Alaska Airlines 737-900 MAX loses a door in-flight out of PDX

I might well be wrong, but in that case I'm struggling to understand what locates the door plug longitudinally, if it isn't the hinge brackets. Can you help?

Further to my post at #347 and Old Ag at #470, without all four safety bolts plug is only held in place by gravity; resting on rollers.

Then under low or negative G, lift assist springs can eject the plug?? Thatís neglecting any friction against stops due to cabin pressure.

So Iím visualising the plug jiggling upwards in minor turbulence before cabin is pressurised and ejecting when pressure builds up.

Then under low or negative G, lift assist springs can eject the plug?? Thatís neglecting any friction against stops due to cabin pressure.

So Iím visualising the plug jiggling upwards in minor turbulence before cabin is pressurised and ejecting when pressure builds up.

I agree that this came loose before pressurization as there doesn't seem to have obvious damage that would happen if they were scraped over the edge under the considerable force of pressurization. It would at least have chipped the paint when the load got concentrated on the edge. But if it popped during taxi or climb out? The interior panel might be enough to limit airflow and would have been the pressure plug until the little retaining straps could take no more.

Join Date: Apr 2010

Location: Alexandria VA USA

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

It looks like the upper guides and lower hinges that guide it into position and hold it there once it is closed but not under pressure. Under pressure, itís the lugs that take over holding the door in position as it presses against them due to differential pressure. The hinges have a secondary role of locating the door as it translates or when it is open. As above, the hinges and lower guides do hold the bottom of door tight to the lower lugs when the door closed but not pressurized.

Any one of the four bolts would have prevented the door from translating upward and opening. The two at the bottom lock the door to the hinge by passing through both the lower hinge guide and the hinge. The two at the top prevent the door and its guides from riding up on the guide pins. If they were all left out, the door would close and appear normal, but it wouldn’t take much differential pressure to force it to translate up. At full differential pressure there would be too much force on the lugs to allow the door to translate up. So there is a small range of diff pressure where the door will open without the bolts. The shear force on the bolts would be well below what it would take to break one. On the ground there is no force on the bolts as gravity does all the work. I imagine the bolts are stronger than the structure they are attached to, so a catastrophic bolt failure would be obvious due surrounding damage. As well, a loose bolt, while concerning, is not a problem if the castellated nut and split pin are installed.

My bet is someone left all the bolts out during interior fit or maintenance.

My bet is someone left all the bolts out during interior fit or maintenance.

Over the 150-odd flights that the aircraft has flown since delivery, the nuts would have vibrated off the bolts, one by one, and the bolts themselves would have successively dropped out.

With all but one bolt gone, the sealing of the door would have been sufficiently compromised to produce the intermittent px warnings on the previous flights, and the final bolt worked its way out during the incident flight.

Obviously, alternative scenarios welcomed.

Join Date: Apr 2010

Location: Alexandria VA USA

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

Each of the 12 fingers that hold against pressure has an adjustment screw and it is possible that those were tightened enough to hold the door in place and compress the seal, which would provide a large amount of friction to hold the door in place regardless of the spring.

I agree that this came loose before pressurization as there doesn't seem to have obvious damage that would happen if they were scraped over the edge under the considerable force of pressurization. It would at least have chipped the paint when the load got concentrated on the edge. But if it popped during taxi or climb out? The interior panel might be enough to limit airflow and would have been the pressure plug until the little retaining straps could take no more.

I agree that this came loose before pressurization as there doesn't seem to have obvious damage that would happen if they were scraped over the edge under the considerable force of pressurization. It would at least have chipped the paint when the load got concentrated on the edge. But if it popped during taxi or climb out? The interior panel might be enough to limit airflow and would have been the pressure plug until the little retaining straps could take no more.

if it popped open during taxi or takeoff and was held against the cables there would have been a hell of a racket and the plane wouldnít have pressurized. It seems clear it popped open all at once in flight.

Join Date: May 2011

Location: U.S.

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

I always take these edited reports with a grain of salt because reporters are only concerned with presenting an edited dramatic story. The video includes the witness and the reporter both stating facts, and it appears the witness video is cut, and the cuts possibly out of sequence. I don't believe anything the reporter says, but the witness is clear with what she knows. She is not the boy's mother, but she must have been talking with him during the remainder of the flight.

I have no source for a "toddler and mother" that I had read about early on, reporters often get those things wrong.

Last edited by lateott; 8th Jan 2024 at 22:18. Reason: Deleted huge photo since thumbnail has same image

Join Date: Jul 2009

Location: France

Age: 62

Posts: 98

Likes: 0

Received 0 Likes

on

0 Posts

The exact pin / bolt that was missing in the Alaska accident does not really matter anymore. According to Jon Ostrower, the inspections at United showed

"Across the five aircraft, there is little consistency in the locations of the errant parts..."

The several million dollar question is now: do all the bolts in all the MAX fuselages need inspection, or only the ones in the door plugs of the Max-9?

"Across the five aircraft, there is little consistency in the locations of the errant parts..."

The several million dollar question is now: do all the bolts in all the MAX fuselages need inspection, or only the ones in the door plugs of the Max-9?

Join Date: Apr 2010

Location: Alexandria VA USA

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

I'll raise you: nuts and bolts fitted, but with no split pins.

Over the 150-odd flights that the aircraft has flown since delivery, the nuts would have vibrated off the bolts, one by one, and the bolts themselves would have successively dropped out.

With all but one bolt gone, the sealing of the door would have been sufficiently compromised to produce the intermittent px warnings on the previous flights, and the final bolt worked its way out during the incident flight.

Obviously, alternative scenarios welcomed.

Over the 150-odd flights that the aircraft has flown since delivery, the nuts would have vibrated off the bolts, one by one, and the bolts themselves would have successively dropped out.

With all but one bolt gone, the sealing of the door would have been sufficiently compromised to produce the intermittent px warnings on the previous flights, and the final bolt worked its way out during the incident flight.

Obviously, alternative scenarios welcomed.

Also, any one of the four bolts would have held the door in place.

Now if we can just get a glimpse of the guides on the inside of the recovered door plug.

Join Date: Feb 2008

Location: Australia

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

I'll raise you: nuts and bolts fitted, but with no split pins.

Over the 150-odd flights that the aircraft has flown since delivery, the nuts would have vibrated off the bolts, one by one, and the bolts themselves would have successively dropped out.

With all but one bolt gone, the sealing of the door would have been sufficiently compromised to produce the intermittent px warnings on the previous flights, and the final bolt worked its way out during the incident flight.

Obviously, alternative scenarios welcomed.

Over the 150-odd flights that the aircraft has flown since delivery, the nuts would have vibrated off the bolts, one by one, and the bolts themselves would have successively dropped out.

With all but one bolt gone, the sealing of the door would have been sufficiently compromised to produce the intermittent px warnings on the previous flights, and the final bolt worked its way out during the incident flight.

Obviously, alternative scenarios welcomed.

That's my hypothesis - I'll get the popcorn..

I don’t think the bolts, even without nuts could have all dropped out that quickly. They are more or less horizontal and probably a pretty tight fit. They also do not rotate or move at all. It just makes more sense that they were removed but never reinstalled. But either scenario is possible.

Also, any one of the four bolts would have held the door in place.

Also, any one of the four bolts would have held the door in place.

But I agree that even with only one bolt still present, the door wouldn't have gone.

We'll know soon enough which, if any, bolts have been found with the door plug, and in what condition.

Psychophysiological entity

Each of the 12 fingers that hold against pressure has an adjustment screw and it is possible that those were tightened enough to hold the door in place and compress the seal, which would provide a large amount of friction to hold the door in place regardless of the spring.

Dave asked:-

I might well be wrong, but in that case I'm struggling to understand what locates the door plug longitudinally, if it isn't the hinge brackets.

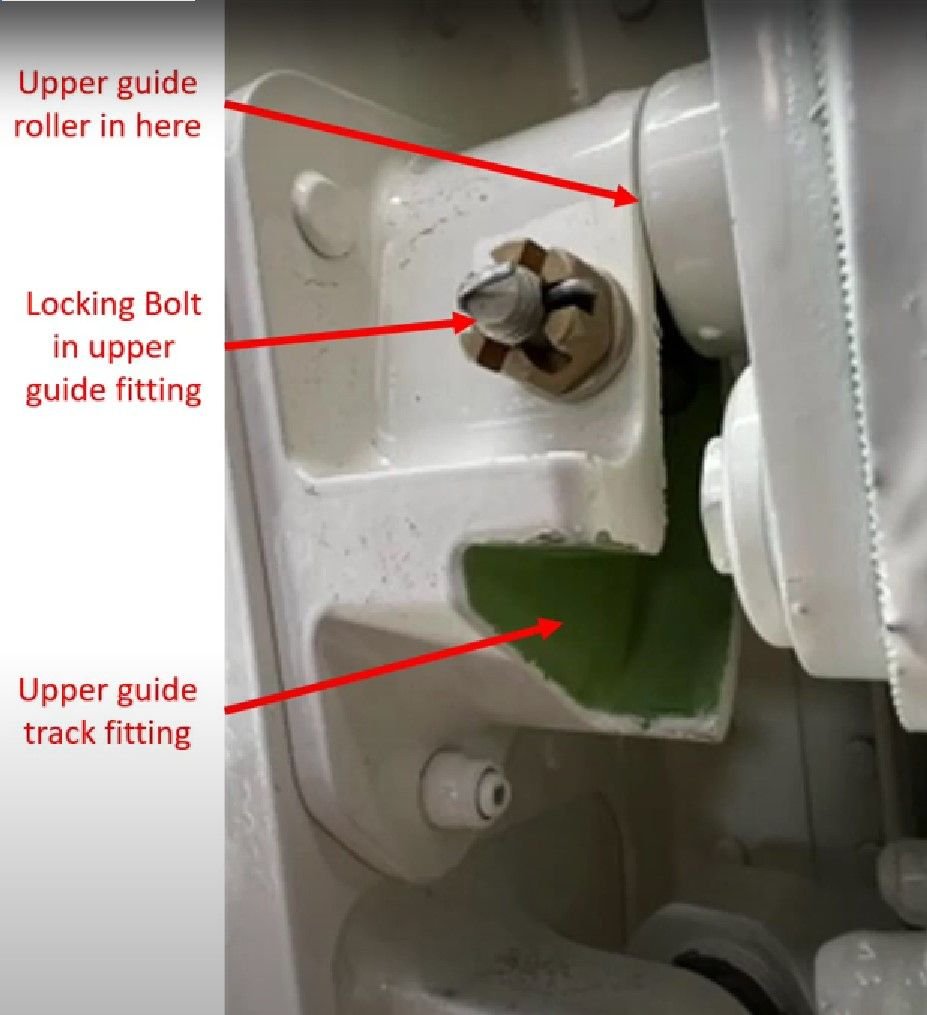

Apropos nothing, the Upper guide track fitting has the paint chipped on the entry edge.

Join Date: Apr 2010

Location: Alexandria VA USA

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

I wouldn't describe something that may have happened progressively over the course of 150 flights as "quickly". And you might be surprised about how many things have departed airframes over the years when they haven't been positively retained.

But I agree that even with only one bolt still present, the door wouldn't have gone.

We'll know soon enough which, if any, bolts have been found with the door plug, and in what condition.

But I agree that even with only one bolt still present, the door wouldn't have gone.

We'll know soon enough which, if any, bolts have been found with the door plug, and in what condition.

Join Date: May 2011

Location: U.S.

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

Nothing to rule that out entirely, but the outer skin of the door is confined by the outer skin of the fuselage pretty tightly, so I would not expect enough motion to make a difference. That gap around the door is going to be very small to cut down turbulence and noise.

Join Date: Dec 2018

Location: Florida

Posts: 249

Likes: 0

Received 0 Likes

on

0 Posts

I suggested earlier in the thread that the absence of passengers might be an indication of 'issues' that made the seats unbookable. There was a response suggesting that US pax prefer aisle seats rather than window, so not so surprising. But if, as now appears, there may have been loose bolts, I wonder if there had been complaints?

Join Date: Jun 2008

Location: Nova Scotia

Age: 56

Posts: 71

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: Nov 2018

Location: VA

Posts: 30

Likes: 0

Received 0 Likes

on

0 Posts

In the video linked below (see 2:40) an eyewitness says a 15-year old named Jack was "in the row" where the plug blew out and had his shirt ripped off, his laptop and phone were sucked out of the plane, and he relocated next to her. It's not clear to me that he was in 26C or on the other side of the isle. There is another photo in which a dark haired man is sitting in 26C, but this is when the plane is already on the ground and he may have relocated there to let paramedics do their thing.

I always take these edited reports with a grain of salt because reporters are only concerned with presenting an edited dramatic story. The video includes the witness and the reporter both stating facts, and it appears the witness video is cut, and the cuts possibly out of sequence. I don't believe anything the reporter says, but the witness is clear with what she knows. She is not the boy's mother, but she must have been talking with him during the remainder of the flight.

I have no source for a "toddler and mother" that I had read about early on, reporters often get those things wrong.

KPTV Video

I always take these edited reports with a grain of salt because reporters are only concerned with presenting an edited dramatic story. The video includes the witness and the reporter both stating facts, and it appears the witness video is cut, and the cuts possibly out of sequence. I don't believe anything the reporter says, but the witness is clear with what she knows. She is not the boy's mother, but she must have been talking with him during the remainder of the flight.

I have no source for a "toddler and mother" that I had read about early on, reporters often get those things wrong.

KPTV Video

Video:

There has been quite a lot of incorrect information about how the door plug section is installed. Here's my understanding of how the plug section is fitted - please correct as required:

- The plug section is held in place against pressurisation loads by the 12 stop fittings, 6 on each side. These do NOT have bolts through them, as they are simply pressed against corresponding adjustable stop pads fixed to the fuselage - the adjustment is to allow the pressure across all 12 fittings to be evened out. (this is identical to an actual door).

- There are guide channels near the top of the plug section, one on each side, the purpose of which is to prevent the plug section moving down and away from the stop fittings. There are corresponding guide rollers in the frame of the opening which engage in the guide channels. (this is identical to an actual door).

- The plug section (as opposed to an E/E door) has bolts inserted below the guide rollers to prevent the plug section moving up - these bolts must be removed to allow the plug section to be removed for maintenance or inspection. They are retained with castellated nuts and locking wires. These bolts would not be present on an actual door.

- At the bottom of the plug section there are 2 hinges, bolted to the fuselage and fixed via sliding sprung assemblies to lugs on the plug section. The slide allows limited vertical movement of the plug section so that it can be raised up high enough for the guide channels to clear the guide rollers, which also means that the stop fittings are clear of the stop pads, which then allows the plug section to rotate outwards and down, away from the fuselage.

- The spring is there principally to ensure that the plug section, once raised, does not fall back down and the guide channels re-engage with the guide rollers, thus closing the plug. In an actual door, the spring also assists the initial release by reducing the upward force required to lift the door to clear the guide rollers.

- This assembly is similar to an actual door, although it is not clear if the spring compression is the same as on an actual door.

- In the plug section, there are bolts that pass through the vertical slide lug on the hinge assembly to prevent any vertical movement (again retained with castellated nuts and locking wires) - these are not present on an actual door.

- For the plug section to be removed (or the equivalent door to be opened), the plug section must be raised sufficiently for the guide channels to clear the guide rollers, and this also means that he stop fittings are clear of the stop pads, which then allows the plug section to rotate outwards and down, away from the fuselage.

Join Date: Jan 2009

Location: Earth

Posts: 74

Likes: 0

Received 0 Likes

on

0 Posts

The NTSB, Alaska Airlines, Boeing, and Spirit Aerosystems owe Mr. Sauer some thanks for going outside on a dark rainy night to search for missing Boeing parts. Amazing that the door plug, two mobile phones, and an airline IFE headphones pair were found relatively undamaged.

From The Oregonian:

Bob Sauer, a science teacher at Catlin Gabel, was monitoring the news over the weekend about the blown-out door plug from the Alaska Airlines flight over Portland, but it wasn’t until Sunday night that he searched his yard — after his ex-wife called and alerted him that authorities suspected the part might have landed nearby.

Sauer, 64, grabbed a flashlight and decided to check around his house around 8 p.m. Sunday.

It was dark and raining out. As he stepped around the corner of his house, he shined his light along a bank of cedar trees that he and his children had planted about 20 years ago to separate his property from his neighbor

https://www.oregonlive.com/portland/...r-in-yard.html

From The Oregonian:

Bob Sauer, a science teacher at Catlin Gabel, was monitoring the news over the weekend about the blown-out door plug from the Alaska Airlines flight over Portland, but it wasn’t until Sunday night that he searched his yard — after his ex-wife called and alerted him that authorities suspected the part might have landed nearby.

Sauer, 64, grabbed a flashlight and decided to check around his house around 8 p.m. Sunday.

It was dark and raining out. As he stepped around the corner of his house, he shined his light along a bank of cedar trees that he and his children had planted about 20 years ago to separate his property from his neighbor

https://www.oregonlive.com/portland/...r-in-yard.html

Join Date: May 2011

Location: U.S.

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

But to create a leak, the plug would need to have moved enough to release the pressure on the stop fittings/pads - they determine how tight the plug is against the frame, not the locking bolts. I agree with everything you've said except that I think all 4 bolts must have fallen out (if they were ever there) and then the door started to migrate upwards. Given the pressure differential at cruise would be sufficient to 'friction lock' the stop pads and fittings, and on the ground the plug would sit in place by gravity (assuming the lift springs arent strong enough to overcome the weight of the plug), there would seem to be a window of opportunity for the plug to move upwards in the early stage of ascent due to jostling etc, before the pressure differential locked the stop fittings/pads. To do that, all 4 locking bolts would have to be missing..

That's my hypothesis - I'll get the popcorn..

That's my hypothesis - I'll get the popcorn..

Possibly upon flight an air leak could occur at the bottom seal if the plug is moving around, secured by one or 2 bolts, during aircraft movement on the ground and low altitudes. It's a substantial sail with a lot of leverage to a tiny bolt. After multiple flight cycles that bolt could rattle loose or even be sheared, especially with the buffeting forces and limited movement prior to full pressure differential.

But I agree, it seems like there is no way to get enough upward movement to free the plug from its stop if even one bolt remained.

The Chris Brady videos state the door plug is lifted 1.5" before opening. Given some extra clearance we can guess the stop fittings have 1 to 1.25 inches or so of overlap with the stop pads. I can imagine the door could be retained at pressure differential with less than full overlap, say 0.5" or even less, before you get some deformation and the stop fittings finally break loose from the pads and the plug opens into the slipstream.

So my guess is one or two bolts must have been present on delivery and first operations. The bolts may have had no nuts, or hand-tightened nuts.

However, for the door plug to have achieved enough upward shift to free the fittings from the stops, all bolts must have been lost.