Alaska Airlines 737-900 MAX loses a door in-flight out of PDX

It's been repeatedly reported (including statements from the NTSB) that there was NO relationship between the pressurization warnings and the door plug.

In short, the pressurization warnings were related to an electrical hiccup in the pressurization system, not a leak or lack of pressure.

Please quit with that dead end...

In short, the pressurization warnings were related to an electrical hiccup in the pressurization system, not a leak or lack of pressure.

Please quit with that dead end...

Non-unionized manufacturing employees in right to work, at will employment states know that their company has less concern for their well being than their executive office espresso drinks machine. So you will get Russian army conscript performance from them, not USAF career noncom performance.

Could your point be expressed as "no 2 independent issues with similar symptons"

How can some come around after the job is done and check that a castelated nut with a split pin is torqued to the right force. You would have to take the split pin out to cheque the torque. And then you would have to replace the split pin with a new one. So in practise redoing the job. No inspector / qualtity control person is going to do that so no wonder some of the bolts have been found to be loose. And you can in this case after they are mounted only see the head with hopefully a number (using something like a mirror or these days a snake cam) and the end of the bolts so that isn't a true check either.

I’d have thought the procedure would be to screw on the castellated nuts until tight, and then tighten further up to 1/6 of a turn to allow the split pins to be inserted. Any later inspection would be simply to check for the presence of the bolts, nuts and split pins.

Join Date: Apr 2015

Location: Under the radar, over the rainbow

Posts: 794

Received 0 Likes

on

0 Posts

Join Date: Jun 2009

Location: Montreal

Age: 65

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

The rivets is easier - if they are using ice-box rivets. These are annealed at a relatively high temperature and then flash frozen so the aluminum alloy doesn't self-harden. If they are kept too long in the freezer or left out too long they start to re-harden from a very soft state to their final high strength. If that hardening happens then instead of bucking them into a nice formed head, the aluminum rips/cracks at the periphery of the formed head. The rivet then needs to be carefully sheared off, so as to not damage the base parts that are being joined and the rivet body driven out and a new rivet installed. Process wise, it doesn't take much to get it wrong. 15 to 20 minutes out of the box, depending on how warm the factory is. If you've ever mixed up too much 5 minute epoxy for the time it takes to fit a bunch of pieces together and it hardens in the mixing cup - very similar error.

The misdrilled holes is more of a mystery to me. I thought with all the CNC equipment that mislocated holes would be a thing of the past; what has been described are "snowman" holes where a hole is drilled in the wrong location, off by a small amount, and another hole is drilled in the correct location, making what sort of looks like the two snowballs of a snowman instead of a single round hole.

The misdrilled holes is more of a mystery to me. I thought with all the CNC equipment that mislocated holes would be a thing of the past; what has been described are "snowman" holes where a hole is drilled in the wrong location, off by a small amount, and another hole is drilled in the correct location, making what sort of looks like the two snowballs of a snowman instead of a single round hole.

These are specified as BJ on the drawing. At one time or another I'm pretty sure most young structures engineers have dreamed about BJ-5's at night we deal with them so much.

MS204xxDD are 2024-T4 which are cold-storage rivets. They are less preferred in the shop because even though they are easier to buck, the out-time limitations are logistically painful.

I would say almost for sure the rivets in question are BJ's.

As for mis-drilling, without more info that's hard to speculate on. A misaligned jig or slight error in robot programming can lead to a whole field of mis-drilled holes.

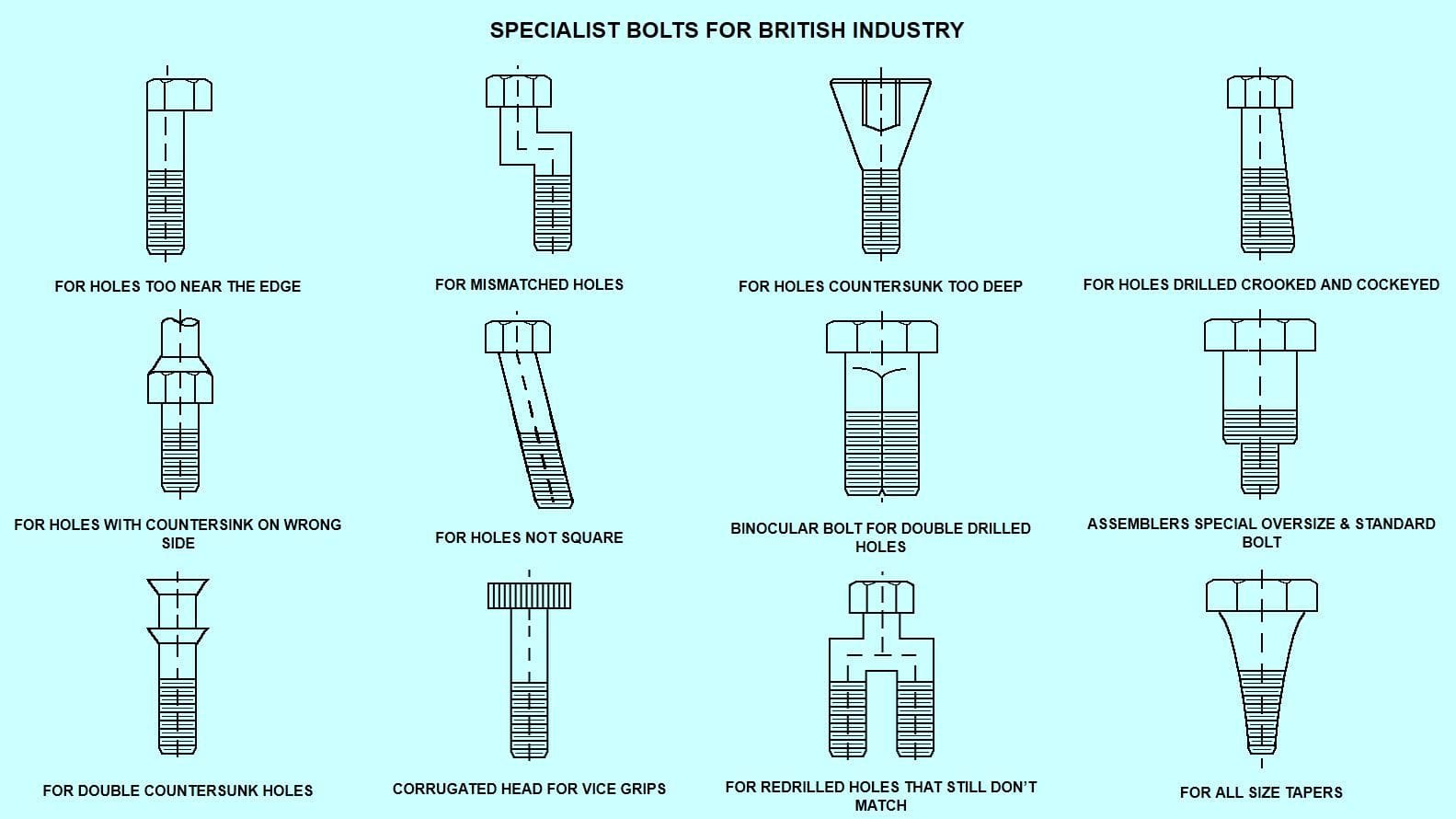

Snowman or figure-8 or binocular holes are easy, you just install a special binocular fastener. Joke. But trust me we wish such things were possible.

(irony)

(irony)

Join Date: Sep 2016

Location: Rochester,NY or SoCal

Posts: 21

Likes: 0

Received 0 Likes

on

0 Posts

Psychophysiological entity

If I were fitting the top safety bolts, they would be scarcely tight enough to damage the paint - and then backed off for the castelation. Those guide should not be crushed. The bottom one could tolerate a bit more torque but it's not needed.

I thought I'd read every post but I'm not sure why there's been so much talk about rivets. Someone even quoted me on some point. The only place I would be concerned about is the fastening of the top skin to the plug frame where there's splitting - that may or may not have occurred before the accident. The top row of fasteners seem to be nuts and bolts while the sides are rivets.

I'd be interested to know what I've missed . . . he said, nudgingly.

I thought I'd read every post but I'm not sure why there's been so much talk about rivets. Someone even quoted me on some point. The only place I would be concerned about is the fastening of the top skin to the plug frame where there's splitting - that may or may not have occurred before the accident. The top row of fasteners seem to be nuts and bolts while the sides are rivets.

I'd be interested to know what I've missed . . . he said, nudgingly.

If I were fitting the top safety bolts, they would be scarcely tight enough to damage the paint - and then backed off for the castelation. Those guide should not be crushed. The bottom one could tolerate a bit more torque but it's not needed.

I thought I'd read every post but I'm not sure why there's been so much talk about rivets. Someone even quoted me on some point. The only place I would be concerned about is the fastening of the top skin to the plug frame where there's splitting - that may or may not have occurred before the accident. The top row of fasteners seem to be nuts and bolts while the sides are rivets.

I'd be interested to know what I've missed . . . he said, nudgingly.

I thought I'd read every post but I'm not sure why there's been so much talk about rivets. Someone even quoted me on some point. The only place I would be concerned about is the fastening of the top skin to the plug frame where there's splitting - that may or may not have occurred before the accident. The top row of fasteners seem to be nuts and bolts while the sides are rivets.

I'd be interested to know what I've missed . . . he said, nudgingly.