Alaska Airlines 737-900 MAX loses a door in-flight out of PDX

That's what I thought when I first saw that axial bore. I further thought, that the bolt may slide into that fitting by installing a tool and pulling towards the center of the plug. However this is not compatible with the infos given by the 737 tech channel.

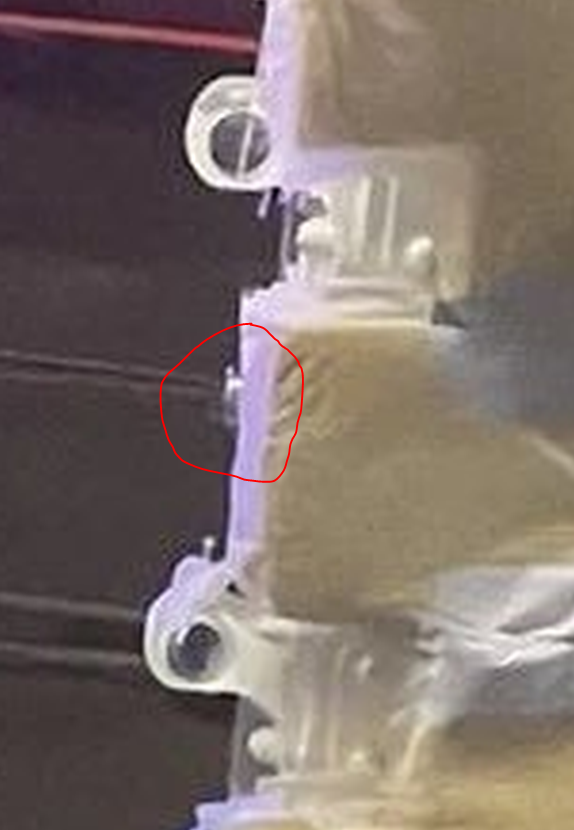

As said before this stub of the roller pin is rather short. I wonder if it is still blocked if wrong diameter locking bolts are used.

As said before this stub of the roller pin is rather short. I wonder if it is still blocked if wrong diameter locking bolts are used.

Just a guess, but the hole in the centre of the roller pin may be for adjustment of this pin. It probably does not allow a bolt to be fitted in there. The suggestion earlier on of using this hole to lock the assembly would not allow for the same provisions for locking the bolt in place, would be more difficult to inspect and would put extra stresses on the roller pin mounting. The locking pin as it is used by Boeing here is a much simpler option as it prevents movement of the pin relative to the guide by blocking this guide, which is what is needed in this case.

Psychophysiological entity

fdr's post of historic incident with Boeing and their sub contractors. Indeed, the latter was caught with their pants down on a Swat style inspection. The specifications for those rings was to an accuracy of 3,000 th of an inch., but were being hand honed with what looked like sanding blocks. Some aircraft had the rings so tight they were hammered into place and it seems, marked with colour to show where. The treatment of those women left me breathless, though I don't know why in the poisonous culture Boeing had allowed to flourish.

Last time that occurred, the Renton QA Staff visited the supplier to Boeing who was doing the ring frames for the NG, and noted that the frames which the production approvals had been based on CAM milling, were being done by hand, over an unapproved homemade jig. The supplier had stated the components were CAM fabricated, and they didn't own a CAM unit. Upshot, Boeing sacked the QA inspectors, and Boeing actually won in court against wrongful dismissal action by the inspectors. The FAA did... nothing. The bogus parts are still flying around today.

The rigidity of tubular fuselages limits torsion deformation. Without deformation there isn't much stress on the door. The main stress is from the pressure load which puts bending loads on the fingers, but if they had failed the guide rollers would likely have been torn loose and they are still present.

A couple comments:

1) Can we all agree that the missing part of the plane is a "door" that replaces an emergency exit "door, That it is NOT a "plug"?, it is not designed as a "plug", does not function as a "plug" under pressurization of the hull. In fact, it performs exactly the opposite. The outward forces work to stress the door against its retainers not the frame in any intrinsic or hermetic manner..

2) The missing door is fitted with a larger window than the emergency door it replaces. It seems from photos that there is less cross bracing in that design. However I am not jumping to conclusions that the door failed. It is more likely that the low altitude and missing bolts conspired to eject this door (not a plug).

1) Can we all agree that the missing part of the plane is a "door" that replaces an emergency exit "door, That it is NOT a "plug"?, it is not designed as a "plug", does not function as a "plug" under pressurization of the hull. In fact, it performs exactly the opposite. The outward forces work to stress the door against its retainers not the frame in any intrinsic or hermetic manner..

2) The missing door is fitted with a larger window than the emergency door it replaces. It seems from photos that there is less cross bracing in that design. However I am not jumping to conclusions that the door failed. It is more likely that the low altitude and missing bolts conspired to eject this door (not a plug).

A door on an aircraft can be a plug type door where cabin pressure forces the door to the closed position.

The item that detached from this aircraft was not a door, it was a panel designed to fill an unused opening in the fuselage.

When owners of older 707/727/737 aircraft choose to no longer use the eyebrow windows in the cockpit, they don't replace them with doors, they replace them with plugs.

Same when passenger aircraft are converted for cargo use, the cabin windows are replaced with plugs. Not doors.

Photos have been posted in this thread showing the inside of both the doors and the plugs that can fill this opening in the fuselage. They are not the same.

SWAG Theories

1) The popular one. Rigging was incorrect, one or more bolts left out that would have prevented the door (not a PLUG) to move from its fully engaged position.

2) a) Photos of one guide pin on the accident plane appear to show a very short length of the guide pin/roller. Its length significantly less than its diameter. b) The dummy door (not a PLUG) differs from an Emergency Exit Door (not a PLUG) in a significant way. The cross bracing is removed to accommodate a larger window. Could the combination of the panel being weaker at that point have allowed the door (not a PLUG) to bow outward and dislodged the upper portion of the door from the guide pins/rollers? The four rigging bolts would do little to retain the door at this point.

1) The popular one. Rigging was incorrect, one or more bolts left out that would have prevented the door (not a PLUG) to move from its fully engaged position.

2) a) Photos of one guide pin on the accident plane appear to show a very short length of the guide pin/roller. Its length significantly less than its diameter. b) The dummy door (not a PLUG) differs from an Emergency Exit Door (not a PLUG) in a significant way. The cross bracing is removed to accommodate a larger window. Could the combination of the panel being weaker at that point have allowed the door (not a PLUG) to bow outward and dislodged the upper portion of the door from the guide pins/rollers? The four rigging bolts would do little to retain the door at this point.

Join Date: Oct 2006

Location: Ankh Morpork, DW

Posts: 652

Likes: 0

Received 0 Likes

on

0 Posts

NTSB B-Roll - Alaska Airlines Flight 1282 Boeing 737-9 MAX

Check out 2:12 - the right side is being examined and light is coming through. Either the NTSB opened the right side for inspection, or the right side was also not secured.

Possibly some confusion with the emergency exit that can be fitted in lieu of the door plug and that can, like any E/E, be opened from both inside and outside.

Even more significant was the air rush sucked the emergency SOP checklist out of the flight deck. Which presumably contained the CVR switch off command. The crew had to do it all from memory instead.

One day the CVR industry will come up with an ever so simple way to avoid this overwriting. Goodness knows how often it has occurred in incidents in the past. I know the requirement is to maintain the last 2 hours, but that didn't extend to any instruction to start overwriting at 2 hours and 1 minute.

One day the CVR industry will come up with an ever so simple way to avoid this overwriting. Goodness knows how often it has occurred in incidents in the past. I know the requirement is to maintain the last 2 hours, but that didn't extend to any instruction to start overwriting at 2 hours and 1 minute.

Or relegate the on board boxes to the back up role.

Before you all get too wrapped up in your anti-Boeing crusade, you might want to consider this little inconvenient fact: The fuselage isn't built by Boeing - all 737 fuselages are assembled in Wichita by Spirit AeroSystems. The fuselages are shipped to Renton by rail as basically complete structures with the plug (or door) already installed. Assuming that this was an assembly issue (as seems likely based on the lack of associated damage from the departed plug, as well as the AD'ed inspection), the blame should fall squarely on Spriit, not Boeing.

While Spirit was "Boeing Wichita" at one time, that hasn't been the case for nearly 20 years (Boeing sold them in 2005) and it has operated as an independent subcontractor since. Spirit is also a major supplier to Airbus.

While an alert inspector at Boeing might have picked up on missing fasteners, given that fuselage portion arrives as a compete, approved assembly, it is very unlikely that there is any task at Boeing Renton to verify that the appropriate fasteners are installed on that door plug.

Unfortunately, QA at Spirit has been an on-going issue for some time - especially with the 737 fuselages (the often-mentioned issue with the miss-drilled aft bulkhead holes also traces back to Spirit.

Interestingly, there was an article in the Seattle Times recently regarding Boeing and Spirit re-negotiating the contract for the 737 fuselages to include improved quality and QA inspections (presumably with an increase in price to Boeing, although I don't think the article specifically said that).

While I doubt it's feasible at this point for Boeing to bring in a new subcontractor for the 737 fuselage, I think Spirit badly needs to step up their game if they expect to receive any future new business (Boeing, Airbus, or anyone else). No airframer wants to be associated with the sort of liability (not to mention bad press) that the recent Spirit screwups have caused Boeing.

While Spirit was "Boeing Wichita" at one time, that hasn't been the case for nearly 20 years (Boeing sold them in 2005) and it has operated as an independent subcontractor since. Spirit is also a major supplier to Airbus.

While an alert inspector at Boeing might have picked up on missing fasteners, given that fuselage portion arrives as a compete, approved assembly, it is very unlikely that there is any task at Boeing Renton to verify that the appropriate fasteners are installed on that door plug.

Unfortunately, QA at Spirit has been an on-going issue for some time - especially with the 737 fuselages (the often-mentioned issue with the miss-drilled aft bulkhead holes also traces back to Spirit.

Interestingly, there was an article in the Seattle Times recently regarding Boeing and Spirit re-negotiating the contract for the 737 fuselages to include improved quality and QA inspections (presumably with an increase in price to Boeing, although I don't think the article specifically said that).

While I doubt it's feasible at this point for Boeing to bring in a new subcontractor for the 737 fuselage, I think Spirit badly needs to step up their game if they expect to receive any future new business (Boeing, Airbus, or anyone else). No airframer wants to be associated with the sort of liability (not to mention bad press) that the recent Spirit screwups have caused Boeing.

Even more significant was the air rush sucked the emergency SOP checklist out of the flight deck. Which presumably contained the CVR switch off command. The crew had to do it all from memory instead.

One day the CVR industry will come up with an ever so simple way to avoid this overwriting. Goodness knows how often it has occurred in incidents in the past. I know the requirement is to maintain the last 2 hours, but that didn't extend to any instruction to start overwriting at 2 hours and 1 minute.

One day the CVR industry will come up with an ever so simple way to avoid this overwriting. Goodness knows how often it has occurred in incidents in the past. I know the requirement is to maintain the last 2 hours, but that didn't extend to any instruction to start overwriting at 2 hours and 1 minute.

Or relegate the on board boxes to the back up role.

With just about every new aircraft having internet access on board you would think it would be very easy to stream the entire aircraft life history to the cloud (no pun intended) as a back up to on board orange boxes.

Or relegate the on board boxes to the back up role.

Or relegate the on board boxes to the back up role.

Transmission to cloud-based storage is currently not sufficiently reliable for real time use, but burst transmission for (infinite) archive would be achievable at what OUGHT to be only a minor cost per hour.

Psychophysiological entity

Something is prompting the NTSB boss to photograph it. I imagine the denuded view will be somewhat interesting.

Not the boss, the plug!

Not the boss, the plug!

Join Date: Jan 2024

Location: UK

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

I don't see that you can conclude the door/plug is not secured from the video. It could be that the decor panel and window surround has separated from the window allowing light to enter between the inside of the window and window surround. Why that might have happened is another matter. It might just be a result of the loss of pressurisation.

Unconfirmed reports that the newly-discovered door plug has one of the two guide rollers jammed in the guide. Given that they are part of the aircraft structure and not the door, if true it would imply that it had sheared off.

That would be an interesting failure mode. Given that the photos appear to show the aft roller still in situ in the doorframe, it would have to be the forward one. With no guide roller engaged in the door, the presence or absence of the locking bolt would be irrelevant and it may have allowed at least the forward edge of the door to creep past the stops.

That would be an interesting failure mode. Given that the photos appear to show the aft roller still in situ in the doorframe, it would have to be the forward one. With no guide roller engaged in the door, the presence or absence of the locking bolt would be irrelevant and it may have allowed at least the forward edge of the door to creep past the stops.

You didn't take up my earlier suggestion to call the NTSB with your findings, then ?

The advance of technology and reduction in cost makes it VERY hard to understand why on-board systems are limited to 2 hours voice - investment in aircraft and piloting tech seems to have left this subsystem behind.

Transmission to cloud-based storage is currently not sufficiently reliable for real time use, but burst transmission for (infinite) archive would be achievable at what OUGHT to be only a minor cost per hour.

Transmission to cloud-based storage is currently not sufficiently reliable for real time use, but burst transmission for (infinite) archive would be achievable at what OUGHT to be only a minor cost per hour.

I take your point about the 2-hour thing but, at some point, it still needs someone to pull the CB. Think 24 hours is going to cut it?

Even if the 4 locking bolts (with their slotted nuts and cotter pins/split pins) were missing, the lower hinge arms which are still attached to the floor bracket, have a double lock nut arrangement on the shaft end and large washer, allowing the semi plug to rise and hinge outwards, spring assist, as it is apparently designed to do; the exterior fuselage does not appear to have any buffet damage from the plug assembly which indicates to be at least that either the washer was not large enough to hold on the bracket structure and the shaft just pulled through; Or the double lock nuts and washer was not present. Accepted the lanyards are unlikely to offer little resistance to the cabin pressure acting on the large plug surface.

I do not have a good definition screen to zero in on the hinge fittings on the outside to see if there is just thread or nuts present, anyone?

I do not have a good definition screen to zero in on the hinge fittings on the outside to see if there is just thread or nuts present, anyone?

Unconfirmed reports that the newly-discovered door plug has one of the two guide rollers jammed in the guide. Given that they are part of the aircraft structure and not the door, if true it would imply that it had sheared off.

That would be an interesting failure mode. Given that the photos appear to show the aft roller still in situ in the doorframe, it would have to be the forward one. With no guide roller engaged in the door, the presence or absence of the locking bolt would be irrelevant and it may have allowed at least the forward edge of the door to creep past the stops.

That would be an interesting failure mode. Given that the photos appear to show the aft roller still in situ in the doorframe, it would have to be the forward one. With no guide roller engaged in the door, the presence or absence of the locking bolt would be irrelevant and it may have allowed at least the forward edge of the door to creep past the stops.