New Takeoff performance with a change of air temperature

The stranger: My post was a comment on the lack of performance training that seems to be the norm these days with new pilot training. It was not a criticism of the OP but rather a reflection on the poor training that he/she seems to have had. I am surprised that you do not seem to think that that scant level of understanding should be considered all right. FlightDetent sums it up.

I definitely don't think my company manuals are awesome, but they do specify exactly when I have to redo the performance numbers. 10 deg temp, 10 kts wind, 0.1" pressure (US) aso. Surprised that is not standard...

Can't believe the discussion going on here. 25 to 30 degrees? Of course you recalculate performance

Your Flex 75 is from the 25 degree data so you need to recalculate your flex temp for 30 degrees otherwise your reduced thrust Flex 75 aircraft wouldnt make it within the limits of the field, obstacle etc OEI. Seriously guys.

Your Flex 75 is from the 25 degree data so you need to recalculate your flex temp for 30 degrees otherwise your reduced thrust Flex 75 aircraft wouldnt make it within the limits of the field, obstacle etc OEI. Seriously guys.

Do you know what assumed temperature is? When you run the performance it gives you a Flex/assumed temperature. That temperature is the highest temperature you can safely take off and meet all the required distances/gradients, and that number is used by the fadec instead of the OAT to set N1/EPR. So unless it is hotter outside than your flex number you can take off. The actual OAT doesn't matter, as long as it is below the Flex number.

If the actual OAT goes up, the aircraft performance goes down (hotter air = less lift at the same airspeed). IF you don't redo your ATM calcualation for the new OAT, you're thrust setting will be too low for that OAT. Plus, if you're talking N1 thrust setting, 100% N1 at 50 degrees creates significantly less thrust than the same physical N1 at 25 (that old "square root theta" thing - thrust is constant at corrected N1, not physical N1).

Just as a matter of interest, I've run the numbers at Wellington, NZ with 25ºC vs 30ºC (yeah ok, maybe not entirely realistic for the windy city, but it does get warm sometimes), all of the speeds, thrust, take-off margin remained the same but the EO acceleration altitude changed. I don't think it is quite correct to just say that performance at one temperature will be identical to performance at another temperature assuming it remains below flex. The system seems to be using ambient temperature to calculate aerodynamic performance, and that does change.

Join Date: Mar 2006

Location: USA

Posts: 2,515

Likes: 0

Received 0 Likes

on

0 Posts

tdracer hans brinker

I just checked my company manuals, and for a FLEX takeoff (Assumed temperature in Boeing speak), as long as the OAT is less than the flex temperature, we don't need new numbers.

I just checked my company manuals, and for a FLEX takeoff (Assumed temperature in Boeing speak), as long as the OAT is less than the flex temperature, we don't need new numbers.

Only half a speed-brake

Let's not mix up

A) tolerance of balanced-risk to accept performance numbers calculated from an expired report

with

B) validity of AST result for varying OAT.

From what I've seen, the OAT does not enter the AST algorithm as an input value (simplified).

A) tolerance of balanced-risk to accept performance numbers calculated from an expired report

with

B) validity of AST result for varying OAT.

From what I've seen, the OAT does not enter the AST algorithm as an input value (simplified).

Last edited by FlightDetent; 30th Dec 2022 at 14:20. Reason: grammar, as ever

Only half a speed-brake

AerocatS2A: I am rather convinced what you see is temperature correction (delta ISA) on the geometrical ACC ALT, the altimetry error goes both ways and a tweaked SW suite can play with hot temps too.

With your last sentence, at face value, I could not disagree more.

With your last sentence, at face value, I could not disagree more.

Join Date: Jun 2007

Location: Wanderlust

Posts: 3,406

Likes: 0

Received 0 Likes

on

0 Posts

If assumed temperature is 75° and OAT is 25°, the takeoff performance calculated is actually better than what would be at 75°OAT because the true airspeed at 75°OAT will be much higher. So some rise in OAT is a non issue.

AerocatS2A: I am rather convinced what you see is temperature correction (delta ISA) on the geometrical ACC ALT, the altimetry error goes both ways and a tweaked SW suite can play with hot temps too.

With your last sentence, at face value, I could not disagree more.

With your last sentence, at face value, I could not disagree more.

Only half a speed-brake

Thanks for the feedback, relieved to hear.

Funny fact: if the paper RTOW are smartly configured before exporting, an all live-iteration EFB will not bring much tangible benefit but this is one.

At least Airbus OEM prints the (single!) eoacc alt already inclusive of the required ALT correction to match the coldest temperature displayed on the chart.

Which carries a double penalty against the Max TOW for hot temps. A) the plane is made to climb aerodynamically higher, up over the alt+correction; B) the plane also climbs geometrically higher due isoplanes expansion.

When making a FLEX data departure under the assumed higher temperature, the above translates into a double performance margin inherent in the result.

Funny fact: if the paper RTOW are smartly configured before exporting, an all live-iteration EFB will not bring much tangible benefit but this is one.

At least Airbus OEM prints the (single!) eoacc alt already inclusive of the required ALT correction to match the coldest temperature displayed on the chart.

Which carries a double penalty against the Max TOW for hot temps. A) the plane is made to climb aerodynamically higher, up over the alt+correction; B) the plane also climbs geometrically higher due isoplanes expansion.

When making a FLEX data departure under the assumed higher temperature, the above translates into a double performance margin inherent in the result.

As always, a good discussion: but don’t shoot the messenger.

The two key points worth emphasising:

The two key points worth emphasising:

- The lack of proper training.

- The lack of required documentation (when/whether to recompute).

Only half a speed-brake

Nope, #22 did not show a lack of knowledge. Came here 2 years later, guns blazing with the opposite of what the correct knowledge is, shaming around.

Both your points are solved with operators who are thorough. It's reading the regulations and AFM alone, without the needed expertise, which could lead a young gun astray. Always has been and no need to ask how we know.

Reading the thread again, #11 has the key issue unanswered. He did not get different speeds after selecting another flap for the modified temperature. The calculation threw him a different OPT flap as a result after adjusting the OAT while still well below the flex and, god knows, even the corner point. That should not be happening, right?

Well, it did. Not as a function of the AST Method but a good outcome of the Perf SW efforts for an optimum result. Following the proper AST methodology, at first, thou shall calculate (max) PerfLIM TOM for the given OAT (and some other bits which might be OEM specific). This search for PLimTOM(@oat) will also involve some serious magic with V1/V2 ratio (a.k.a improved climb) and clandestine adjustments to ASDA. Even for a minuscule difference of 1 kg rounded up, the result for OAT=9 might give you 1+F but OAT=10 shows flap 2.

And then, the WHOLE performance calc is run again (and again) with ever-increasing fake OAT (even above max allowed environmental envelope) until the value of PLimTOW(max assumed temp) drops down to the actual TOW which is when Tflex is found. Most likely by a present or missing SW feature, the flap setting providing the best PLimTOM(oat) at the first step is locked, and the iteration for max assumed temperature is only done with a single tkof configuration.

The associated N1 for TOGA @ (max flex temp+ELEV+QNH+bleed+anti-ice) is known from the Engine manufacturer. The pilot will feed the chosen Tflex somehow into the engine data pipeline and the engine will later respond with the same N1 which would be the TOGA N1 if it actually was Tflex outside. The sweet part already mentioned is that the thrust provided by N1(flex@oat) is markedly greater than that calculated for N1(toga@t-flex) as the density of air received is higher and the mass of air accelerated air heavier (F=-a*m) eventhough N1(flex@oat) is purposely selected identical to N1(toga@t-flex).

Those impressed by the inherent margin uncovered above should also consider the correlated effect of increased density on airfoil performance. If not completely flabbergasted then, there is a truckful of GS(v1) & distance-to-IAS(v1) happiness to be discussed under the calculated assumed temp v.s. real OAT, nicely perched on top of the whole majestic Ekin(v1) pedestal.

Not satisfied yet? Go fly something else than the venerable B737 and get an extra 1 second of recognition time and an adjusted bite of deceleration.

Both your points are solved with operators who are thorough. It's reading the regulations and AFM alone, without the needed expertise, which could lead a young gun astray. Always has been and no need to ask how we know.

Reading the thread again, #11 has the key issue unanswered. He did not get different speeds after selecting another flap for the modified temperature. The calculation threw him a different OPT flap as a result after adjusting the OAT while still well below the flex and, god knows, even the corner point. That should not be happening, right?

Well, it did. Not as a function of the AST Method but a good outcome of the Perf SW efforts for an optimum result. Following the proper AST methodology, at first, thou shall calculate (max) PerfLIM TOM for the given OAT (and some other bits which might be OEM specific). This search for PLimTOM(@oat) will also involve some serious magic with V1/V2 ratio (a.k.a improved climb) and clandestine adjustments to ASDA. Even for a minuscule difference of 1 kg rounded up, the result for OAT=9 might give you 1+F but OAT=10 shows flap 2.

And then, the WHOLE performance calc is run again (and again) with ever-increasing fake OAT (even above max allowed environmental envelope) until the value of PLimTOW(max assumed temp) drops down to the actual TOW which is when Tflex is found. Most likely by a present or missing SW feature, the flap setting providing the best PLimTOM(oat) at the first step is locked, and the iteration for max assumed temperature is only done with a single tkof configuration.

The associated N1 for TOGA @ (max flex temp+ELEV+QNH+bleed+anti-ice) is known from the Engine manufacturer. The pilot will feed the chosen Tflex somehow into the engine data pipeline and the engine will later respond with the same N1 which would be the TOGA N1 if it actually was Tflex outside. The sweet part already mentioned is that the thrust provided by N1(flex@oat) is markedly greater than that calculated for N1(toga@t-flex) as the density of air received is higher and the mass of air accelerated air heavier (F=-a*m) eventhough N1(flex@oat) is purposely selected identical to N1(toga@t-flex).

Those impressed by the inherent margin uncovered above should also consider the correlated effect of increased density on airfoil performance. If not completely flabbergasted then, there is a truckful of GS(v1) & distance-to-IAS(v1) happiness to be discussed under the calculated assumed temp v.s. real OAT, nicely perched on top of the whole majestic Ekin(v1) pedestal.

Not satisfied yet? Go fly something else than the venerable B737 and get an extra 1 second of recognition time and an adjusted bite of deceleration.

Last edited by FlightDetent; 30th Dec 2022 at 15:53.

Only half a speed-brake

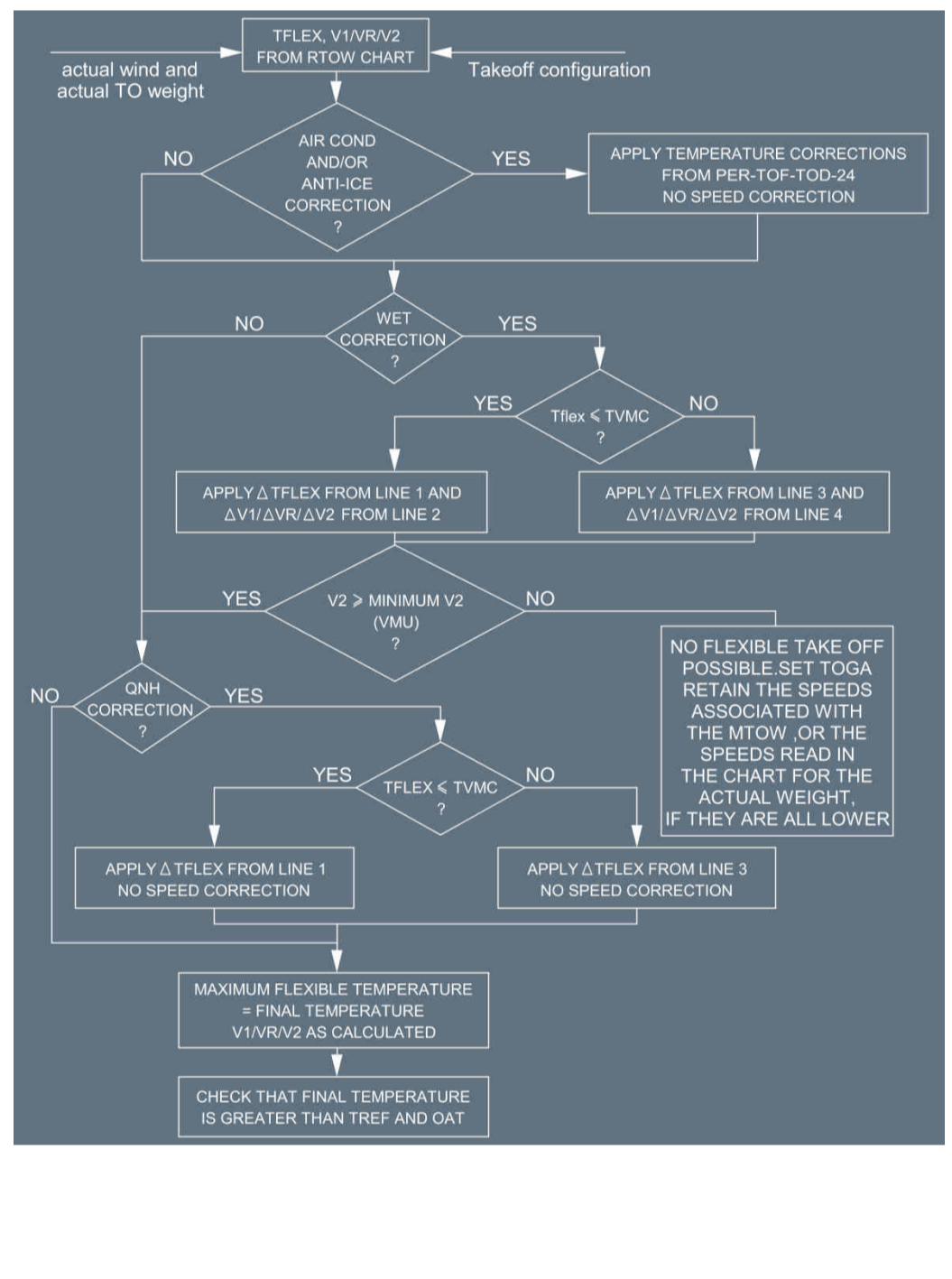

That particular flow defines some of the required compensations between an RTOW chart and reality (whether or not is the chart smartly configured to match the operating conditions) and a couple of validity checks (Vmu, min V2, dry/wet). What I called 'some other bits maybe OEM specific' in the post above.

Needed, but only a small stop on the path to understanding. Just a note for other readers not to get stuck looking into the picture for something not on it.

Needed, but only a small stop on the path to understanding. Just a note for other readers not to get stuck looking into the picture for something not on it.

Join Date: May 1999

Location: Bristol, England

Age: 65

Posts: 1,804

Received 0 Likes

on

0 Posts

This thread has kept me awake at night. My take-away so far is that the RTOW flex method and the software calculation have different starting points. The RTOW uses a fixed configuration and therefore a change in, for instance, OAT between the time of planning and the actual take-off will not produce different numbers on a Flex TO provided that OAT remains below TFLEX. The software starts by optimising configuration for the PLTOM at OAT and then runs an iterative process at that configuration to find TFLEX. Thus, with the software, configuration may be changed as OAT changes but with the RTOW method, not. Is that correct?

One other question ... . I know the Airbus EFB software optimises V2 for each take-off under the guise of V2/VS ratio, but do Boeing do the same?

One other question ... . I know the Airbus EFB software optimises V2 for each take-off under the guise of V2/VS ratio, but do Boeing do the same?

Join Date: Jun 2007

Location: Wanderlust

Posts: 3,406

Likes: 0

Received 0 Likes

on

0 Posts

This thread has kept me awake at night. My take-away so far is that the RTOW flex method and the software calculation have different starting points. The RTOW uses a fixed configuration and therefore a change in, for instance, OAT between the time of planning and the actual take-off will not produce different numbers on a Flex TO provided that OAT remains below TFLEX. The software starts by optimising configuration for the PLTOM at OAT and then runs an iterative process at that configuration to find TFLEX. Thus, with the software, configuration may be changed as OAT changes but with the RTOW method, not. Is that correct?

One other question ... . I know the Airbus EFB software optimises V2 for each take-off under the guise of V2/VS ratio, but do Boeing do the same?

One other question ... . I know the Airbus EFB software optimises V2 for each take-off under the guise of V2/VS ratio, but do Boeing do the same?

Only half a speed-brake

A.W., agreed.

A change of OAT does not invalidate the AST result, and the calculated numbers remain valid. By necessity of how the figures are determined.

Although RTOW charts may exist with dual configuration printed on them, this does not change a thing.

It is entirely possible a Perfo SW suite could come up with a different configuration due to OAT adhustment, however that is also awailable for manual calculation if you decuded to dive deep enough.

The back office / mainframe or EFB calculations cannot provide any better results over the printed RTOWs. As the RTOWs are in fact a result of the same calculation core (SCAP module they used to call it).

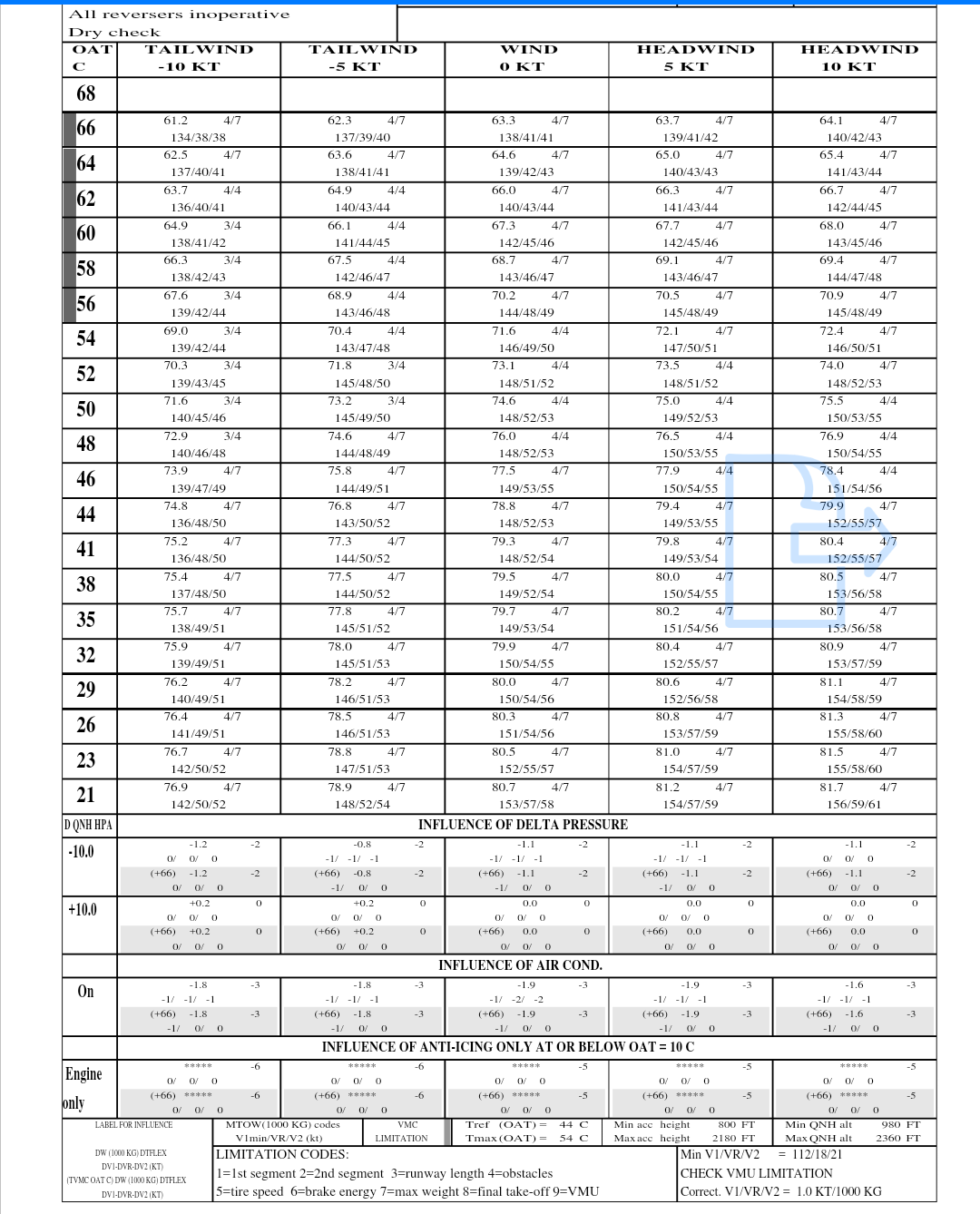

The differences between the RTOW pre-conditins and outside world of the day will require applying corrections which are fixed to the most critical situation and thus overly conservative for 98% of the chart. And combination of corrections makes it a lot worse. Altimeter indication cold temp I chose on purpouse because it is hidden from the reader in the standard layout.

That is when the EFB delivers with pride, QNH of 1013 should not really be -1100 kgs penalty compared to 1013.25.

Second question, absolutely yes. Try a search for 'improved climb'.

A change of OAT does not invalidate the AST result, and the calculated numbers remain valid. By necessity of how the figures are determined.

Although RTOW charts may exist with dual configuration printed on them, this does not change a thing.

It is entirely possible a Perfo SW suite could come up with a different configuration due to OAT adhustment, however that is also awailable for manual calculation if you decuded to dive deep enough.

The back office / mainframe or EFB calculations cannot provide any better results over the printed RTOWs. As the RTOWs are in fact a result of the same calculation core (SCAP module they used to call it).

The differences between the RTOW pre-conditins and outside world of the day will require applying corrections which are fixed to the most critical situation and thus overly conservative for 98% of the chart. And combination of corrections makes it a lot worse. Altimeter indication cold temp I chose on purpouse because it is hidden from the reader in the standard layout.

That is when the EFB delivers with pride, QNH of 1013 should not really be -1100 kgs penalty compared to 1013.25.

Second question, absolutely yes. Try a search for 'improved climb'.