Alaska Airlines 737-900 MAX loses a door in-flight out of PDX

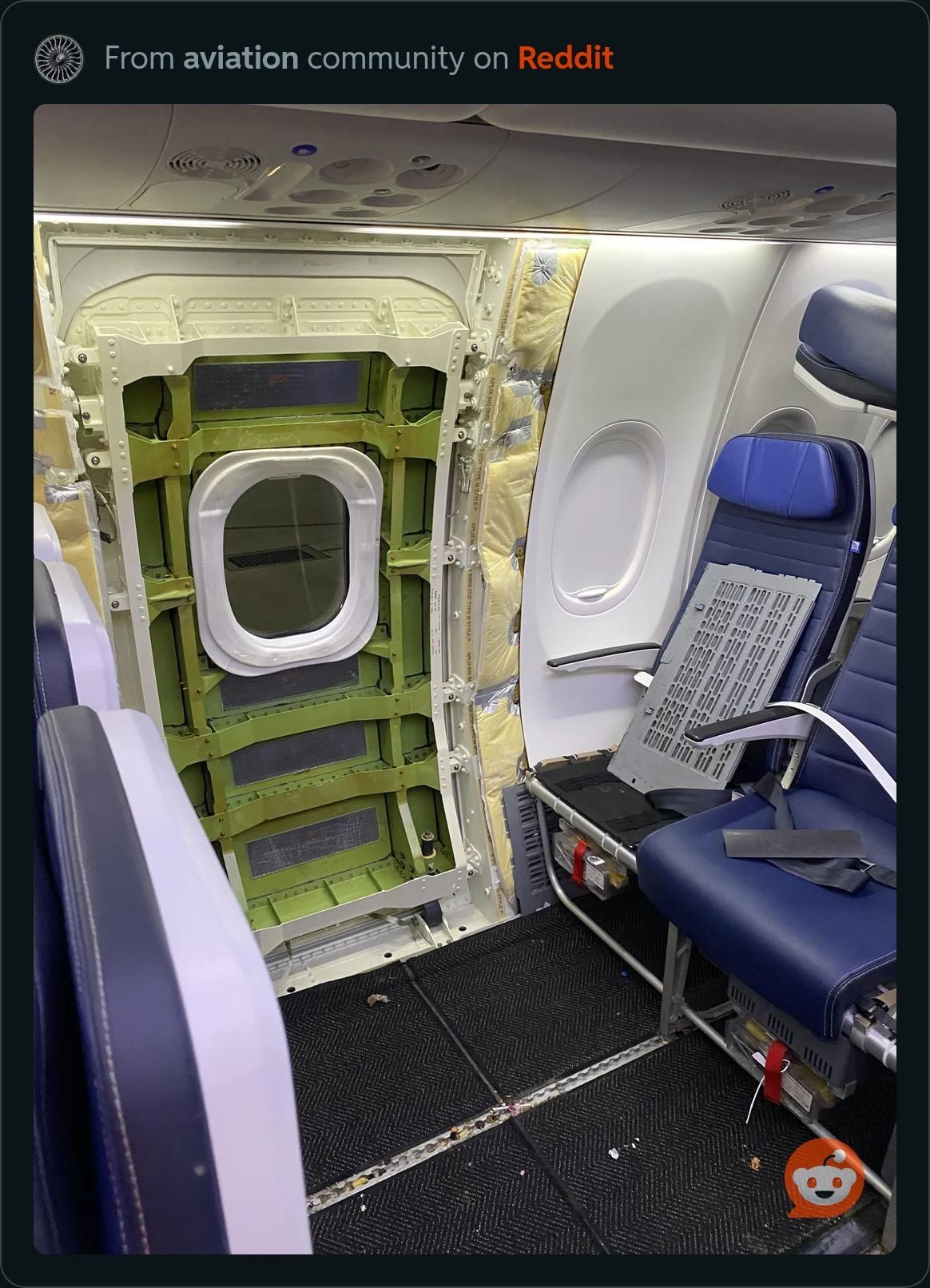

That picture shows a cam style track in the exit plug and roller with a lock bolt between the top and second stop pad bracket which would require the semi plug to be slid in from the outside from above and then the locking bolt inserted (? lock bolt and nut or bolt into thread raises ? which direction should it be inserted); at floor level some sort of claw and pip pin.

In the actual post event picture I can see the roller!

The community picture on Reddit, has a seat config which would suggest the use as an emergency exit when required?

In the actual post event picture I can see the roller!

The community picture on Reddit, has a seat config which would suggest the use as an emergency exit when required?

Join Date: Jun 2021

Location: Geetown

Posts: 4

Likes: 0

Received 0 Likes

on

0 Posts

26a, 26b seats next to door plug / panel not occupied.

Hi. I have just heard on a news broadcast in Aus, that the two seats adjacent to this panel / Door plug, 26A, and 26B were not occupied on this flight???

Maybe a lucky coincidence or suspicious. Maybe some noise from this area during previous cabin pressure incidents? Who knows?

Anyway no one injured good outcome inn the end.

Maybe a lucky coincidence or suspicious. Maybe some noise from this area during previous cabin pressure incidents? Who knows?

Anyway no one injured good outcome inn the end.

Join Date: Jan 2009

Location: Earth

Posts: 74

Likes: 0

Received 0 Likes

on

0 Posts

Well this just enforces my view re 737 Max and indeed makes me question my whole view of Boing as a company. I spent most of my working career on their products, but now actively avoid their products. I dont like the 787 and avoid 737 Max for pretty obvious reasons, though I was on a LH 747 up from Singapore at the end of last year, and she was fine and felt at ease. The new Boeings are a shadow of their predecessor's. To put in context I fly probably 2-3 times a week long and short haul over the year. If I am thinking like this and I am only humble SLF, how many others are taking this view re Boeings new products ? Get the company base back to Seattle, kick the accountant's back to where they belong, and let engineers design things. Accountancy is a support function in a business, not the defining thing unless you are an accountancy practice. There will be books written in the future about the demise of this business !!

https://www.penguinrandomhouse.com/b...-peter-robison

Great book about Boeing's loss of its safety oriented culture, especially after McDonnell Douglas used Boeing's money to purchase Boeing. Some weird political detours, but the book is solid.

(the accountants can stay in Chicago or Arlington or wherever, but the leadership should return home).

That's something Boeing has to deal with since the 737Max is marketed as a product of Boeing and not of Spirit or any other subcontractor. With regards to your complaint that Boeing gets more heat than Airbus, well unfortunately the 737Max's previous run-ins don't do it any favors from the general public's viewpoint. If the A320neo family had successive fatal incidents due to alleged negligence then they would also be subjected to the same heat that Boeing now faces. The ball is in Boeing's court to change this public perception --- whatever method they use.

Mother Nature doesn't listen to politicians either (ref: MAX 7 exemption, FAA funding reductions down the decades, etc).

Join Date: Jan 2009

Location: Earth

Posts: 74

Likes: 0

Received 0 Likes

on

0 Posts

Before you all get too wrapped up in your anti-Boeing crusade, you might want to consider this little inconvenient fact: The fuselage isn't built by Boeing - all 737 fuselages are assembled in Wichita by Spirit AeroSystems. The fuselages are shipped to Renton by rail as basically complete structures with the plug (or door) already installed. Assuming that this was an assembly issue (as seems likely based on the lack of associated damage from the departed plug, as well as the AD'ed inspection), the blame should fall squarely on Spriit, not Boeing.

While Spirit was "Boeing Wichita" at one time, that hasn't been the case for nearly 20 years (Boeing sold them in 2005) and it has operated as an independent subcontractor since. Spirit is also a major supplier to Airbus.

While Spirit was "Boeing Wichita" at one time, that hasn't been the case for nearly 20 years (Boeing sold them in 2005) and it has operated as an independent subcontractor since. Spirit is also a major supplier to Airbus.

If Spirit is building junk and delivering it to Boeing Renton without proper QA, why is Boeing accepting junk without proper QA?

What other flaws, problems, defects, missing fastener nuts, oval bulkhead holes, flawed flight control software, extra wrenches, bonus rags, and other rubbish is Boeing also accepting and happily delivering as-is to customers?

Join Date: Dec 2013

Location: Dallas

Posts: 108

Likes: 0

Received 0 Likes

on

0 Posts

As aeromech notes, something was holding that door in place prior to the failure. The ability to detect that it wasn't properly installed is a direct function of what was holding it in place. If, as aeromech suspects, it's something like 'short bolts', then it would be next to impossible to detect without a detailed inspection. OTOH, if bolts were completely missing, and it was being held in place by something like sealant - then yes, I'd expect a competent mechanic to notice the defect prior to installing the interior panels. Problem is we don't know - condemnation of the Renton workforce is premature.

We'll only know the answer to that until the investigation is done (or, if another improperly installed is detected during the mandated inspections).

We'll only know the answer to that until the investigation is done (or, if another improperly installed is detected during the mandated inspections).

Join Date: Jun 2009

Location: Montreal

Age: 65

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

As aeromech notes, something was holding that door in place prior to the failure. The ability to detect that it wasn't properly installed is a direct function of what was holding it in place. If, as aeromech suspects, it's something like 'short bolts', then it would be next to impossible to detect without a detailed inspection. OTOH, if bolts were completely missing, and it was being held in place by something like sealant - then yes, I'd expect a competent mechanic to notice the defect prior to installing the interior panels. Problem is we don't know - condemnation of the Renton workforce is premature.

We'll only know the answer to that until the investigation is done (or, if another improperly installed is detected during the mandated inspections).

We'll only know the answer to that until the investigation is done (or, if another improperly installed is detected during the mandated inspections).

Indeed, seems like there is something specific to go looking for. It'll be interesting to see if this turns into a full root cause investigation, the "why did this specific issue occur, and what else might be related to it?" line of questioning. I fear not...

All technically correct, but Boeing will proudly say that they are responsible for the entire aircraft delivered. I believe Boeing owns the type certificate for the entire airframe,not just parts not built by Spirit.

If Spirit is building junk and delivering it to Boeing Renton without proper QA, why is Boeing accepting junk without proper QA?

What other flaws, problems, defects, missing fastener nuts, oval bulkhead holes, flawed flight control software, extra wrenches, bonus rags, and other rubbish is Boeing also accepting and happily delivering as-is to customers?

If Spirit is building junk and delivering it to Boeing Renton without proper QA, why is Boeing accepting junk without proper QA?

What other flaws, problems, defects, missing fastener nuts, oval bulkhead holes, flawed flight control software, extra wrenches, bonus rags, and other rubbish is Boeing also accepting and happily delivering as-is to customers?

If the guys across the Sound from me can't get their act together, we're all going to need to get used to overhead luggage compartments that barely fit a wallet.

Join Date: Jun 2011

Location: Costa Rica

Age: 55

Posts: 48

Likes: 0

Received 0 Likes

on

0 Posts

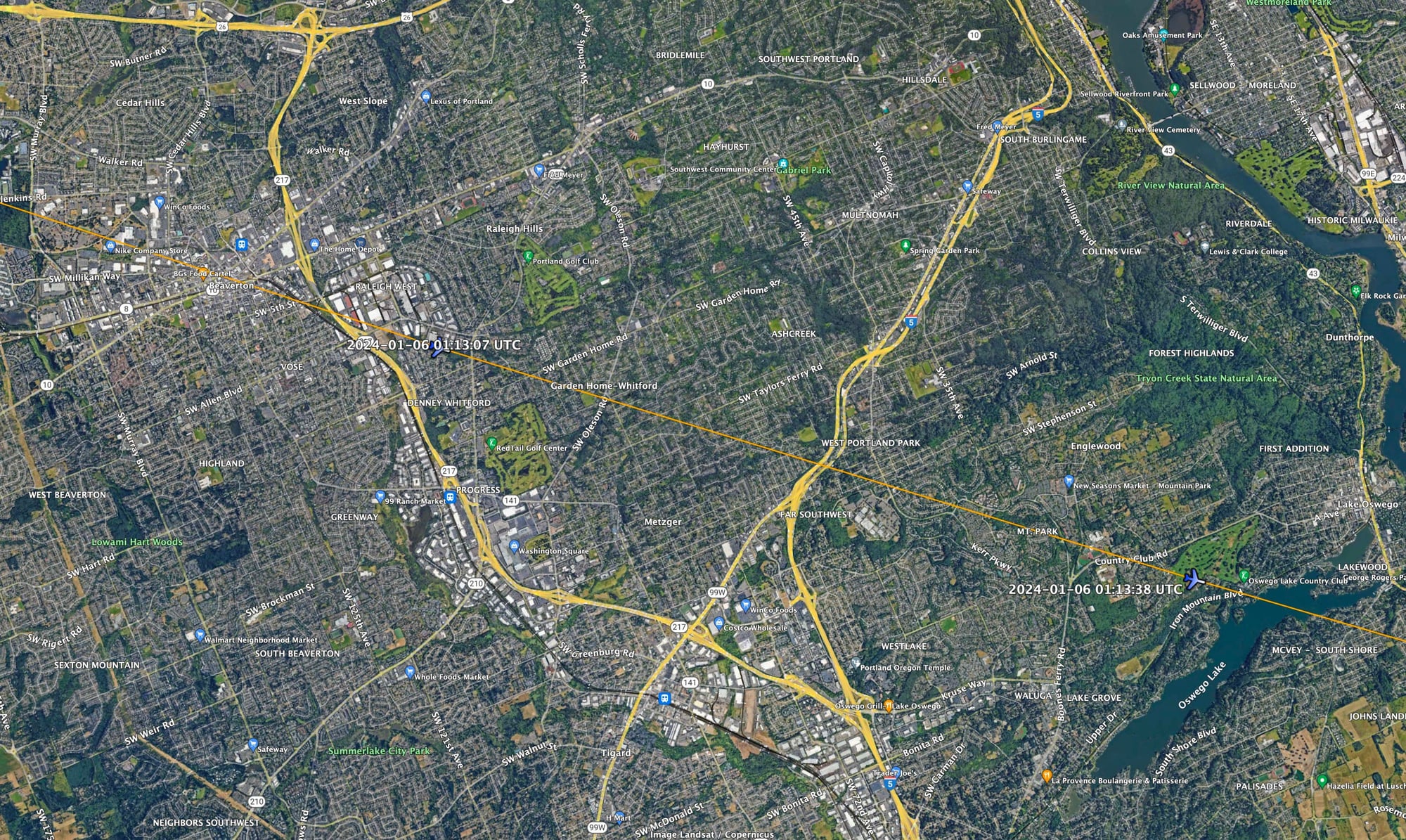

According to the NTSB briefing tonight, there were only SEVEN (7) empty seats so just 4%. Alaska had 178 seats on the aircraft and the spokesman said there were 171 passengers. It is an official accident with lead investigator John Lovell (NTSB investigator in MAX crash in Ethiopia) leading the investigation. She said they have a general location based on primary radar for the door. Aircraft delivered to Alaska on November 11, 2023. Row 25 and 26 seats A missing headrests. On 26A, the back of the seat is missing. Clothing items in the area. Stops on door frame still intact. Door is not an emergency exit but can be opened for inspection.

Join Date: Jun 2011

Location: Costa Rica

Age: 55

Posts: 48

Likes: 0

Received 0 Likes

on

0 Posts

Ref: back to Reddit pic in post 199, the floor fitting looks substantial enough to prevent the plug from lifting sufficiently to disengage the roller to cam track, unless the grey fitting is an open claw and not an eye, I do concede the top guide rollers seem a little thin, I am guessing a mere 5mm engagement with the track bracket.

I am sum-what surprised, after having years of dealings with a pedantic QA department, that some have not pointed out that production failings are not their remit, and so on behalf of them, please refer to Quality Control in issues of production or maintenance failings

I am sum-what surprised, after having years of dealings with a pedantic QA department, that some have not pointed out that production failings are not their remit, and so on behalf of them, please refer to Quality Control in issues of production or maintenance failings

Join Date: Jul 2022

Location: USA

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

tdracer

"As aeromech notes, something was holding that door in place prior to the failure. The ability to detect that it wasn't properly installed is a direct function of what was holding it in place."

Kinda wondering the same thing. Something held it in place for 2-3 months. I would speculate that it may have been the stop fittings serving as guides that held the door until they wore out/sheared then released the door all while upper bolts were missing. Also may have leaked just prior causing previous pressurization reports.

"As aeromech notes, something was holding that door in place prior to the failure. The ability to detect that it wasn't properly installed is a direct function of what was holding it in place."

Kinda wondering the same thing. Something held it in place for 2-3 months. I would speculate that it may have been the stop fittings serving as guides that held the door until they wore out/sheared then released the door all while upper bolts were missing. Also may have leaked just prior causing previous pressurization reports.

Join Date: Jan 2023

Location: Here

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

Looking at two pictures showing the plug in installed vs the opening you can see the pin that's mounted on the aircraft frame is pretty short. The plug has a retaining bolt that seems to hold the door down under this pin.Could it be that the pin is infact too short and allows the door/plug to move past the pin if the frame expands or the door moves left or right it seems very close to being able to move upward?

In days of old, with a difficult to find pressurisation leak (no visible tobacco stains or window condensation) we would do a ground pressurisation run, mostly it required an engine supply as the APU would only give about 0.5psi diff. a mechanic would go around outside feeling windows and doors for air escape.

The same could be done with a down route / on ramp ADC change to confirm, by watching rate of climb/decent indicator, whether the hose had been connected leak free, external ports were plugged for this!

I believe now, best safety practices and all that, almost a steel net is required over the aircraft, hence finding leaks nowadays must be quite a task?

The same could be done with a down route / on ramp ADC change to confirm, by watching rate of climb/decent indicator, whether the hose had been connected leak free, external ports were plugged for this!

I believe now, best safety practices and all that, almost a steel net is required over the aircraft, hence finding leaks nowadays must be quite a task?

That's something Boeing has to deal with since the 737Max is marketed as a product of Boeing and not of Spirit or any other subcontractor. With regards to your complaint that Boeing gets more heat than Airbus, well unfortunately the 737Max's previous run-ins don't do it any favors from the general public's viewpoint. If the A320neo family had successive fatal incidents due to alleged negligence then they would also be subjected to the same heat that Boeing now faces. The ball is in Boeing's court to change this public perception --- whatever method they use.

It becomes a problem for a prime contractor to have to put into place a parallel and even larger QA system to over see all the QA systems of the subcontractors. It defeats a large amount of the reason to have subcontractors if their every action on the factory floor and every action by the QA/QC workers/engineers has to be double checked.

No one died from this, but it wasn't for lack of effort to do so - perhaps there is some criminal charge that can be brought against the Spirit QA/QC team and anyone who signed off that the installation was correctly done.

Also concerning to me about Alaska is they took a new plane off the ETOPS list for a pressurization defect they couldn't diagnose but kept it in service. The plane should be in full working order from the factory, and it appears that it was. Then that changed and didn't send up a giant red flag? No call to Boeing to figure out why the plane was leaking?

The sucky thing about this is the door has to be able to be removed to check for corrosion around the opening. Which means there is the chance, as in another 10,000 locations, to not assemble it correctly. And all of those locations are flight-safety critical to a similar extent as this door. There is no good design solution to an item that has to be removable to be unremovable. Even if one puts in redundant features, that just means when the primary feature isn't there you are down to one, but have increase the odds that some feature won't be installed correctly.

The best I can get is re-purposing the indicators that the conventional exit door has in place for this door. If it moves up even a millimeter, that's too far, and a switch would indicate that. I suspect someone in human factors decided that it would confuse pilots to have an indicator for a door that no one can use. That would be an interesting investigation to make. Had that light been flickering every time there was a pressure problem it might have been a better diagnostic. Still, the maintainers should not have shrugged the pressurization problem off and allowed it to remain in service.

For personal experience, I was once seated at a 737 over wing exit row and noticed the engine sound was extremely harsh as the plane started and got pushed back, not muffled at all. It appeared to be coming from the door and, after a short investigation, it was clear there was daylight from about 1/8th of an inch gap at the seal. This was the old style actual plug exit door, so I knew it could not be departing. Soon after takeoff, when the plane was pressurized, the door moved the slight amount and the seal did its job. I did mention this to the flight attendant. I don't know if it got passed to the airline; maybe I should have called them with the tail number. I expect a similar thing was happening on this aircraft, but it was behind the interior panel that would muffle the sound and prevent a view of the seal. It still should have been louder at that seat than anywhere else in the plane.

Perhaps add that to the maintainer's tools - that if air can leak out, so can sound. Put a high-pitched (8kHz), high volume (100dB) sound source inside the unpressurized fuselage and, if it can be more clearly heard outside with the doors shut at some location over the others, that may be a place a leak is happening. Move the source down the fuselage at the same time the people outside listening for it are moving. I know, I know - keep the hangar doors closed and avoid trying this during engine run-ups of neighboring aircraft.

To my old eyes, the latch cam lock bolts look like they go from outer to inside, a hard job for someone to fit with restricted access. Also, it's hard to tell but the retainer nuts on the lock bolts look castellated, if they are, perhaps the split pins/ cotter pins weren't fitted.

This seems consistent with the videos explaining it, but it immediately raises the questions:

Why is the plug door, which is never meant to be opened, designed such that it can be raised out of its stop fittings, as if to open? Why is so much of the opening mechanism apparently present in this non-opening plug? Why is opening only prevented by a few bolts? Why is the plug not fundamentally shaped so that it cannot move at all, and certainly not beyond the stop fittings, under any circumstance?

Why is the plug door, which is never meant to be opened, designed such that it can be raised out of its stop fittings, as if to open? Why is so much of the opening mechanism apparently present in this non-opening plug? Why is opening only prevented by a few bolts? Why is the plug not fundamentally shaped so that it cannot move at all, and certainly not beyond the stop fittings, under any circumstance?

All good questions. The plane is built with this opening because it was certified to have this opening for certain seating capacities to provide additional exits and certifying a second configuration without this opening is stupid expensive. It's also cheaper (OK, also stupid expensive) if the owner wants to add the exit later rather than having to saw a hole.

Because of the opening a door has to be there, whether the conventional exit door or this door, either blanked off by the interior panel in the event that a seating arrangement doesn't require the exit.

They have to be able to be opened because there is a gap between the door and the fuselage that cannot dependably be filled with sealant or easily examined, so the door has to be able to be opened to inspect that gap and door opening for corrosion and for the possibility of crack formation. As a result it has to be able to be moved up so that it can be opened for inspection and is the reverse of how it is installed, by moving it down.

There may be some other option, but typically the one that has the fewest parts is the best and this has a door and 4 bolts. It is also a good practice to make as few changes from a baseline design as possible so that new defects, such as this one appears to have had, don't creep in, so it duplicated a lot of the features of the exit door, but without the operating linkages and inflatable slide.

Why this one may have been installed incorrectly, as so far appears to be the case, is not clear. NTSB will be looking into that and will gain access to more information than the general public can get.