MAX’s Return Delayed by FAA Reevaluation of 737 Safety Procedures

Join Date: Jul 2019

Location: Mass

Posts: 23

Likes: 0

Received 0 Likes

on

0 Posts

I had a similar question about flaps. Why is MCAS disabled with flaps deployed? Does the stick force curve meet regulatory requirements when flaps are deployed (even at flaps 1)?

Thread Starter

Join Date: Apr 2015

Location: Under the radar, over the rainbow

Posts: 788

Likes: 0

Received 0 Likes

on

0 Posts

Right. One of the reasons that a rather large number of inquiring minds have questioned the assertion that MCAS was created simply to deal with a stick force issue.

Salute!

You're thinking more as I have been for most of this year, Gordon, et al

Must be more than a simple "stick lightening", possibly actual pitch coefficient problems whereby even a constant stick force might result in continued nose up under some AoA and/or mach conditions. Jez sayin'

Gums sends...

You're thinking more as I have been for most of this year, Gordon, et al

Must be more than a simple "stick lightening", possibly actual pitch coefficient problems whereby even a constant stick force might result in continued nose up under some AoA and/or mach conditions. Jez sayin'

Gums sends...

Join Date: Dec 2015

Location: Cape Town, ZA

Age: 62

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

Salute!

You're thinking more as I have been for most of this year, Gordon, et al

Must be more than a simple "stick lightening", possibly actual pitch coefficient problems whereby even a constant stick force might result in continued nose up under some AoA and/or mach conditions. Jez sayin'

Gums sends...

You're thinking more as I have been for most of this year, Gordon, et al

Must be more than a simple "stick lightening", possibly actual pitch coefficient problems whereby even a constant stick force might result in continued nose up under some AoA and/or mach conditions. Jez sayin'

Gums sends...

Join Date: Jun 2008

Location: Cambridge UK

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

In https://leehamnews.com/2019/09/27/bj...-wire-part-10/

MCAS is not active on the 737 MAX when flaps are deployed. This is because when flaps are out the slats are out as well and these

diminish the disturbance to the pitch moment curve from the larger and further forward-higher slung engine nacelles.

Join Date: Dec 2015

Location: Cape Town, ZA

Age: 62

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

I wondered this when Icelandair were doing flaps-1 ferries, and found this:

In https://leehamnews.com/2019/09/27/bj...-wire-part-10/

MCAS is not active on the 737 MAX when flaps are deployed. This is because when flaps are out the slats are out as well and these

diminish the disturbance to the pitch moment curve from the larger and further forward-higher slung engine nacelles.

In https://leehamnews.com/2019/09/27/bj...-wire-part-10/

MCAS is not active on the 737 MAX when flaps are deployed. This is because when flaps are out the slats are out as well and these

diminish the disturbance to the pitch moment curve from the larger and further forward-higher slung engine nacelles.

This is only true for a system that is basically stable and where a linear input produces a proportional linear output. Controllers for systems which have less or no inherent stability are highly complex and their design needs to incorporate more factors and functions and limitations than a "simple" proportional controller. It took years for instance to develop the stability controller of a Harrier jump-jet in the hover state. In an aircraft, a crossfeed of the other axes and/or configurations may also be required (e.g up-stick when the plane rolls into a turn). An autopilot that needs less up-stick in a standard turn than in a tight one might not be easy to implement.

Join Date: Mar 2015

Location: Washington state

Posts: 209

Likes: 0

Received 0 Likes

on

0 Posts

I wondered this when Icelandair were doing flaps-1 ferries, and found this:

In https://leehamnews.com/2019/09/27/bj...-wire-part-10/

MCAS is not active on the 737 MAX when flaps are deployed. This is because when flaps are out the slats are out as well and these

diminish the disturbance to the pitch moment curve from the larger and further forward-higher slung engine nacelles.

In https://leehamnews.com/2019/09/27/bj...-wire-part-10/

MCAS is not active on the 737 MAX when flaps are deployed. This is because when flaps are out the slats are out as well and these

diminish the disturbance to the pitch moment curve from the larger and further forward-higher slung engine nacelles.

So why not set slats/flaps whenever the system senses approaching MCAS conditions?

Join Date: Jan 2018

Location: Amantido

Posts: 866

Likes: 0

Received 0 Likes

on

0 Posts

How would you do that at 270-280 knots? Or above 20.000 ft?

Assuming flaps placard speeds are similar to the -800, Flaps 1 Vfe is 250 knots and max altitude for flaps extension is 20.000 ft.

Assuming flaps placard speeds are similar to the -800, Flaps 1 Vfe is 250 knots and max altitude for flaps extension is 20.000 ft.

Obviously that is only needed for slow speed and low alt. For those MCAS triggering scenarios we have seen. For the high speed end of the envelope MCAS might work on.

I'm anything but an expert and feel singularly thick tonight, but I have read the entire thread without the thought above entering my mind. Is it a fair comment?

Salute!

Adding to previous post....

1) About every plane I flew caused ther nose to go down when I lowered the flaps, even the T-33 which had split flaps and not the fancy ones I had in other jets. So looks to me that the pitcvhing moment was lowered when at the slow ( low q and mach) part of the envelope. The leading edge devices prolly also lower the pitching moment induced by those big motors way out in front and higher than the NG or previous.

2) At high mach use of MCAS, might be the new motor configuration introduces some shock wave phenomena, but not like that at low speed/high AoA. Hence the different amount of deflection.

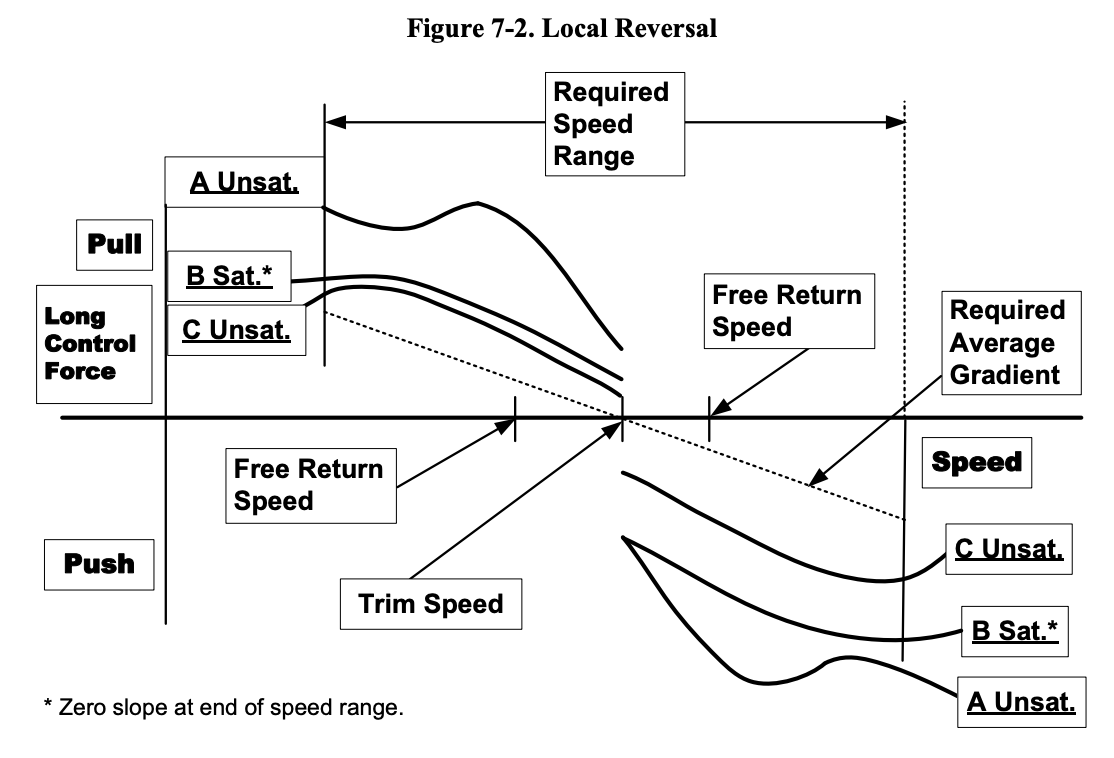

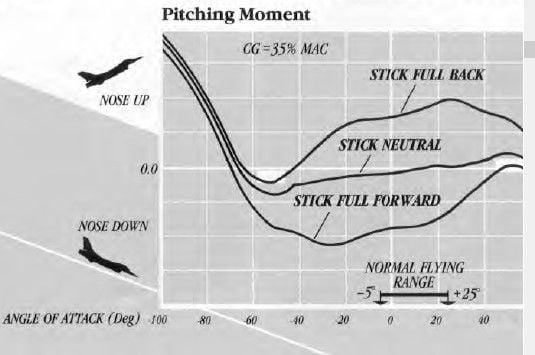

3) The pitching moment comes from more than just the stab and or flaps. Adding new, big motors at a higher position and further forward can definitely affect the moments. So I show again an actual aircraft moment diagram that shows a positive pitch moment even with neutral stick at about 10°. And that was on the left side of our normal AoA during hard maneuvers. Scary, huh? Our problem was running outta nose down stab capability.

Gums sends....

Adding to previous post....

1) About every plane I flew caused ther nose to go down when I lowered the flaps, even the T-33 which had split flaps and not the fancy ones I had in other jets. So looks to me that the pitcvhing moment was lowered when at the slow ( low q and mach) part of the envelope. The leading edge devices prolly also lower the pitching moment induced by those big motors way out in front and higher than the NG or previous.

2) At high mach use of MCAS, might be the new motor configuration introduces some shock wave phenomena, but not like that at low speed/high AoA. Hence the different amount of deflection.

3) The pitching moment comes from more than just the stab and or flaps. Adding new, big motors at a higher position and further forward can definitely affect the moments. So I show again an actual aircraft moment diagram that shows a positive pitch moment even with neutral stick at about 10°. And that was on the left side of our normal AoA during hard maneuvers. Scary, huh? Our problem was running outta nose down stab capability.

Gums sends....

The BAe146 / Avro RJ has a very strong opposite pitch tendency, needing loads of pitch up trim on flap retraction, and requiring very positive handling.

Join Date: Mar 2019

Location: Prague

Posts: 65

Likes: 0

Received 0 Likes

on

0 Posts

Well, maybe I misunderstood something but what is the difference? It would be like flying with poorly trimmed aircraft. Trimmed nose down, I'm pulling back and aircraft does not climb or descend. I just need more pulling or force to get it "up".

Psychophysiological entity

The article, Canada, and indeed this thread seem to be swinging us back to a period of analysis I'd have expected shortly after the second crash. We know full well the aircraft handling has to be 'augmented', and we thrashed through weeks of aerodynamic hardware suggestions that would obviate the need for MCAS. I think we concluded it would be hard to do a modification that did not degrade the aerodynamics, unless it was an active system: horribly expensive. A no-go. So we, as a fairly passionate community, seemed to swing back to fixing the MCAS fix. It was, perhaps is, an eloquent solution to an alarming post-design discovery. So what are people becoming so alarmed about at this (hopefully) late stage? It would be disastrous if MCAS, along with all the work so far, has to be scrapped in favour of some as yet unspecified device.

Boeing kept their control cable ethos for a long time, and seemingly extended it into the 737's MAX era as part of a hurried development that could carry the LEAP engine. If it had come from a clean-sheet design, I doubt it would have had conventional controls, or short legs. In other words, it would have been a different species . . . and too late.

It's about this time in Boeing's time-line that you should found your judgement. It's not just because of the immediate problem, but trying to get into the heads of senior management and imagine what they were thinking when the pressure was on. They had a chance to develop what would become the world's biggest seller - the commercial driving forces must have been incredible. It doesn't make them right, just incredible.

But let's consider a time when it's back in service and the 'average pilot' is coping with crosswind limits - and in the real world, rather more. That very expensive pod is frighteningly near the ground, even when the wing is neutral and the undercarriage under no great pressure. I'd feel very uneasy about contemplating the next ten or fifteen years never thumping it on, or perhaps catching it when a low-hour colleague, suddenly and quite inexplicably, aims it below the concrete. It's a multi-million dollar piece of kit that's just a little too near the ground for comfort. Furthermore, it has inherited one of the NG's lesser-known problems of hand cranking the stabilizer, plus, it's got a smaller wheel with which to haul 200 feet of cable, there and back. It starts life with some serious question marks hanging over it.

Boeing can't change horses now, they have to press on with what they're doing. It's horrible, but Hobson's choice. I agree that adding lines of code just adds to the fog but I can't see they've got any other option. I've posted before about being able to press a master cut-out at the first hint of a problem, and then reintroduce functions in diagnostic stages. It's simple, and clean, and the crew would be using time-honoured logic and solid wiring. However, I doubt the MCAS problem will be lifted out of the darkness of black boxes and pilots will remain blind to what's going on. As someone that always wanted a clear idea of what was going on, having the potential for another ghost in the machine is just not acceptable - unless I can disable it at a touch, without losing my electric trim for longer than it takes to reset that one channel.

Boeing kept their control cable ethos for a long time, and seemingly extended it into the 737's MAX era as part of a hurried development that could carry the LEAP engine. If it had come from a clean-sheet design, I doubt it would have had conventional controls, or short legs. In other words, it would have been a different species . . . and too late.

It's about this time in Boeing's time-line that you should found your judgement. It's not just because of the immediate problem, but trying to get into the heads of senior management and imagine what they were thinking when the pressure was on. They had a chance to develop what would become the world's biggest seller - the commercial driving forces must have been incredible. It doesn't make them right, just incredible.

But let's consider a time when it's back in service and the 'average pilot' is coping with crosswind limits - and in the real world, rather more. That very expensive pod is frighteningly near the ground, even when the wing is neutral and the undercarriage under no great pressure. I'd feel very uneasy about contemplating the next ten or fifteen years never thumping it on, or perhaps catching it when a low-hour colleague, suddenly and quite inexplicably, aims it below the concrete. It's a multi-million dollar piece of kit that's just a little too near the ground for comfort. Furthermore, it has inherited one of the NG's lesser-known problems of hand cranking the stabilizer, plus, it's got a smaller wheel with which to haul 200 feet of cable, there and back. It starts life with some serious question marks hanging over it.

Boeing can't change horses now, they have to press on with what they're doing. It's horrible, but Hobson's choice. I agree that adding lines of code just adds to the fog but I can't see they've got any other option. I've posted before about being able to press a master cut-out at the first hint of a problem, and then reintroduce functions in diagnostic stages. It's simple, and clean, and the crew would be using time-honoured logic and solid wiring. However, I doubt the MCAS problem will be lifted out of the darkness of black boxes and pilots will remain blind to what's going on. As someone that always wanted a clear idea of what was going on, having the potential for another ghost in the machine is just not acceptable - unless I can disable it at a touch, without losing my electric trim for longer than it takes to reset that one channel.

Funnily enough, the 300 series 146 has a flap trim compensator which automatically runs the electric trim when the flaps are running.

Join Date: Feb 2006

Location: USA

Posts: 487

Likes: 0

Received 0 Likes

on

0 Posts

https://www.nytimes.com/2019/11/24/w...indonesia.html

With Boeing in Cross Hairs, Lion Air Gets a Pass on Poor Safety Record

A focus on Boeing after two fatal crashes has given cover to an Indonesian air carrier with global ambitions — a company that will neither fully admit to, nor swiftly address, its safety issues.

By Hannah Beech and Muktita Suhartono

Nov. 24, 2019, 3:21 a.m. ET

When things go wrong, those in power often promise to make it right. But do they? In this series, The Times investigates to see if those promises were kept.

JAKARTA, Indonesia — When Lion Air Flight 610 took off in clear skies a year ago, the 737 jetliner carried with it an anti-stall system designed by Boeing that would propel the plane into a nose-dive minutes after takeoff, killing all 189 aboard.

But the plane was saddled with another safety burden. Flight 610 was operated by Lion Air, a low-cost Indonesian carrier that has benefited from its political connections to become one of the world’s fastest growing airlines, despite a questionable safety record.

While Boeing has faced intense scrutiny after two fatal crashes in less than five months, Lion Air has escaped similar attention, despite obvious failings that contributed to the disaster of Flight 610.

An investigation by The New York Times, based on interviews with dozens of officials and airline employees, including pilots and members of maintenance teams, found that Lion Air has a track record of working its pilots to the point of exhaustion, faking pilot training certification and forcing pilots to fly planes they worried were unsafe, including the plane that crashed.

Despite making vague promises of improvements after last year’s accident, the air carrier has neither fully acknowledged nor expeditiously addressed the concerns that have been raised about its safety practices, both by government investigators and whistle-blowers interviewed by The Times.

“The Boeing issue was an absolute godsend for Lion Air,” said John Goglia, a former member of the United States National Transportation Safety Board and an aviation safety expert. “It means Lion Air doesn’t have to deal with what is clearly failure after failure after failure and make the changes needed.”

Of the nine factors that caused the crash, according to the final report issued by the Indonesian National Transportation Safety Committee last month, a fatal Boeing design flaw in an automated system was what captured the world’s attention, especially after the crash of another plane in Ethiopia linked to its anti-stall system.

Although the report documented lapses on Lion Air’s part, like shoddy maintenance and undertrained pilots, examples of Lion Air’s culpability were underplayed when the report was presented, dismaying critics who note that Indonesia, the world’s fourth-most populous country, struggles with endemic corruption.

“You get the sense that the raw data that makes Lion look bad is buried in the report for whatever political reasons,” Mr. Goglia said.

Lion Air has not accepted responsibility for the failures listed in the report, and it dismissed most of the safety issues raised to The Times by current and former employees.

In a response attached to the final report, the airline wrote that it was “aware of efforts that have been made to criticize the Lion Air pilots, engineers and maintenance personnel who operated or worked” on the aircraft.

The carrier said “such criticisms are misplaced and should not be considered as contributing factors of the Flight JT610 accident.”

Despite the life-or-death urgency of some of the government report’s safety recommendations, including making improvements to Lion’s hazard-reporting process and its safety training, the company seems to be mulling its next steps, rather than taking immediate, decisive action.

“Give me time,” Daniel Putut, Lion Air’s managing director, said in an interview, when asked how quickly the carrier could implement the recommendations. “Let’s say another one or three months because we need to study it to learn if there are things we need to change.”

“The report,” he added by way of explaining the delay, “is 323 pages long.”

While denying that the deficiencies cited in the report played a part in the crash, Mr. Putut said that Lion Air has “tried to improve” how it identifies safety hazards since the disaster.

“The accident hurt us so we have done a deep study of our operational safety to prevent something from occurring again,” he said.

At the same time, however, Mr. Putut defended Lion Air’s business culture, which critics say prioritizes growth over safety.

A former Lion Air chief pilot, Jimmy Kalebos, said that refusing to acknowledge problems was symptomatic of the company’s approach to safety before the crash. That it continues to do so after so many deaths, he added, does not bode well.

“How can you fix a problem,” Mr. Kalebos asked, “if you don’t admit it exists?”

WHAT WE FOUND

‘Absolutely Not Improved’

In the view of some of the company’s most important employees — its pilots — Lion Air has not taken steps to fix numerous flaws since the crash.

The safety culture at Lion Air has “absolutely not improved,” a pilot said. Like other current and former Lion Air staff members, he agreed to speak only on condition of anonymity to protect his career.

Not a single Lion Air employee has been fired as a result of last year’s accident, according to both government investigators and current and former employees. Mr. Putut refused to confirm or deny if anyone had been let go.

Just as the company does not seem pressed to adopt changes from the report (which is actually 322 pages long), Indonesian officials were quick to defend a carrier that has had 11 accidents and incidents since its founding in 1999, according to the Aviation Safety Network.

In comparison, Spirit Airlines, the American low-cost carrier founded in 1980, has suffered two in its history, one in 2002, the other in 2005. Neither was fatal.

What’s more, many additional serious safety lapses at Lion Air were never investigated by the government because the carrier downplayed them or failed to divulge their likely causes, pilots and maintenance workers at the airline said.

In one case in 2016, a Lion Air jet suffered a total loss of engine oil, forcing the pilot to shut down the engine in flight, according to former employees. Yet the Indonesian National Transportation Safety Committee was never called in to investigate.

“What we see in the news is only the visible part of the iceberg,” one pilot said.

But members of the Indonesian government seemed sanguine about the airline’s safety.

“Lion Air maintenance is good,” said Luhut Pandjaitan, a government minister whose portfolio includes oversight of Indonesia’s transportation network. “Lion pilots have no problem. Lion Air facilities are very good.”

He said much of the criticism was fueled by “Western arrogance.”

But Ahmadji Sumankidjo, one of the minister’s own deputies, said there was an unwritten government preference for civil servants to avoid flying Lion Air.

“You can fly Lion Air,” he said, “but you need to pray to God.”

WHAT WE FOUND

‘I Want to Stop, but I Can’t’

Few airline businesses grew as quickly as Lion Air Group, which oversees several carriers in addition to Lion Air. In 1999, Rusdi Kirana started a low-cost carrier with a few rickety jets. By the time of the crash, Lion Air Group had signed deals for 450 brand-new planes from Boeing and Airbus.

On many routes within Indonesia, whose sprawling archipelago makes air travel an everyday necessity, Lion Air was often the only choice, making its peremptory motto oddly appropriate: “We make people fly.”

The Indonesian government has hailed Mr. Kirana as a visionary whose company employed 30,000 people. A Christian in a Muslim majority country, Mr. Kirana took on a leadership position in an Islamic political party with ties to the government and was named ambassador to Malaysia.

As Lion Air grew, all those new planes needed captains, and the company soon suffered from a dangerous shortage of pilots, according to those who watched the company transform.

In 2016, for example, Lion Air had about 3.5 flight crews (a chief pilot and first officer) for each plane in its fleet, according to company insiders, while the industry norm for airlines operating similar kinds of routes with similar planes is at least twice that.

“Do the math,” said Mr. Kalebos, the former Lion Air pilot. “It just doesn’t add up to safety being No. 1.”

While that ratio has since improved, according to current and former employees, the conditions for pilots remain onerous.

Under Indonesian law, pilots are not allowed to fly more than 110 hours a month. But faked logs of flying hours were rampant at the company, according to former and current pilots.

Eki Adriansjah, a former chief pilot at Lion who also served as a flight instructor, said he once worked 300 hours in a month and was chided by government regulators.

“I told them, ‘Why are you catching me and not the company?’” he said. “Lion was the one pushing me to work like that.”

Airline representatives denied its pilots were overworked.

The carrier also hired pilots with contracts that tied them to the carrier for up to 20 years unless they paid a hefty release fee.

“We are all tired,” said a current Lion Air pilot bound by such a restrictive contract. “I want to stop but I can’t.”

On Nov. 18, a co-pilot for Wings Air, another airline within the Lion Air Group, committed suicide after receiving a termination letter from the carrier telling him he owed $500,000 in penalties for the training he had received. In a statement after his death, Wings Air said it had taken employment actions against an “undisciplined” employee.

Some Lion Air pilots say the workload has improved since last year’s crash, with a computerized system, strengthened after the catastrophe, making it harder to cheat on flying hours.

“This was a problem at Lion, but now not so much,” said Koko Indra Perdana, a Lion Air chief pilot and secretary general of the Indonesian Pilots Professional Association.

Others are skeptical.

“I talk to my friends, and they say it’s the same now, they’re just more careful about hiding it,” Mr. Kalebos said.

WHAT WE FOUND

Fly, No Matter What

Current and former pilots at Lion Air recounted dozens of instances, both before and after the crash, in which they felt pressured to fly, despite concerns about the weather, the plane’s airworthiness or even their own alertness.

In two cases, pilots said they were ordered to fly to airports near where forest fires were raging and smoke obscured visibility.

“The manager told me, ‘Oh, you don’t need to see the runway because we have instruments that can see for you,’” said Mr. Eki, the former Lion pilot.

In another case, a Lion Air maintenance crew signed off on a plane as good to go. But the pilot wasn’t confident the plane was fit to fly, and he refused to take off.

Frustrated, a member of the maintenance team contacted a top executive at Lion Air. The pilot soon took to the skies.

Lion Air also had trouble giving its pilots the training necessary to pass a safety audit by the International Air Transport Association, which helps formulate global aviation standards.

Allowing the pilots time for training was hard because the understaffed airline needed them in the air, not in classrooms.

When it became clear that Lion Air would not be able to meet its training targets, a new solution was found, multiple people with the airline at the time said: faking documentation that training had been conducted.

“Fake certificates and a fake attendance list,” said one pilot who was party to the deception. “Now, magically, the S.M.S. training is compliant on paper,” the pilot added, referring to safety management system training. Lion received its I.A.T.A. safety certification in 2016.

Mr. Putut, the carrier’s managing director, said he was not aware of any falsified paperwork. “I’ve never heard about it, these fake certificates,” he said. “I need to check on that.”

WHAT WE FOUND

‘An Accident Waiting to Happen’

The Indonesian report on the crash notes how the plane experienced problems with speed and altitude readings for several days before the Oct. 29 crash.

On the morning of Oct. 28, a different flight crew aboard the doomed plane was told to fly it to the island of Bali because an engineer said a fix would be more easily found there.

Friends of the pilot said he was uncomfortable with the decision, given that on the previous leg, the plane had given him highly irregular data readings. But he flew there anyway on the plane that would crash the next day. The pilot did not respond to queries for comment.

“In any other country, making a pilot fly an unsafe plane like that is illegal,” said Mr. Goglia, the former National Transportation Safety Board member. “I don’t have words to describe how bad it is.”

At the Bali airport, a vane, known as an angle of attack sensor, was replaced.

Crash investigators were presented with photographs supposedly showing that a mandatory test was done after the vane had been replaced. But upon further inspection, investigators concluded the photos were from a different aircraft.

“This is a test that Lion Air was required to do, and they didn’t,” said John Cox, an aviation safety consultant.

If the test had been done, engineers likely would have realized the vane was calibrated incorrectly by 21 degrees. The misalignment would prove fatal because it mistakenly catalyzed Boeing’s anti-stall system, forcing the plane into its final plummet.

No government action has been taken related to the doctored photographs.

Questionable decisions continued after the plane took off from Bali on its next-to-last flight. While in the air, the faulty sensor and the automated anti-stall system kept compelling the plane’s nose down.

But once on the ground in Jakarta late on Oct. 28, the flight crew failed to document the full extent of the problems in the plane’s log, 31 pages of which were missing when it was presented to investigators, a breach for which Lion Air was never chided.

As the plane took off on its final flight, the crew of Flight 610 had no idea of all the troubles faced by the pilots a few hours earlier.

“That plane was unairworthy for days,” Mr. Goglia said. “It continued to be unairworthy because Lion Air didn’t take proper corrective action. It was an accident waiting to happen, and it happened.”

WHAT WE FOUND

Cozy Ties, Conflicts of Interest

In Indonesia, there are close ties between airlines and regulators, which industry experts believe have muted criticism and influenced investigations.

Last year, Nurcahyo Utomo, a lead investigator for the National Transportation Safety Committee, repeatedly said at a news conference that the crashed plane was “unairworthy” on its second-to-last flight.

Lion complained. The next morning, the government agency released a statement saying that Mr. Nurcahyo had “NEVER said” what he had, in fact, said.

Government employees in the aviation sector need to fly to keep their pilot licenses. To do so, they fly for and get paid by airlines like Lion Air. This money can outstrip their government paychecks.

The flow of staff from airline to government — and back again — occurs in management ranks, too.

The lead investigator of Lion Air’s first fatal accident, in which 25 people died in 2004 after a pilot overshot the runway, was Ertata Lananggalih. Four years after releasing a report that critics said underplayed Lion Air’s culpability in the crash, he joined the company, working his way up to managing director. He left Lion Air in 2012 and returned to government work as a senior air safety investigator.

“Indonesia is a corrupt country, but the corruption at Lion is the biggest of all,” said Wicaksono Budiarto, a former pilot for the airline who joined 17 others, including Mr. Eki and Mr. Kalebos, in a lawsuit against the company for dismissing them after they refused to fly in what they considered unsafe flying conditions.

The pilots won significant damages, but Lion Air has refused to pay.

“Nothing’s going to change,” Mr. Wicaksono said. “Lion has too much power.”

The Takeaway: After a crash, a company — and a government — deny problems, deflect blame and drag their feet on improvements.

Hannah Beech has been the Southeast Asia bureau chief since 2017, based in Bangkok. Before joining The Times, she reported for Time magazine for 20 years from bases in Shanghai, Beijing, Bangkok and Hong Kong. @hkbeech

Muktita Suhartono reports for The New York Times in Indonesia and Thailand. She joined The Times in 2018 and is based in Bangkok.

A version of this article appears in print on Nov. 24, 2019, Section A, Page 1 of the New York edition with the headline: Lapses Plague Lion Air, Year After Disaster.

A focus on Boeing after two fatal crashes has given cover to an Indonesian air carrier with global ambitions — a company that will neither fully admit to, nor swiftly address, its safety issues.

By Hannah Beech and Muktita Suhartono

Nov. 24, 2019, 3:21 a.m. ET

When things go wrong, those in power often promise to make it right. But do they? In this series, The Times investigates to see if those promises were kept.

JAKARTA, Indonesia — When Lion Air Flight 610 took off in clear skies a year ago, the 737 jetliner carried with it an anti-stall system designed by Boeing that would propel the plane into a nose-dive minutes after takeoff, killing all 189 aboard.

But the plane was saddled with another safety burden. Flight 610 was operated by Lion Air, a low-cost Indonesian carrier that has benefited from its political connections to become one of the world’s fastest growing airlines, despite a questionable safety record.

While Boeing has faced intense scrutiny after two fatal crashes in less than five months, Lion Air has escaped similar attention, despite obvious failings that contributed to the disaster of Flight 610.

An investigation by The New York Times, based on interviews with dozens of officials and airline employees, including pilots and members of maintenance teams, found that Lion Air has a track record of working its pilots to the point of exhaustion, faking pilot training certification and forcing pilots to fly planes they worried were unsafe, including the plane that crashed.

Despite making vague promises of improvements after last year’s accident, the air carrier has neither fully acknowledged nor expeditiously addressed the concerns that have been raised about its safety practices, both by government investigators and whistle-blowers interviewed by The Times.

“The Boeing issue was an absolute godsend for Lion Air,” said John Goglia, a former member of the United States National Transportation Safety Board and an aviation safety expert. “It means Lion Air doesn’t have to deal with what is clearly failure after failure after failure and make the changes needed.”

Of the nine factors that caused the crash, according to the final report issued by the Indonesian National Transportation Safety Committee last month, a fatal Boeing design flaw in an automated system was what captured the world’s attention, especially after the crash of another plane in Ethiopia linked to its anti-stall system.

Although the report documented lapses on Lion Air’s part, like shoddy maintenance and undertrained pilots, examples of Lion Air’s culpability were underplayed when the report was presented, dismaying critics who note that Indonesia, the world’s fourth-most populous country, struggles with endemic corruption.

“You get the sense that the raw data that makes Lion look bad is buried in the report for whatever political reasons,” Mr. Goglia said.

Lion Air has not accepted responsibility for the failures listed in the report, and it dismissed most of the safety issues raised to The Times by current and former employees.

In a response attached to the final report, the airline wrote that it was “aware of efforts that have been made to criticize the Lion Air pilots, engineers and maintenance personnel who operated or worked” on the aircraft.

The carrier said “such criticisms are misplaced and should not be considered as contributing factors of the Flight JT610 accident.”

Despite the life-or-death urgency of some of the government report’s safety recommendations, including making improvements to Lion’s hazard-reporting process and its safety training, the company seems to be mulling its next steps, rather than taking immediate, decisive action.

“Give me time,” Daniel Putut, Lion Air’s managing director, said in an interview, when asked how quickly the carrier could implement the recommendations. “Let’s say another one or three months because we need to study it to learn if there are things we need to change.”

“The report,” he added by way of explaining the delay, “is 323 pages long.”

While denying that the deficiencies cited in the report played a part in the crash, Mr. Putut said that Lion Air has “tried to improve” how it identifies safety hazards since the disaster.

“The accident hurt us so we have done a deep study of our operational safety to prevent something from occurring again,” he said.

At the same time, however, Mr. Putut defended Lion Air’s business culture, which critics say prioritizes growth over safety.

A former Lion Air chief pilot, Jimmy Kalebos, said that refusing to acknowledge problems was symptomatic of the company’s approach to safety before the crash. That it continues to do so after so many deaths, he added, does not bode well.

“How can you fix a problem,” Mr. Kalebos asked, “if you don’t admit it exists?”

WHAT WE FOUND

‘Absolutely Not Improved’

In the view of some of the company’s most important employees — its pilots — Lion Air has not taken steps to fix numerous flaws since the crash.

The safety culture at Lion Air has “absolutely not improved,” a pilot said. Like other current and former Lion Air staff members, he agreed to speak only on condition of anonymity to protect his career.

Not a single Lion Air employee has been fired as a result of last year’s accident, according to both government investigators and current and former employees. Mr. Putut refused to confirm or deny if anyone had been let go.

Just as the company does not seem pressed to adopt changes from the report (which is actually 322 pages long), Indonesian officials were quick to defend a carrier that has had 11 accidents and incidents since its founding in 1999, according to the Aviation Safety Network.

In comparison, Spirit Airlines, the American low-cost carrier founded in 1980, has suffered two in its history, one in 2002, the other in 2005. Neither was fatal.

What’s more, many additional serious safety lapses at Lion Air were never investigated by the government because the carrier downplayed them or failed to divulge their likely causes, pilots and maintenance workers at the airline said.

In one case in 2016, a Lion Air jet suffered a total loss of engine oil, forcing the pilot to shut down the engine in flight, according to former employees. Yet the Indonesian National Transportation Safety Committee was never called in to investigate.

“What we see in the news is only the visible part of the iceberg,” one pilot said.

But members of the Indonesian government seemed sanguine about the airline’s safety.

“Lion Air maintenance is good,” said Luhut Pandjaitan, a government minister whose portfolio includes oversight of Indonesia’s transportation network. “Lion pilots have no problem. Lion Air facilities are very good.”

He said much of the criticism was fueled by “Western arrogance.”

But Ahmadji Sumankidjo, one of the minister’s own deputies, said there was an unwritten government preference for civil servants to avoid flying Lion Air.

“You can fly Lion Air,” he said, “but you need to pray to God.”

WHAT WE FOUND

‘I Want to Stop, but I Can’t’

Few airline businesses grew as quickly as Lion Air Group, which oversees several carriers in addition to Lion Air. In 1999, Rusdi Kirana started a low-cost carrier with a few rickety jets. By the time of the crash, Lion Air Group had signed deals for 450 brand-new planes from Boeing and Airbus.

On many routes within Indonesia, whose sprawling archipelago makes air travel an everyday necessity, Lion Air was often the only choice, making its peremptory motto oddly appropriate: “We make people fly.”

The Indonesian government has hailed Mr. Kirana as a visionary whose company employed 30,000 people. A Christian in a Muslim majority country, Mr. Kirana took on a leadership position in an Islamic political party with ties to the government and was named ambassador to Malaysia.

As Lion Air grew, all those new planes needed captains, and the company soon suffered from a dangerous shortage of pilots, according to those who watched the company transform.

In 2016, for example, Lion Air had about 3.5 flight crews (a chief pilot and first officer) for each plane in its fleet, according to company insiders, while the industry norm for airlines operating similar kinds of routes with similar planes is at least twice that.

“Do the math,” said Mr. Kalebos, the former Lion Air pilot. “It just doesn’t add up to safety being No. 1.”

While that ratio has since improved, according to current and former employees, the conditions for pilots remain onerous.

Under Indonesian law, pilots are not allowed to fly more than 110 hours a month. But faked logs of flying hours were rampant at the company, according to former and current pilots.

Eki Adriansjah, a former chief pilot at Lion who also served as a flight instructor, said he once worked 300 hours in a month and was chided by government regulators.

“I told them, ‘Why are you catching me and not the company?’” he said. “Lion was the one pushing me to work like that.”

Airline representatives denied its pilots were overworked.

The carrier also hired pilots with contracts that tied them to the carrier for up to 20 years unless they paid a hefty release fee.

“We are all tired,” said a current Lion Air pilot bound by such a restrictive contract. “I want to stop but I can’t.”

On Nov. 18, a co-pilot for Wings Air, another airline within the Lion Air Group, committed suicide after receiving a termination letter from the carrier telling him he owed $500,000 in penalties for the training he had received. In a statement after his death, Wings Air said it had taken employment actions against an “undisciplined” employee.

Some Lion Air pilots say the workload has improved since last year’s crash, with a computerized system, strengthened after the catastrophe, making it harder to cheat on flying hours.

“This was a problem at Lion, but now not so much,” said Koko Indra Perdana, a Lion Air chief pilot and secretary general of the Indonesian Pilots Professional Association.

Others are skeptical.

“I talk to my friends, and they say it’s the same now, they’re just more careful about hiding it,” Mr. Kalebos said.

WHAT WE FOUND

Fly, No Matter What

Current and former pilots at Lion Air recounted dozens of instances, both before and after the crash, in which they felt pressured to fly, despite concerns about the weather, the plane’s airworthiness or even their own alertness.

In two cases, pilots said they were ordered to fly to airports near where forest fires were raging and smoke obscured visibility.

“The manager told me, ‘Oh, you don’t need to see the runway because we have instruments that can see for you,’” said Mr. Eki, the former Lion pilot.

In another case, a Lion Air maintenance crew signed off on a plane as good to go. But the pilot wasn’t confident the plane was fit to fly, and he refused to take off.

Frustrated, a member of the maintenance team contacted a top executive at Lion Air. The pilot soon took to the skies.

Lion Air also had trouble giving its pilots the training necessary to pass a safety audit by the International Air Transport Association, which helps formulate global aviation standards.

Allowing the pilots time for training was hard because the understaffed airline needed them in the air, not in classrooms.

When it became clear that Lion Air would not be able to meet its training targets, a new solution was found, multiple people with the airline at the time said: faking documentation that training had been conducted.

“Fake certificates and a fake attendance list,” said one pilot who was party to the deception. “Now, magically, the S.M.S. training is compliant on paper,” the pilot added, referring to safety management system training. Lion received its I.A.T.A. safety certification in 2016.

Mr. Putut, the carrier’s managing director, said he was not aware of any falsified paperwork. “I’ve never heard about it, these fake certificates,” he said. “I need to check on that.”

WHAT WE FOUND

‘An Accident Waiting to Happen’

The Indonesian report on the crash notes how the plane experienced problems with speed and altitude readings for several days before the Oct. 29 crash.

On the morning of Oct. 28, a different flight crew aboard the doomed plane was told to fly it to the island of Bali because an engineer said a fix would be more easily found there.

Friends of the pilot said he was uncomfortable with the decision, given that on the previous leg, the plane had given him highly irregular data readings. But he flew there anyway on the plane that would crash the next day. The pilot did not respond to queries for comment.

“In any other country, making a pilot fly an unsafe plane like that is illegal,” said Mr. Goglia, the former National Transportation Safety Board member. “I don’t have words to describe how bad it is.”

At the Bali airport, a vane, known as an angle of attack sensor, was replaced.

Crash investigators were presented with photographs supposedly showing that a mandatory test was done after the vane had been replaced. But upon further inspection, investigators concluded the photos were from a different aircraft.

“This is a test that Lion Air was required to do, and they didn’t,” said John Cox, an aviation safety consultant.

If the test had been done, engineers likely would have realized the vane was calibrated incorrectly by 21 degrees. The misalignment would prove fatal because it mistakenly catalyzed Boeing’s anti-stall system, forcing the plane into its final plummet.

No government action has been taken related to the doctored photographs.

Questionable decisions continued after the plane took off from Bali on its next-to-last flight. While in the air, the faulty sensor and the automated anti-stall system kept compelling the plane’s nose down.

But once on the ground in Jakarta late on Oct. 28, the flight crew failed to document the full extent of the problems in the plane’s log, 31 pages of which were missing when it was presented to investigators, a breach for which Lion Air was never chided.

As the plane took off on its final flight, the crew of Flight 610 had no idea of all the troubles faced by the pilots a few hours earlier.

“That plane was unairworthy for days,” Mr. Goglia said. “It continued to be unairworthy because Lion Air didn’t take proper corrective action. It was an accident waiting to happen, and it happened.”

WHAT WE FOUND

Cozy Ties, Conflicts of Interest

In Indonesia, there are close ties between airlines and regulators, which industry experts believe have muted criticism and influenced investigations.

Last year, Nurcahyo Utomo, a lead investigator for the National Transportation Safety Committee, repeatedly said at a news conference that the crashed plane was “unairworthy” on its second-to-last flight.

Lion complained. The next morning, the government agency released a statement saying that Mr. Nurcahyo had “NEVER said” what he had, in fact, said.

Government employees in the aviation sector need to fly to keep their pilot licenses. To do so, they fly for and get paid by airlines like Lion Air. This money can outstrip their government paychecks.

The flow of staff from airline to government — and back again — occurs in management ranks, too.

The lead investigator of Lion Air’s first fatal accident, in which 25 people died in 2004 after a pilot overshot the runway, was Ertata Lananggalih. Four years after releasing a report that critics said underplayed Lion Air’s culpability in the crash, he joined the company, working his way up to managing director. He left Lion Air in 2012 and returned to government work as a senior air safety investigator.

“Indonesia is a corrupt country, but the corruption at Lion is the biggest of all,” said Wicaksono Budiarto, a former pilot for the airline who joined 17 others, including Mr. Eki and Mr. Kalebos, in a lawsuit against the company for dismissing them after they refused to fly in what they considered unsafe flying conditions.

The pilots won significant damages, but Lion Air has refused to pay.

“Nothing’s going to change,” Mr. Wicaksono said. “Lion has too much power.”

The Takeaway: After a crash, a company — and a government — deny problems, deflect blame and drag their feet on improvements.

Hannah Beech has been the Southeast Asia bureau chief since 2017, based in Bangkok. Before joining The Times, she reported for Time magazine for 20 years from bases in Shanghai, Beijing, Bangkok and Hong Kong. @hkbeech

Muktita Suhartono reports for The New York Times in Indonesia and Thailand. She joined The Times in 2018 and is based in Bangkok.

A version of this article appears in print on Nov. 24, 2019, Section A, Page 1 of the New York edition with the headline: Lapses Plague Lion Air, Year After Disaster.

- Will airframe insurers be happy to insure an airframe cleared to fly by the FAA but not by EASA, CAAC, etc.? Where does that put the leasing companies?

- Will passengers' travel insurance exclude death and injury cover for carriage on an airframe cleared to fly by the FAA but not by EASA, CAAC, etc.?

Join Date: Dec 2015

Location: Cape Town, ZA

Age: 62

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

The response may be linear the first time, but definitely not for sustained maneuvers. This was true very early in the discussion, and remains so. No half-cooked computer system such as MCAS can be safe, effective and reliable, all of the time.

Loose rivets I think this is more a reaction of disgust than alarm. All the attention is implying that the system is almost ready, and we can soon move forwards.

The recent comments from across the spectrum seem to emphasise that nobody is truly happy with this band-aid/kludge/fix, and that the aircraft/manufacturer/regulator are permanently tainted in the view of inquiring minds.