R22 & R44 blade delamination

Thread Starter

Join Date: May 2001

Location: queensland australia

Age: 77

Posts: 563

Likes: 0

Received 1 Like

on

1 Post

R22 & R44 blade delamination

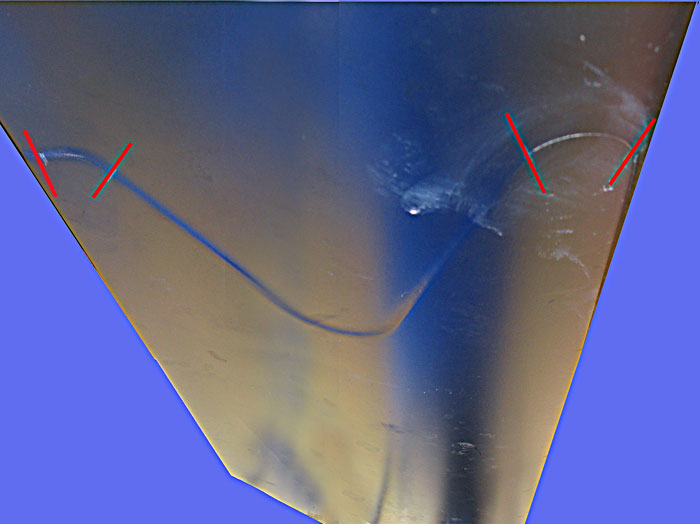

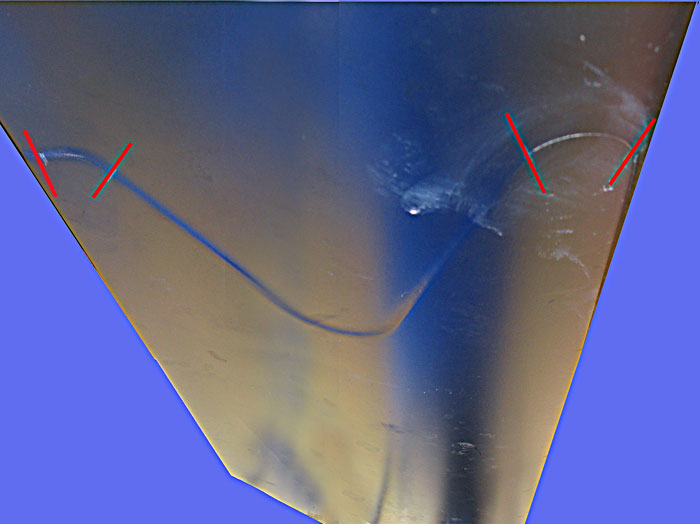

this photograph is the lower side of a new (300 hour) stainless r22 blade.

the cracks extend between the red lines.

most of the hours have been done at a flying school.

one of the four different incidents of blade delaminations was only detected when the blade was removed by a service centre.

there has been one instance from canada i am told. of the four instances in australia they have all been well under 1000 hours

go back to the old blade regime and do a thorough examination of the blade root laminates. even maybe the old tap test.

a defect report has been lodged with casa but nothing yet.

the cracks extend between the red lines.

most of the hours have been done at a flying school.

one of the four different incidents of blade delaminations was only detected when the blade was removed by a service centre.

there has been one instance from canada i am told. of the four instances in australia they have all been well under 1000 hours

go back to the old blade regime and do a thorough examination of the blade root laminates. even maybe the old tap test.

a defect report has been lodged with casa but nothing yet.

Last edited by imabell; 19th Apr 2006 at 05:25.

Join Date: Mar 2002

Location: Queensland Australia

Posts: 267

Likes: 0

Received 0 Likes

on

0 Posts

Imabell

I can't see the cracks too well in the photo. Are they following the curve of the thicker "blade grip" (whatever it's called) Is there some sort of epoxy under the paint at the edge of the "grip" to smooth out the edge? Is the crack just in the epoxy (if it exists) or is the crack from truly lifted layer of metal?

I can't see the cracks too well in the photo. Are they following the curve of the thicker "blade grip" (whatever it's called) Is there some sort of epoxy under the paint at the edge of the "grip" to smooth out the edge? Is the crack just in the epoxy (if it exists) or is the crack from truly lifted layer of metal?

Join Date: Jul 2004

Location: Victoria

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

wear & tear

undue fatigue possible from overspeed or other unusual high stressing of blade?

or is this an unusual early delamination from a relatively new & well taken care of bird, (no known incidents).

being from a flying school, potential for the unknown has increased; is the student likely to admit or even be aware of the error if they did something untowards (even if unintentionally).

or is this an unusual early delamination from a relatively new & well taken care of bird, (no known incidents).

being from a flying school, potential for the unknown has increased; is the student likely to admit or even be aware of the error if they did something untowards (even if unintentionally).

Thread Starter

Join Date: May 2001

Location: queensland australia

Age: 77

Posts: 563

Likes: 0

Received 1 Like

on

1 Post

the cracks are the marks that you can see. the doubler has come away from the blade itself.

gadget, i really don't think it is related to overstressing in any way but we are looking at all aspects.

gadget, i really don't think it is related to overstressing in any way but we are looking at all aspects.

Join Date: Jul 2003

Location: Port Townsend,WA. USA

Posts: 440

Likes: 0

Received 0 Likes

on

0 Posts

Is this a crack or a doubler disbond?

A crack is not the same as a disbond.

I think maybe the correct word here is disbond.

The word delamination normally applies to composite plies separating.

Disbond is the word for metal parts that come unglued.

A crack is not the same as a disbond.

I think maybe the correct word here is disbond.

The word delamination normally applies to composite plies separating.

Disbond is the word for metal parts that come unglued.

Join Date: Mar 2006

Location: On the move...

Age: 58

Posts: 358

Likes: 0

Received 0 Likes

on

0 Posts

That's scary to see, but good training on what to look for in daily's.

That's scary to see, but good training on what to look for in daily's.You said that the delam was on the underside, due to coning is it never going to happen on the top?

Do you know the history of the machine? Do they overload the '22? Overpitch, etc?

Thank God it was found! Good work whoever saw it AND spoke up.

Thread Starter

Join Date: May 2001

Location: queensland australia

Age: 77

Posts: 563

Likes: 0

Received 1 Like

on

1 Post

another r22 blade has been found in northern queensland with a delamination of the doubler today. apparently there have been three cases reported in the states as well.

robinson has told this owner to send the blade back and they will look at repairing it.

slowrotor, i think the term you are looking for is debonding but who cares what we call it, it is a bad situation we are talking about, lots of down time and lots of money.

there are a lot of people relying on their machines staying in the air for a very big season and to have what seems to be an emerging problem confronting them can be a bit worrying to say the least.

this is now the fifth machine this year with well under a thousand hours, (two at under 300), to suffer from this problem and there has been no words of assurance or otherwise emanating from the powers that be.

two defect notices have been lodged with australia's civil aviation safety authority now. so we sit and wait. the first defect notice was lodged over 6 weeks ago and no word yet, the second one was a couple of days ago. we operate three robbies at the moment and don't need them sitting on the ground.

robinson has told this owner to send the blade back and they will look at repairing it.

slowrotor, i think the term you are looking for is debonding but who cares what we call it, it is a bad situation we are talking about, lots of down time and lots of money.

there are a lot of people relying on their machines staying in the air for a very big season and to have what seems to be an emerging problem confronting them can be a bit worrying to say the least.

this is now the fifth machine this year with well under a thousand hours, (two at under 300), to suffer from this problem and there has been no words of assurance or otherwise emanating from the powers that be.

two defect notices have been lodged with australia's civil aviation safety authority now. so we sit and wait. the first defect notice was lodged over 6 weeks ago and no word yet, the second one was a couple of days ago. we operate three robbies at the moment and don't need them sitting on the ground.

Join Date: Jul 2004

Location: Victoria

Posts: 188

Likes: 0

Received 0 Likes

on

0 Posts

don't mind me - I'll ask all the dumb questions

re: overpitching & coning

what are the tell-tale signs of excessive coning (never seen one or photos of one) are there visible wrinkles on the topside of the blade ?

if excessive coning was a culprit would the 'debond' be likely to occur on the underside prior to any other indications.

am interested in what other people have seen / experienced

so would appreciate anybody setting me straight.

not trying to point the finger just asking the obvious i suppose.

being robbies are currently all i have the opportunity to fly - it is a little disconcerting.

what are the tell-tale signs of excessive coning (never seen one or photos of one) are there visible wrinkles on the topside of the blade ?

if excessive coning was a culprit would the 'debond' be likely to occur on the underside prior to any other indications.

am interested in what other people have seen / experienced

so would appreciate anybody setting me straight.

not trying to point the finger just asking the obvious i suppose.

being robbies are currently all i have the opportunity to fly - it is a little disconcerting.

Join Date: Feb 2006

Location: Tucson, Arizona

Age: 52

Posts: 10

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: Jul 2002

Location: Somewhere, Over the Rainbow

Posts: 200

Likes: 0

Received 0 Likes

on

0 Posts

In another end of the world

We get "delamination" at the roots of the blades on our Blackhawks fairly frequently (right at the very inside of the blade, where the root meets the blade for the first time) -- the prop and rotor guys put a bit of pro-seal and spray-paint on it and call it fixed until it shows up again. It looks like a crack, but is only a split of the sealing compound (so they say).

Granted, the R22 blade may be vastly different in construction, or there may be some uneducated prop-and-rotor guys in the military, but had I seen a crack like that on an R22 I was pre-flighting, I wouldn't fly... not to say I wouldn't trust a qualified mechanic to say it was good to go.

Heres to safe flying

-Mike

Granted, the R22 blade may be vastly different in construction, or there may be some uneducated prop-and-rotor guys in the military, but had I seen a crack like that on an R22 I was pre-flighting, I wouldn't fly... not to say I wouldn't trust a qualified mechanic to say it was good to go.

Heres to safe flying

-Mike

Join Date: Jul 2003

Location: Port Townsend,WA. USA

Posts: 440

Likes: 0

Received 0 Likes

on

0 Posts

imabell,

The reason I was asking if the blade is cracked or disbonded is because it might be repairable as twinhueyman has suggested. It might be a crack in the paint, I cannot tell from the photo. I dont know what is acceptable in this case because I dont work on Robinson.

Not all surface imperfections are cause for alarm. Get the proper information.

I have seen props replaced by mechanics that did not have the proper maintenance manual that clearly listed acceptable surface cracks that occur in normal use. So who cares what you call it you ask. I would care if I owned this aircraft.

If the blade is not repairable, then of course I understand your frustration.

slowrotor

(retired mechanic/inspector)

The reason I was asking if the blade is cracked or disbonded is because it might be repairable as twinhueyman has suggested. It might be a crack in the paint, I cannot tell from the photo. I dont know what is acceptable in this case because I dont work on Robinson.

Not all surface imperfections are cause for alarm. Get the proper information.

I have seen props replaced by mechanics that did not have the proper maintenance manual that clearly listed acceptable surface cracks that occur in normal use. So who cares what you call it you ask. I would care if I owned this aircraft.

If the blade is not repairable, then of course I understand your frustration.

slowrotor

(retired mechanic/inspector)

Last edited by slowrotor; 20th Apr 2006 at 15:32.

Thread Starter

Join Date: May 2001

Location: queensland australia

Age: 77

Posts: 563

Likes: 0

Received 1 Like

on

1 Post

slow rotor, the doubler has delaminated it is not a crack it is a delamination.

i have all the facts, i have all the proper information, this is not hearsay i have seen the blade.

bushbandit, i don't know how much load you guys put on blades and machines but i have seen film of some obviously heavy loads slingshotted of mountains and carried out by some mountain pilots in new zealand.

i would have to be reasonably sure that testing of the loads to breaking point of any helicopter rotor blade would be at least to double the weight of the machine. i am reasonably sure that any manufacturer would not manufacture blades that are rated to within a couple of kilos over max gross. the margin for safety has to be large or you would not have the confidence to fly. i am sure even in the new zealand alps your robbies cannot lift enough to break a blade. (i have flown there).

there are repair allowances for the doublers on 47's and jet rangers by cutting the doubler back beyond the debonded section and feathered back to the blade skin. this is what robinson is now looking at trying (experimenting).

twinhueyman, i'm with you, if the engineer says it's ok, just keep an eye on it i'll go flying. the problem here is nobody is saying anything and the engineers are grounding helicopters.

i have all the facts, i have all the proper information, this is not hearsay i have seen the blade.

bushbandit, i don't know how much load you guys put on blades and machines but i have seen film of some obviously heavy loads slingshotted of mountains and carried out by some mountain pilots in new zealand.

i would have to be reasonably sure that testing of the loads to breaking point of any helicopter rotor blade would be at least to double the weight of the machine. i am reasonably sure that any manufacturer would not manufacture blades that are rated to within a couple of kilos over max gross. the margin for safety has to be large or you would not have the confidence to fly. i am sure even in the new zealand alps your robbies cannot lift enough to break a blade. (i have flown there).

there are repair allowances for the doublers on 47's and jet rangers by cutting the doubler back beyond the debonded section and feathered back to the blade skin. this is what robinson is now looking at trying (experimenting).

twinhueyman, i'm with you, if the engineer says it's ok, just keep an eye on it i'll go flying. the problem here is nobody is saying anything and the engineers are grounding helicopters.

imabell

Anyone who has had anything to do with R22's in a working environment (which I'm sure you have) knows what disc loading they are capable of.

If there is some type of fault with the glue or the bonding process at manufacture a flying school would be the perfect place to test it out. Doing autos all the time the machine would be subject to the most demanding aspect in that area (High coning angle/low RRPM).

There is overspeed limits, MTOW limits but there is no coning angle limit at the bottom of an auto. I would guess that it is assumed that if you exceed the coning angle limit your attention would be more focused on the bent skids and wrinkled firewall.

As far as lifting too much goes I would tend to think that is a load of crap. An R22 won't get off the ground if its AUW is causing excessive coning. They would be subject to such things anyway in the form of G loading in certain manouvers.

Though other aircraft do debond/delaminate/come unstuck/unglue/f*%$#n break in that area they appear to have a bit more reliance when it comes to the integrity of the blade. ie B47.

I am sure that you would agree that the R22 is a sensational machine but these things do turn up on them from time to time and I would be more enclined to think that this is some type of manufacturing anomally. I hope for your sake Frank sees it that way.

Anyone who has had anything to do with R22's in a working environment (which I'm sure you have) knows what disc loading they are capable of.

If there is some type of fault with the glue or the bonding process at manufacture a flying school would be the perfect place to test it out. Doing autos all the time the machine would be subject to the most demanding aspect in that area (High coning angle/low RRPM).

There is overspeed limits, MTOW limits but there is no coning angle limit at the bottom of an auto. I would guess that it is assumed that if you exceed the coning angle limit your attention would be more focused on the bent skids and wrinkled firewall.

As far as lifting too much goes I would tend to think that is a load of crap. An R22 won't get off the ground if its AUW is causing excessive coning. They would be subject to such things anyway in the form of G loading in certain manouvers.

Though other aircraft do debond/delaminate/come unstuck/unglue/f*%$#n break in that area they appear to have a bit more reliance when it comes to the integrity of the blade. ie B47.

I am sure that you would agree that the R22 is a sensational machine but these things do turn up on them from time to time and I would be more enclined to think that this is some type of manufacturing anomally. I hope for your sake Frank sees it that way.

Thread Starter

Join Date: May 2001

Location: queensland australia

Age: 77

Posts: 563

Likes: 0

Received 1 Like

on

1 Post

yes bellfest to all of those things.

having a blade delaminate and talking about it is one thing but the repercussions involved with multiple occurrences is our major worry. we operate three robbies, one with a delamination, and three bells, but you have to imagine the plight of the single and multiple robbie operator whoe suffers this problem, the time frame to fix it, right at the begginning of the mustering season.

there are abot 200 machines used in mustering and every one of the owners has their collective fingers crossed that this does not escalate.

i have since learnt of another blade that has come unstuck in australia that makes six.

i also have heard a rumour that there have been instances at the factory before delivery but i cannot substantiate this.

having a blade delaminate and talking about it is one thing but the repercussions involved with multiple occurrences is our major worry. we operate three robbies, one with a delamination, and three bells, but you have to imagine the plight of the single and multiple robbie operator whoe suffers this problem, the time frame to fix it, right at the begginning of the mustering season.

there are abot 200 machines used in mustering and every one of the owners has their collective fingers crossed that this does not escalate.

i have since learnt of another blade that has come unstuck in australia that makes six.

i also have heard a rumour that there have been instances at the factory before delivery but i cannot substantiate this.

Join Date: Feb 2005

Location: Australia

Posts: 1,957

Likes: 0

Received 0 Likes

on

0 Posts

R22 blades

407

That looks like only half the pic, what did the drag brace area look like?

Heard of an incident many moons ago from a company in east OZ. They had a fruit loop (aren’t we all?) driving a 12E in mustering mode. Hero hits a tree and did more damage than your pic and decided to hack saw the offending bent areas off, about nine inches or so. The story of course does not stop there, our hero turned engineer all of sudden and reckons that he needs to balance the system so cuts the same amount off of the other but so far unblemished blade and flies around for another fifty or so hours until the next 100. Rumour has it that our hero left his place of employ on foot, at a very fast clip, without even picking up his check when confronted by the boss.

Twin huey

I am with you too, if your gut feeling is nogo, then I don’t go, contracts don’t pay for expensive holes in the ground.

Acsj

You’re onto it, but the price of fuel gees every drop saved counts, or maybe you could suggest to Frank he could use a scaled model of one of those two mentioned types of blades on the R22. Hmmmm an 269 series blade onto the R22 series, given the history of why-for the R22, that would stir a real ruckus in Torrance HQ!!

Slowrotor

From the MM sect 9.130 h) 1. “Blades must be tap tested using a 1965 (or later US quarter in good condition.” (Really, yep a bloody 1965 quater! I read that a few times to make sure. Did HAA hang that one on him and did one qrtr each get sent with all of the exported models?)

Allowable; “no single void larger than .10 square inch.” I read that as 1 inch long a tenth of an inch deep. That is not much. I could easily stand to be corrected!

Section 9.130 is called up by section 2.410 Item 13. (Part of the 100 hourly)

Make sure that no-one does a tap test until referring to the diagrams or they are well briefed as to where the bonded areas are. If they tap outside a bonded area they’re liable to U.S. the blade. BE CAREFUL THEY ARE FRAGILE.

So far I am hearing that they are all early production blades but that is being checked.

No doubt Torrance HQ is working around the clock on this, after all the viability of 4,000 helicopters hangs on a viable operational outcome quite soon.

Not to mention that a multitude of operators in North Australia who have been delayed on their mustering season start because of so much cyclonic activity and the entire north Australian cattle industry who also depend on these helicopters.

If these defects have been known for a while one might have thought that there could/should be a daily inspection both visual and tap test required by now by Robinson and or CASA, FAA and NZ CAA. That is assuming all authorities received Defect reports!

There is of course already a requirement in the POH to visually check the blades for cracks; however a special purpose AD or SB would be a good idea at least to clarify –is it or isn’t it OK- do you know????

How many people really check for cracks when doing a daily, or even venture up toward the head? There are only three things in a daily that will kill you if you miss them no matter how big or small the aircraft.

They are the three C’s. 1. CRACK, 2. CHAFING, 3 CORROSION and the little S, for Security.

Re cost, the MM states also that; “Voids or debonds are NOT field repairable.”

This means return to factory, it should mean return to approved service centre for approved repair. The time and cost to ship blades across a continent and then the Pacific Ocean and back again all without being damaged would be monumental. If necessary it would be much better and cheaper to have a Robinson senior technician attend and supervise these repairs at some of the major service centres.

IMABELL paints a horrible financial picture if the blade security is not attended to quickly. Fair enough!

That looks like only half the pic, what did the drag brace area look like?

Heard of an incident many moons ago from a company in east OZ. They had a fruit loop (aren’t we all?) driving a 12E in mustering mode. Hero hits a tree and did more damage than your pic and decided to hack saw the offending bent areas off, about nine inches or so. The story of course does not stop there, our hero turned engineer all of sudden and reckons that he needs to balance the system so cuts the same amount off of the other but so far unblemished blade and flies around for another fifty or so hours until the next 100. Rumour has it that our hero left his place of employ on foot, at a very fast clip, without even picking up his check when confronted by the boss.

Twin huey

I am with you too, if your gut feeling is nogo, then I don’t go, contracts don’t pay for expensive holes in the ground.

Acsj

You’re onto it, but the price of fuel gees every drop saved counts, or maybe you could suggest to Frank he could use a scaled model of one of those two mentioned types of blades on the R22. Hmmmm an 269 series blade onto the R22 series, given the history of why-for the R22, that would stir a real ruckus in Torrance HQ!!

Slowrotor

From the MM sect 9.130 h) 1. “Blades must be tap tested using a 1965 (or later US quarter in good condition.” (Really, yep a bloody 1965 quater! I read that a few times to make sure. Did HAA hang that one on him and did one qrtr each get sent with all of the exported models?)

Allowable; “no single void larger than .10 square inch.” I read that as 1 inch long a tenth of an inch deep. That is not much. I could easily stand to be corrected!

Section 9.130 is called up by section 2.410 Item 13. (Part of the 100 hourly)

Make sure that no-one does a tap test until referring to the diagrams or they are well briefed as to where the bonded areas are. If they tap outside a bonded area they’re liable to U.S. the blade. BE CAREFUL THEY ARE FRAGILE.

So far I am hearing that they are all early production blades but that is being checked.

No doubt Torrance HQ is working around the clock on this, after all the viability of 4,000 helicopters hangs on a viable operational outcome quite soon.

Not to mention that a multitude of operators in North Australia who have been delayed on their mustering season start because of so much cyclonic activity and the entire north Australian cattle industry who also depend on these helicopters.

If these defects have been known for a while one might have thought that there could/should be a daily inspection both visual and tap test required by now by Robinson and or CASA, FAA and NZ CAA. That is assuming all authorities received Defect reports!

There is of course already a requirement in the POH to visually check the blades for cracks; however a special purpose AD or SB would be a good idea at least to clarify –is it or isn’t it OK- do you know????

How many people really check for cracks when doing a daily, or even venture up toward the head? There are only three things in a daily that will kill you if you miss them no matter how big or small the aircraft.

They are the three C’s. 1. CRACK, 2. CHAFING, 3 CORROSION and the little S, for Security.

Re cost, the MM states also that; “Voids or debonds are NOT field repairable.”

This means return to factory, it should mean return to approved service centre for approved repair. The time and cost to ship blades across a continent and then the Pacific Ocean and back again all without being damaged would be monumental. If necessary it would be much better and cheaper to have a Robinson senior technician attend and supervise these repairs at some of the major service centres.

IMABELL paints a horrible financial picture if the blade security is not attended to quickly. Fair enough!

or do we all have to fly 300s

or do we all have to fly 300s