Ethiopian airliner down in Africa

Join Date: Mar 2000

Location: uk

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

If it had customers it could build them almost for ever.

The bigger question is how long would it take to spin up the production of NG engines and other parts. I suspect that getting back to building 100 plus NG engines per month would take 6 plus months to fully achieve.

The bigger question is how long would it take to spin up the production of NG engines and other parts. I suspect that getting back to building 100 plus NG engines per month would take 6 plus months to fully achieve.

If it had customers it could build them almost for ever.

The bigger question is how long would it take to spin up the production of NG engines and other parts. I suspect that getting back to building 100 plus NG engines per month would take 6 plus months to fully achieve.

Join Date: Mar 2000

Location: uk

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

Perfectly possible. Train the training captains first, let them have some real, non-sim experience of it on test flights, all to a plan, start revenue flights with two captains, then progressively have them train the FO's, starting with the experienced ones. It's not hard to come up with that. Isn't devising this sort of transition what the role of Chief Pilot is all about ?

Particularly when they only have 200 hours total.

Join Date: Aug 2000

Posts: 1,501

Likes: 0

Received 0 Likes

on

0 Posts

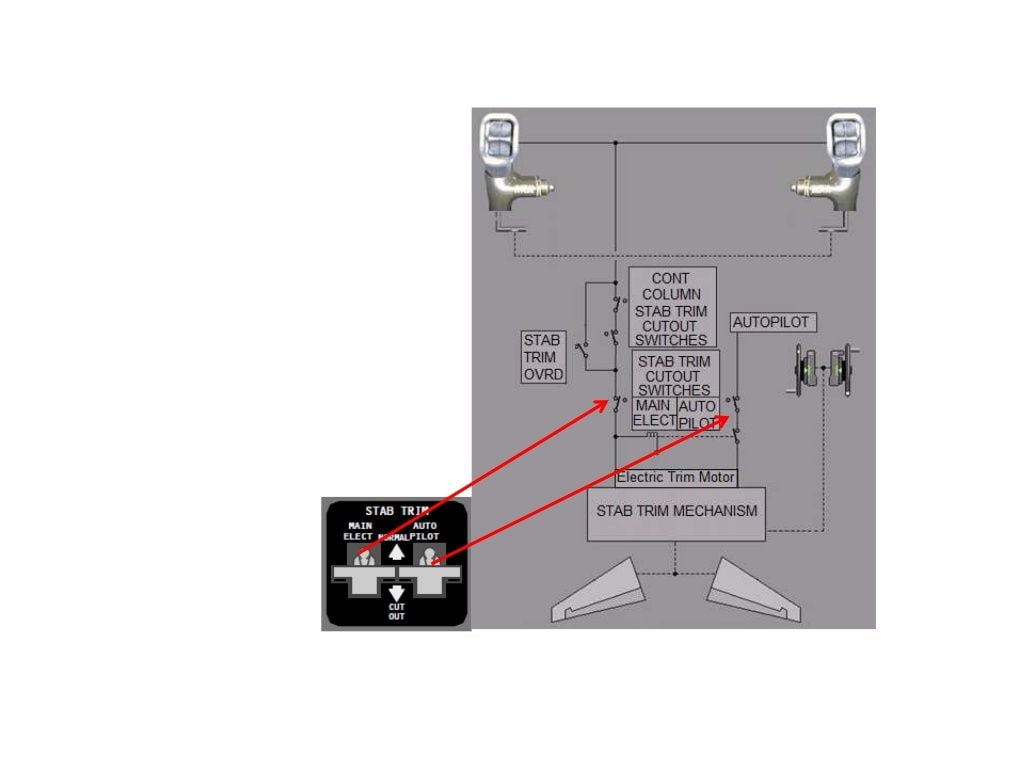

So this means the STS system will trim even if the column cut out switches are in the cut out position?

My understanding is that, while regulators like the FAA, EASA, etc have imposed territorial bans on the Max flying through the airspace that they have jurisdiction over, Boeing has sought the grounding of the worldwide fleet (I don't know if that has actually happened yet).

The FAA, as well as being responsible for what is and isn't allowed in US airspace, is also the continuing airworthiness authority for the 737. It has the power to grant a request by Boeing to temporarily suspend the aircraft's Type Certificate (in respect of only the Max, obviously). If it did so, other airworthiness authorities (EASA, ANAC, etc) would have no option but to follow suit and the Max would be effectively grounded worldwide.

Join Date: Jan 2008

Location: UK

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Average

Join Date: Sep 2006

Location: Pergatory

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

Another SLFie who may be stating the obvious, but surely the goal of any airframer is to produce an aircraft that even the minimum standard of pilot can fly and have a decent chance of successfully troubleshooting in the event of something going awry? Not prejudging anything BTW

I'm not letting Boeing off the hook for such a poor design, but there's a reason that several other crews have documented this very issue and landed safely.

Join Date: Feb 2006

Location: USA

Posts: 487

Likes: 0

Received 0 Likes

on

0 Posts

NTSB to France

NTSB Sends Additional Investigators to Assist in Ethiopian Investigation

3/14/2019

WASHINGTON (March 14, 2019) —The U.S. National Transportation Safety Board is dispatching three investigators to France Thursday to assist with the downloading and analysis of flight recorders from the Boeing 737 MAX 8 that crashed Sunday near Addis Ababa, Ethiopia.

The NTSB investigators have expertise in recorders, flight crew operations and human factors. The French Bureau d'Enquêtes et d'Analyses (BEA) will be downloading the flight data recorder and cockpit voice recorder in support of the Ethiopian investigation.

The investigation is being led by the Ethiopian Aircraft Accident Investigations Bureau in accordance with the standards defined in International Civil Aviation Organization Annex 13. The NTSB appointed an accredited representative to the investigation under the ICAO standards because the airplane was manufactured in the United States. All investigative data regarding the investigation will be released by Ethiopian authorities.

For more information on NTSB participation in foreign investigations go to: https://go.usa.gov/xEswV.

The NTSB investigators dispatched to France will work in coordination with investigators on the ground in Addis Ababa. Those investigators were sent immediately after the accident and have been integral to the efforts underway in Ethiopia. They are being assisted by technical advisers from the Federal Aviation Administration, Boeing and GE/Safran, the manufacturer of the engines.

The NTSB is an independent U.S. federal agency charged with investigating transportation accidents and issuing recommendations to improve safety.

3/14/2019

WASHINGTON (March 14, 2019) —The U.S. National Transportation Safety Board is dispatching three investigators to France Thursday to assist with the downloading and analysis of flight recorders from the Boeing 737 MAX 8 that crashed Sunday near Addis Ababa, Ethiopia.

The NTSB investigators have expertise in recorders, flight crew operations and human factors. The French Bureau d'Enquêtes et d'Analyses (BEA) will be downloading the flight data recorder and cockpit voice recorder in support of the Ethiopian investigation.

The investigation is being led by the Ethiopian Aircraft Accident Investigations Bureau in accordance with the standards defined in International Civil Aviation Organization Annex 13. The NTSB appointed an accredited representative to the investigation under the ICAO standards because the airplane was manufactured in the United States. All investigative data regarding the investigation will be released by Ethiopian authorities.

For more information on NTSB participation in foreign investigations go to: https://go.usa.gov/xEswV.

The NTSB investigators dispatched to France will work in coordination with investigators on the ground in Addis Ababa. Those investigators were sent immediately after the accident and have been integral to the efforts underway in Ethiopia. They are being assisted by technical advisers from the Federal Aviation Administration, Boeing and GE/Safran, the manufacturer of the engines.

The NTSB is an independent U.S. federal agency charged with investigating transportation accidents and issuing recommendations to improve safety.

###

Join Date: Mar 2012

Location: Having a margarita on the beach

Posts: 2,424

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: Sep 2011

Location: Belgium

Age: 64

Posts: 138

Likes: 0

Received 0 Likes

on

0 Posts

If the airframe/sensors are feeding the pilots/systems with wrong information, it does not matter if they have 20.000 or 200 hrs PIC.

If at high speed and low altitude as in this case, there is NO time.

If error codes refresh so fast on screen that you can not follow them visually? You have no time to fall back on experience and evaluate and have mere minutes/seconds till impact.

If at high speed and low altitude as in this case, there is NO time.

If error codes refresh so fast on screen that you can not follow them visually? You have no time to fall back on experience and evaluate and have mere minutes/seconds till impact.

Join Date: Aug 2016

Location: Geneva

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

For those who want to understand how we came to this amateur job:

It’s unique to the MAX because the 737 MAX no longer has the docile pitch characteristics of the 737NG at high Angles Of Attack (AOA). This is caused by the larger engine nacelles covering the higher bypass LEAP-1B engines. The nacelles for the MAX are larger and placed higher and further forward of the wing,

By placing the nacelle further forward of the wing, it could be placed higher. Combined with a higher nose landing gear, which raises the nacelle further, the same ground clearance could be achieved for the nacelle as for the 737NG.

The drawback of a larger nacelle, placed further forward, is it destabilizes the aircraft in pitch. All objects on an aircraft placed ahead of the Center of Gravity will contribute to destabilize the aircraft in pitch.

The 737 is a classical flight control aircraft. It relies on a naturally stable base aircraft for its flight control design, augmented in selected areas. Once such area is the artificial yaw damping, present on virtually all larger aircraft (to stop passengers getting sick from the aircraft’s natural tendency to Dutch Roll = Wagging its tail).

Until the MAX, there was no need for artificial aids in pitch. Once the aircraft entered a stall, there were several actions described l which assisted the pilot to exit the stall.

The larger nacelles, called for by the higher bypass LEAP-1B engines, changed this. When flying at normal angles of attack (3° at cruise and say 5° in a turn) the destabilizing effect of the larger engines are not felt.

The nacelles are designed to not generate lift in normal flight. It would generate unnecessary drag as the aspect ratio of an engine nacelle is lousy. The aircraft designer focuses the lift to the high aspect ratio wings.

But if the pilot for whatever reason manoeuvres the aircraft hard, generating an angle of attack close to the stall angle of around 14°, the previously neutral engine nacelle generates lift. A lift which is felt by the aircraft as a pitch up moment (as its ahead of the CG line), now stronger than on the 737NG. This destabilizes the MAX in pitch at higher Angles Of Attack (AOA). The most difficult situation is when the manoeuvre has a high pitch ratio. The aircraft’s inertia can then provoke an over-swing into stall AOA.

To counter the MAX’s lower stability margins at high AOA, Boeing introduced MCAS. Dependent on AOA value and rate, altitude (air density) and Mach (changed flow conditions) the MCAS, which is a software loop in the Flight Control computer, initiates a nose down trim above a threshold AOA.

It can be stopped by the Pilot counter-trimming on the Yoke or by him hitting the CUTOUT switches on the center pedestal. It’s not stopped by the Pilot pulling the Yoke, which for normal trim from the autopilot or runaway manual trim triggers trim hold sensors. This would negate why MCAS was implemented, the Pilot pulling so hard on the Yoke that the aircraft is flying close to stall.

It’s probably this counterintuitive characteristic, which goes against what has been trained many times in the simulator for unwanted autopilot trim or manual trim runaway, which has confused the pilots of JT610. They learned that holding against the trim stopped the nose down, and then they could take action, like counter-trimming or outright CUTOUT the trim servo. But it didn’t. After a 10 second trim to a 2.5° nose down stabilizer position, the trimming started again despite the Pilots pulling against it. The faulty high AOA signal was still present.

How should they know that pulling on the Yoke didn’t stop the trim? It was described nowhere; neither in the aircraft’s manual, the AFM, nor in the Pilot’s manual, the FCOM. This has created strong reactions from airlines with the 737 MAX on the flight line and their Pilots. They have learned the NG and the MAX flies the same. They fly them interchangeably during the week.

They do fly the same as long as no fault appears. Then there are differences, and the Pilots should have been informed about the differences.

Source: https://leehamnews.com/2018/11/14/bo...to-the-pilots/

Unfortunately the lion and Ethiopian's pilots have not had this chance

It’s unique to the MAX because the 737 MAX no longer has the docile pitch characteristics of the 737NG at high Angles Of Attack (AOA). This is caused by the larger engine nacelles covering the higher bypass LEAP-1B engines. The nacelles for the MAX are larger and placed higher and further forward of the wing,

By placing the nacelle further forward of the wing, it could be placed higher. Combined with a higher nose landing gear, which raises the nacelle further, the same ground clearance could be achieved for the nacelle as for the 737NG.

The drawback of a larger nacelle, placed further forward, is it destabilizes the aircraft in pitch. All objects on an aircraft placed ahead of the Center of Gravity will contribute to destabilize the aircraft in pitch.

The 737 is a classical flight control aircraft. It relies on a naturally stable base aircraft for its flight control design, augmented in selected areas. Once such area is the artificial yaw damping, present on virtually all larger aircraft (to stop passengers getting sick from the aircraft’s natural tendency to Dutch Roll = Wagging its tail).

Until the MAX, there was no need for artificial aids in pitch. Once the aircraft entered a stall, there were several actions described l which assisted the pilot to exit the stall.

The larger nacelles, called for by the higher bypass LEAP-1B engines, changed this. When flying at normal angles of attack (3° at cruise and say 5° in a turn) the destabilizing effect of the larger engines are not felt.

The nacelles are designed to not generate lift in normal flight. It would generate unnecessary drag as the aspect ratio of an engine nacelle is lousy. The aircraft designer focuses the lift to the high aspect ratio wings.

But if the pilot for whatever reason manoeuvres the aircraft hard, generating an angle of attack close to the stall angle of around 14°, the previously neutral engine nacelle generates lift. A lift which is felt by the aircraft as a pitch up moment (as its ahead of the CG line), now stronger than on the 737NG. This destabilizes the MAX in pitch at higher Angles Of Attack (AOA). The most difficult situation is when the manoeuvre has a high pitch ratio. The aircraft’s inertia can then provoke an over-swing into stall AOA.

To counter the MAX’s lower stability margins at high AOA, Boeing introduced MCAS. Dependent on AOA value and rate, altitude (air density) and Mach (changed flow conditions) the MCAS, which is a software loop in the Flight Control computer, initiates a nose down trim above a threshold AOA.

It can be stopped by the Pilot counter-trimming on the Yoke or by him hitting the CUTOUT switches on the center pedestal. It’s not stopped by the Pilot pulling the Yoke, which for normal trim from the autopilot or runaway manual trim triggers trim hold sensors. This would negate why MCAS was implemented, the Pilot pulling so hard on the Yoke that the aircraft is flying close to stall.

It’s probably this counterintuitive characteristic, which goes against what has been trained many times in the simulator for unwanted autopilot trim or manual trim runaway, which has confused the pilots of JT610. They learned that holding against the trim stopped the nose down, and then they could take action, like counter-trimming or outright CUTOUT the trim servo. But it didn’t. After a 10 second trim to a 2.5° nose down stabilizer position, the trimming started again despite the Pilots pulling against it. The faulty high AOA signal was still present.

How should they know that pulling on the Yoke didn’t stop the trim? It was described nowhere; neither in the aircraft’s manual, the AFM, nor in the Pilot’s manual, the FCOM. This has created strong reactions from airlines with the 737 MAX on the flight line and their Pilots. They have learned the NG and the MAX flies the same. They fly them interchangeably during the week.

They do fly the same as long as no fault appears. Then there are differences, and the Pilots should have been informed about the differences.

Source: https://leehamnews.com/2018/11/14/bo...to-the-pilots/

Unfortunately the lion and Ethiopian's pilots have not had this chance

Last edited by cervo77; 14th Mar 2019 at 15:27.

Otherwise, an excellent summary of the issues, though you might want to delete your other copy of the same post in the Software Fixes thread as the mods tend not to like cross-posting the same thing twice.

Join Date: Mar 2019

Location: Vermont, USA

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

The last 2 days of articles I've read sure could use a LOT more of that approach.

How would you (guys) react to a serious, well-stated question that could clarify some of the complexities of THIS situation, from an admitted Journalist?

Thread Starter

Previous 737 groundings 1989

Just recalled this from 1989 - 30 years ago...

Most of the world's 46 new Boeing 737-400 jetliners have been grounded in recent days after an engine type that has become increasingly suspect failed twice in the last week.

The airplanes affected are the 28 foreign 737-400's that are powered by that engine and 5 more planes, all flown by Piedmont Airlines, which use a similar engine.

The groundings followed an advisory, issued by Boeing on Tuesday, that urged airlines not to fly the planes until engine parts were replaced and power output was restricted. A Boeing 737-400 using the same engine crashed in Britain in January, killing 47 people a British Midland Airways 737-400 G-OBME

The Boeing advisory was followed by an emergency airworthiness directive issued yesterday by the Federal Aviation Administration. That directive officially grounded the Piedmont planes, which, having already been taken out of service and repaired, according to the Boeing advisory, were expected to resume flying today.

The engines involved are the CFM56-3C in the foreign planes and the CFM56-3B in the Piedmont planes.

In its emergency order, the F.A.A. warned that without the modifications the engine's fan blades might fracture, causing ''a complete loss of engine power.'' Engines that had failed on British 737-400's this past week showed signs of such fractures. In the Air Europe, BMA, Dan Air and Air UK Leisure fleets.

The most recent problems with the engine developed last Friday, when a Dan Air 737-400 carrying 100 passengers from London to Menorca returned to London after developing severe vibration in one engine. On Sunday, a Boeing 737-400 flown by British Midland Airways also had to return to London after developing engine trouble.

Piedmont Airlines, whose parent company is USAir Inc., is the sole operator of the 737-400 in this country. Although the Piedmont planes are powered by a different model engine, they had been flown at the higher power levels while being tested by Boeing and therefore fell under the F.A.A.'s emergency order.

Most of the world's 46 new Boeing 737-400 jetliners have been grounded in recent days after an engine type that has become increasingly suspect failed twice in the last week.

The airplanes affected are the 28 foreign 737-400's that are powered by that engine and 5 more planes, all flown by Piedmont Airlines, which use a similar engine.

The groundings followed an advisory, issued by Boeing on Tuesday, that urged airlines not to fly the planes until engine parts were replaced and power output was restricted. A Boeing 737-400 using the same engine crashed in Britain in January, killing 47 people a British Midland Airways 737-400 G-OBME

The Boeing advisory was followed by an emergency airworthiness directive issued yesterday by the Federal Aviation Administration. That directive officially grounded the Piedmont planes, which, having already been taken out of service and repaired, according to the Boeing advisory, were expected to resume flying today.

The engines involved are the CFM56-3C in the foreign planes and the CFM56-3B in the Piedmont planes.

In its emergency order, the F.A.A. warned that without the modifications the engine's fan blades might fracture, causing ''a complete loss of engine power.'' Engines that had failed on British 737-400's this past week showed signs of such fractures. In the Air Europe, BMA, Dan Air and Air UK Leisure fleets.

The most recent problems with the engine developed last Friday, when a Dan Air 737-400 carrying 100 passengers from London to Menorca returned to London after developing severe vibration in one engine. On Sunday, a Boeing 737-400 flown by British Midland Airways also had to return to London after developing engine trouble.

Piedmont Airlines, whose parent company is USAir Inc., is the sole operator of the 737-400 in this country. Although the Piedmont planes are powered by a different model engine, they had been flown at the higher power levels while being tested by Boeing and therefore fell under the F.A.A.'s emergency order.

Join Date: Aug 2016

Location: Geneva

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

Almost, but not quite. The Max has typically 2-3 inches less ground clearance under the engines than the NG.

Otherwise, an excellent summary of the issues, though you might want to delete your other copy of the same post in the Software Fixes thread as the mods tend not to like cross-posting the same thing twice.

Otherwise, an excellent summary of the issues, though you might want to delete your other copy of the same post in the Software Fixes thread as the mods tend not to like cross-posting the same thing twice.

done!

cervo77 obviously a well thought out and accurate explanation of MCAS and why it exists. as a Captain on the 737 MAX and previous generation 737s I don't agree with this last statement of yours, the Ethiopian crew *was* trained about MCAS per their CEO as all 737 MAX pilots in the world were by emergency AD after the Lion Air accident. further while i fully admit that a great deal of confusion can exist if you aren't aware of MCAS because of yoke behavior etc. it doesn't prevent one important fact being true, if you have improper trimming occurring that is not being made by you, the pilot, the stab trim cutout switches are right next to you and have been for decades on this aircraft. they fix this. heck you can physically grasp and hold the trim wheel itself and it will prevent this. lots of blame to go around here and hopefully when it comes to MCAS the software fix coming shortly as Boeing describes is very comprehensive (as it should have been on day 1.)

Join Date: Mar 2000

Location: uk

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

To go from low rate production mostly for spares back up to more than 100 a month won’t be quick.