Helicopter down outside Leicester City Football Club

Avoid imitations

Join Date: Nov 2000

Location: Wandering the FIR and cyberspace often at highly unsociable times

Posts: 14,573

Received 422 Likes

on

222 Posts

Crab,

My understanding of a "Duplex" bearing is that it's actually two ball (or roller) bearings sitting side by side in one case. They are used in various applications such as vehicle wheel bearings. They provide an alternative to having two separate bearings with a space between them and are used where lateral "rocking" or "run-out" needs to be minimised and also provide load sharing between the two races. They need to be carefully installed to avoid damage, more so than simple ball or roller bearings. If they are knocked in too hard (such as to overcome too tight an interference fit), they can suffer damage.

Are you sure you're not mixing this up with what is known as a "linear" bearing? A car gear change assembly I rebuilt had a small linear bearing in the housing. It allows the gear linkage's horizontal shaft to slide fore and aft (as when going from 1st to 2nd or 3rd to 4th) and rotate from side to side, as when going from 2nd to 3rd. These have rows of small ball bearings sitting in longitudinal slots in a tubular, centre cage which holds them in alignment. I ditched the rusted out one in my gear change and because I had great difficulty in finding a suitable replacement I fitted a plain, sintered bronze bush instead.

My understanding of a "Duplex" bearing is that it's actually two ball (or roller) bearings sitting side by side in one case. They are used in various applications such as vehicle wheel bearings. They provide an alternative to having two separate bearings with a space between them and are used where lateral "rocking" or "run-out" needs to be minimised and also provide load sharing between the two races. They need to be carefully installed to avoid damage, more so than simple ball or roller bearings. If they are knocked in too hard (such as to overcome too tight an interference fit), they can suffer damage.

Are you sure you're not mixing this up with what is known as a "linear" bearing? A car gear change assembly I rebuilt had a small linear bearing in the housing. It allows the gear linkage's horizontal shaft to slide fore and aft (as when going from 1st to 2nd or 3rd to 4th) and rotate from side to side, as when going from 2nd to 3rd. These have rows of small ball bearings sitting in longitudinal slots in a tubular, centre cage which holds them in alignment. I ditched the rusted out one in my gear change and because I had great difficulty in finding a suitable replacement I fitted a plain, sintered bronze bush instead.

Join Date: Jan 2011

Location: on the cusp

Age: 52

Posts: 217

Likes: 0

Received 0 Likes

on

0 Posts

The bearing is to allow rotation of the hub around the static control rod. It's a duplex bearing because it has two races precisely matched to maintain alignment when the shaft is moved horizontally.

In my personal opinion it looks like the inspections are checking both ends of the control rod for anything that may cause it to jam or break.

In my personal opinion it looks like the inspections are checking both ends of the control rod for anything that may cause it to jam or break.

Join Date: Dec 2011

Location: UK

Posts: 53

Likes: 0

Received 0 Likes

on

0 Posts

The bearing is to allow rotation of the hub around the static control rod. It's a duplex bearing because it has two races precisely matched to maintain alignment when the shaft is moved horizontally.

In my personal opinion it looks like the inspections are checking both ends of the control rod for anything that may cause it to jam or break.

In my personal opinion it looks like the inspections are checking both ends of the control rod for anything that may cause it to jam or break.

Originally Posted by [email protected]

14 is where the pitch change arm and the TR servo attachment is on a 365.

Gray - what they call a duplex bearing is what allows you to superimpose horizontal pitch change movement onto the rotating drive shaft - you probably already knew that but I though I'd clarify just in case.

Gray - what they call a duplex bearing is what allows you to superimpose horizontal pitch change movement onto the rotating drive shaft - you probably already knew that but I though I'd clarify just in case.

Its likely a similiar position to it enough that I can relate it to the 169 at least.

They use a double row ball bearing that seems undersized for it's function. Only seen a couple failures though, but nothing catastrophic.

I just wasnt sure where it was located and how it was connected to the nut issue previously.

I am not familiar with the 169 directions of rotation, or left/right hand threads for that nut. but can anyone say for certainty what could happen if the bearing seizes? will it rotate that shaft and un-thread the nut with enough force to overcome the torque, and safety locks?

GHH,

If you look back through the message thread there are a few pics of the arrangement. The locking in the pic implies a RH threaded nut and the directions of rotation would imply your theory could be correct.

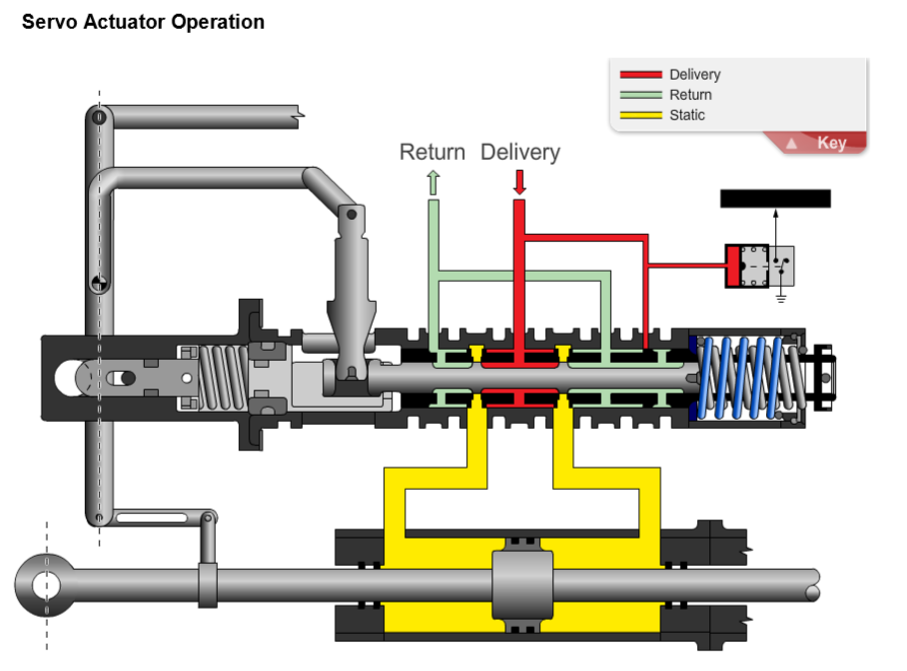

Normally the servo piston is keyed in some way to stop this happening but you can't tell from the IPC drawing. Having a split/cotter pin and locking kind of implies that this is the only locking. If it was keyed you wouldn't go to that length.

Similar things have happened before but not through design issues.

Once the feedback link is disconnected the servo would invariably motor to the end of full travel and stay there.

Pic at #682 and IPC at #630

I am not familiar with the 169 directions of rotation, or left/right hand threads for that nut. but can anyone say for certainty what could happen if the bearing seizes? will it rotate that shaft and un-thread the nut with enough force to overcome the torque, and safety locks?

Normally the servo piston is keyed in some way to stop this happening but you can't tell from the IPC drawing. Having a split/cotter pin and locking kind of implies that this is the only locking. If it was keyed you wouldn't go to that length.

Similar things have happened before but not through design issues.

Once the feedback link is disconnected the servo would invariably motor to the end of full travel and stay there.

Pic at #682 and IPC at #630

Join Date: Jan 2011

Location: on the cusp

Age: 52

Posts: 217

Likes: 0

Received 0 Likes

on

0 Posts

I am not familiar with the 169 directions of rotation, or left/right hand threads for that nut. but can anyone say for certainty what could happen if the bearing seizes? will it rotate that shaft and un-thread the nut with enough force to overcome the torque, and safety locks?

Surely the issue is that if the bearing seizes then your tail rotor pitch control is now jammed. Whereas if it is just the nut coming off then it means that control is lost.

to the static shaft.

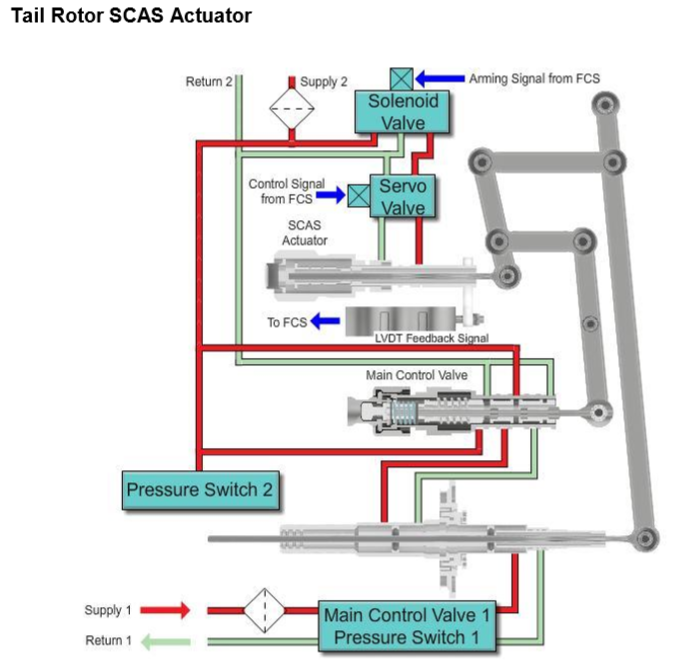

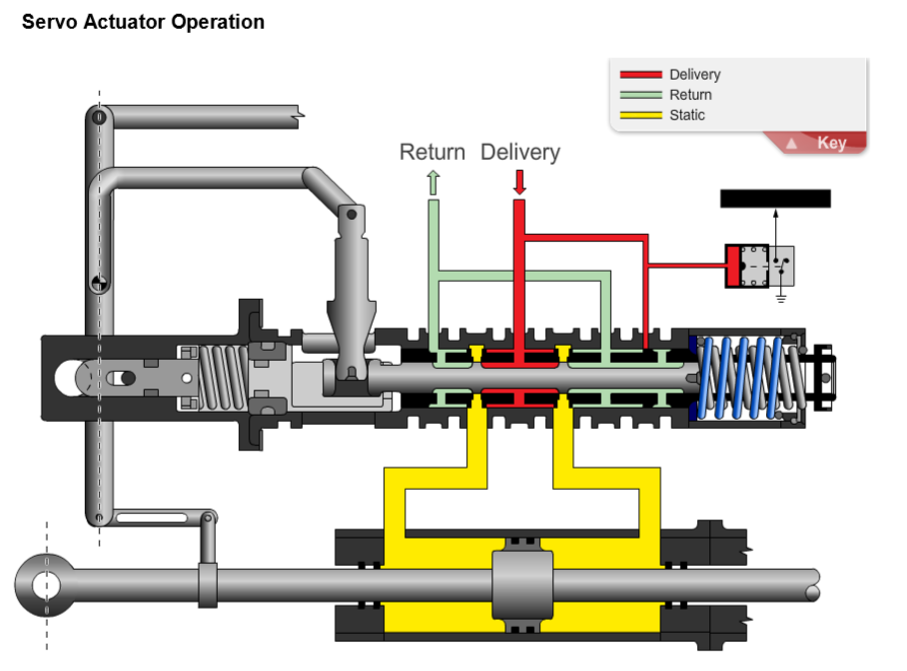

The nut connects the static pitch change to the feedback lever. The feedback lever cancels the pilot valve input once the piston reaches the desired position. Standard servo actuator behaviour.

Without feedback the pilot valve input will not cancel.

Join Date: Jan 2011

Location: on the cusp

Age: 52

Posts: 217

Likes: 0

Received 0 Likes

on

0 Posts

If the bearing fails then a number of possibilities then exist. Losing the nut at either end is one, but a misalignment of the static rod leading to it jamming is another.

The servo may run hard over, or may run to neutral depending on how the feedback control is connected. I don't have any details of the servo to be able to say with certainty.

Join Date: Mar 2007

Location: UK

Posts: 321

Likes: 0

Received 0 Likes

on

0 Posts

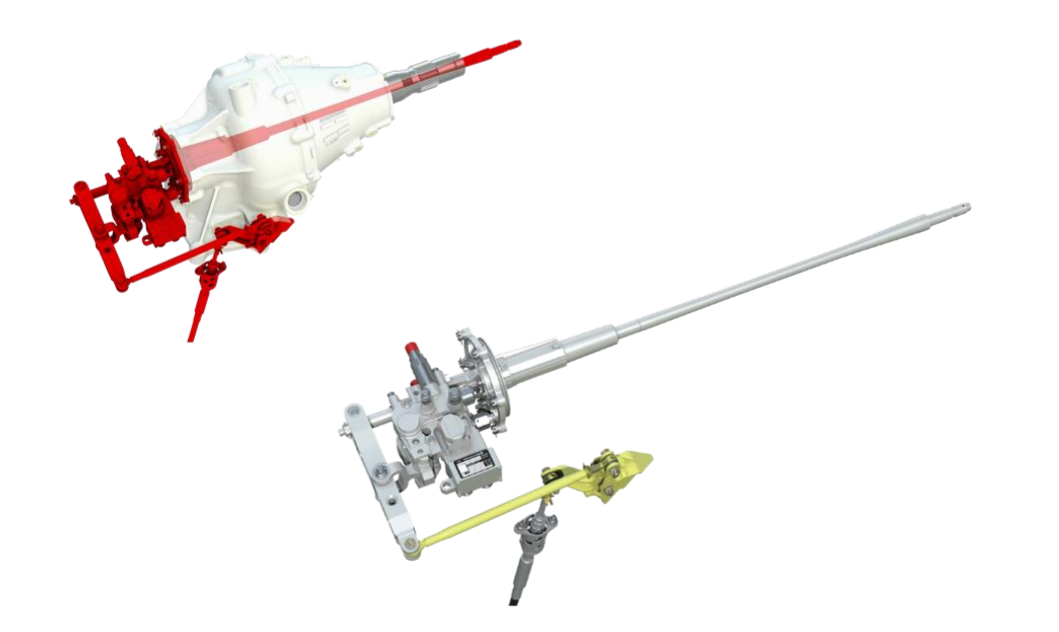

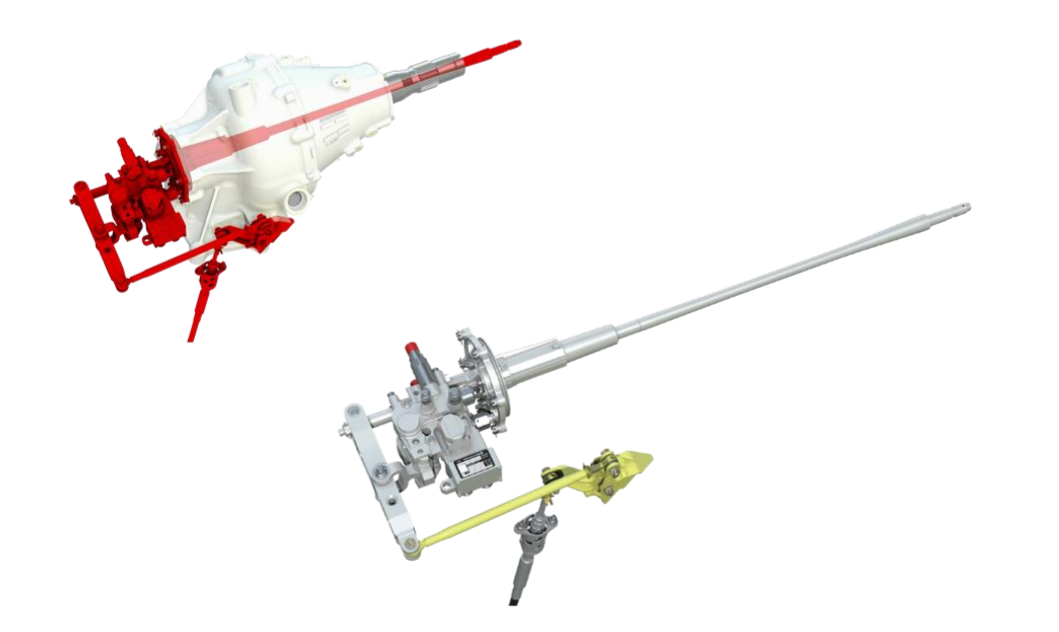

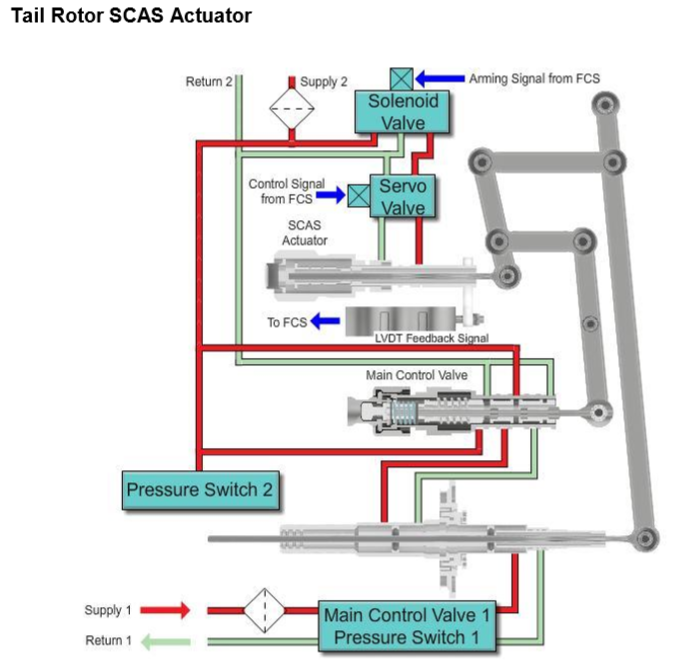

Tired of listening to 'I'm not familiar with the AW169' and the utter rubbish. The duplex bearing is at the end of the grey bit, at the output end of the red bit. Knock yourselves out guys -

Join Date: Dec 2006

Location: UK and MALTA

Age: 61

Posts: 1,297

Likes: 0

Received 18 Likes

on

4 Posts

regardless of experience on type and you're oh so helpful "red bit and grey bit" descriptions, I'm sorry my experience isnt helpful to you in anyway and I'm only triggering you.

Looking at your 365 diagram, number 21 is about the closest you could get to where the duplex bearing is.The duplex bearing is outboard of the tailrotor and is nowhere near the hydraulic part of the servo.

Thank you for posting accurate diagrams NODRAMA.

Join Date: Mar 2007

Location: UK

Posts: 321

Likes: 0

Received 0 Likes

on

0 Posts

For those that can read English.

Where it is physically is irrelevant - it performs that same function.

The issue that is in the debate is the consequences of a failure of the duplex bearing.

Thanks for the pics nodrama.

As you seem to be conversant with the type can you inform us as to how the pitch change shaft is locked against rotation at the servo end apart from the clamp up and a split pin and a bit of lockwire .

Ignore the fact that this is actually a 365 but the principal is near enough -

The issue that is in the debate is the consequences of a failure of the duplex bearing.

Thanks for the pics nodrama.

As you seem to be conversant with the type can you inform us as to how the pitch change shaft is locked against rotation at the servo end apart from the clamp up and a split pin and a bit of lockwire .

Why all this pointless armchair speculation/discussion? The only authoritative body here is the AAIB. Why not wait for their report! I suspect there are many who are seeking to say

"I told you so!"

TF

"I told you so!"

TF

Hardly believe it's pointless.

if you fly one or fix one, its proactive discussion.

but if you would rather wait a year or two be my guest...no one is forcing you to participate in the discussion.

if you fly one or fix one, its proactive discussion.

but if you would rather wait a year or two be my guest...no one is forcing you to participate in the discussion.

Agreed

It is actually one of the main interests of this forum IMHO. Sometimes it certainly gets irritating but on average I find these discussions usefull.

It is actually one of the main interests of this forum IMHO. Sometimes it certainly gets irritating but on average I find these discussions usefull.

Join Date: Aug 2014

Location: somerset

Posts: 50

Likes: 0

Received 0 Likes

on

0 Posts

Because this forum is for armchair speculation/discussion. Whether or not it's all pointless is a matter of opinion...

As for, "I told you so"...here's my theory. Somehow the aircraft was released from the factory in 2016 with an 'incorrect installation of the TR servo-actuator'. In practice, probably meaning that the cotter pin and lock-wire were never fitted, allowing the nut to work its way loose over time until the final (as it turned out) pedal input allowed it to fall off, resulting in complete loss of tail rotor control.

This is entirely pointless (but, I believe, harmless) speculation from my armchair based, almost entirely, on the preceding 42 pages of discussion.

As for, "I told you so"...here's my theory. Somehow the aircraft was released from the factory in 2016 with an 'incorrect installation of the TR servo-actuator'. In practice, probably meaning that the cotter pin and lock-wire were never fitted, allowing the nut to work its way loose over time until the final (as it turned out) pedal input allowed it to fall off, resulting in complete loss of tail rotor control.

This is entirely pointless (but, I believe, harmless) speculation from my armchair based, almost entirely, on the preceding 42 pages of discussion.

If you look at p11,#216,pic of tail rotor,it appears that the t/r `spider is intact,and appears to have a `device` on the outside of the `spider`...perhaps `nodrama` can comment if this appears normal..? nut /bolt still attached...?