Ethiopian airliner down in Africa

Join Date: Jul 2007

Location: Germany

Posts: 556

Likes: 0

Received 0 Likes

on

0 Posts

Sadly I haven't been able to keep up with all the posts in this thread so apologies if this is a duplicate.

How did the MEL change with respect to AoA sensors with the introduction of MCAS?

My understanding from this:

http://fsims.faa.gov/wdocs/mmel/b-737_rev%2057.pdf

is that only one AoA sensor is required before despatch?

How did the MEL change with respect to AoA sensors with the introduction of MCAS?

My understanding from this:

http://fsims.faa.gov/wdocs/mmel/b-737_rev%2057.pdf

is that only one AoA sensor is required before despatch?

The line referring to the alpha vanes explicitly only lists Original and Classic models (-100/-200/-300/-400/-500). Not NG (or MAX).

Bernd

Join Date: Jun 2007

Location: Highbury, London

Age: 66

Posts: 61

Likes: 0

Received 0 Likes

on

0 Posts

Yes, and this has been discussed a dozen times here. Of course one reason for the certification requirement for certain control forces at increasing angles of attack is there to make it harder to stall the aircraft inadvertently, but the primary reason for MCAS is to fulfill very specific criteria for control forces (14 CFR, §25.173), and even more specific instructions on how to demonstrate their fulfillment (14 CFR, §25.175).

Ok, I'm with you - I've read most of this thread and yes, the intent of MCAS seems clear. Perhaps I wouldn't have reacted if he'd said "intended to be a handling qualities function" instead of "is...". Maybe wrongly, I mentally separate emulation from underlying functionality (computer background) and that doesn't apply here? As if, in this case, "sure, it's just like the NG but boy, we had to screw with the kernel to get that working".

Join Date: May 2016

Location: Nantes

Posts: 63

Likes: 0

Received 0 Likes

on

0 Posts

my apologies. Misunderstanding. I was just referring to 737 needing AND trim all the time during acceleration.

all you say is correct. The NNP for runaway stab. Is predicated on staying ahead of trim requirements. To avoid the last ditch heave up , and unload- TRIM TRIM TRIM NU routine. Use trim switches NU until stab back in trim - not blip blip , but major NU input over several seconds. STAB OFF. TRIM Manually thereafter. In runaway stab in previous variants by the time you notice, the stab. will be a couple of divisions AND. Or more and requires a sustained ANU input.

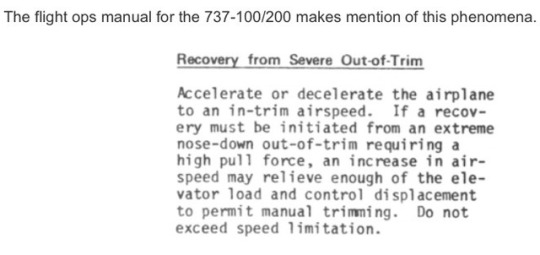

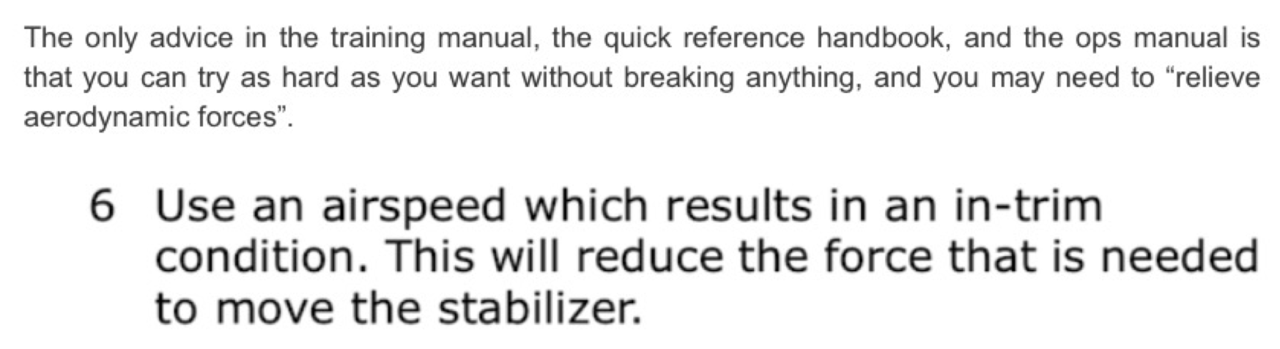

Recent training handbook also recommend using the speed for which the aircraft is trimmed, i.e. AND => increasing speed

In the case of ET 302, it is clear that INCREASING speed had no chance of success and lead to loosing control.

REDUCING speed would have caused a pitch down moment induced by static stability and by reduced thrust, which AMHO could have been counteracted by elevator, until the moment when the aerodynamic loads would have been alleviated enough to permit manual trimming. If manuel trim were still jammed, aft forces required on the column to maintain level flight would have been lower (due to logic of feel and centering system) with no risk of elevator blowback anymore.

Join Date: May 2016

Location: Nantes

Posts: 63

Likes: 0

Received 0 Likes

on

0 Posts

MCAS was not there to prevent stall (which was already very unlikely) it was there to improve already excellent (though not certifiable) flying qualities

Join Date: Jul 2007

Location: the City by the Bay

Posts: 547

Likes: 0

Received 0 Likes

on

0 Posts

These accidents cast doubt not only on the max but also on Boeing itself and on the FAA. The aljazeera expose on the 787 didn’t put Boeing in a good light about the 787. Now I wonder about the 777x. What did they cock up on that plane that we don’t know about yet? After all who the heck heard of MCAS before? Now it’s Boeing’s 4 letter word as in “ don’t MCAS it up now Jimmy”.

if that plane turns up broken or poorly thought out then Boeing will have nothing but flawed planes. I’m less proud and trustful of Boeing now than I was before. Same goes for the FAA being the authority it used to be.

killing Ralph Naders niece on the Egyptian flight was also bad for PR . Watch out he doesn’t come out with a new book.

“ unsafe at any speed -Boeing’s Corvair”.

Think i I will avoid the Max and the new 777x for a while

if that plane turns up broken or poorly thought out then Boeing will have nothing but flawed planes. I’m less proud and trustful of Boeing now than I was before. Same goes for the FAA being the authority it used to be.

killing Ralph Naders niece on the Egyptian flight was also bad for PR . Watch out he doesn’t come out with a new book.

“ unsafe at any speed -Boeing’s Corvair”.

Think i I will avoid the Max and the new 777x for a while

Last edited by armchairpilot94116; 10th Apr 2019 at 14:31.

Join Date: Jul 2007

Location: Germany

Posts: 556

Likes: 0

Received 0 Likes

on

0 Posts

"Someone had this brilliant idea and it's obviously so much better!" is not sufficient.

Neither is "it doesn't suffer from this particular problem, therefore it's always better."

Bernd

Alchad

https://utcaerospacesystems.com/prod...-data-systems/

https://www.swiss-airdata.com

https://www.flightglobal.com/FlightP...20-%202855.PDF

The "alternative to AoA vanes" have been in use on commercial jet aircraft for quite a while. A moving vane is old style.

https://www.swiss-airdata.com

https://www.flightglobal.com/FlightP...20-%202855.PDF

The "alternative to AoA vanes" have been in use on commercial jet aircraft for quite a while. A moving vane is old style.

Join Date: Nov 2018

Location: Vancouver

Posts: 68

Likes: 0

Received 0 Likes

on

0 Posts

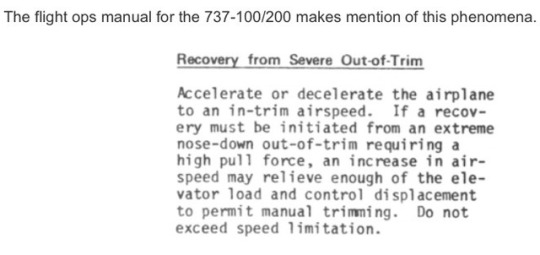

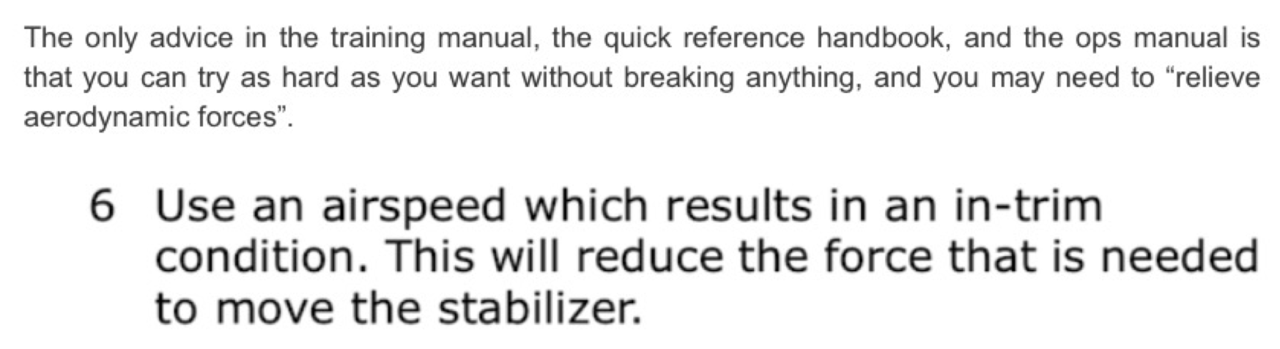

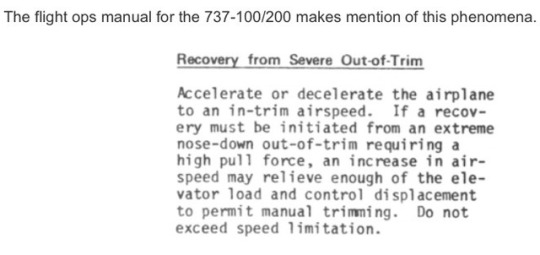

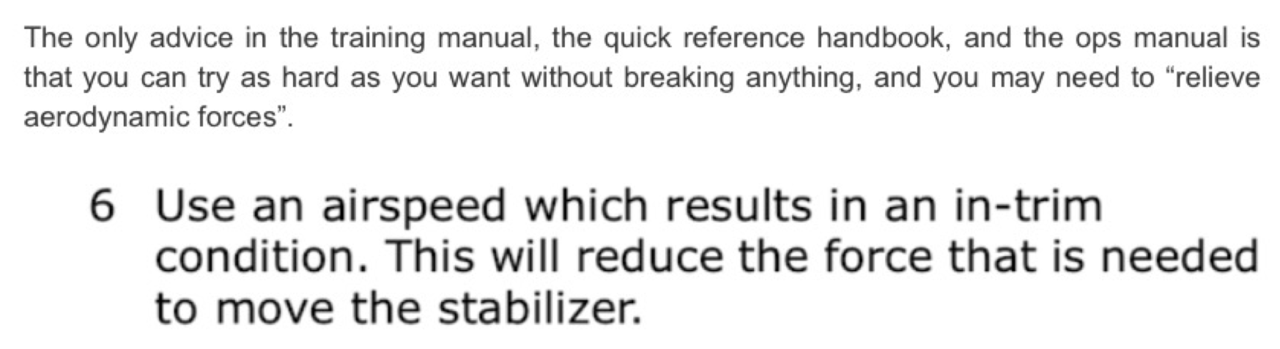

Here is what I was referring to (published by satguru) :

Recent training handbook also recommend using the speed for which the aircraft is trimmed, i.e. AND => increasing speed

In the case of ET 302, it is clear that INCREASING speed had no chance of success and lead to loosing control.

REDUCING speed would have caused a pitch down moment induced by static stability and by reduced thrust, which AMHO could have been counteracted by elevator, until the moment when the aerodynamic loads would have been alleviated enough to permit manual trimming. If manuel trim were still jammed, aft forces required on the column to maintain level flight would have been lower (due to logic of feel and centering system) with no risk of elevator blowback anymore.

Recent training handbook also recommend using the speed for which the aircraft is trimmed, i.e. AND => increasing speed

In the case of ET 302, it is clear that INCREASING speed had no chance of success and lead to loosing control.

REDUCING speed would have caused a pitch down moment induced by static stability and by reduced thrust, which AMHO could have been counteracted by elevator, until the moment when the aerodynamic loads would have been alleviated enough to permit manual trimming. If manuel trim were still jammed, aft forces required on the column to maintain level flight would have been lower (due to logic of feel and centering system) with no risk of elevator blowback anymore.

..

Or, you can watch most of it here...

-

Join Date: Jul 2007

Location: Germany

Posts: 556

Likes: 0

Received 0 Likes

on

0 Posts

https://utcaerospacesystems.com/prod...-data-systems/

https://www.swiss-airdata.com

https://www.flightglobal.com/FlightP...20-%202855.PDF

The "alternative to AoA vanes" have been in use on commercial jet aircraft for quite a while. A moving vane is old style.

https://www.swiss-airdata.com

https://www.flightglobal.com/FlightP...20-%202855.PDF

The "alternative to AoA vanes" have been in use on commercial jet aircraft for quite a while. A moving vane is old style.

But what's probably more important: they are robust. The "smart sensors" measure pressures at various holes to compute AoA, and these small holes are much more susceptible to icing and being clogged by dirt, in other words, these probes are much more sensitive to less-than-perfect environmental conditions. A partial obstruction of only one of those holes will (perhaps subtly) alter the value. And while that may be fine for an immaculately polished business jet, it is probably not ideal for commercial line operation.

How do you think any of the known accidents involving AoA probes would have been prevented by "modern" sensors?

- QF 72: A problem with the ADIRU sending wrong data to the flight control computers. Nothing to do with the mechanical properties of the sensor

- XL Airways Perpignan: AoA vane frozen solid because of improper washing procedures: Could just as easily have happened with "smart" vanes. Possibly slightly different failure more, but small orifices can easily ice over or get clogged

- Lion Air: We don't know, but possibly also data processing, or else mechanical damage or improper installation. "Smart" probes will also give undefined/wrong values when damaged or installed improperly

- Ethiopian: quite likely a sheared off vane. Any force that does that would also severely impact a "smart" probe.

So? Just because something is "old style" doesn't mean it's bad, or that newer things are necessarily better. I think AoA sensors without moving parts have not yet proven to be as good as traditional vanes.

Bernd

Join Date: May 2010

Location: Boston

Age: 73

Posts: 443

Likes: 0

Received 0 Likes

on

0 Posts

And what do you think is the reason the use of these is not more widespread? I would assume that the main reasons are: mechanical vanes are straightforward, and a standby instrument can just display a value without any computation.

But what's probably more important: they are robust. The "smart sensors" measure pressures at various holes to compute AoA, and these small holes are much more susceptible to icing and being clogged by dirt, in other words, these probes are much more sensitive to less-than-perfect environmental conditions. A partial obstruction of only one of those holes will (perhaps subtly) alter the value. And while that may be fine for an immaculately polished business jet, it is probably not ideal for commercial line operation.

...

...

So? Just because something is "old style" doesn't mean it's bad, or that newer things are necessarily better. I think AoA sensors without moving parts have not yet proven to be as good as traditional vanes.

Bernd

But what's probably more important: they are robust. The "smart sensors" measure pressures at various holes to compute AoA, and these small holes are much more susceptible to icing and being clogged by dirt, in other words, these probes are much more sensitive to less-than-perfect environmental conditions. A partial obstruction of only one of those holes will (perhaps subtly) alter the value. And while that may be fine for an immaculately polished business jet, it is probably not ideal for commercial line operation.

...

...

So? Just because something is "old style" doesn't mean it's bad, or that newer things are necessarily better. I think AoA sensors without moving parts have not yet proven to be as good as traditional vanes.

Bernd

This would greatly reduce chances of a common design/environmental fault affecting AoA values.

BTW: The B2 that was totalled in Guam went down due to blocked/miscalibrated sensors, so they are not infallible either.

And what do you think is the reason the use of these is not more widespread? I would assume that the main reasons are: mechanical vanes are straightforward, and a standby instrument can just display a value without any computation.

But what's probably more important: they are robust. The "smart sensors" measure pressures at various holes to compute AoA, and these small holes are much more susceptible to icing and being clogged by dirt, in other words, these probes are much more sensitive to less-than-perfect environmental conditions. A partial obstruction of only one of those holes will (perhaps subtly) alter the value. And while that may be fine for an immaculately polished business jet, it is probably not ideal for commercial line operation.

Bernd

But what's probably more important: they are robust. The "smart sensors" measure pressures at various holes to compute AoA, and these small holes are much more susceptible to icing and being clogged by dirt, in other words, these probes are much more sensitive to less-than-perfect environmental conditions. A partial obstruction of only one of those holes will (perhaps subtly) alter the value. And while that may be fine for an immaculately polished business jet, it is probably not ideal for commercial line operation.

Bernd

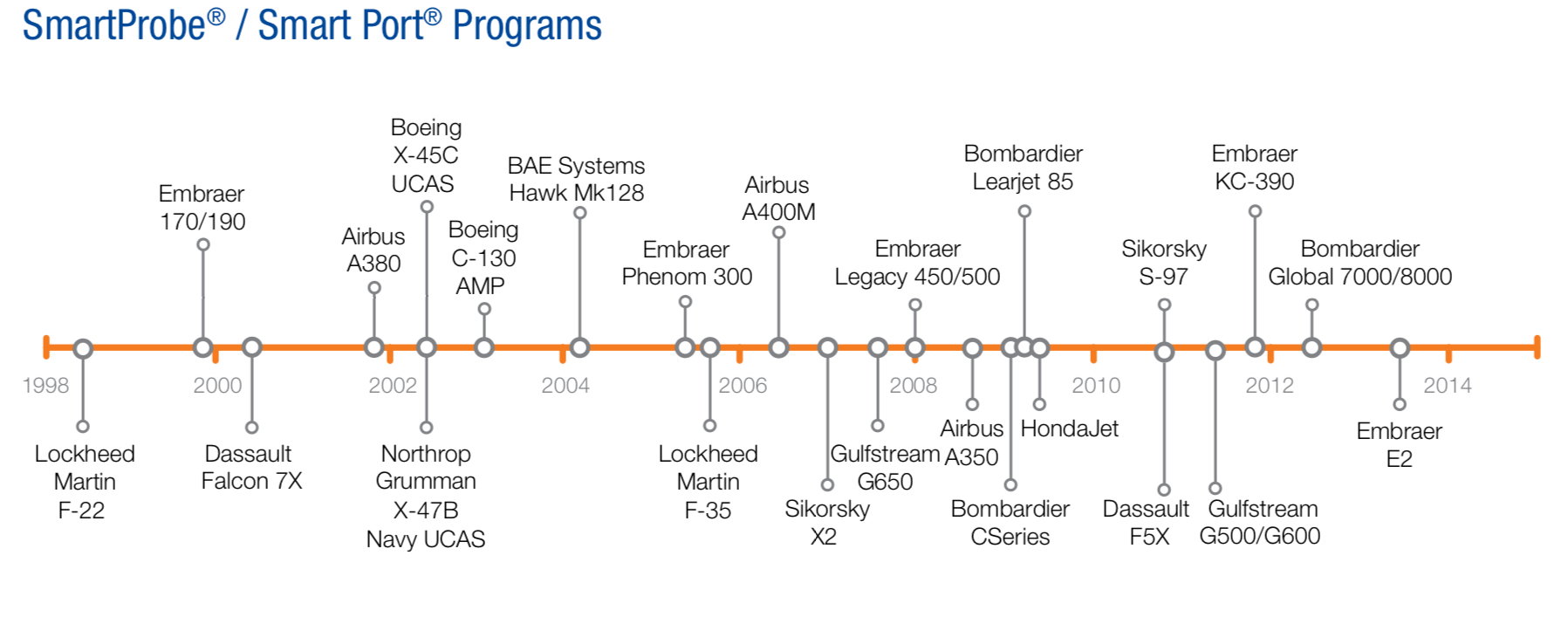

Maybe your idea of widespread is different to mine as just one manufacturer of this style of probe has quite a broad customer base - including Boeing, LM, Airbus, Northrop Grumman, BAES, Bombardier, Embraer, Sikorsky, Dassault, Gulfstream et al.

Your claim on sensitivity to environmental conditions looks odd for a probe type used on everything from battlefield helicopters and tactical airlifters all the way through to supersonic fighter aircraft and supersonic bombers. Airbus have been using them for nearly 20 years across a number of types!

Join Date: Jul 2004

Location: Found in Toronto

Posts: 615

Likes: 0

Received 0 Likes

on

0 Posts

I am not worried about the video because:

1) They purposely trimmed THE WRONG WAY just to see what happens.

2) It is a simulator and may not accurately reflect actual aircraft operation in the same situation.

Last edited by Lost in Saigon; 10th Apr 2019 at 17:01.

Join Date: Jun 2009

Location: Dorset

Posts: 31

Likes: 0

Received 0 Likes

on

0 Posts

From #3820 “Aviation Week: Boeing Expands MCAS Demos To Speed Lifting Of 737 MAX Grounding”: There is not a single mention of SMYD, obviously Boeing cannot allow the stick shaker to still be driven by an invalid AoA. Boeing would not need to mention SMYD if, for the MAX, they had changed AoA processing and supplied AoA L & R data from the FCC directly to the SYMD via the ARINC 429 bus. It would make sense to do the processing only in one system and may help with CPU loading.

The idea that the invalid AoA problem is a fault, or different faults, in 3 AoA sensors seems to me to be very unlikely, purely from a consideration of reliability figures. AoA sensors are very reliable, from satcom.guru on 28th March:-

Reliability of the AoA sensor was evaluated over a 4-6 year period, with a mean time between unscheduled removals was 93,000 hours. A typical airframe is modeled at about 100,000 hours, so the AoA vane typically last nearly the lifetime of the airplane.

As has been suggested in an earlier post, there could be vulnerability in a new harness which causes a short circuit on a resolver signal. Or (back on my favoured suspect) a latent software fault which affects the processing of the AoA data.

There is an anomaly in the FDR for ET302 (Preliminary Report, page 26) at 05:38:42. It seems to show the Control Column L was pushed forward a second or two before Stick Shaker L started! This could be because the SMYD, if it gets its AoA data from the FCC, is running a cycle behind the FCC. Or it could just be an aspect of the ARINC bus data rates. If I recall correctly, there are various data rates available, and a fast changing control parameter going from one system to another (such as Control Column Position) would go at the fastest rate. A slow changing parameter only for diagnostics (such as Stick Shaker) would go at the slowest rate.

The idea that the invalid AoA problem is a fault, or different faults, in 3 AoA sensors seems to me to be very unlikely, purely from a consideration of reliability figures. AoA sensors are very reliable, from satcom.guru on 28th March:-

Reliability of the AoA sensor was evaluated over a 4-6 year period, with a mean time between unscheduled removals was 93,000 hours. A typical airframe is modeled at about 100,000 hours, so the AoA vane typically last nearly the lifetime of the airplane.

As has been suggested in an earlier post, there could be vulnerability in a new harness which causes a short circuit on a resolver signal. Or (back on my favoured suspect) a latent software fault which affects the processing of the AoA data.

There is an anomaly in the FDR for ET302 (Preliminary Report, page 26) at 05:38:42. It seems to show the Control Column L was pushed forward a second or two before Stick Shaker L started! This could be because the SMYD, if it gets its AoA data from the FCC, is running a cycle behind the FCC. Or it could just be an aspect of the ARINC bus data rates. If I recall correctly, there are various data rates available, and a fast changing control parameter going from one system to another (such as Control Column Position) would go at the fastest rate. A slow changing parameter only for diagnostics (such as Stick Shaker) would go at the slowest rate.

Join Date: Dec 2015

Location: Cape Town, ZA

Age: 62

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

An edited GIF version of Mentour Pilot Video...

..Or, you can watch most of it here...

- https://vimeo.com/329558134

..Or, you can watch most of it here...

- https://vimeo.com/329558134

I wonder if Boeing's lawyers saw this last week, and said to the CEO: "If the jury ever sees this, we have lost already"...

If you don't want to watch the video, the transcript is equally compelling reading...

The original sim session transcript [C=CAPT; F=FO]:

C: We have an IAS disagree.

C: So, IAS disagree memory items.

F: Autopilot if engaged, disengage.

C: Disengaged!

F: Autothrottle if engaged, disengage.

C: Disengaged!

F: Flight directors - Both up

F: With flaps up established a flight path 4 degrees and 75% N1.

C: So, 75% N1.

F: We have 77, 76,...

C: A little bit less...

F: And, there you go.

C: 4 degrees.

F: 4 degrees.

C: So I am trying to establish this now.

F: Check!

F: We are descending...?

F: We probably... Are you feeling troubled with...

F :Any trouble with the flight control?

C: Yeah, I'm trying to trim it but...

C: It continues to trim against me when I'm trimming

C: So state the malfunction, please.

F: Yeah, this doesn't look right. Looks like uh...

F: How do you feel the stabilizer, the trim system?

F: Can you control it?

C: I'm trimming it. It is responding but...

F: It's a runaway stabilizer, if you agree?

C: For every time that I trim backward, it keeps trimming forward.

F: It's trimming forward. Yeah, it's runaway stabilizer.

C: So, runaway stabilizer memory items...

C: And i'm trying to keep this thing at 4 degrees.

F: Control column, hold firmly.

C: I am... [CAPT is holding the yoke firmly with both hands]

F: Autopilot - if engaged, disengage.

C: It's disengaged.

F: Autothrottle - if engaged, disengage.

C: It's..., if you can disengage it for me, make sure that it's disengaged.

F: It's disengaged.

F: And, do you feel that the failure stop?

F: Negative?

C: No, it's still moving.

F: Stab trim cutoff switches to cutoff.

F: OK. It stops. It looks like it stops.

C: You can see now I'm using almost full back pressure here.

F: Exactly.

C: How many degrees nose down?

F: We have 4 units nose down now

C: 4 units nose down?

F: Yup.

C: OK, I'm struggling.

C: I'm actually using almost my full force to keep the aircraft level here.

F: Do you want me to help you?

C: What I would like to do.

C: Just for the sake of exercise, can you trim this forward? [to simulate MCAS trim AND]

C: See if we can reach even zero nose down.

C: And see if I can even hold it.

[FO is trying to crank the trim wheel to reach zero nose down, simulating MCAS AND]

C: So, now we are doing this just as an exercise!

C: Do not try this at home.

C: This...

C: We are at 300 knots now.

F: I'm fighting.

C: I'm sttrugling to to keep this aircraft flying.

F: My god! [FO surprised at how hard it is to trim further nose down]

C: Yeah, the thing is with higher speed the force on the stabilizer will be higher and higher as well.

C: So it becomes almost impossible to move it.

C: So we are now at about 3 degrees.

F: Yup. [FO still tries to continue trimming nose down, the wheels is so difficult to spin]

C: We're still about 3 degrees away from full nose down trim.

C: And I am using everything that I have. [CAPT still holding on to his yoke with both hands]

F: My God ! [the trim wheel barely move for the down trim]

C: This is realistic guys.

C: This is how much of effort it would take to trim the stabilizer at this kind of speed.

C: Umph... [Capt is still trying to hold on to his yoke with his hands]

C: I'm just in control of it, though. But it's getting harder and harder.

C: And remember we're still 2.5 degrees away...

F: My God! [FO still struggles to spin the refused-to-be-spun trim wheel]

C: It's not possible, is it?

C: All right, we stop at that.

C: The reason that we have to try...

C: The reason we have to trim this manually is because the normal trim system wouldn't do this, OK.

C: It would require manual trim to get it away from this.

C: That's fine.

C: Trim it backward. [This time to illustrate the effort to trim the nose back up after "MCAS" brought the AC further nose down]

C: Trim it backward as you can.

F: Oh my God! I couldn't... [FO can't spin the wheel to trim up]

C: OK.

C: Eh...

C: Juan, press the red button! [CAPT called the sim operator...]

C: Press the red button now. [to stop the sim session]

C: This is at 340 knots.

C: And the trim is at...It's still at almost 2.5 degrees.

F: Yeah, 2.5 degrees.

Alchad

Last edited by Alchad; 10th Apr 2019 at 17:18.

Join Date: Dec 2015

Location: Cape Town, ZA

Age: 62

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

Alchad

Many people (still) blame the pilots for getting into that situation, by not taking action sooner. All sorts of clever answers are possible, for those sitting at home, and having had time to read the accident report.

I've nothing to do with the aviation industry, but that video is very disturbing, those guys knew it was a simulation, if your (and others) life depended on it, truly frightening. If any pilot on here cares to explain that it's not realistic, or a fair approximation of what happened, please do.