Helicopter down outside Leicester City Football Club

Shy,

At the risk of telling you how to suck eggs -

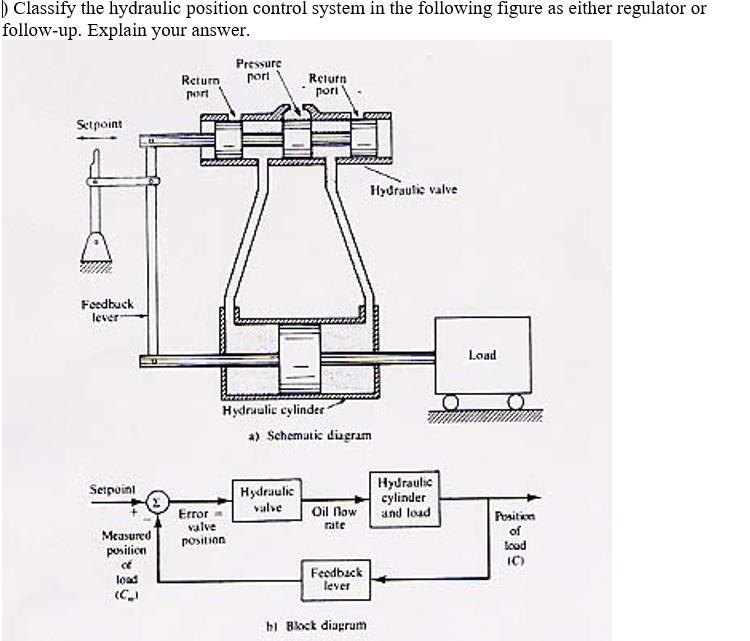

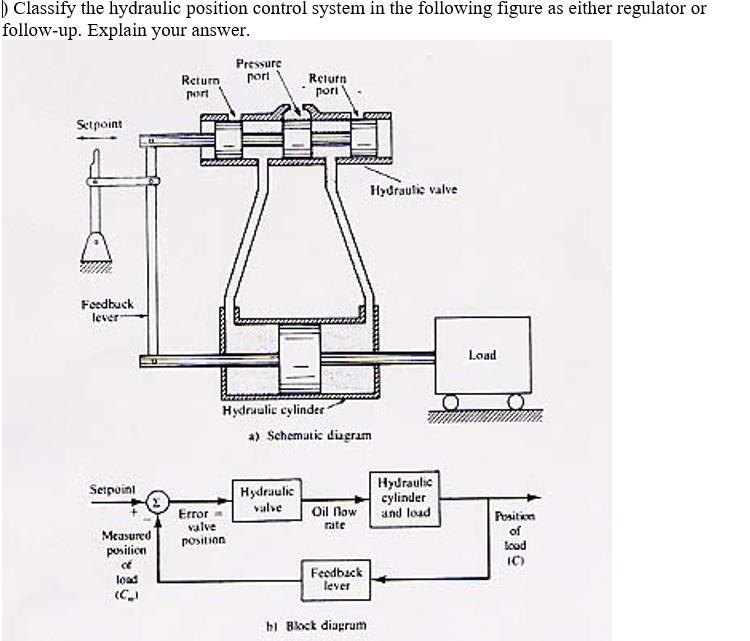

Setpoint = TR pedal control

Load = TR Pitch change or duplex bearing

Feedback lever disconnected at the hydraulic cylinder (servo)

Disconnect the feedback lever after the hydraulic valve has moved and there is nothing for the input side to work against to shift it again. Moving the pedals would more than likely just move the free end of the feedback lever not the pilot valve.

At the risk of telling you how to suck eggs -

Setpoint = TR pedal control

Load = TR Pitch change or duplex bearing

Feedback lever disconnected at the hydraulic cylinder (servo)

Disconnect the feedback lever after the hydraulic valve has moved and there is nothing for the input side to work against to shift it again. Moving the pedals would more than likely just move the free end of the feedback lever not the pilot valve.

Rainy cold day here....second cup of Coffee in hand and some time on my hands while I anticipate the Army-Navy Football game this afternoon at which the World pauses for a few hours (for those like me anyway)!

After reading all of the posts I have garnered some thoughts on this tragedy....mostly relating to the design of the Tail Rotor Control system on the Mishap Aircraft.

I have only the knowledge gathered by means of the posts here and some articles in the media.

I assume the 169 and 189 share a common design ( or identical systems common to the two types) thus the AD's apply only to the 169/189.

The design must not be as "simple" as suggested due to the various discussions upon what role all the various components played in that event.

The conversation about which Nut loosened/tighten and so forth....was indicative of that.

Some questions:

Why did the 169/189 wind up with this particular design of Tail Rotor Control system?

Is the design "new" and "different" to all previous such systems used by AW?

If so....if a new and unique design for the 169/189.....why?

Did the Design Team ever consider such a failure mode during the design and testing process?

If so....how did they resolve any issues that arose?

Is this design "failure tolerant" to the minimum degree necessary assuming inspection and servicing intervals and procedures were properly carried out at the factory and by the operator ?

Is this design an actual improvement over past designs or is it too complicated/complex in design?

Are there design flaws that set the stage for just such a failure as this to occur?

Is there a method to shut off the hydraulic pressure to the Tail Rotor Servo(s) and if so....would the Tail Rotor assume a somewhat neutral position?

(As violent and rapidly as the aircraft reacted to this actual failure.....I am thinking there would have been scant time for analyzing the problem by any Pilot.)

Anyone else have these or similar questions about the AW-169/189 Tail Rotor Control System?

After reading all of the posts I have garnered some thoughts on this tragedy....mostly relating to the design of the Tail Rotor Control system on the Mishap Aircraft.

I have only the knowledge gathered by means of the posts here and some articles in the media.

I assume the 169 and 189 share a common design ( or identical systems common to the two types) thus the AD's apply only to the 169/189.

The design must not be as "simple" as suggested due to the various discussions upon what role all the various components played in that event.

The conversation about which Nut loosened/tighten and so forth....was indicative of that.

Some questions:

Why did the 169/189 wind up with this particular design of Tail Rotor Control system?

Is the design "new" and "different" to all previous such systems used by AW?

If so....if a new and unique design for the 169/189.....why?

Did the Design Team ever consider such a failure mode during the design and testing process?

If so....how did they resolve any issues that arose?

Is this design "failure tolerant" to the minimum degree necessary assuming inspection and servicing intervals and procedures were properly carried out at the factory and by the operator ?

Is this design an actual improvement over past designs or is it too complicated/complex in design?

Are there design flaws that set the stage for just such a failure as this to occur?

Is there a method to shut off the hydraulic pressure to the Tail Rotor Servo(s) and if so....would the Tail Rotor assume a somewhat neutral position?

(As violent and rapidly as the aircraft reacted to this actual failure.....I am thinking there would have been scant time for analyzing the problem by any Pilot.)

Anyone else have these or similar questions about the AW-169/189 Tail Rotor Control System?

Join Date: Mar 2007

Location: UK

Posts: 321

Likes: 0

Received 0 Likes

on

0 Posts

The TR pitch control is hydraulically operated (dual system), not hydraulically assisted. There is no manually 'selectable' TR hydraulic system shut off or manual reversion. This isn't a unique design particular to this helicopter type.

Last edited by nodrama; 8th Dec 2018 at 15:04. Reason: accuracy of wording

Avoid imitations

Join Date: Nov 2000

Location: Wandering the FIR and cyberspace often at highly unsociable times

Posts: 14,576

Received 426 Likes

on

225 Posts

Shy take a look at how the thing works. It was not the input that failed but lets say the "output" to cancel the input via the feedback mechanism.

It's pretty simple - when all 3 points attached to the lever line up with the servo valve in the neutral position nothing happens as the control shaft moves and cancels the input request.

As the feed back end became detached - nothing to cancel the input - servo motors to the stop and in this case full right pedal?

BTW - Sikorsky has been fitting centreing as the result of accidents or incidents not unlike this one - not pro-actively.

The design and acceptance of the AW models may be under review shortly. If not I will be very surprised.

It's pretty simple - when all 3 points attached to the lever line up with the servo valve in the neutral position nothing happens as the control shaft moves and cancels the input request.

As the feed back end became detached - nothing to cancel the input - servo motors to the stop and in this case full right pedal?

BTW - Sikorsky has been fitting centreing as the result of accidents or incidents not unlike this one - not pro-actively.

The design and acceptance of the AW models may be under review shortly. If not I will be very surprised.

BTW - Sikorsky has been fitting centreing as the result of accidents or incidents not unlike this one - not pro-actively.

Last edited by ShyTorque; 8th Dec 2018 at 15:07.

Am I correct in assuming the Tail Rotor cannot be controlled manually in the event of a dual hydraulic failure?

Loss of feedback.

Remember as a little boy seeing the remains of a mill boiler house after the steam engine flywheel exploded -because the speed governor was BELT driven from the power output shaft, and the belt had broken!!!!

No loss of life on that occasion, but more by luck than judgement.

Lessons were learned, not least by this budding engineer.

Remember as a little boy seeing the remains of a mill boiler house after the steam engine flywheel exploded -because the speed governor was BELT driven from the power output shaft, and the belt had broken!!!!

No loss of life on that occasion, but more by luck than judgement.

Lessons were learned, not least by this budding engineer.

There will be a reason for the bearing failure that probably is the main cause of the subsequent accident. Questions about the overall design of the input assembly might come into it. However, there will be great effort made to identify why the bearing failed and, the mitigation of that process. It might be anything from: a major redesign, an improved bearing, improved QC of the bearing, revised servicing or an improved inspection.

OAP

OAP

It is a single point of failure and, worryingly, one that is designed to fail at some point.

Unfortunately, I cannot tell if the T/R system offers any level of T/R manual-only control or, the response of the T/R blade pitch to total loss of Hyd power. I will have to take issue with the writers of the report here. Under the paragraph "Tail rotor control operation" there is scant detail. Particularly, the "servo actuator" component is arrowed twice on the illustrations but not referred to in the para. Additionally, this part of the para "The lever pivots around the connection at the control shaft end and creates a demand on the hydraulic system via the SOLENOID VALVE, which moves the hydraulic piston and control shaft of the actuator" seems to be in error as a solenoid valve is an electrically operated valve. Should one read this to understand that movement of the lever is switching a solenoid valve? Hmmmm

OAP

OAP,part of the yaw channel AFCS...?

Hi sycamore,

No idea I am afraid. My reference to the para "The lever pivots around the connection at the control shaft end and creates a demand on the hydraulic system via the solenoid valve, which moves the hydraulic piston and control shaft of the actuator" is to highlight words that seem to me to be either; badly written, incorrect or confusing.

OAP

No idea I am afraid. My reference to the para "The lever pivots around the connection at the control shaft end and creates a demand on the hydraulic system via the solenoid valve, which moves the hydraulic piston and control shaft of the actuator" is to highlight words that seem to me to be either; badly written, incorrect or confusing.

OAP

Among my Laundry List of questions was this one......

Are we seeing in the various posts before and after my question showing up....confirmation that understanding how this 168/189 Tail Rotor Control system operates is far more difficult than at first glance?

I appreciate all the posts as they come from knowledgeable people and that quality of discussion is very informative.

This is where having a Maintenance Manual for the 169 would be very useful....to read what the Manufacturer has to say about it all.

Oh....and by the way....Army BEAT Navy yesterday! Go Army-Beat Navy!

The design must not be as "simple" as suggested due to the various discussions upon what role all the various components played in that event.

I appreciate all the posts as they come from knowledgeable people and that quality of discussion is very informative.

This is where having a Maintenance Manual for the 169 would be very useful....to read what the Manufacturer has to say about it all.

Oh....and by the way....Army BEAT Navy yesterday! Go Army-Beat Navy!

Join Date: Mar 2007

Location: UK

Posts: 321

Likes: 0

Received 0 Likes

on

0 Posts

Forget the fact that I have type knowledge, from a maintenance engineer's point of view I found the report poorly written, with poor terminology, and confusing. This has been proven by the majority of the posts and questions in this thread since the report was published.

The use of the word 'solenoid', as quoted above, was incorrect and misleading. As has been pointed out, a solenoid is an electrical-mechanical component. I would refer to the item that the report is referring to as a servo valve, or spool valve. These are standard hydraulic servo component terms.

The AW169 tail rotor servo and pitch control system really is pretty straight forward and not particularly unique, compared to some I've seen over the years. It's not always easy though to visualise these things unless you have one in front of you, or a series of detailed photos. I still think that the report could have done a better job of clearly relaying the technical information to the industry and public.

The use of the word 'solenoid', as quoted above, was incorrect and misleading. As has been pointed out, a solenoid is an electrical-mechanical component. I would refer to the item that the report is referring to as a servo valve, or spool valve. These are standard hydraulic servo component terms.

The AW169 tail rotor servo and pitch control system really is pretty straight forward and not particularly unique, compared to some I've seen over the years. It's not always easy though to visualise these things unless you have one in front of you, or a series of detailed photos. I still think that the report could have done a better job of clearly relaying the technical information to the industry and public.

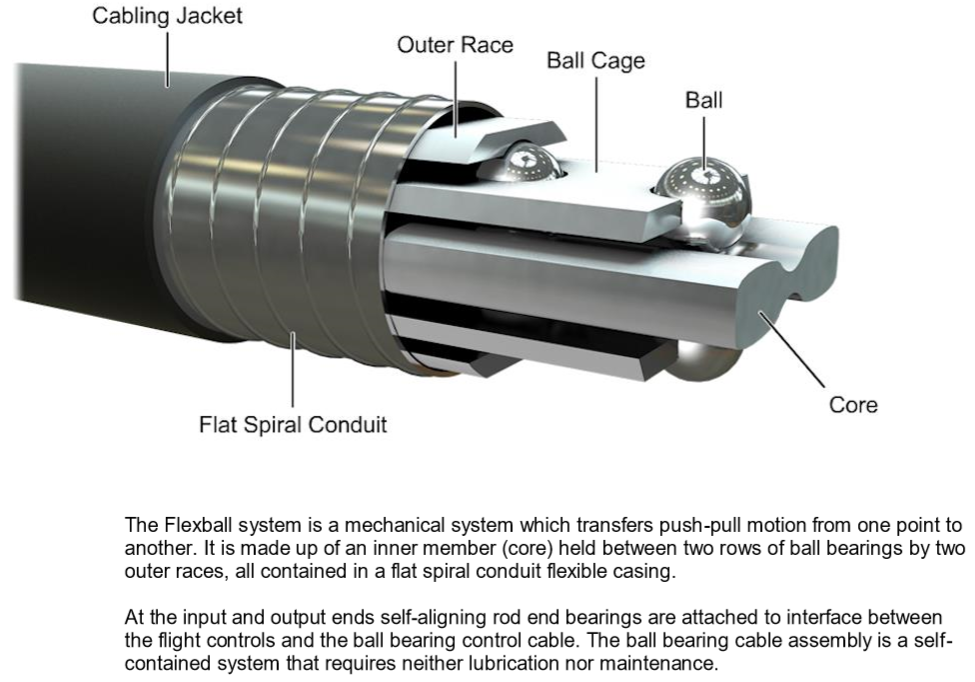

nodrama, perhaps you could elaborate on the `cable` arrangement to the tail ,from the pedals..? ..Is this a new terminology for a `teleflex` control,as cables are usually `pullers,not pushers`..?Why not carbon fibre rods ?

If one had a hyd failure,does the servo have a `bypass`loop,..?to allow manual inputs from the pedals..?

Can the controls be checked on the ground for `full,free and correct` operation prior to start,or only with an ext,hyd rig...?

Could you also confirm the spider pitch links go to the rear of the t/r blades,ie behind the feathering axis....?

thanks in advance...

If one had a hyd failure,does the servo have a `bypass`loop,..?to allow manual inputs from the pedals..?

Can the controls be checked on the ground for `full,free and correct` operation prior to start,or only with an ext,hyd rig...?

Could you also confirm the spider pitch links go to the rear of the t/r blades,ie behind the feathering axis....?

thanks in advance...

Join Date: Mar 2007

Location: UK

Posts: 321

Likes: 0

Received 0 Likes

on

0 Posts

A ‘flexiball cable’ is what it is called. They’ve been used successfully by several helicopter manufacturers for the last 20+ years (e.g Eurocopter/ Airbus, MD, Agusta), though a flexiball control was attributed to the cause of an EC135 crash in Japan in 2007. The last statement with reference to no maintenance and lubrication isn’t strictly true. They are subject to periodic friction force checks and the eye-end sliders sometimes get greased (depends on aircraft type).

Join Date: Mar 2007

Location: UK

Posts: 321

Likes: 0

Received 0 Likes

on

0 Posts

If one had a hyd failure,does the servo have a `bypass`loop,..?to allow manual inputs from the pedals..?

Can the controls be checked on the ground for `full,free and correct` operation prior to start,or only with an ext,hyd rig...?

Could you also confirm the spider pitch links go to the rear of the t/r blades,ie behind the feathering axis....?

thanks in advance...

Can the controls be checked on the ground for `full,free and correct` operation prior to start,or only with an ext,hyd rig...?

Could you also confirm the spider pitch links go to the rear of the t/r blades,ie behind the feathering axis....?

thanks in advance...

2. With one engine running in 'Acc Drive'

3. Yes

Join Date: Mar 2014

Location: Isle of Man

Age: 72

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

nodrama. I would be interested in your thoughts on lubrication of the failed bearing, with the burned 'black grease' on the rod nearby. In my experience with classic cars, black graphite grease can 'dry out' if not used regularly - and this a/c was apparently not used all that frequently?

Nodrama,thanks for that; assume `acc drive` is similar to WX,S-K,Lynx...

Leonardo (the Engineer),said `Friction keeps the World together,Lubrication (grease,oil, money ), allows it to spin``...pity his namesake didn`t take note......

Leonardo (the Engineer),said `Friction keeps the World together,Lubrication (grease,oil, money ), allows it to spin``...pity his namesake didn`t take note......

With my 28 yrs of aircraft maintenance involvement I can only agree with nodrama, that report is surprisingly ambiguous - AAIB was always a first-class source of information. Using term "solenoid valve" for a hydraulic system component is softly said, misleading. (except in case there is truly an electromagnetic valve involved - in that case I will have to bury myself )

nodrama, can you comment or confirm that torque applied to castellated nut, that holds duplex bearing in place on control rod, has no effect on the bearing itself i.e. that overtorquing it will not "squeeze" balls between inner and outer race, but "only" overload the rod-threads?

Is duplex bearing actually made of two completelly separate bearings, turned one against the other, or is it one component? From the Fig. 4 in AAIB S2/2018 it seems there are two inner races, but one outer race. Such design implies that nut torque could have an effect on bearing friction? (if there is a gap between inner races-depends on design) Please help clarifying this, if you can!

hoistop

nodrama, can you comment or confirm that torque applied to castellated nut, that holds duplex bearing in place on control rod, has no effect on the bearing itself i.e. that overtorquing it will not "squeeze" balls between inner and outer race, but "only" overload the rod-threads?

Is duplex bearing actually made of two completelly separate bearings, turned one against the other, or is it one component? From the Fig. 4 in AAIB S2/2018 it seems there are two inner races, but one outer race. Such design implies that nut torque could have an effect on bearing friction? (if there is a gap between inner races-depends on design) Please help clarifying this, if you can!

hoistop