Alaska Airlines 737-900 MAX loses a door in-flight out of PDX

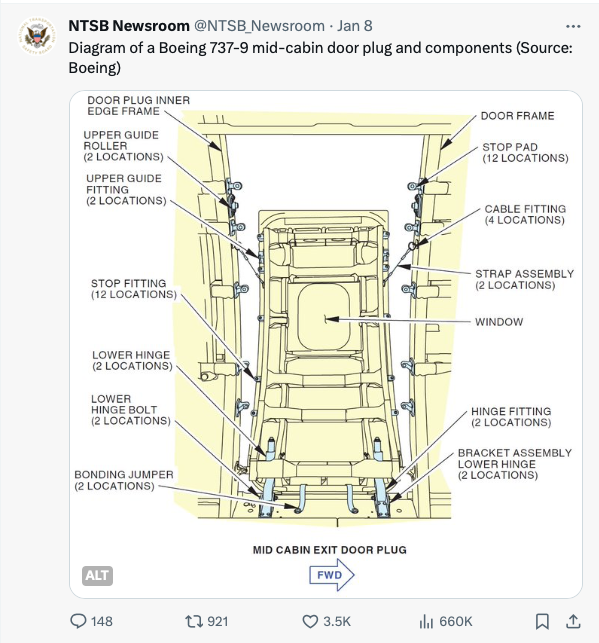

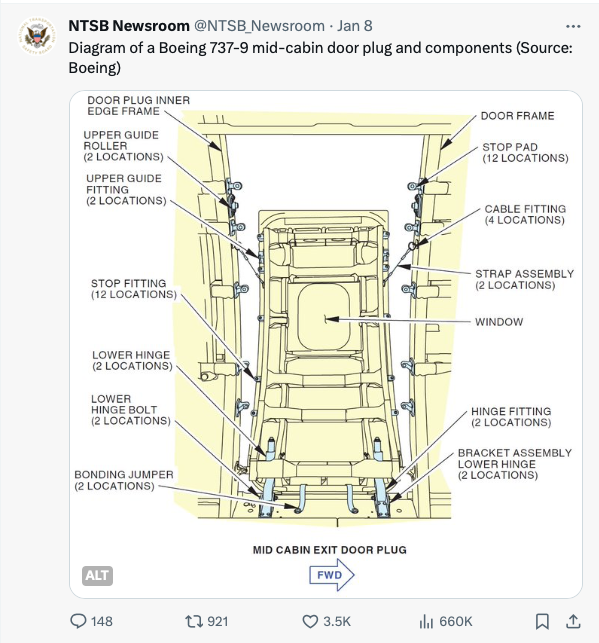

Surprisingly, the door plug diagram published by NTSB, sourced from Boeing (sic!), shows the two bottom spring rods in a compressed position in a door plug open situation, while the door plug remains flush with the bottom doorframe. In reality, of course, in an open door plug situation the spring rods would be flush with the top of their guide brackets attached to the door plug frame and the door plug itself would be lifted from the bottom doorframe, commensurate with the distance travelled by the spring rods.

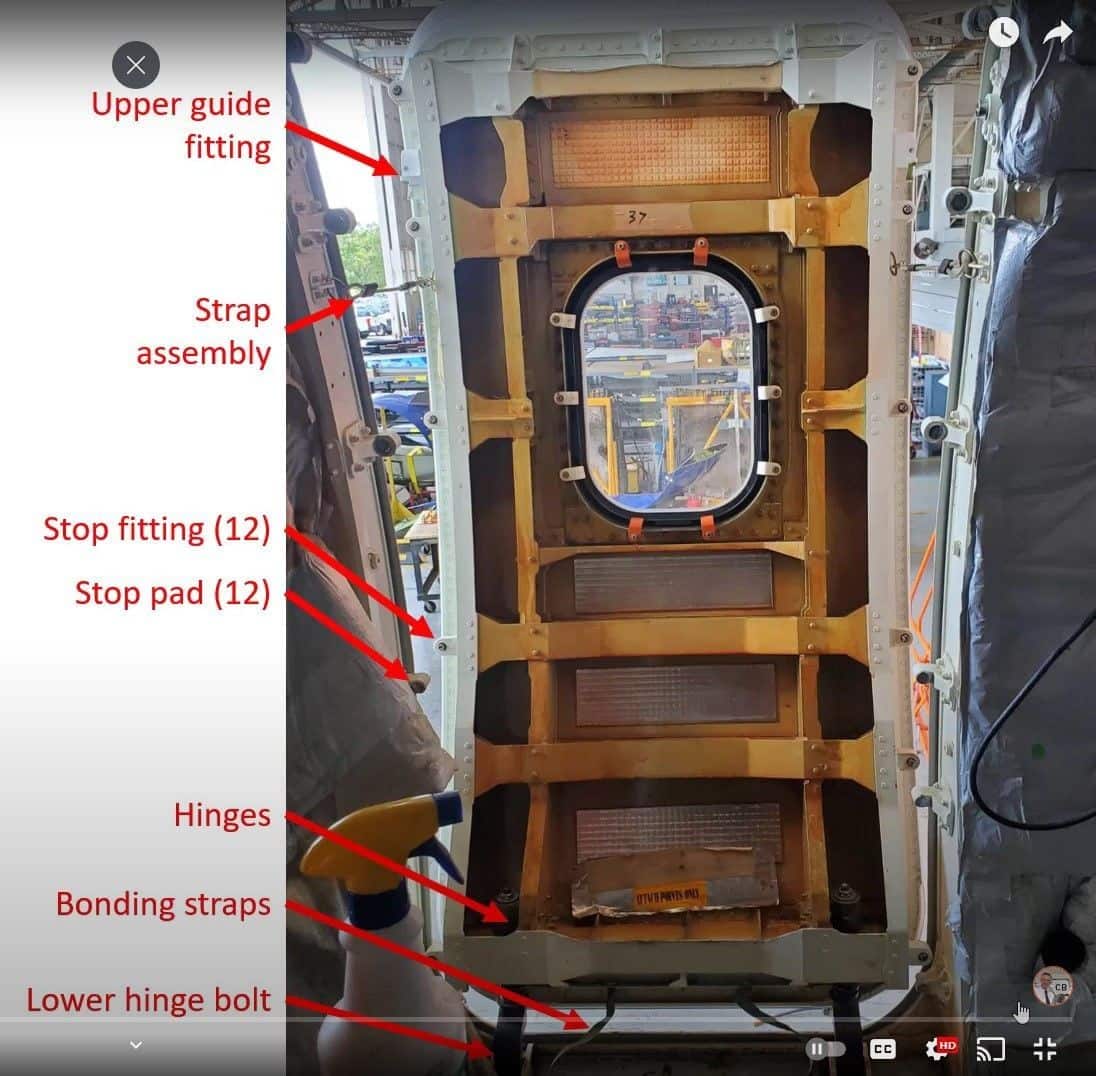

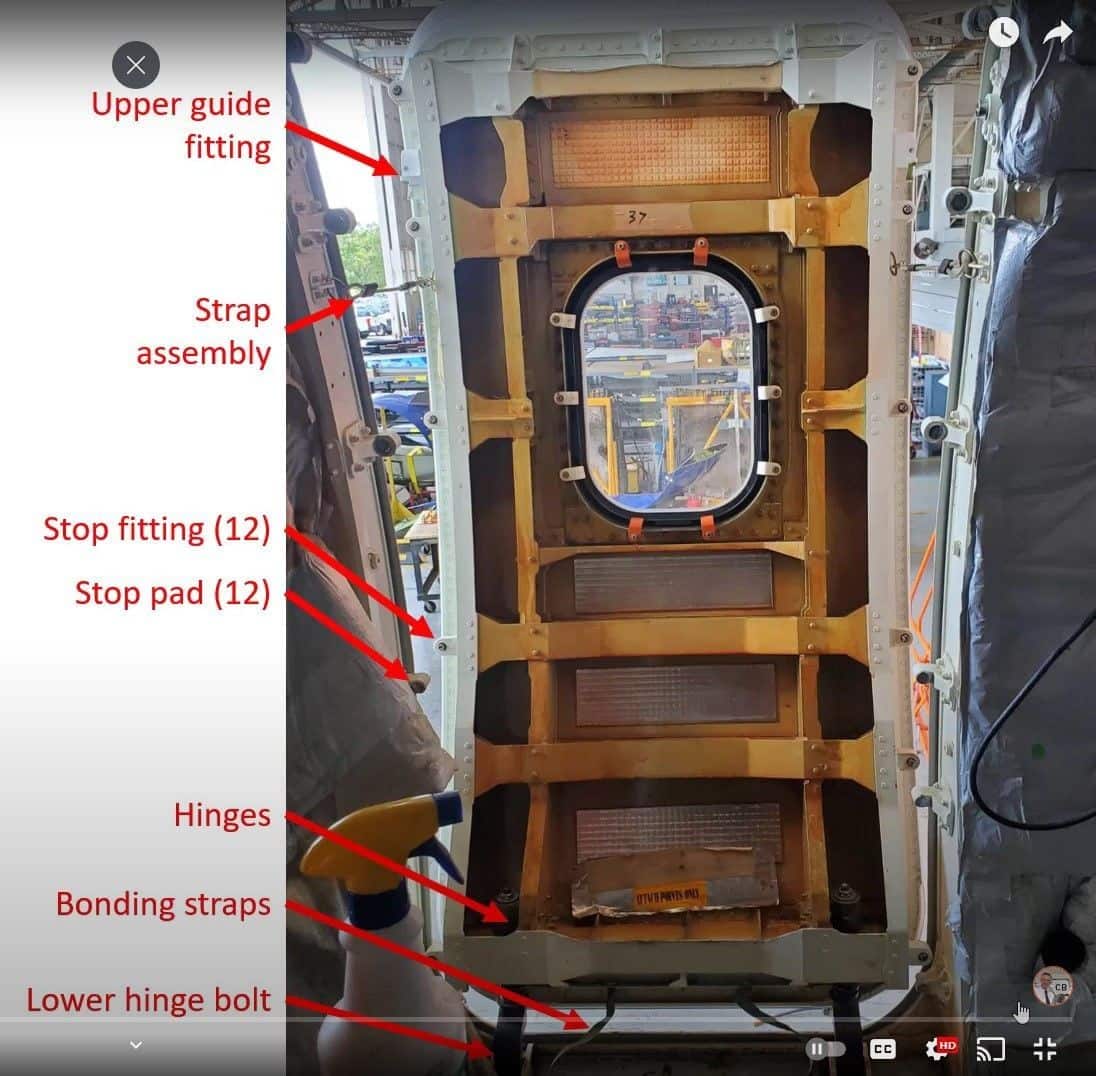

Looking at the photo of the recovered door plug, it looks as if the 12 restraining pads are not just pads, but are Adjustable Pads.

So my guess is that the closure procedure would be..

1./ Locate the plug in position, aided by the spring assist.

2./ Use the bolts to hold the Pins into the Tracks.

3./ Tighten each of the 12 Pad Adjusters to a specific torque, to achieve the desired plug sealing force.

4./ Restore all cosmetic trim pieces.

If any Aircraft Technician has the actual Boeing Procedure, we would love to hear from you.

So my guess is that the closure procedure would be..

1./ Locate the plug in position, aided by the spring assist.

2./ Use the bolts to hold the Pins into the Tracks.

3./ Tighten each of the 12 Pad Adjusters to a specific torque, to achieve the desired plug sealing force.

4./ Restore all cosmetic trim pieces.

If any Aircraft Technician has the actual Boeing Procedure, we would love to hear from you.

Join Date: Jun 2009

Location: Paris, France

Age: 62

Posts: 61

Likes: 0

Received 0 Likes

on

0 Posts

Can you source the information that LN 8799 is N705AL, rather than N704AL, e.g. by telling from what the second picture is a screen capture?

Note: I consider well-established that Line Unit 8799 is (hand!) written on the accident door, and that N704AL is the accident plane.

Too mean to buy a long personal title

https://theaircurrent.com/industry-s...nding-fallout/

From the last paragraph:

The precise duration of the Max 9 grounding remains uncertain . . . Yet almost certainly according to interviews with multiple senior executives at Boeing's most important customers and suppliers, there is an expectation of significant new delays in certifying the 737 Max 7 and 10.

"It's almost surreal" said one top U.S. airline executive of another Max-related grounding . . . "There's no way out of this".

From the last paragraph:

The precise duration of the Max 9 grounding remains uncertain . . . Yet almost certainly according to interviews with multiple senior executives at Boeing's most important customers and suppliers, there is an expectation of significant new delays in certifying the 737 Max 7 and 10.

"It's almost surreal" said one top U.S. airline executive of another Max-related grounding . . . "There's no way out of this".

Join Date: Mar 2022

Location: Nearby

Posts: 41

Likes: 0

Received 0 Likes

on

0 Posts

Seems we’re back to previous reports of noise in the vicinity of the plug (was the plug moving around?), and the unanswered miraculous coincidence (Alaska Air?) of no one being seated in the adjacent two seats.

Join Date: Apr 2010

Location: Alexandria VA USA

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

The auto pressurization system doesn't function that way. If both controllers sensed an excessive cabin rate of climb (over 2000 ft/min) it would throw an auto fail without attempting to transfer to the alternate (no ALTN annunciation but a Manual annunciation), requiring manual control of the outflow valve. There is no indication of that happening and the NTSB is still looking into any pressure anomaly even if it doesn't meet the threshold to cause an auto pressurization error.

Join Date: May 2011

Location: U.S.

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

1) The first half of your statement is false. Physics.

2 The second part of your statement is also false. Otherwise, why do we have this thread?

Last edited by lateott; 16th Jan 2024 at 15:42. Reason: Typo

Re-examining some pictures I suddenly realised that the door plug wasn't intended to be fitted on N704AL (LN 8789), but on N705AL (LN8799), the latter delivered last December. Coincidence, normal practice? Original door plug intended for N704AL with issues, e.g. not a good fit?

Join Date: May 2011

Location: U.S.

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

Looking at the photo of the recovered door plug, it looks as if the 12 restraining pads are not just pads, but are Adjustable Pads.

So my guess is that the closure procedure would be..

1./ Locate the plug in position, aided by the spring assist.

2./ Use the bolts to hold the Pins into the Tracks.

3./ Tighten each of the 12 Pad Adjusters to a specific torque, to achieve the desired plug sealing force.

4./ Restore all cosmetic trim pieces.

If any Aircraft Technician has the actual Boeing Procedure, we would love to hear from you.

So my guess is that the closure procedure would be..

1./ Locate the plug in position, aided by the spring assist.

2./ Use the bolts to hold the Pins into the Tracks.

3./ Tighten each of the 12 Pad Adjusters to a specific torque, to achieve the desired plug sealing force.

4./ Restore all cosmetic trim pieces.

If any Aircraft Technician has the actual Boeing Procedure, we would love to hear from you.

For #3, unlikely, as this would mean the plug install would have a different procedure from the E/E door option which cannot be installed with friction between the pads and pins. More likely there is a specified gap which is closed upon pressurization. Also, your step #3 would mean the 12 adjustments would need to be made every time the plug is opened and every time it is closed.

My old Physics Master would have been astounded reading the 1000's of detailed Posts and comments here regarding Springs, Bolts, Pins, Pads, fasteners, spigots, Plugs, active pressure controllers, Torques et al LOL

And he would have loved all of the diagrams but I'm still none the wiser TBH.

Hated Physics :P

And he would have loved all of the diagrams but I'm still none the wiser TBH.

Hated Physics :P

Join Date: May 2011

Location: U.S.

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

So I wont be accused of overreaching and parroting a parrot, here is an excerpt from NPR reporter Steve Inskeep's interview with the chair of the National Transportation Safety Board Jennifer Homendy on the topic of the warning lights. While not completely ruled out, the NTSB made it clear they don't see a linkage between the warning light and the incident event but will keep looking:

HOMENDY: "Well, those warning lights, we - first of all, we have a team that is looking at those warning lights. At this time, we have no indication that those warning lights were in any way related to the expulsion of the door. And let me just take a second to describe that. That system monitors and adjusts cabin pressure and - automatically. There's a primary system, there's a secondary system and there's a manual system. So there are two backups on the aircraft. It's a triple redundant system. We know the two other systems were working on the aircraft, and the Federal Aviation Administration allows airlines to continue flying the aircraft with those other backup systems. So in this case, what we want - we do want to make sure there was no linkage, so we are pulling the memory cards and looking at the maintenance and testing that was done on those systems."

So they are continuing to look at pressurization data, but the system the Chairwoman is talking about is the automatic pressurization system that threw the warning. The Chairwoman describes it as triple redundant with two automatic controllers and a manual control. The failure modes associated with the warnings generated by that system when one component fails and the others are working, as described above by the Chairwoman, have nothing to do with a loss or fluctuation of cabin pressure.

Again, the way the system works is that if one controller throws an error, and the others don't, the system illuminates the AUTO FAIL light and automatically switches to the alternate system as indicated by the ALTN annunciator. So I am saying that the ALTN light was illuminated.

Alaska chose not to perform ETOPS flights, but it wasn't due to any pressurization issue. It was due to the transient pressurization controller errors.

When I say the issue was resolved, I mean the Auto Fail light illumination and loss of automatic pressurization. Failover was automatic although It seems the AUTO FAIL light was extinguished by the flight crew, in at least one case, switching the mode switch to ALTN. It didn't magically fix the pressure controller that kept throwing errors, but the warning went away for the remainder of the flight with the green ALTN annunciator remaining illuminated.

And there was much histrionics about the "pressure warning light" which was suggested by the press early on to be a pressurization issue. That has been picked up here and elsewhere and incorrectly used to claim that the plug was causing pressurization issues prior to the incident flight.

Bottom line is this, the illumination of the "warning lights" has nothing to do with failure to pressurize, loss of pressurization or fluctuation of pressure. Thats not to say there weren't pressurization issues prior to the incident, but to say the "warning lights" might indicate a plug induced pressurization issue is simply not supported by the way the system functions and the facts as we know them now.

HOMENDY: "Well, those warning lights, we - first of all, we have a team that is looking at those warning lights. At this time, we have no indication that those warning lights were in any way related to the expulsion of the door. And let me just take a second to describe that. That system monitors and adjusts cabin pressure and - automatically. There's a primary system, there's a secondary system and there's a manual system. So there are two backups on the aircraft. It's a triple redundant system. We know the two other systems were working on the aircraft, and the Federal Aviation Administration allows airlines to continue flying the aircraft with those other backup systems. So in this case, what we want - we do want to make sure there was no linkage, so we are pulling the memory cards and looking at the maintenance and testing that was done on those systems."

So they are continuing to look at pressurization data, but the system the Chairwoman is talking about is the automatic pressurization system that threw the warning. The Chairwoman describes it as triple redundant with two automatic controllers and a manual control. The failure modes associated with the warnings generated by that system when one component fails and the others are working, as described above by the Chairwoman, have nothing to do with a loss or fluctuation of cabin pressure.

Again, the way the system works is that if one controller throws an error, and the others don't, the system illuminates the AUTO FAIL light and automatically switches to the alternate system as indicated by the ALTN annunciator. So I am saying that the ALTN light was illuminated.

Alaska chose not to perform ETOPS flights, but it wasn't due to any pressurization issue. It was due to the transient pressurization controller errors.

When I say the issue was resolved, I mean the Auto Fail light illumination and loss of automatic pressurization. Failover was automatic although It seems the AUTO FAIL light was extinguished by the flight crew, in at least one case, switching the mode switch to ALTN. It didn't magically fix the pressure controller that kept throwing errors, but the warning went away for the remainder of the flight with the green ALTN annunciator remaining illuminated.

And there was much histrionics about the "pressure warning light" which was suggested by the press early on to be a pressurization issue. That has been picked up here and elsewhere and incorrectly used to claim that the plug was causing pressurization issues prior to the incident flight.

Bottom line is this, the illumination of the "warning lights" has nothing to do with failure to pressurize, loss of pressurization or fluctuation of pressure. Thats not to say there weren't pressurization issues prior to the incident, but to say the "warning lights" might indicate a plug induced pressurization issue is simply not supported by the way the system functions and the facts as we know them now.

By the way, in the quote you included, Homendy was responding to the question, "Should this plane have been flying at all?"

Your conclusion, "Bottom line is this, the illumination of the "warning lights" has nothing to do with failure to pressurize, loss of pressurization or fluctuation of pressure" does seem like an overreach to me. But maybe you know more than me.

The link is here in case anybody wants to read what you quoted: Link

For #1, how do you think the "spring assist" helps locate the plug in position? In fact installation would require pushing down the plug against the springs, which are working against alignment of the stops.

For #3, unlikely, as this would mean the plug install would have a different procedure from the E/E door option which cannot be installed with friction between the pads and pins. More likely there is a specified gap which is closed upon pressurization. Also, your step #3 would mean the 12 adjustments would need to be made every time the plug is opened and every time it is closed.

For #3, unlikely, as this would mean the plug install would have a different procedure from the E/E door option which cannot be installed with friction between the pads and pins. More likely there is a specified gap which is closed upon pressurization. Also, your step #3 would mean the 12 adjustments would need to be made every time the plug is opened and every time it is closed.

Join Date: Oct 1999

Location: UK

Age: 70

Posts: 288

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: Jan 2024

Location: Naples

Posts: 15

Likes: 0

Received 0 Likes

on

0 Posts

For #1, how do you think the "spring assist" helps locate the plug in position? In fact installation would require pushing down the plug against the springs, which are working against alignment of the stops.

For #3, unlikely, as this would mean the plug install would have a different procedure from the E/E door option which cannot be installed with friction between the pads and pins. More likely there is a specified gap which is closed upon pressurization. Also, your step #3 would mean the 12 adjustments would need to be made every time the plug is opened and every time it is closed.

For #3, unlikely, as this would mean the plug install would have a different procedure from the E/E door option which cannot be installed with friction between the pads and pins. More likely there is a specified gap which is closed upon pressurization. Also, your step #3 would mean the 12 adjustments would need to be made every time the plug is opened and every time it is closed.

All my hope is on Chris Brady and his videos here. Come on Chris, please give us the next slice of info to solve the assy riddle.

I have some doubt that the 12 stop pins are torqued against the lip seal. Simply because the system apperas to be totally overconstraint. When the door is closed it can only move inboard (preloading the seal) within the radial backlash of the 2 roller pins in their mating cam tracks at the top, and at the bottom only within the backlash of the hinge guide tubes in the hinge guide fittings`s bushes.

One would never be sure if the stop pin torque has been achieved owing to the correct seal preload being achieved or because you have run into some "hard stop" when running out of backlash.

Most probably the soft lipseal is quite tolerant in preload and will not require this precise fine tuning.

But I am wondering how the contact of the stop pin contact point with their corresponding contact pads actually is adjusted. 12 points, totally overconstraint. But on most of the pictures one can see very simmilar contact marks of the 12 contact points their mating pads, suggesting a quite even load distribution. So there must be some procedure to compensate for the multi components torecance stack up.

The auto pressurization system doesn't function that way. If both controllers sensed an excessive cabin rate of climb (over 2000 ft/min) it would throw an auto fail without attempting to transfer to the alternate (no ALTN annunciation but a Manual annunciation), requiring manual control of the outflow valve. There is no indication of that happening and the NTSB is still looking into any pressure anomaly even if it doesn't meet the threshold to cause an auto pressurization error.

I think it is likely that both controllers in this case may have sensed a temporary change in the cabin rate of climb caused by the door plug shifting position momentarily during previous flights and that this may have generated the reported AUTO FAIL in the previous incidences. It would also confirm why no fault with the pressurisation system was found and why the aircraft was released back to the line.

Last edited by hec7or; 16th Jan 2024 at 21:09.

Join Date: Jan 2020

Location: Bucharest

Posts: 93

Likes: 0

Received 0 Likes

on

0 Posts

... and whether those are traceable changes that are properly documented in the Quality Management Systems at Renton and/or Wichita. Slightly surprised to see the use of Magic Marker on the part to record s/n, p/n and line number but maybe there is a proper plate somewhere else.

Join Date: May 2004

Location: Toronto, Canada

Age: 73

Posts: 78

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: May 2011

Location: U.S.

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

Yes, the assy procedure would shed some light on how the system is intended to work.

All my hope is on Chris Brady and his videos here. Come on Chris, please give us the next slice of info to solve the assy riddle.

I have some doubt that the 12 stop pins are torqued against the lip seal. Simply because the system apperas to be totally overconstraint. When the door is closed it can only move inboard (preloading the seal) within the radial backlash of the 2 roller pins in their mating cam tracks at the top, and at the bottom only within the backlash of the hinge guide tubes in the hinge guide fittings`s bushes.

One would never be sure if the stop pin torque has been achieved owing to the correct seal preload being achieved or because you have run into some "hard stop" when running out of backlash.

Most probably the soft lipseal is quite tolerant in preload and will not require this precise fine tuning.

But I am wondering how the contact of the stop pin contact point with their corresponding contact pads actually is adjusted. 12 points, totally overconstraint. But on most of the pictures one can see very simmilar contact marks of the 12 contact points their mating pads, suggesting a quite even load distribution. So there must be some procedure to compensate for the multi components torecance stack up.

All my hope is on Chris Brady and his videos here. Come on Chris, please give us the next slice of info to solve the assy riddle.

I have some doubt that the 12 stop pins are torqued against the lip seal. Simply because the system apperas to be totally overconstraint. When the door is closed it can only move inboard (preloading the seal) within the radial backlash of the 2 roller pins in their mating cam tracks at the top, and at the bottom only within the backlash of the hinge guide tubes in the hinge guide fittings`s bushes.

One would never be sure if the stop pin torque has been achieved owing to the correct seal preload being achieved or because you have run into some "hard stop" when running out of backlash.

Most probably the soft lipseal is quite tolerant in preload and will not require this precise fine tuning.

But I am wondering how the contact of the stop pin contact point with their corresponding contact pads actually is adjusted. 12 points, totally overconstraint. But on most of the pictures one can see very simmilar contact marks of the 12 contact points their mating pads, suggesting a quite even load distribution. So there must be some procedure to compensate for the multi components torecance stack up.

I have speculated previously that there is no contact when depressurized, that there is actually a gap specification which is measured in the absence of pressure differential. That gap would close and make contact when the cabin is pressurized.

Contact and friction would not serve the needs of an emergency exit, and in fact could prevent the door from opening when needed most! I highly doubt there is a different specification when the plug option is used in place of an actual exit door, think of the added certification and testing costs.

Join Date: May 2011

Location: U.S.

Posts: 84

Likes: 0

Received 0 Likes

on

0 Posts

Looking at the photo of the recovered door plug, it looks as if the 12 restraining pads are not just pads, but are Adjustable Pads.

So my guess is that the closure procedure would be..

1./ Locate the plug in position, aided by the spring assist.

2./ Use the bolts to hold the Pins into the Tracks.

3./ Tighten each of the 12 Pad Adjusters to a specific torque, to achieve the desired plug sealing force.

4./ Restore all cosmetic trim pieces.

If any Aircraft Technician has the actual Boeing Procedure, we would love to hear from you.

So my guess is that the closure procedure would be..

1./ Locate the plug in position, aided by the spring assist.

2./ Use the bolts to hold the Pins into the Tracks.

3./ Tighten each of the 12 Pad Adjusters to a specific torque, to achieve the desired plug sealing force.

4./ Restore all cosmetic trim pieces.

If any Aircraft Technician has the actual Boeing Procedure, we would love to hear from you.