787 Batteries and Chargers - Part 1

Join Date: Jan 2008

Location: Denver, CO

Posts: 265

Likes: 0

Received 0 Likes

on

0 Posts

Sys writes:

Still early days, but my money is still on the charger or temperature

sensing within the battery.

Still early days, but my money is still on the charger or temperature

sensing within the battery.

I wonder what they were and where they were at.

If a harness was mis-wired so that charge sensing was swapped between two cells - cell A being read as cell B and vice versa - it would eventually lead to an overcharge situation.

If the swap happened on cell temp, then a cell going into thermal runaway would be allowed to do so as the corrective action would be applied to the wrong cell.

Wow.

Join Date: Feb 2011

Location: Nearby SBBR and SDAM

Posts: 875

Likes: 0

Received 0 Likes

on

0 Posts

Current control of dangerous batteries (787 design lacks it?)

rottenray

On inconceivable look to the battery picture. Certainly the design doesn´t control the CHARGING current independently in each cell.

This may explain BOTH INCIDENTS!

And on discharge control:

1) How you would design it? What kind of part to perform it?

2) We will learn soon to confirm. I suspect there is not this feature in 787 main battery (main one is my bigger concern)

Mac

This picture just shows the high current cell conections (strips) and the sensors wiring. There is no provision for independent cell charging!

On inconceivable look to the battery picture. Certainly the design doesn´t control the CHARGING current independently in each cell.

This may explain BOTH INCIDENTS!

And on discharge control:

1) How you would design it? What kind of part to perform it?

2) We will learn soon to confirm. I suspect there is not this feature in 787 main battery (main one is my bigger concern)

Mac

This picture just shows the high current cell conections (strips) and the sensors wiring. There is no provision for independent cell charging!

Last edited by RR_NDB; 26th Jan 2013 at 00:28. Reason: Bold, red and bigger size and CHARGING added

Rottenray:

I didn't see that post, but it seems unlikely, since the manufacturing

process for such an item would have have visual inspection and test rigs

to ensure that the wiring was correct. and that it functioned as expected.

If voltage sensing were swapped between two cells, i'm not sure it would

make that much difference if all the cells are charged in series, since

you can only vary the overall charge rate for all cells, not individually.

Would make a lot of difference if there were a charging circuit for each

cell, though from the pics of the internals, doesn't look like that is

the case.

There's another point that may be relevant as well: It's not clear from the

pics if there is a temperature sensor per cell, or a single sensor for

the enclosure. I don't have figures, but the cells could have significantly

less thermal mass than say lead acid or nicad. ie: they might heat up much

faster than the latter. They also have a fairly low max operating temp of

65 C. If you have a single sensor at one side of the enclosure and a cell

starts to overheat at the opposite side, would that single sensor detect the

overheat condition in time to shutdown the battery ?.

May be irrelevant, if there's a temp sensor per cell, but the failure also

raises the question of whether they tested the overall system for all

fault conditions, including that to destruction...

Regards,

Chris

Some time in the past, a poster (here or somewhere else) mentioned that an inspection showed wiring errors.

I wonder what they were and where they were at.

If a harness was mis-wired so that charge sensing was swapped between two cells - cell A being read as cell B and vice versa - it would eventually lead to an overcharge situation.

If the swap happened on cell temp, then a cell going into thermal runaway would be allowed to do so as the corrective action would be applied to the wrong cell.

I wonder what they were and where they were at.

If a harness was mis-wired so that charge sensing was swapped between two cells - cell A being read as cell B and vice versa - it would eventually lead to an overcharge situation.

If the swap happened on cell temp, then a cell going into thermal runaway would be allowed to do so as the corrective action would be applied to the wrong cell.

process for such an item would have have visual inspection and test rigs

to ensure that the wiring was correct. and that it functioned as expected.

If voltage sensing were swapped between two cells, i'm not sure it would

make that much difference if all the cells are charged in series, since

you can only vary the overall charge rate for all cells, not individually.

Would make a lot of difference if there were a charging circuit for each

cell, though from the pics of the internals, doesn't look like that is

the case.

There's another point that may be relevant as well: It's not clear from the

pics if there is a temperature sensor per cell, or a single sensor for

the enclosure. I don't have figures, but the cells could have significantly

less thermal mass than say lead acid or nicad. ie: they might heat up much

faster than the latter. They also have a fairly low max operating temp of

65 C. If you have a single sensor at one side of the enclosure and a cell

starts to overheat at the opposite side, would that single sensor detect the

overheat condition in time to shutdown the battery ?.

May be irrelevant, if there's a temp sensor per cell, but the failure also

raises the question of whether they tested the overall system for all

fault conditions, including that to destruction...

Regards,

Chris

Join Date: Jan 2008

Location: Denver, CO

Posts: 265

Likes: 0

Received 0 Likes

on

0 Posts

RR NDB writes:

On inconceivable look to the battery picture. Certainly the design doesn´t control the current independently in each cell.

On inconceivable look to the battery picture. Certainly the design doesn´t control the current independently in each cell.

Sys writes:

There's another point that may be relevant as well: It's not clear from the

pics if there is a temperature sensor per cell, or a single sensor for

the enclosure. I don't have figures, but the cells could have significantly

less thermal mass than say lead acid or nicad. ie: they might heat up much

faster than the latter. They also have a fairly low max operating temp of

65 C. If you have a single sensor at one side of the enclosure and a cell

starts to overheat at the opposite side, would that single sensor detect the

overheat condition in time to shutdown the battery ?.

There's another point that may be relevant as well: It's not clear from the

pics if there is a temperature sensor per cell, or a single sensor for

the enclosure. I don't have figures, but the cells could have significantly

less thermal mass than say lead acid or nicad. ie: they might heat up much

faster than the latter. They also have a fairly low max operating temp of

65 C. If you have a single sensor at one side of the enclosure and a cell

starts to overheat at the opposite side, would that single sensor detect the

overheat condition in time to shutdown the battery ?.

Given the relatively "light" weight of these cells, and the corresponding lower rate of thermal inertia, I'd guess that a cell could overheat in one area before a sensor located on the opposite side could sense the climb. Perhaps thermal curves could be modeled to predict this, but if I were designing the bugger I'd certainly have at least 2 sensors per cell.

Cheers!

Join Date: Feb 2011

Location: Nearby SBBR and SDAM

Posts: 875

Likes: 0

Received 0 Likes

on

0 Posts

Safer design when using critical batteries in airliners

rottenray:

Before editing i made implicit first point was on CHARGING. I consider a safer design to charge the cells INDEPENDENTLY. Why not?

Another point on safer design. There are certainly better locations for this DANGEROUS battery.

I wasn't aware you were referring to independent current control. And I'm not aware of any multi-cell Li battery packs which do limit current on a cell-by-cell basis.

Another point on safer design. There are certainly better locations for this DANGEROUS battery.

Join Date: Aug 2011

Location: Grassy Valley

Posts: 2,074

Likes: 0

Received 0 Likes

on

0 Posts

syseng68k

From published data, it certainly appears that testing to destruction was not done. That is inconceivable; Boeing certainly would have done that, if only to know what solutions were available to conform to the regs. If there was fire...

That was Boeing's position, initially, that the battery performed as designed.

If they hadn't done the testing to arrive at a default solution to failure that did conform, they would not have pleaded to FAA: "give us instructions on a fix..."

Which suggests they don't have one, ergo, they did not test the system to failure that did not comply.

Scary

From published data, it certainly appears that testing to destruction was not done. That is inconceivable; Boeing certainly would have done that, if only to know what solutions were available to conform to the regs. If there was fire...

That was Boeing's position, initially, that the battery performed as designed.

If they hadn't done the testing to arrive at a default solution to failure that did conform, they would not have pleaded to FAA: "give us instructions on a fix..."

Which suggests they don't have one, ergo, they did not test the system to failure that did not comply.

Scary

Last edited by Lyman; 26th Jan 2013 at 05:52.

Join Date: Aug 2011

Location: hong kong

Age: 63

Posts: 93

Likes: 0

Received 0 Likes

on

0 Posts

Parallel charging, overload, mis-wiring

I apologize for my earlier analogy, it is a lot worse than a fart out of the tail pipe.

Parallel charging

There will be differences between cells, a few %. The cell of the lowest capacity determines the total charge-able and discharge-able battery capacity. Cells age, available capacity diminishes over time and varies more and more amongst cells.

Parallel charging enables to micro-manage the charge per cell in particular when cells are individually loaded (battery tapped). Very rare scenario in this day and age.

Here, batteries are discharged in series. Discharging must be stopped when the cell of the lowest charge is empty and charging must be stopped when it is full. Parallel charging would have little if any practical benefit beyond micro-management.

Parallel charging would require one isolated inverter per cell, capable of the maximum fast charge current + associated heavy wiring. 4V 30-60A x 8. Please consider size, weight, connection, cooling and reliability.

Actually, switching and rectifying losses depend mostly on the current and in practice would be almost same for a single 4V inverter and a 32V series charger.

Electrically, a parallel charge arrangement here would have 1/8th of the efficiency of the current 32V charge arrangement.

Then, these eight chargers must be managed and monitored!

No thanks, KISS

Overload

Generally, Li based cell chemistries will tolerate transient overload less than others. Au, Ni or Pb based cells can handle lots of abuse as these do not chemically deteriorate, at least not very quickly.

Important to all batteries is that the cells match, by effective inner resistance, throughout the event. Gross mismatch could even reverse a weak cell. The result would be rapid cell deterioration or outright destruction.

A partial cell failure, resulting in capacity loss or effective inner resistance increase, could trigger this scenario.

Mis-wiring

Swap of monitoring connections would identify the wrong cell to the management system, but would likely be detected by a production test.

This is a serial charge and discharge arrangement. Operationally, the weakest cell counts. Mis-wiring by swapping amongst cells would have no effect on charge/discharge management.

Parallel charging

There will be differences between cells, a few %. The cell of the lowest capacity determines the total charge-able and discharge-able battery capacity. Cells age, available capacity diminishes over time and varies more and more amongst cells.

Parallel charging enables to micro-manage the charge per cell in particular when cells are individually loaded (battery tapped). Very rare scenario in this day and age.

Here, batteries are discharged in series. Discharging must be stopped when the cell of the lowest charge is empty and charging must be stopped when it is full. Parallel charging would have little if any practical benefit beyond micro-management.

Parallel charging would require one isolated inverter per cell, capable of the maximum fast charge current + associated heavy wiring. 4V 30-60A x 8. Please consider size, weight, connection, cooling and reliability.

Actually, switching and rectifying losses depend mostly on the current and in practice would be almost same for a single 4V inverter and a 32V series charger.

Electrically, a parallel charge arrangement here would have 1/8th of the efficiency of the current 32V charge arrangement.

Then, these eight chargers must be managed and monitored!

No thanks, KISS

Overload

Generally, Li based cell chemistries will tolerate transient overload less than others. Au, Ni or Pb based cells can handle lots of abuse as these do not chemically deteriorate, at least not very quickly.

Important to all batteries is that the cells match, by effective inner resistance, throughout the event. Gross mismatch could even reverse a weak cell. The result would be rapid cell deterioration or outright destruction.

A partial cell failure, resulting in capacity loss or effective inner resistance increase, could trigger this scenario.

Mis-wiring

Swap of monitoring connections would identify the wrong cell to the management system, but would likely be detected by a production test.

This is a serial charge and discharge arrangement. Operationally, the weakest cell counts. Mis-wiring by swapping amongst cells would have no effect on charge/discharge management.

Last edited by saptzae; 26th Jan 2013 at 09:48. Reason: Punctuation and other fixes

Join Date: Aug 2011

Location: hong kong

Age: 63

Posts: 93

Likes: 0

Received 0 Likes

on

0 Posts

Battery and cell monitoring

Temperature would be used to limit fast charge current. Management system will lower max charge current at higher temperature.

Cell voltage change precedes temperature change. Once the temperature rises substantially, it will be too late to manage.

When a cell arcs internally or shorts, the voltage will fluctuate a lot and reduce to near zero.

When a cell electrically opens, voltage across it will revert and the battery shows a high inner resistance.

Important is to keep individual cell voltages in the allowed range at _all_ times, or disconnect the battery.

Thus, per cell temperature monitoring would not be a big benefit to battery management.

Important is that charge current be reduced quickly when any cell's voltage approaches it's limit, and that it never increases the design limit.

When _any_ cell over/under/reverse voltage is detected, the entire battery must be taken off-line (disconnected) within a very short time to prevent secondary damage to it.

Cell voltage change precedes temperature change. Once the temperature rises substantially, it will be too late to manage.

When a cell arcs internally or shorts, the voltage will fluctuate a lot and reduce to near zero.

When a cell electrically opens, voltage across it will revert and the battery shows a high inner resistance.

Important is to keep individual cell voltages in the allowed range at _all_ times, or disconnect the battery.

Thus, per cell temperature monitoring would not be a big benefit to battery management.

Important is that charge current be reduced quickly when any cell's voltage approaches it's limit, and that it never increases the design limit.

When _any_ cell over/under/reverse voltage is detected, the entire battery must be taken off-line (disconnected) within a very short time to prevent secondary damage to it.

Join Date: Aug 2011

Location: hong kong

Age: 63

Posts: 93

Likes: 0

Received 0 Likes

on

0 Posts

Failure scenario

There three main management issues.

a) Cell production quality

b) Cell operational management

c) Cell failure handling.

It was reported that a cell was found shorted. We do not know whether this was the initial failure, or whether due to a) or b). It does not really matter because c) should have worked better, and may be what did the real damage.

If short was the initial failure, from an electrical perspective:

It is not going to be a solid short from one moment to the next. The energy is just too great. Cell could not ever dissipate it's 200 - 300 Watt hours quietly. It would short, arc, burn out the short and do more damage along the way. There would be over pressure, relieve valves opening, electrolyte blown out. More shorting as separators fail by the heat. The whole cycle continues until energy is dissipated and some spot shortened can not be burned out.

Throughout all this, terminal voltage will fluctuate and other cells be subjected to voltage and current spikes, until the next one fails and the cycle repeats itself even faster.

a) Cell production quality

b) Cell operational management

c) Cell failure handling.

It was reported that a cell was found shorted. We do not know whether this was the initial failure, or whether due to a) or b). It does not really matter because c) should have worked better, and may be what did the real damage.

If short was the initial failure, from an electrical perspective:

- A cell fails and shorts - (reason either a) or b) above

- Cell voltage drops, removing (most) of its 4V share of the 32V

- Bus voltage remains essentially the same at 32V

- Other cells take up 4V / 7, thus are subjected to severest over-charge in terms of voltage and current

- More cells fail in a cascading manner

- Combined per-cell energy and the bus feed battery destruction

It is not going to be a solid short from one moment to the next. The energy is just too great. Cell could not ever dissipate it's 200 - 300 Watt hours quietly. It would short, arc, burn out the short and do more damage along the way. There would be over pressure, relieve valves opening, electrolyte blown out. More shorting as separators fail by the heat. The whole cycle continues until energy is dissipated and some spot shortened can not be burned out.

Throughout all this, terminal voltage will fluctuate and other cells be subjected to voltage and current spikes, until the next one fails and the cycle repeats itself even faster.

Last edited by saptzae; 26th Jan 2013 at 10:49. Reason: Tenses, clarify shorting

Join Date: Mar 2006

Location: Choroni, sometimes

Posts: 1,974

Likes: 0

Received 0 Likes

on

0 Posts

Then, these eight chargers must be managed and monitored!

No thanks, KISS

No thanks, KISS

Battery Management System (BMS)

One of the main functions of the BMS is to keep the cells operating within their designed operating window (the green box above). This is not too difficult to achieve using safety devices and thermal management systems. As an additional safety factor some manufacturers set their operating limits to more restricted levels indicated by the dotted lines.

There is however very little te BMS can do to protect aginst an internal short circuit. The only prevention action that can be taken is strict process control of all the cell manufacturing operations.

Lithium Charged but Not Guilty?The cause of many fires has been attributed to Lithium batteries and there is a fear of Lithium because of its well known vigorous reaction with water. Under normal circumstances, most (but not all) batteries do not contain any free Lithium. The Lithium content is combined into other compounds which do not react with water. The amount of Lithium deposited during the Lithium plating when cells are damaged as described above is very small and not usually responsible for the fires which have occurred. Furthermore, many of the reported fires are due to burning electrolyte rather than the Lithium compounds.

The guilty party

Although investigation has shown that some Lithium fires are due to internal short circuits as described above, many, if not most fires are caused by abuse by the user. This may be "deliberate or negligent" abuse such as overcharging or operating in a high temperature environment or physical damage due to mishandling, but quite often it is unconscious abuse. Surprisingly many of the most serious fires have been initiated by inadvertent short circuits caused by careless disposal of cells in the rubbish. While strict regulations for transporting Lithium batteries by air have been implemeted, the sources of several aircraft / transport fires have been identified as spare laptop batteries being carried in passenger luggage shorting against other items packed with them.

Note: Large batteries such as those used in automotive applications usually incorporate short circuit protection, but smaller laptop batteries do not usually have this facility.

Join Date: Aug 2011

Location: hong kong

Age: 63

Posts: 93

Likes: 0

Received 0 Likes

on

0 Posts

Management

@Hetfield

Yes, serial management is sufficient. All it must do is to keep cell voltages in range. It's important for any battery chemistry. It's critical for Li based cells, which are sensitive also to short-term over-discharge.

Importantly, when cell management fails, failure mitigation must kick in. It seems that it did not.

Yes, serial management is sufficient. All it must do is to keep cell voltages in range. It's important for any battery chemistry. It's critical for Li based cells, which are sensitive also to short-term over-discharge.

Importantly, when cell management fails, failure mitigation must kick in. It seems that it did not.

rottenray:

A temp sensor per cell becomes more important where fast charging is used.

There will be significant temperature rise and that coupled with a low

max temp of 65 C means that a single temp sensor to cover such a large

area is not enough. From what i've read, the fast charge timescale is about an hour

30mins.

2 would provide redundancy, but if the temp and voltage sensing were

combined into a single chip device, it could be embedded into the cell

casing at very little cost and have enough diagnostics to detect either

the voltage or temp sensor's failure.

There's another point as well: It looks like there are printed circuit

boards inside the battery casing. Hmm: pcb's + electrolyte = trouble,

even if the boards have a conformal coating. You only need a single cell

case to split, for whatever reason and you have electrolyte and vapour

which could play havoc with electronics. Inside a battery casing is

the last place I would put a pcb, especially if that is handling the

sensors

Regards,

Chris

I read somewhere that temp sensing is overall, rather than cell by cell.

There will be significant temperature rise and that coupled with a low

max temp of 65 C means that a single temp sensor to cover such a large

area is not enough. From what i've read, the fast charge timescale is about an hour

30mins.

Given the relatively "light" weight of these cells, and the

corresponding lower rate of thermal inertia, I'd guess that a cell could

overheat in one area before a sensor located on the opposite side could

sense the climb. Perhaps thermal curves could be modeled to predict

this, but if I were designing the bugger I'd certainly have at least 2

sensors per cell.

corresponding lower rate of thermal inertia, I'd guess that a cell could

overheat in one area before a sensor located on the opposite side could

sense the climb. Perhaps thermal curves could be modeled to predict

this, but if I were designing the bugger I'd certainly have at least 2

sensors per cell.

combined into a single chip device, it could be embedded into the cell

casing at very little cost and have enough diagnostics to detect either

the voltage or temp sensor's failure.

There's another point as well: It looks like there are printed circuit

boards inside the battery casing. Hmm: pcb's + electrolyte = trouble,

even if the boards have a conformal coating. You only need a single cell

case to split, for whatever reason and you have electrolyte and vapour

which could play havoc with electronics. Inside a battery casing is

the last place I would put a pcb, especially if that is handling the

sensors

Regards,

Chris

Join Date: Jan 2008

Location: Denmark

Age: 79

Posts: 158

Likes: 0

Received 0 Likes

on

0 Posts

Battery shutdown?

syseng68k,

Quote from your post#143:

If you have a single sensor at one side of the enclosure and a cell

starts to overheat at the opposite side, would that single sensor detect the

overheat condition in time to shutdown the battery?

How do you shutdown a battery that is experiencing a thermal runaway? I thought that a runaway in a lithium-ion battery cell could not be stopped.

By the way, thanks for all your very informative posts!

Quote from your post#143:

If you have a single sensor at one side of the enclosure and a cell

starts to overheat at the opposite side, would that single sensor detect the

overheat condition in time to shutdown the battery?

How do you shutdown a battery that is experiencing a thermal runaway? I thought that a runaway in a lithium-ion battery cell could not be stopped.

By the way, thanks for all your very informative posts!

Last edited by grebllaw123d; 26th Jan 2013 at 14:52.

Saptzae,

Thanks for your latest posts. For a layman like me, they seem to summarise the issues facing Boeing, Securaplane, Thales, and (perhaps) Yuasu very clearly; particularly your description of the cascade effect following the shorting of one cell during charging.

Could you just clarify the last sentence of this part of your penultimate post, please (my bold)?

“Shorting

It is not going to be a solid short from one moment to the next. The energy is just too great. Cell could not ever dissipate it's 200 - 300 Watt hours quietly. It would short, arc, burn out the short and do more damage along the way. There would be over pressure, relieve valves opening, electrolyte blown out. More shorting as separators fail by the heat. The whole cycle continues until energy is dissipated and some spot shortened can not be burned out.”

Also, do you think that a manganese (spinel) type of Li-ion battery would have been a safer choice than the cobalt type, and would its performance be adequate for the task? If so, could its retrofit be one of the options currently under consideration?

Thanks for your latest posts. For a layman like me, they seem to summarise the issues facing Boeing, Securaplane, Thales, and (perhaps) Yuasu very clearly; particularly your description of the cascade effect following the shorting of one cell during charging.

Could you just clarify the last sentence of this part of your penultimate post, please (my bold)?

“Shorting

It is not going to be a solid short from one moment to the next. The energy is just too great. Cell could not ever dissipate it's 200 - 300 Watt hours quietly. It would short, arc, burn out the short and do more damage along the way. There would be over pressure, relieve valves opening, electrolyte blown out. More shorting as separators fail by the heat. The whole cycle continues until energy is dissipated and some spot shortened can not be burned out.”

Also, do you think that a manganese (spinel) type of Li-ion battery would have been a safer choice than the cobalt type, and would its performance be adequate for the task? If so, could its retrofit be one of the options currently under consideration?

grebllaw:

Once there's a runaway condition, it's probably too late. The whole

idea is to have accurate and timely info from the cells, to allow the

electronics to stop the charge or dump the load before runaway happens.

If the battery is managed correctly, it should never happen, other

than from gross component failure.

LI is far more fussy about operating temperature range and min / max

cell voltages than either lead acid or nicad and both need to be

continuously monitored to ensure safe operation. It doesn't mean there's

anything inherently wrong with the technology, but the overall system

design of battery, charger and load profile need to be to be much

better matched and to a tighter spec.

Analysis of this problem is interesting, even if we are stumbling

around in the dark a bit :-)...

Regards,

Chris

Once there's a runaway condition, it's probably too late. The whole

idea is to have accurate and timely info from the cells, to allow the

electronics to stop the charge or dump the load before runaway happens.

If the battery is managed correctly, it should never happen, other

than from gross component failure.

LI is far more fussy about operating temperature range and min / max

cell voltages than either lead acid or nicad and both need to be

continuously monitored to ensure safe operation. It doesn't mean there's

anything inherently wrong with the technology, but the overall system

design of battery, charger and load profile need to be to be much

better matched and to a tighter spec.

Analysis of this problem is interesting, even if we are stumbling

around in the dark a bit :-)...

Regards,

Chris

Thread Starter

Join Date: Jul 2007

Location: My Stringy Brane

Posts: 377

Likes: 0

Received 0 Likes

on

0 Posts

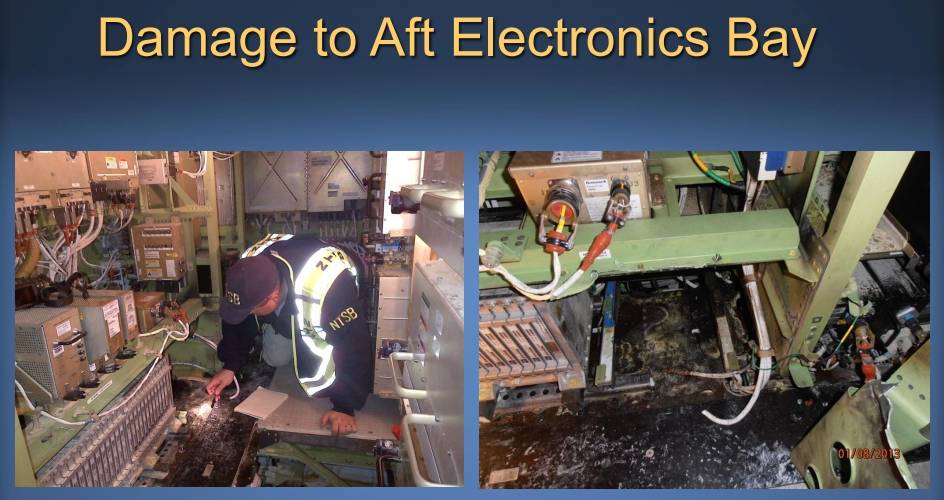

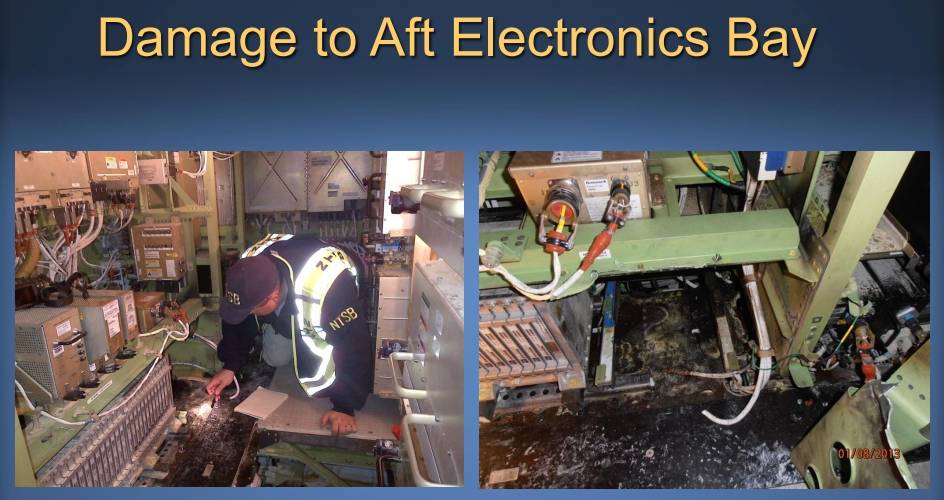

The Chicago Tribune reports:

Burnt circuit boards snag Japan Boeing 787 probe

The PCB's are large and possess significant monitoring/management capability. As has been stated, the protections failed to prevent thermal runaway.

Let's hope the ANA units are testable and yield good information.

Best outcome may be discovering a bad batch of PCB's.

Burnt circuit boards snag Japan Boeing 787 probe

Circuit boards that control and monitor the performance of the plane's lithium-ion battery unit were charred and may be of little use to the teams investigating why the battery effectively melted, forcing safety investigators to scramble for possible clues from other components in the plane's electronics...

Japanese safety officials plan to take the damaged circuit boards to the manufacturer, Fujisawa-based Kanto Aircraft Instrument, for a detailed inspection.

The PCB's are large and possess significant monitoring/management capability. As has been stated, the protections failed to prevent thermal runaway.

Let's hope the ANA units are testable and yield good information.

Best outcome may be discovering a bad batch of PCB's.

Lyman:

Perhaps, but let's put it into perspective: After arguably the most serious

level of battery failure possible, the fire was contained within the battery

enclosure, even if the contents did leak out and make a bit of a mess. The

smoke was discharged as per design. Inconvenienced, but no one in any

serious danger, nor lost their life, which is the most important thing..

It's what actually happens, not what might.

These events should provide a lot of new data, even if it is a bit expensive and

whether they were expecting it or not ...

...

Regards,

Chris

Scary

level of battery failure possible, the fire was contained within the battery

enclosure, even if the contents did leak out and make a bit of a mess. The

smoke was discharged as per design. Inconvenienced, but no one in any

serious danger, nor lost their life, which is the most important thing..

It's what actually happens, not what might.

These events should provide a lot of new data, even if it is a bit expensive and

whether they were expecting it or not

...

...Regards,

Chris

Join Date: Mar 2006

Location: Choroni, sometimes

Posts: 1,974

Likes: 0

Received 0 Likes

on

0 Posts

Thx Machaca.

So,

- "GS Yuasa" is the manufacter of the Li-Ion cells

- "Kanto Aircraft Instrument" deliver the "circuit boards",

- "Securaplane" the chargers (two different models)

- "Thales" put it all together, besides the chargers

The "circuit boards" are very important. To my knowledge, they do the "balancing" and monitoring of each of the 8 cells which is crucial.

Outsourcing at its best....

So,

- "GS Yuasa" is the manufacter of the Li-Ion cells

- "Kanto Aircraft Instrument" deliver the "circuit boards",

- "Securaplane" the chargers (two different models)

- "Thales" put it all together, besides the chargers

The "circuit boards" are very important. To my knowledge, they do the "balancing" and monitoring of each of the 8 cells which is crucial.

Outsourcing at its best....