Corrosion found in RR Trent 1000 Gearboxes

Thread Starter

Corrosion found in RR Trent 1000 Gearboxes

Good Evening All:

Taken from the Toronto Globe and Mail

Japanese airline ANA grounds five Boeing Dreamliner planes

ANDREW PARKER

LONDON — The Globe and Mail

Published Monday, Jul. 23 2012, 8:10 PM EDT

Last updated Monday, Jul. 23 2012, 8:19 PM EDT

ANA, the Japanese airline, grounded five of its 11 new Boeing 787 Dreamliner aircraft after a problem was identified with engines made by Rolls-Royce.

Two 787s were grounded by ANA last Wednesday, and a further three on Saturday, after a potential corrosion problem inside gearboxes on Rolls-Royce’s Trent 1000 engines was discovered.

More Related to this Story

Wary airlines spoil jet makers’ party

Bombardier takes $1-billion order for 15 C Series jetliners

Gallery New planes, fierce competition at 2012's Farnborough Airshow

investing

Rolls-Royce is replacing the gearboxes, and three of the five 787s that ANA grounded are now back in service, but the corrosion issue is also believed to affect some Trent 1000 engines made for Dreamliners that have not yet been delivered by Boeing to airlines.

Analysts said the issue appeared to be relatively minor at this stage – but some noted that Rolls-Royce recorded earnings charges after one of its Trent 900 engines exploded on an Airbus A380 superjumbo in 2010.

The Trent 1000 engine was designed for the Dreamliner, Boeing’s next generation wide-body aircraft.

Rolls-Royce’s shares fell 2.9 per cent on Monday. Shares in UTC, parent of Hamilton Sundstrand, which makes the gearbox for the Rolls-Royce Trent 1000 engine, fell 2 per cent in New York morning trading to $72.8. Boeing’s shares fell 1.9 per cent to $72.5.

The 787 programme has been dogged by delays because of technology difficulties and outsourcing problems. The first aircraft was delivered to ANA last September more than three years late.

Boeing has so far supplied 15 Dreamliners to two customers – ANA and Japan Airlines. Japan Airlines’ four 787s have engines made by General Electric.

ANA’s 11 Dreamliners all have Trent 1000 engines, but the potential corrosion issue inside the gearboxes is confined to five 787s. It was discovered by Rolls-Royce during engine testing, and has been traced to a manufacturing process.

Rolls-Royce said: “We have identified that a component on Trent 1000 engines being fitted to Boeing 787 Dreamliners has a reduced service life. As a proactive measure, this component is being replaced in a number of engines.”

Hamilton Sundstrand said: “We are … aware of the issue and working closely with Boeing and Rolls-Royce to resolve.”

Boeing said it had advised ANA to remove the five 787s from service to replace the affected gearboxes.

It added that no further Dreamliners would be delivered to customers with the potential corrosion issue.

ANA said: “Three [of] the five [Dreamliners] are already back in operation, and the rest of them will be back within a few weeks.”

Rolls-Royce recorded a £56-million charge against its 2011 earnings after the Trent 900 engine blowout on a Qantas A380 in 2010, which resulted in the Australian airline grounding its superjumbo fleet.

Taken from the Toronto Globe and Mail

Japanese airline ANA grounds five Boeing Dreamliner planes

ANDREW PARKER

LONDON — The Globe and Mail

Published Monday, Jul. 23 2012, 8:10 PM EDT

Last updated Monday, Jul. 23 2012, 8:19 PM EDT

ANA, the Japanese airline, grounded five of its 11 new Boeing 787 Dreamliner aircraft after a problem was identified with engines made by Rolls-Royce.

Two 787s were grounded by ANA last Wednesday, and a further three on Saturday, after a potential corrosion problem inside gearboxes on Rolls-Royce’s Trent 1000 engines was discovered.

More Related to this Story

Wary airlines spoil jet makers’ party

Bombardier takes $1-billion order for 15 C Series jetliners

Gallery New planes, fierce competition at 2012's Farnborough Airshow

investing

Rolls-Royce is replacing the gearboxes, and three of the five 787s that ANA grounded are now back in service, but the corrosion issue is also believed to affect some Trent 1000 engines made for Dreamliners that have not yet been delivered by Boeing to airlines.

Analysts said the issue appeared to be relatively minor at this stage – but some noted that Rolls-Royce recorded earnings charges after one of its Trent 900 engines exploded on an Airbus A380 superjumbo in 2010.

The Trent 1000 engine was designed for the Dreamliner, Boeing’s next generation wide-body aircraft.

Rolls-Royce’s shares fell 2.9 per cent on Monday. Shares in UTC, parent of Hamilton Sundstrand, which makes the gearbox for the Rolls-Royce Trent 1000 engine, fell 2 per cent in New York morning trading to $72.8. Boeing’s shares fell 1.9 per cent to $72.5.

The 787 programme has been dogged by delays because of technology difficulties and outsourcing problems. The first aircraft was delivered to ANA last September more than three years late.

Boeing has so far supplied 15 Dreamliners to two customers – ANA and Japan Airlines. Japan Airlines’ four 787s have engines made by General Electric.

ANA’s 11 Dreamliners all have Trent 1000 engines, but the potential corrosion issue inside the gearboxes is confined to five 787s. It was discovered by Rolls-Royce during engine testing, and has been traced to a manufacturing process.

Rolls-Royce said: “We have identified that a component on Trent 1000 engines being fitted to Boeing 787 Dreamliners has a reduced service life. As a proactive measure, this component is being replaced in a number of engines.”

Hamilton Sundstrand said: “We are … aware of the issue and working closely with Boeing and Rolls-Royce to resolve.”

Boeing said it had advised ANA to remove the five 787s from service to replace the affected gearboxes.

It added that no further Dreamliners would be delivered to customers with the potential corrosion issue.

ANA said: “Three [of] the five [Dreamliners] are already back in operation, and the rest of them will be back within a few weeks.”

Rolls-Royce recorded a £56-million charge against its 2011 earnings after the Trent 900 engine blowout on a Qantas A380 in 2010, which resulted in the Australian airline grounding its superjumbo fleet.

Last edited by a330pilotcanada; 24th Jul 2012 at 01:17. Reason: Clarity

Join Date: Aug 2011

Location: Grassy Valley

Posts: 2,074

Likes: 0

Received 0 Likes

on

0 Posts

Does the 1000 have the same architecture as the 900 re: gearbox? After the lengthy thread about the Qantas uncontainment, another "manufacturing defect"? I doubt the 56M charge off was the only one, won't they be a quarterly deal?

The drive shaft for the gearbox takes its power off the High Pressure shaft, just forward of the Turbine. It seems like an awful lot of rpm for a power take off.

How does the corrosion happen, is it present prior to assembly? That makes it a QA problem. What in the transmission could cause corrosion?

The drive shaft for the gearbox takes its power off the High Pressure shaft, just forward of the Turbine. It seems like an awful lot of rpm for a power take off.

How does the corrosion happen, is it present prior to assembly? That makes it a QA problem. What in the transmission could cause corrosion?

Join Date: Oct 2007

Location: UK

Age: 60

Posts: 22

Likes: 0

Received 0 Likes

on

0 Posts

Corrosion found in RR Trent 1000 Gearboxes

Found this link in local paper, surprised nothing appeared earlier.

Aircraft grounded after fault discovered in engines | This is Derbyshire

Aircraft grounded after fault discovered in engines | This is Derbyshire

How does the corrosion happen, is it present prior to assembly? That makes it a QA problem.

It could be caused by a bad (incorrectly installed or bad specification) seal or gasket allowing contaminants in. Or an error in the manufacturing process (some solvent not properly rinsed out). It could also be due to contact and galvanic corrosion between dissimilar metals, which could be an assembly or design error.

I'd be more interested in hearing what the consequences of an eventual failure due to this corrosion would be. A seized gearbox? Oil leak and possible subsequent fire?

Join Date: Aug 2002

Location: Down East

Posts: 103

Likes: 0

Received 0 Likes

on

0 Posts

History seems to be repeating itself with a new AC type being grounded because of faulty RR components.. This is similiar to the early L1011"s that were grounded because of faulty fan disks with the RB 211 engines.

OLD RED DAMASK

Join Date: Apr 2004

Location: Lancashire born. In Cebu now

Age: 70

Posts: 368

Likes: 0

Received 0 Likes

on

0 Posts

Maybe it would help if Royces went back to making engines instead of just assembling them ??

Rolls Royce fan blade technology is second to none and they make all the main blades at Barnoldswick.

Rolls have cured the problem and admitted fault, think that should be it then. Don't see why Rolls should be castigated so much.

Join Date: Aug 2009

Location: Takeshima

Age: 55

Posts: 99

Likes: 0

Received 0 Likes

on

0 Posts

History seems to be repeating itself with a new AC type being grounded because of faulty RR components.. This is similiar to the early L1011"s that were grounded because of faulty fan disks with the RB 211 engines.

Join Date: Dec 2010

Location: Middle America

Age: 84

Posts: 1,167

Likes: 0

Received 0 Likes

on

0 Posts

Hi Lyman,

With what information has been provided on the Trent 1000 engine gearbox, it is not possible to know which component had the corrosion problem as the gearbox is jam packed with components of different materials.

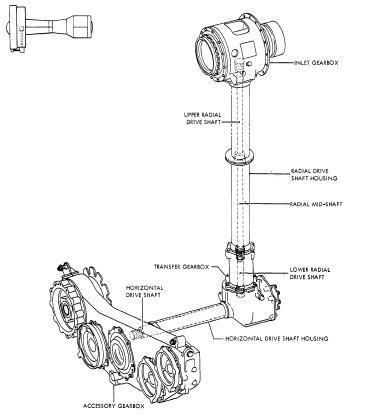

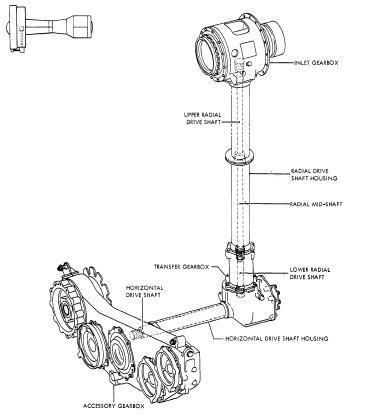

Relative to comparison to the Trent 900 engine, the Trent 1000 gearbox would be significantly different as it would be customized for the Boeing 787 application. For the Trent 900, the gearbox and radial drive would look something like this except the radial drive shaft would be angled forward and the gearbox itself is mounted on the fan casing. The power is taken from the HP compressor shaft as it is a three shafted engine design.

For the Boeing 787, the gearbox is mounted just behind the fan casing. It is different as this aircraft is an MEA (More Electric Aircraft) than the Airbus A-380. For one thing, there is no longer hot bleed air taken off the engine compressor which was used for cabin pressurization, nacelle & wing ice protection and engine starting. Bleed air is replaced by electric generators to perform these functions and others. This means the mechanics inside the gearbox are changed to accept these larger generators that were not required in a more conventional aircraft. The design, function and ultimate location of the gear box is a team effort by the aircraft designers, engine manufacturer and gearbox producer. The engine folks used to do the design and even the gearbox assembly at one time, but that has changed as there are companies that specialize in this complicated item today. RR chose Hamilton-Sunstrand a division of United Aircraft Corp. (think Pratt & Whitney), while GE chose Avio Group in Italy for their gearbox on the GEnx1-B engine for the B787. You can see what the GEnx1-B gearbox looks like by going to this site:

http://www.aviogroup.com/files/catal.../genx_eng9.pdf

As the article points out, the gearbox for the GEnx2-B is different from the 1-B engine as the Boeing 747-8 is more conventional and still uses engine compressor bleed air. In a conventional aircraft during engine starting, the gearbox runs in reverse to help start the engine in case you didn't know.

Hopefully, this answers at least part of your question/comments...

With what information has been provided on the Trent 1000 engine gearbox, it is not possible to know which component had the corrosion problem as the gearbox is jam packed with components of different materials.

Relative to comparison to the Trent 900 engine, the Trent 1000 gearbox would be significantly different as it would be customized for the Boeing 787 application. For the Trent 900, the gearbox and radial drive would look something like this except the radial drive shaft would be angled forward and the gearbox itself is mounted on the fan casing. The power is taken from the HP compressor shaft as it is a three shafted engine design.

For the Boeing 787, the gearbox is mounted just behind the fan casing. It is different as this aircraft is an MEA (More Electric Aircraft) than the Airbus A-380. For one thing, there is no longer hot bleed air taken off the engine compressor which was used for cabin pressurization, nacelle & wing ice protection and engine starting. Bleed air is replaced by electric generators to perform these functions and others. This means the mechanics inside the gearbox are changed to accept these larger generators that were not required in a more conventional aircraft. The design, function and ultimate location of the gear box is a team effort by the aircraft designers, engine manufacturer and gearbox producer. The engine folks used to do the design and even the gearbox assembly at one time, but that has changed as there are companies that specialize in this complicated item today. RR chose Hamilton-Sunstrand a division of United Aircraft Corp. (think Pratt & Whitney), while GE chose Avio Group in Italy for their gearbox on the GEnx1-B engine for the B787. You can see what the GEnx1-B gearbox looks like by going to this site:

http://www.aviogroup.com/files/catal.../genx_eng9.pdf

As the article points out, the gearbox for the GEnx2-B is different from the 1-B engine as the Boeing 747-8 is more conventional and still uses engine compressor bleed air. In a conventional aircraft during engine starting, the gearbox runs in reverse to help start the engine in case you didn't know.

Hopefully, this answers at least part of your question/comments...

Join Date: Jun 2008

Location: Derbyshire, UK

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

The Trent 1000 radial drive shaft actually takes it's drive from the IP spool on the Trent 1000. This is unique to the Trent 1000. The original design had the drive from the IP, with a clutch that also connected the HP for starting, to meet the quick starting requirements for ANA. This meant that both HP and IP were cranked when starting.

However after testing it was found start performance was just as good when only the IP was spun up at start up, so the clutch was removed as a weight reduction and simplicity measure.

I believe previous comments from RR point out that the issue was found on an engine stripped after a ground test, so these gearboxes are being changed as a precaution, and to allow strip and investigation. Seems very sensible.

However after testing it was found start performance was just as good when only the IP was spun up at start up, so the clutch was removed as a weight reduction and simplicity measure.

I believe previous comments from RR point out that the issue was found on an engine stripped after a ground test, so these gearboxes are being changed as a precaution, and to allow strip and investigation. Seems very sensible.

Join Date: Dec 2010

Location: Middle America

Age: 84

Posts: 1,167

Likes: 0

Received 0 Likes

on

0 Posts

Forgot one thing in my previous post:

Corrosion generally happens over time in engine operation. As the article stated, the problem was found during engine testing. One of the things you do, or should do, is have an engine running on a test stand, accumulating cycles far advance of those engines in the field, it is a "Best Practice". At various points of cycling this engine, it is completely dis-assembled and reviewed for any problems that require attention so that corrective action can be taken on field engines before an "event" takes place. So I think this is how RR discovered the problem and decided it was best to change out the defective part/parts in ANA's engines ASAP to avoid another in service "incident".

Your quote: How does the corrosion happen, is it present prior to assembly? That makes it a QA problem.

Last edited by Jetdriver; 24th Jul 2012 at 18:03.

Join Date: Aug 2011

Location: Grassy Valley

Posts: 2,074

Likes: 0

Received 0 Likes

on

0 Posts

Thanks TD.

I had not even considered the differences in architecture due loss of bleeds, and pneumatics playing such an enhanced role. "In the gearbox" does not actually involve the drive system. "Reduced service life" does have a haunting familiarity, however. It communicates a foresight that I believe was ignored in the -900.

It also does not address what might happen if a problem appears on wing. Anything that shortens a service life, unaddressed, might shorten, well, other types of life.

Tentative hat tip in the direction of Derby, then?

I had not even considered the differences in architecture due loss of bleeds, and pneumatics playing such an enhanced role. "In the gearbox" does not actually involve the drive system. "Reduced service life" does have a haunting familiarity, however. It communicates a foresight that I believe was ignored in the -900.

It also does not address what might happen if a problem appears on wing. Anything that shortens a service life, unaddressed, might shorten, well, other types of life.

Tentative hat tip in the direction of Derby, then?

Join Date: Dec 2010

Location: Middle America

Age: 84

Posts: 1,167

Likes: 0

Received 0 Likes

on

0 Posts

Hi Lyman,

I would tend to agree with you on the -900. For this -1000 problem, it is unusual and as somewhat indicated, it was due to a manufacturing process problem, something in the gearbox that was supposed to be corrosion resistant wasn't because a processing step wasn't done properly. Usually the major gearbox problem is oil leakage, not internal component corrosion. Other parts of the engine can be susceptible to corrosion attack, particularly engines that operate out of airports next to the salt water seas and there are many of them. We used to run test engines virtually "on the beach" with the inlet facing the sea to be sure the anti-corrosion coatings on some components actually did what they were supposed to do over the time span required before component removal and servicing.

bvcu ,

Actually, Hamilton Sundstrand is a very good supplier of gearboxes. I am pretty sure the gearbox for the GP7200 engine for the Airbus A-380 has a gearbox designed by them.

I would tend to agree with you on the -900. For this -1000 problem, it is unusual and as somewhat indicated, it was due to a manufacturing process problem, something in the gearbox that was supposed to be corrosion resistant wasn't because a processing step wasn't done properly. Usually the major gearbox problem is oil leakage, not internal component corrosion. Other parts of the engine can be susceptible to corrosion attack, particularly engines that operate out of airports next to the salt water seas and there are many of them. We used to run test engines virtually "on the beach" with the inlet facing the sea to be sure the anti-corrosion coatings on some components actually did what they were supposed to do over the time span required before component removal and servicing.

bvcu ,

Actually, Hamilton Sundstrand is a very good supplier of gearboxes. I am pretty sure the gearbox for the GP7200 engine for the Airbus A-380 has a gearbox designed by them.

Join Date: Aug 2002

Location: Down East

Posts: 103

Likes: 0

Received 0 Likes

on

0 Posts

gerago

The problems that RR had developing the RB 211 forced the company into bankruptcy and led to the spin off of the automobile division.

The problems that RR had developing the RB 211 forced the company into bankruptcy and led to the spin off of the automobile division.

Last edited by tsgas; 24th Jul 2012 at 21:24.

Actually, I posted this on 22 July in South-East Asia and Far East, but the whole thread immediately got moved to Spectators' Balcony!

http://www.pprune.org/spectators-bal...ml#post7308293

http://www.pprune.org/spectators-bal...ml#post7308293