Why build his own engine?

- Why is his corporate structures so complex?

- Why does he have no employees?

- Why does he have his personal fingers in absolutely everything? Design, manufacture, finance, procurement, insurance etc etc

- What happens if JH gets runs over by a bus?

Other than the above, sign me up! Seriously, I weirdly hope that I am being a sceptic, that it all works out and I will tip my hat to you brave guys that made it happen. And I will regret not selling my legacy Bell 206 while the prices were high.

The following users liked this post: