Atlas Air 767 down/Texas

"Mildly" Eccentric Stardriver

Full marks to the FAA for the video. There is a faint chance that someone who knows what they are talking about may spot a point overlooked by the investigators. Note I did say someone who knows what they are talking about.

Join Date: Nov 1999

Location: Mk. 1 desk at present...

Posts: 365

Likes: 0

Received 0 Likes

on

0 Posts

From the fact that it was the Sheriff being interviewed in the second clip, I think it's fair to conclude that it was the Sheriff that invited the reporter in, not the NTSB; it seems the NTSB do not have 'exclusive custody' of the wreckage.

Join Date: Feb 2004

Location: Australia

Posts: 1,307

Likes: 0

Received 0 Likes

on

0 Posts

Where does the transponder get power from on the 767?

Join Date: Jun 2001

Location: Rockytop, Tennessee, USA

Posts: 5,898

Likes: 0

Received 1 Like

on

1 Post

Join Date: Jun 2001

Location: Rockytop, Tennessee, USA

Posts: 5,898

Likes: 0

Received 1 Like

on

1 Post

If there is evidence of a crime, the DOJ may also claim jurisdiction. Normally this is not a problem but there have been disputes, or so it is claimed. One famous example is the TWA 800 crash in 1996.

Join Date: Feb 2004

Location: Australia

Posts: 1,307

Likes: 0

Received 0 Likes

on

0 Posts

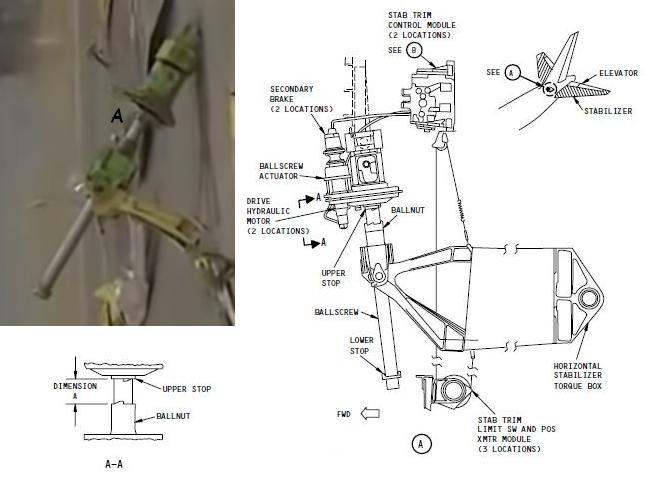

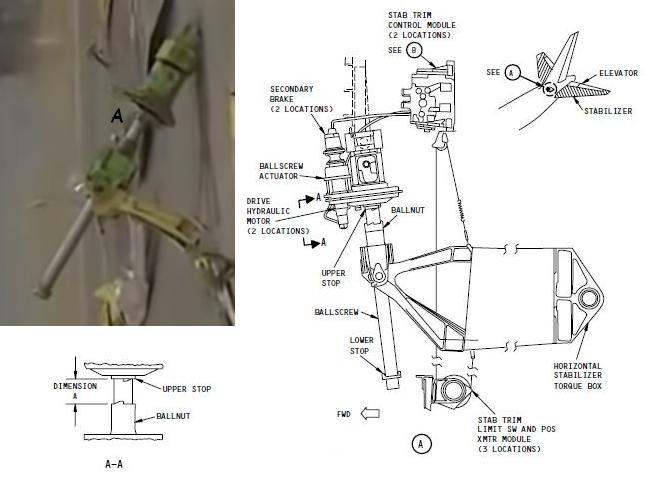

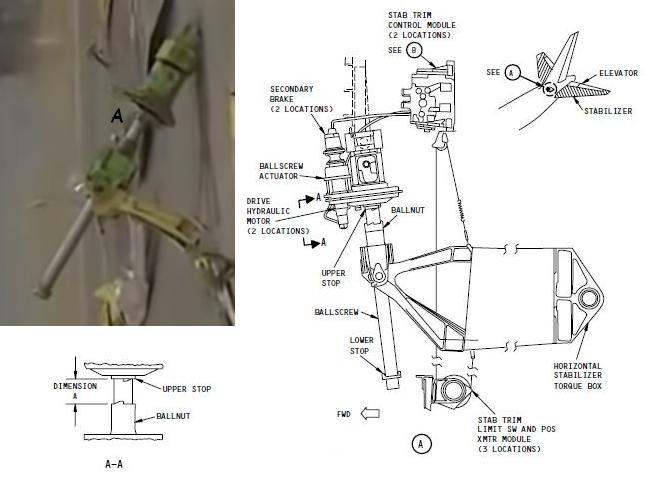

There is no mention of total jackscrew length or diameter in the manual, so it will be difficult to create scale diagrams of the assembly. The trim only moves the assembly 21.51 inches during control column trimming (less if the flaps are less than 5 units). i.e. from 0.25 units (full nose down) to 12.8 units (full nose up) with column switches. Maximum range of the stabilizer is 0~14.2 units. 2 units is neutral.

At full nose down (0.25 units), the top of the moving part (ballnut) is within an inch of the upper stop.

Join Date: Jun 2001

Location: Rockytop, Tennessee, USA

Posts: 5,898

Likes: 0

Received 1 Like

on

1 Post

Good find.

Positioning in the video looks "close to" neutral. Not close to either stop. Unless it jammed there (and neutral was not the trim needed) or the whole unit broke loose from its mounts, that seems to minimize the odds of a THS jackscrew problem. (But you just never know).

On another note - probably having no significance to the accident - I have tentatively ID'd the "biggest part found so far" (shown at 5:10 in the reporter's first walk-around video, post 362) as the bottom half of the left winglet, and its junction with the wing tip.

Positioning in the video looks "close to" neutral. Not close to either stop. Unless it jammed there (and neutral was not the trim needed) or the whole unit broke loose from its mounts, that seems to minimize the odds of a THS jackscrew problem. (But you just never know).

On another note - probably having no significance to the accident - I have tentatively ID'd the "biggest part found so far" (shown at 5:10 in the reporter's first walk-around video, post 362) as the bottom half of the left winglet, and its junction with the wing tip.

Join Date: Jun 2010

Location: Nanaimo, B.C.

Age: 66

Posts: 49

Likes: 0

Received 0 Likes

on

0 Posts

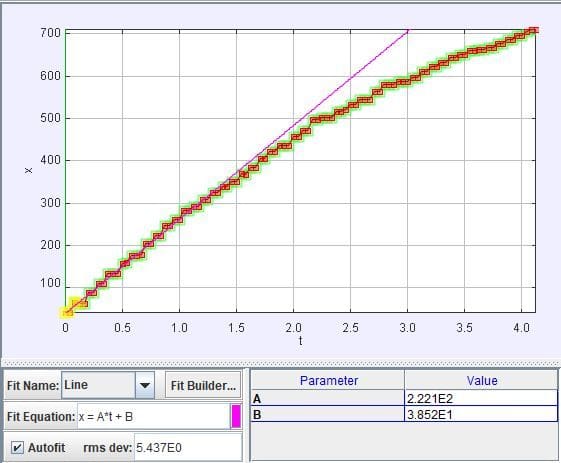

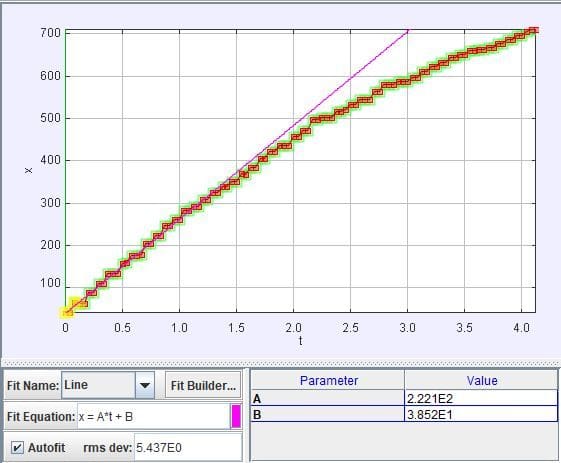

Tracker Video Analysis

This is an analysis of the video using the Tracker video analysis program. I used the wingspan to calibrate distance, set the x-axis along the aircraft's track, and used the starboard engine to track the motion. I had to interpolate some frames when the aircraft was hidden behind the tree so take the middle of the graph with a grain of salt. There were also repeated frames in the video for some reason. FWIW, this is the result. Analysis shows that the ROD appears to change from over 200 m/s to just over 100 m/s towards the end of the sequence. Another source of error is using the wingspan to calibrate because the aircraft is banked relative to the camera.

Join Date: Jun 2010

Location: Nanaimo, B.C.

Age: 66

Posts: 49

Likes: 0

Received 0 Likes

on

0 Posts

Correct. The zero reference point was set at the tail of the aircraft in the first frame it was visible. The slope of this graph is ROD. Time is on the x-axis, displacement from the reference point on the y-axis.

Join Date: Jul 2013

Location: Norway

Age: 57

Posts: 140

Likes: 0

Received 0 Likes

on

0 Posts

dash34,

The video is grainy, and the branch is in the way too, but I think I am seing that the wings towards the end of the video is deflected significantly upwards, like in a very hard pull up at very high speed. Such an observation is in line with your suggestion that the ROD was decreasing significantly at the end of the video.

The video is grainy, and the branch is in the way too, but I think I am seing that the wings towards the end of the video is deflected significantly upwards, like in a very hard pull up at very high speed. Such an observation is in line with your suggestion that the ROD was decreasing significantly at the end of the video.

Join Date: Jul 2013

Location: Norway

Age: 57

Posts: 140

Likes: 0

Received 0 Likes

on

0 Posts

I haven't spent much time in the forward stabilizer compartment, but your image seems to match the maintenance manual.

There is no mention of total jackscrew length or diameter in the manual, so it will be difficult to create scale diagrams of the assembly. The trim only moves the assembly 21.51 inches during control column trimming (less if the flaps are less than 5 units). i.e. from 0.25 units (full nose down) to 12.8 units (full nose up) with column switches. Maximum range of the stabilizer is 0~14.2 units. 2 units is neutral.

At full nose down (0.25 units), the top of the moving part (ballnut) is within an inch of the upper stop.

There is no mention of total jackscrew length or diameter in the manual, so it will be difficult to create scale diagrams of the assembly. The trim only moves the assembly 21.51 inches during control column trimming (less if the flaps are less than 5 units). i.e. from 0.25 units (full nose down) to 12.8 units (full nose up) with column switches. Maximum range of the stabilizer is 0~14.2 units. 2 units is neutral.

At full nose down (0.25 units), the top of the moving part (ballnut) is within an inch of the upper stop.

This is obviously the HS jack screw. It seems like it is at about position 2.5 or 3. So, close to neutral or slightly nose up.

Last edited by SteinarN; 9th Mar 2019 at 13:47.

Positioning in the video looks "close to" neutral. Not close to either stop. Unless it jammed there (and neutral was not the trim needed) or the whole unit broke loose from its mounts, that seems to minimize the odds of a THS jackscrew problem. (But you just never know).

On the other hand, we could be looking at a perfectly serviceable jackscrew. There just isn't enough definition in the photo to tell.

Join Date: Aug 2017

Location: London

Posts: 94

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: Sep 2014

Location: UK

Posts: 98

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: Feb 2004

Location: Australia

Posts: 1,307

Likes: 0

Received 0 Likes

on

0 Posts

"Based on that, looks to me like recovered part is in full nose down position. Am I missing something? "

Pilot input required here. If you're flying straight and level with the flap setting required at 6000 feet (?), what's the average trim setting? (aka... how long is a piece of string).

If the Statement:

"At full nose down (0.25 units), the top of the moving part (ballnut) is within an inch of the upper stop."

is correct, then the photographed screwjack is 80 to 90% Nose Down.

(look at the length of screwjack extending below the ballnut to the lower stop).

Whether this was how it was recovered, or if all the threads were stripped, would reduce the significance of the photo.

"At full nose down (0.25 units), the top of the moving part (ballnut) is within an inch of the upper stop."

is correct, then the photographed screwjack is 80 to 90% Nose Down.

(look at the length of screwjack extending below the ballnut to the lower stop).

Whether this was how it was recovered, or if all the threads were stripped, would reduce the significance of the photo.