Engineering Challenges Facing New VTOL Aircraft

Imposing a requirement (autorotation) from one type of aircraft (helicopter) onto another type (multirotor) seems a negative step. What is required is the same or better level of reliability and survivability. If a multirotor can achieve this with two or more distinctly separate power and control systems, why should it be saddled with the weight, complexity and additional possible failure modes of an autorotation system?

The following users liked this post:

Imposing a requirement (autorotation) from one type of aircraft (helicopter) onto another type (multirotor) seems a negative step. What is required is the same or better level of reliability and survivability. If a multirotor can achieve this with two or more distinctly separate power and control systems, why should it be saddled with the weight, complexity and additional possible failure modes of an autorotation system?

The following 3 users liked this post by SplineDrive:

SplineDrive: Thanks for your comprehensive review / assessment in post #16. A fair bit to absorb!

I had overlooked you already mentioned X-2 in your post #11 (as 60FltMech did in the original post!) and have only now realised it formed the principles of their SB-1 Defiant bid. You made the comment "It [rigid contra-rotating rotors] might even lose to a simple winged helicopter in a few years". Do you mean something like the Sikorsky S-67 (https://en.wikipedia.org/wiki/Sikorsky_S-67_Blackhawk)!!

As you have obviously thought carefully about overall rotorcraft design, you might also like to comment on whether there could be a future in a modern-day version of the Fairey Rotodyne gyroplane (https://en.wikipedia.org/wiki/Fairey_Rotodyne)? I am sure design techniques are now available to substantially reduce the noise generated by the rotor tip jets. Perhaps this isn't so much a technical challenge anymore, rather one of overcoming protest over use of such rotorcraft in built up areas (where they might otherwise still attract a commuter market).

I had overlooked you already mentioned X-2 in your post #11 (as 60FltMech did in the original post!) and have only now realised it formed the principles of their SB-1 Defiant bid. You made the comment "It [rigid contra-rotating rotors] might even lose to a simple winged helicopter in a few years". Do you mean something like the Sikorsky S-67 (https://en.wikipedia.org/wiki/Sikorsky_S-67_Blackhawk)!!

As you have obviously thought carefully about overall rotorcraft design, you might also like to comment on whether there could be a future in a modern-day version of the Fairey Rotodyne gyroplane (https://en.wikipedia.org/wiki/Fairey_Rotodyne)? I am sure design techniques are now available to substantially reduce the noise generated by the rotor tip jets. Perhaps this isn't so much a technical challenge anymore, rather one of overcoming protest over use of such rotorcraft in built up areas (where they might otherwise still attract a commuter market).

SplineDrive: Thanks for your comprehensive review / assessment in post #16. A fair bit to absorb!

I had overlooked you already mentioned X-2 in your post #11 and have only now realised it formed the principles of their SB-1 Defiant bid. You made the comment "It [rigid contra-rotating rotors] might even lose to a simple winged helicopter in a few years". Do you mean something like the Sikorsky S-67 (https://en.wikipedia.org/wiki/Sikorsky_S-67_Blackhawk)!!

As you have obviously thought carefully about overall rotorcraft design, you might also like to comment on whether there could be a future in a modern-day version of the Fairey Rotodyne gyroplane (https://en.wikipedia.org/wiki/Fairey_Rotodyne)? I am sure design techniques are now available to substantially reduce the noise generated by the rotor tip jets. Perhaps this isn't so much a technical challenge anymore, rather one of overcoming protest over use of such rotorcraft in built up areas (where they might otherwise still attract a commuter market).

I had overlooked you already mentioned X-2 in your post #11 and have only now realised it formed the principles of their SB-1 Defiant bid. You made the comment "It [rigid contra-rotating rotors] might even lose to a simple winged helicopter in a few years". Do you mean something like the Sikorsky S-67 (https://en.wikipedia.org/wiki/Sikorsky_S-67_Blackhawk)!!

As you have obviously thought carefully about overall rotorcraft design, you might also like to comment on whether there could be a future in a modern-day version of the Fairey Rotodyne gyroplane (https://en.wikipedia.org/wiki/Fairey_Rotodyne)? I am sure design techniques are now available to substantially reduce the noise generated by the rotor tip jets. Perhaps this isn't so much a technical challenge anymore, rather one of overcoming protest over use of such rotorcraft in built up areas (where they might otherwise still attract a commuter market).

I have a hard time imagining that tip jet powered aircraft will make a comeback. Noise, fuel and aerodynamic efficiency, etc. are pretty serious problems. I could be wrong, though. Historically abandoned ideas do make the occasional revival.

The following users liked this post:

Join Date: Aug 2006

Location: California

Posts: 78

Likes: 0

Received 0 Likes

on

0 Posts

Imposing a requirement (autorotation) from one type of aircraft (helicopter) onto another type (multirotor) seems a negative step. What is required is the same or better level of reliability and survivability. If a multirotor can achieve this with two or more distinctly separate power and control systems, why should it be saddled with the weight, complexity and additional possible failure modes of an autorotation system?

A distinctly separate battery is a non-starter. In the event of a main power bus (single battery) failure, the aircraft becomes a brick.

JohnDix,

I just canít see an aircraft with a mass of push pull tubes, mixers, bellcranks and Hydraulic lines being the future of Army Aviation(or VTOL in general), someone has to crack the code on simplifying these systems, while also keeping redundancy for battle damage or other emergencies.

FltMech

I just canít see an aircraft with a mass of push pull tubes, mixers, bellcranks and Hydraulic lines being the future of Army Aviation(or VTOL in general), someone has to crack the code on simplifying these systems, while also keeping redundancy for battle damage or other emergencies.

FltMech

no one has certified a civil FBW rotorcraft or tiltrotor yet and it is not because of the workload. Itís very challenging to prove safety to dozens of strongly opinionated regulatory specialists from all major authorities. EVTOLís can naively project confidence but they are massively unprepared for the gauntlet of ďwhat if-ismsĒ that will come on the way to type cert.

it sure is a ton simpler to just use SAS/SCAS to reduce pilot workload while still preserving basic mechanical function in nearly all conditions. Mechanical failure is extremely rare in reality.

The following users liked this post:

Since the Joby and others are being certified under Part 21, they need to post those criteria in the federal register for the legal framework. Same with Archer and the others needing their separate posted criteria. This is one place the EASA is ahead of the FAA as they already have official guidance in place: SC-VTOL-1.

My read is that (g) means the aircraft can protect the passengers in a power off landing, though means other than gliding or autorotation can be acceptable (like a ballistic chute).

I think you’ll find the plan forward has always been around failure probability vs chutes or autos. Hence the reason to modify the existing regulatory language. In general terms, if one can prove any “critical loss of thrust” is “extremely improbable” then the "controlled emergency landing" required in paragraph (g) becomes moot or limited.

And to note, “extremely improbable” is defined as one failure in 1 billion flight hours. The EASA SC-VTOL-1 has a similar requirement.

We'll see. All these ships have a long road to certification

*not including China.

Last edited by wrench1; 22nd May 2023 at 19:46. Reason: add missing info

the illusion of FBW is simplicity. It is imminently more complex than push pull or cable systems. Software is a vast ocean of possibilities and decisions with many hidden (and deadly) traps as evidenced by numerous complex failures from software based systems of the past.

no one has certified a civil FBW rotorcraft or tiltrotor yet and it is not because of the workload.

it sure is a ton simpler to just use SAS/SCAS to reduce pilot workload while still preserving basic mechanical function in nearly all conditions. Mechanical failure is extremely rare in reality.

FBW civil certification

I'll be interested to see how that plays out. John Dixson has mentioned any number of times the mismatch between the early FBW development for rotary wing versus the capacity to figure out requirements for that among regulators (at least on the FAA side).

The future passengers of these new aircraft agree with you.

Two that come to mind are the 609 (civilian tilt rotor) and the 525 (Bell). I am sure that there are others, to include the odd event with S-97 - WoW and fly by wire mode conflict - a few years ago at West Palm.

Isn't Relentless (Bell 525) almost there?

I agree. Sometimes I wonder if the "can" and "should" thinking fits the needs of the aircraft.

The future passengers of these new aircraft agree with you.

Two that come to mind are the 609 (civilian tilt rotor) and the 525 (Bell). I am sure that there are others, to include the odd event with S-97 - WoW and fly by wire mode conflict - a few years ago at West Palm.

Isn't Relentless (Bell 525) almost there?

I agree. Sometimes I wonder if the "can" and "should" thinking fits the needs of the aircraft.

North Carolina hydraulic fluid incident was truly a software glitch in the warning light system

Anything like the V-22 I'd imagine would have to be certified to continue to an airport for a safe landing, autorotation is not possible with ROD's in the 15 to 20,000 FPM range (quote from the lecture), nor was the ability to autorotate part of the design brief..

Software glitch:

Megan,

As I understand it, all that you wrote is true. You didn't mention that the Push-To-Reset function was incorrectly connected to an incremental increase in the helicopter flight mode collective position of one of the rotors, The rabbit punching of the reset button incrementally increased one of the rotor's collective position (which was obviously not understood by the pilot) until the aircraft rolled over and went in. This is the software glitch I was referring to. (Correct me if I'm wrong.) Ott.

As I understand it, all that you wrote is true. You didn't mention that the Push-To-Reset function was incorrectly connected to an incremental increase in the helicopter flight mode collective position of one of the rotors, The rabbit punching of the reset button incrementally increased one of the rotor's collective position (which was obviously not understood by the pilot) until the aircraft rolled over and went in. This is the software glitch I was referring to. (Correct me if I'm wrong.) Ott.

Correct me if I'm wrong

Push-To-Reset function was incorrectly connected to an incremental increase in the helicopter flight mode collective position of one of the rotors

Would anyone like to comment on the viability of the 'Wisk' aircraft with its series of small rotors to provide vertical lift (https://wisk.aero)?

I guess the aircraft has to contend with the weight and drag penalty of the vertical lift system when in forward flight, and the graph SplineDrive shared in post #17 also hasn't gone un-noticed, but this arrangement is probably less mechanically complicated than a tilt-rotor?

I guess the aircraft has to contend with the weight and drag penalty of the vertical lift system when in forward flight, and the graph SplineDrive shared in post #17 also hasn't gone un-noticed, but this arrangement is probably less mechanically complicated than a tilt-rotor?

Last edited by helispotter; 4th Jun 2023 at 09:23.

JohnDix,

When I wrote the post opening this thread I had two questions in mind that I wanted to ask: first was about fly by wire and the second question, which is regarding flight control hydraulic systems.

It seems that if you could develop a rugged fly by wire system you would be well on your way to simplifying your flight control hydraulic systems.

Regarding V-280, I assume Bell will use what they have learned on their 525 FBW and hydraulic systems. But as you pointed out the standards for such systems for VTOL aircraft arenít fully established, so how does it all come together in the end?

I just canít see an aircraft with a mass of push pull tubes, mixers, bellcranks and Hydraulic lines being the future of Army Aviation(or VTOL in general), someone has to crack the code on simplifying these systems, while also keeping redundancy for battle damage or other emergencies.

FltMech

When I wrote the post opening this thread I had two questions in mind that I wanted to ask: first was about fly by wire and the second question, which is regarding flight control hydraulic systems.

It seems that if you could develop a rugged fly by wire system you would be well on your way to simplifying your flight control hydraulic systems.

Regarding V-280, I assume Bell will use what they have learned on their 525 FBW and hydraulic systems. But as you pointed out the standards for such systems for VTOL aircraft arenít fully established, so how does it all come together in the end?

I just canít see an aircraft with a mass of push pull tubes, mixers, bellcranks and Hydraulic lines being the future of Army Aviation(or VTOL in general), someone has to crack the code on simplifying these systems, while also keeping redundancy for battle damage or other emergencies.

FltMech

First, thanks for starting this thread, this site has become dry of new topics of late.

Many people donít realize that the FAA FARs are only the equivalent of a cover page. Interpretation of FARs correctly is impossible without referencing the advisory circulars (ACs). ACs provide guidance and describe acceptable methods for demonstrating compliance to the FARs.

Where the rotorcraft ACs fall short, are for new and novel technologies, like FBW. But FBW is only new on commercial rotorcraft (Part 27 and 29). For Part 25, Transport aircraft, FBW is well established. So using Part 25 ACs to provide guidance for Part 27 and 29 FBW has been the path for the AW609 and Bell 525.

This path drives FBW rotorcraft to be designed to many of the same requirements as a large Transport aircraft like a Boeing 777 or Airbus 350 airliners. So cost and weight become a major factors. This is why eVTOL developers are trying to circumvent this path to certification. Like you, I fear this will result in the loss of many lives if it is allowed to happen.

The only three production FBW rotorcraft, the V-22, NH90, and CH-148 were built to military or company standards, and donít meet FAA certification requirements. Sikorsky attempted to get FAA certification for the CH-148 FBW system, but designís architecture was inadequate.

The AW609 and Bell 525 will be the first civil certified FBW rotorcraft, and both have the same FBW system design. Their FBW systems build on the lessons learned from the V-22, but are very different in design. Bell realized 25 years ago that a V-22 FBW architecture could not be FAA certified. Additionally, cost, reliability, and maintainability aspects of the V-22 architecture were incompatible with a commercial customer. So Bell started from scratch, designing a FBW design based on the KISS principle (as simple as a FBW system can be). Because of the long delays in AW609 and 525 certification, Bell (and Leonardo) engineers have had decades to develop these FBW systems.

When the FAA eventually publishes ACs providing guidance on FBW for rotorcraft, it will be based on the standards set by AW609 and 525.

The Bell V-280 FLRAA and 360 FARA FBW systems are based on the 609 and 525 architectures. Since the US Army is now requiring FAA levels of critical failure reliability for these platforms, Bell was well prepared with an FBW system solution.

Last edited by CTR; 4th Jun 2023 at 19:27.

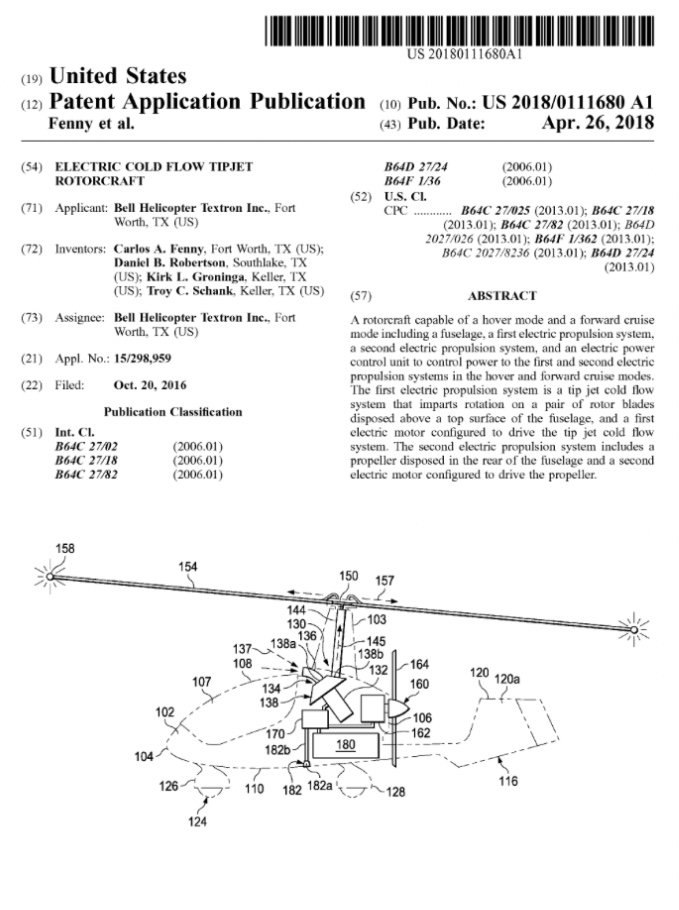

Perhaps the revival time for a tip jet may have come ;-)

Bell Patent for Electric TipJet Rotorcraft

Last edited by CTR; 4th Jun 2023 at 15:03.

The following users liked this post:

Would anyone like to comment on the viability of the 'Wisk' aircraft with its series of small rotors to provide vertical lift (https://wisk.aero)?

I guess the aircraft has to contend with the weight and drag penalty of the vertical lift system when in forward flight, and the graph SplineDrive shared in post #17 also hasn't gone un-noticed, but this arrangement is probably less mechanically complicated than a tilt-rotor?

I guess the aircraft has to contend with the weight and drag penalty of the vertical lift system when in forward flight, and the graph SplineDrive shared in post #17 also hasn't gone un-noticed, but this arrangement is probably less mechanically complicated than a tilt-rotor?

Wisk has moved to the increasingly common "lift + tilt cruise" approach for distributed lift. Their front 6 props are five blade each and appear to have collective pitch control. The aft 6 lift props are four blades each and I can't tell if they have pitch control or will use variable RPM to control thrust. Most of the "lift + tilt cruise" aircraft are focusing on 2 bladed lift props but these will have significant 2P load and vibration problems during transition , particularly as the prop diameter grows to accommodate realistic payloads and vehicle weights. Since these aircraft tend to have "rigid" lift props with collective control (and sometimes not even that), the maximum practical rotor diameter is limited. I'm not sure where that limit is for the rear lift props, and it depends on a number of factors, but it could be somewhere in the range of 6-8 feet unless you either have low blade loading, significant flapping compliance in the blade, or some form of active vibration control. So vehicle growth has to happen by adding more rotors instead of larger diameter rotors.

The front tilt props have higher blade count which will reduce vibrations but there will still be significant loads/vibrations that a propeller designer is entirely not used to.

I question the argument of reduced part count and complexity on the multi rotor configurations and the claim that there are no single point failure elements. At a bare minimum, each blade is is a wear item that has to be inspected periodically and each blade (that has pitch control) has bearings and more bearings than a conventional variable pitch prop. Wisk Gen 6 has 54 blades and potentially 108 blade feathering/retention bearings and yet more bearings in the pitch link / control system for each blade. Add in actuators for each prop and actuators for any moving airfoil surfaces and you've got a lot of parts that I just do not believe will not require some scheduled inspection in service.

All of the lift + tilt cruise aircraft look (to me) weak in yaw authority in hover operations. Landing on a targeted pad in variable 20+ knot winds might not be easy. Cruise speed, range, and payload all compare poorly to a light turbine helicopter or even some piston helicopters. There is zero point zero chance of autorotation (as discussed earlier in the thread), so any controlled emergency landing capability from a VTOL flight condition will involve some low altitude ballistic chute? As an autonomous aircraft, I guess Wisk will argue the computer will never fly the aircraft to energy starvation and there is enough electrical redundancy to avoid a complete loss of energy onboard. The difficulty in certifying a fly by wire system and the autonomy required, in an FAA environment, I think has been grossly underestimated.

To me, these lift + cruise aircraft don't compete favorably with a conventional helicopter and the configuration doesn't scale well and will remain limited to the price sensitive small end of the VTOL pool (or museums). High development and certification costs and lower profit margins make for a questionable financial plan, though the vertical integration of vehicle OEM and operator will attempt to bypass some of the economics. I also wonder if firms like Wisk and Joby are going to self-insure the aircraft and operations or if they've been engaging the insurance industry to make sure they're onboard with the configuration and concept of operations as well.

Obviously, a bunch of startup eVTOL firms and billions of (previously) low interest rate dollars think I'm wrong. My opinion is worth exactly what you paid for it :-)

The following 3 users liked this post by SplineDrive:

https://en.wikipedia.org/wiki/SNCASO_SO.1221_Djinn

The following users liked this post:

Proponents of these little proof-of-concept vehicles never talk about other things as well. To accommodate four (or so) passengers who don't know much about aircraft and don't care, the hardware (door handles and such) will have to be really heavy-duty, not flimsy like an Enstrom or R-22 door. Passengers are going to want creature comforts - you know, comfortable seats, a nicely-appointed interior...heat in the winter and a/c in the summer. How much weight does that add up to? Can these little eggshells be scaled-up that far? I'm sure that battery technology will improve...but...really? Oh yeah, what happens if a passenger gets airsick and pukes? (Think it won't happen?) Will the drone be able to detect it? Either way, that machine goes out of service.

The idea of autonomous eVTOL drones zooming around crowded cities is enticing, I'll grant you that. And I don't want to be so arrogant and pessimistic as to say it will *never* happen... But it won't, let's be honest. Not as long as the FAA governs things that fly in the air, and not as long as the public are as risk-averse as they are today. But perhaps I'm wrong! Perhaps people will become *less* risk-averse in the future. Yeah, that could happen...not.

60 Flt Mech. Sorry for not responding to the following from Post #7:

“It seems that if you could develop a rugged fly by wire system you would be well on your way to simplifying your flight control hydraulic systems.

Regarding V-280, I assume Bell will use what they have learned on their 525 FBW and hydraulic systems. But as you pointed out the standards for such systems for VTOL aircraft aren’t fully established, so how does it all come together in the end?

I just can’t see an aircraft with a mass of push pull tubes, mixers, bellcranks and Hydraulic lines being the future of Army Aviation(or VTOL in general), someone has to crack the code on simplifying these systems, while also keeping redundancy for battle damage or other emergencies.”

As to simplifying hydraulic system, the Canadian MHP S-92 offers a glimpse of the future. All of the hydraulic clap-trap that is required on the top deck in front of the main rotor on S-70 and S-92 models, boost actuators, SAS actuators, control mixer devices, and in the tail cone, the tail rotor control quadrant . There is weight to be saved, maintenance man hours/inspection hours to be eliminated, areas where mistakes in maintenance can cause fatal accidents to be eliminated. There are other capabilities that beckon in the future for FBW, present in some military machines.

This is the one area of helicopter design where general standards do not exist. One sympathizes with the Bell/Augusta 609 and Bell 525 teams in their quest for certification.

Given that the expertise is resident in the OEM’s engineering departments, is the solution a VFS Committee of FBW specialists writing general standards?

“It seems that if you could develop a rugged fly by wire system you would be well on your way to simplifying your flight control hydraulic systems.

Regarding V-280, I assume Bell will use what they have learned on their 525 FBW and hydraulic systems. But as you pointed out the standards for such systems for VTOL aircraft aren’t fully established, so how does it all come together in the end?

I just can’t see an aircraft with a mass of push pull tubes, mixers, bellcranks and Hydraulic lines being the future of Army Aviation(or VTOL in general), someone has to crack the code on simplifying these systems, while also keeping redundancy for battle damage or other emergencies.”

As to simplifying hydraulic system, the Canadian MHP S-92 offers a glimpse of the future. All of the hydraulic clap-trap that is required on the top deck in front of the main rotor on S-70 and S-92 models, boost actuators, SAS actuators, control mixer devices, and in the tail cone, the tail rotor control quadrant . There is weight to be saved, maintenance man hours/inspection hours to be eliminated, areas where mistakes in maintenance can cause fatal accidents to be eliminated. There are other capabilities that beckon in the future for FBW, present in some military machines.

This is the one area of helicopter design where general standards do not exist. One sympathizes with the Bell/Augusta 609 and Bell 525 teams in their quest for certification.

Given that the expertise is resident in the OEM’s engineering departments, is the solution a VFS Committee of FBW specialists writing general standards?