Alaska Airlines 737-900 MAX loses a door in-flight out of PDX

Funny, I don't recall similar "Airbus Sucks" threads when the A350 had issues due to the Rolls engine shutdown rate, or A220/A320s ending up AOG because of issues with the Pratt geared turbofan...

Yes, it all reflects badly on Boeing, and the general public don't know the difference. But I expect a little better from aviation 'professionals'.

Yes, it all reflects badly on Boeing, and the general public don't know the difference. But I expect a little better from aviation 'professionals'.

Spirit is a product of the Boeing culture, Cheap, Fast, Nasty. Boeing contractually incentivizes the quantity over quality mindset that virtually guarantees the pickle fork debacle, extra holes in the pressure bulkhead, departing exit EE plugs etc etc all of which are a direct result of bean counter management that knows the price of everything and the value of nothing.

Boeing is the poster child of an organization that never has the time, people, or money to do the job right, then has to scramble to find the time, people, and money to do the job over.

What a sad end to a company that was the world leader in commercial aviation.

Boeing is the poster child of an organization that never has the time, people, or money to do the job right, then has to scramble to find the time, people, and money to do the job over.

What a sad end to a company that was the world leader in commercial aviation.

Hard to judge this without knowing a valid engineering answer to what happened to the hardware,

The fuselage isn't built by Boeing - all 737 fuselages are assembled in Wichita by Spirit AeroSystems. The fuselages are shipped to Renton by rail as basically complete structures with the plug (or door) already installed. Assuming that this was an assembly issue (as seems likely based on the lack of associated damage from the departed plug, as well as the AD'ed inspection), the blame should fall squarely on Spriit, not Boeing.

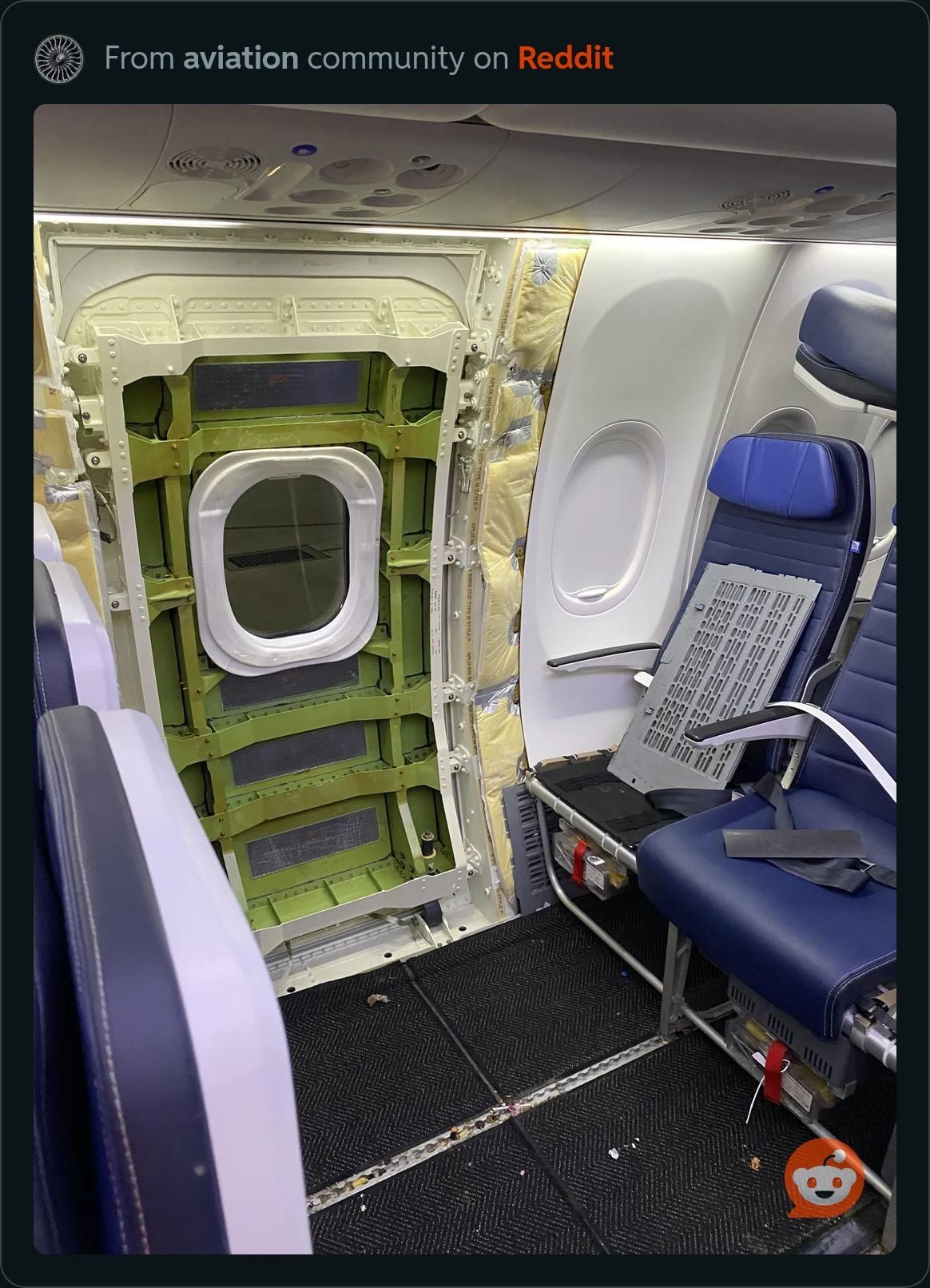

Discussion as to whether the stop fitting/bolts were not fitted; I cannot see a way for this semi plug to stay in position without some retention, even whilst the cabin trim panel is being fitted. Plain cabin windows can be temporarily held by tape whilst the clamping device is fitted, but a 'door' this size nah!

And certainly not whilst being ground transported from the manufacturer as a complete assembly, if that is the case mentioned earlier thread.

Sad to say, as a proud retired BAC1-11 licensed engineer, but short bolts seem a likely cause.

And certainly not whilst being ground transported from the manufacturer as a complete assembly, if that is the case mentioned earlier thread.

Sad to say, as a proud retired BAC1-11 licensed engineer, but short bolts seem a likely cause.

Psychophysiological entity

BAC 1-11. Do you remember the g lock on the front door?

The door had a myriad flat plates, as did the frame. To open outwards the door lifted first and thus required the g lock for safety.

The door had a myriad flat plates, as did the frame. To open outwards the door lifted first and thus required the g lock for safety.

Join Date: Nov 1999

Location: Mk. 1 desk at present...

Posts: 365

Likes: 0

Received 0 Likes

on

0 Posts

Before you all get too wrapped up in your anti-Boeing crusade, you might want to consider this little inconvenient fact: The fuselage isn't built by Boeing - all 737 fuselages are assembled in Wichita by Spirit AeroSystems. The fuselages are shipped to Renton by rail as basically complete structures with the plug (or door) already installed.

The last nail in the coffin of that old saw appears to be an aircraft that was designed by Boeing, marketed by Boeing, and built by no-one in particular...

Join Date: Jan 2021

Location: Perth

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

Just wondering how forceful a suck hole would that have been?

Still remembering the New Zealander sucked out over the Pacific when an improperly closed cargo door ripped some fuselage with it.

Still remembering the New Zealander sucked out over the Pacific when an improperly closed cargo door ripped some fuselage with it.

https://static01.nyt.com/images/2024...oLargeAt2X.jpg

Join Date: May 2008

Location: us

Posts: 19

Likes: 0

Received 0 Likes

on

0 Posts

be facing an unprecedented PR nightmare.

Join Date: Sep 2022

Location: Cebu

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

Before you all get too wrapped up in your anti-Boeing crusade, you might want to consider this little inconvenient fact: The fuselage isn't built by Boeing - all 737 fuselages are assembled in Wichita by Spirit AeroSystems. The fuselages are shipped to Renton by rail as basically complete structures with the plug (or door) already installed. Assuming that this was an assembly issue (as seems likely based on the lack of associated damage from the departed plug, as well as the AD'ed inspection), the blame should fall squarely on Spriit, not Boeing.

While Spirit was "Boeing Wichita" at one time, that hasn't been the case for nearly 20 years (Boeing sold them in 2005) and it has operated as an independent subcontractor since. Spirit is also a major supplier to Airbus.

While an alert inspector at Boeing might have picked up on missing fasteners, given that fuselage portion arrives as a compete, approved assembly, it is very unlikely that there is any task at Boeing Renton to verify that the appropriate fasteners are installed on that door plug.

Unfortunately, QA at Spirit has been an on-going issue for some time - especially with the 737 fuselages (the often-mentioned issue with the miss-drilled aft bulkhead holes also traces back to Spirit.

Interestingly, there was an article in the Seattle Times recently regarding Boeing and Spirit re-negotiating the contract for the 737 fuselages to include improved quality and QA inspections (presumably with an increase in price to Boeing, although I don't think the article specifically said that).

While I doubt it's feasible at this point for Boeing to bring in a new subcontractor for the 737 fuselage, I think Spirit badly needs to step up their game if they expect to receive any future new business (Boeing, Airbus, or anyone else). No airframer wants to be associated with the sort of liability (not to mention bad press) that the recent Spirit screwups have caused Boeing.

While Spirit was "Boeing Wichita" at one time, that hasn't been the case for nearly 20 years (Boeing sold them in 2005) and it has operated as an independent subcontractor since. Spirit is also a major supplier to Airbus.

While an alert inspector at Boeing might have picked up on missing fasteners, given that fuselage portion arrives as a compete, approved assembly, it is very unlikely that there is any task at Boeing Renton to verify that the appropriate fasteners are installed on that door plug.

Unfortunately, QA at Spirit has been an on-going issue for some time - especially with the 737 fuselages (the often-mentioned issue with the miss-drilled aft bulkhead holes also traces back to Spirit.

Interestingly, there was an article in the Seattle Times recently regarding Boeing and Spirit re-negotiating the contract for the 737 fuselages to include improved quality and QA inspections (presumably with an increase in price to Boeing, although I don't think the article specifically said that).

While I doubt it's feasible at this point for Boeing to bring in a new subcontractor for the 737 fuselage, I think Spirit badly needs to step up their game if they expect to receive any future new business (Boeing, Airbus, or anyone else). No airframer wants to be associated with the sort of liability (not to mention bad press) that the recent Spirit screwups have caused Boeing.

The doors trajectory is going to have a complex solution, and that won't have a high probability of being correct. There will be a probabilistic solution giving likelihood of any given outcome, wild guess, the probability of impact with the tail is going to be somewhere around 5-6%, and then the probability of severe damage from that is going to be another complex solution, but it will be about 30-45% or somewhere near that. Worst case outcome is not good at all, and the pax have obviously had good clean living that was paying off, the chance of someone going skydiving (sadly not Putin) was pretty high. Debris impacts are not unknown and can range from expensive to catastrophic, remember what a chunk of foam can do to a space shuttle leading edge. When released, it's not going to go far out laterally from the fuselage, and it will slow down rapidly. The panel will be unstable initially which would tend to make it follow close to the upwash of flow to the airframe, so it is not going to be so far from the stabiliser, wild guess, still passing below it and at part span. Presume the forward lower hinge will fail first, but the dudes at NTSB will be interested in the stresses on those to get an idea of where it went. Overall, it is irrelevant, once departed it was not a desirable state, lots of opportunities for dragons to rear their heads. As a problem to solve, it is far more demanding than assessing the probable trajectory of a burst disk. Good luck working that out.

But although the sheet metal items may be built by a subcontractor, they don't also install the cabin linings, do they ? These are commonly customer-specific anyway. These would have been fitted across where the bolt positions we now see in the photographs are, as part of the interior fitout. This picture seems to show the interion Boeing receive

We'll only know the answer to that until the investigation is done (or, if another improperly installed is detected during the mandated inspections).