Originally Posted by

admikar

You just lost me at **** that does not make sense. You mean **** like door handles?

like the position lights, like the bearings, and the big one: The Engine.

Originally Posted by

CGameProgrammerr

The Cabri G2.

The cabri G2 has two sections in carbon the cabin and the tail boom joined by a traditional tubular sub section

smarter in many ways:

- modules are small enough to fit in lower cost autoclave (no infusion)

- high stress attachment points (engine / transmission) are diffused away by the metal frame.

- another specialized company does it

Originally Posted by

Shagpile

Which is why the entire thing has gone through finite element analysis, blah blah, and is planned to pass all certification / crash requirements. Which he regularly discusses in detail.

FEA for composite materials is a very immature science, easy to model homogeneous materials like metal, quite another thing to predict behaviour of multi materials, especially with the variability of the infusion process.

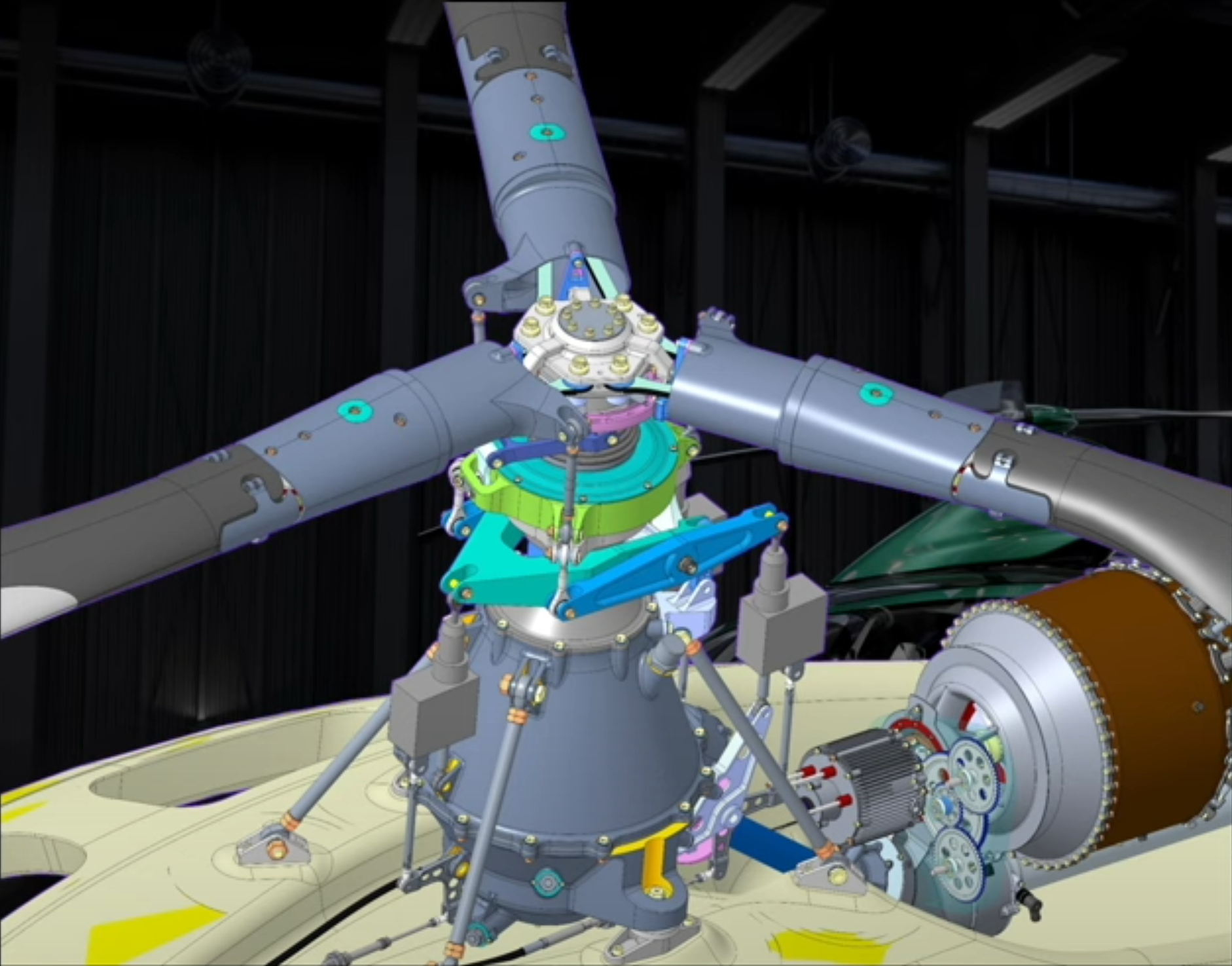

I especially worry about those lifting rod attachement points in the picture below, if they go bad, the fuselage is a write off.