Helicopter crash off the coast of Newfoundland - 18 aboard, March 2009

Join Date: Nov 2003

Location: Canada

Posts: 68

Likes: 0

Received 0 Likes

on

0 Posts

Sorry to be picky SASless but according to the report published by CBC, zero pressure has been lost at 5740 feet not 800, which in my view highlight even more your questionning:

12:17:42 CHI advises Gander ACC that they have lost all main gearbox oil pressure. CHI91 is descending through an altitude of 5,740 feet.

Back of what you say I agree, and the following months will tell us a lot more.

FH

12:17:42 CHI advises Gander ACC that they have lost all main gearbox oil pressure. CHI91 is descending through an altitude of 5,740 feet.

Back of what you say I agree, and the following months will tell us a lot more.

FH

Geoff,

No I do not have an electronic copy of the HARP Report (CAP 491 - 1984) but, courtesy of Adobe Acrobat and OCR, here is section 7.7 - Gear box and Transmission:

The text in paragraph 8.5 (referred to above) contains recommendations for 'condition monitoring'; methods include: chip detectors; vibration monitoring; thermal detection or imaging in flight; oil sampling; telemetry (i.e. instantaneous download of HUMS data); and usage monitoring.

Jim

No I do not have an electronic copy of the HARP Report (CAP 491 - 1984) but, courtesy of Adobe Acrobat and OCR, here is section 7.7 - Gear box and Transmission:

The most complex element of a helicopter, after perhaps the engine, is the transmission gearbox, taking the drive at high speed from one, two or more engines generally in a horizontal plane, and gearing it down by 80 or 100 to 1, or so, to a single vertical shaft carrying the rotor head, with another drive going rearward to a tail rotor (or another rotor head system), the engines having free Wheels, and accessory drives being taken off for generators and oil pumps.

These gearboxes are remarkable examples of the art of the mechanical engineer. Although simplicity is a good starting point in the conceptual stage, complexity is inevitable, and it is not surprising that each designer has found his own solutions. The panel has seen spur gear trains, epicyclics, bevels; it has seen normal straight teeth, 'conformal' tooth profiles; it has seen ball bearings, rollers, tapered rollers, shafts with separate ball races and shafts with rollers running direct on them; we have seen aluminium and magnesium alloy cases. The only common element noted was in the gear material, a traditional low carbon nickel-chrome case hardening steel, either carburised or nitrided, and invariably made of high purity vacuum melted stock.

Notwithstanding the exceptional facilities for gear production we were shown, and the great attention to quality control being paid we are bound to record that in our view it will never be possible to eliminate completely the possibility of failure of some part of so complex a mechanism in service, between specified inspection or overhaul periods.

Although minor surface damage to a gear or bearing is unlikely to be instantly catastrophic, and should be detectable, and although gearboxes are tested to run for a period such as 30 minutes with the oil supply failed, the possibility of a major failure within the box is ever present.

Since with present knowledge a main rotor cannot be duplicated although a tail rotor gearbox might (conceivably a helicopter may survive the failure of the latter) we now come up against the fundamental difference between normal aircraft and rotorcraft -the inability to guard against a possible defect by duplication.

The Panel believes that, while gearbox development and testing should be as stringent as practicable, other means must be introduced to monitor the condition or "health" of the gearbox, preferably in flight. Elementary condition monitoring is already practiced (e.g. oil chip detectors), but much more attention should be paid to this. We make our detail recommendations on this subject later in para. 8.5.

There have been failures of transmission systems taking the drive to the tail rotor, or coupling twin rotor heads. We believe it may be possible to achieve a degree of redundancy here, or at any rate 'damage tolerance'. On the other hand it may be simpler to have some other method of cancelling main rotor torque to use in an emergency (bleed gas jet, rudder surface •••••• )

These gearboxes are remarkable examples of the art of the mechanical engineer. Although simplicity is a good starting point in the conceptual stage, complexity is inevitable, and it is not surprising that each designer has found his own solutions. The panel has seen spur gear trains, epicyclics, bevels; it has seen normal straight teeth, 'conformal' tooth profiles; it has seen ball bearings, rollers, tapered rollers, shafts with separate ball races and shafts with rollers running direct on them; we have seen aluminium and magnesium alloy cases. The only common element noted was in the gear material, a traditional low carbon nickel-chrome case hardening steel, either carburised or nitrided, and invariably made of high purity vacuum melted stock.

Notwithstanding the exceptional facilities for gear production we were shown, and the great attention to quality control being paid we are bound to record that in our view it will never be possible to eliminate completely the possibility of failure of some part of so complex a mechanism in service, between specified inspection or overhaul periods.

Although minor surface damage to a gear or bearing is unlikely to be instantly catastrophic, and should be detectable, and although gearboxes are tested to run for a period such as 30 minutes with the oil supply failed, the possibility of a major failure within the box is ever present.

Since with present knowledge a main rotor cannot be duplicated although a tail rotor gearbox might (conceivably a helicopter may survive the failure of the latter) we now come up against the fundamental difference between normal aircraft and rotorcraft -the inability to guard against a possible defect by duplication.

The Panel believes that, while gearbox development and testing should be as stringent as practicable, other means must be introduced to monitor the condition or "health" of the gearbox, preferably in flight. Elementary condition monitoring is already practiced (e.g. oil chip detectors), but much more attention should be paid to this. We make our detail recommendations on this subject later in para. 8.5.

There have been failures of transmission systems taking the drive to the tail rotor, or coupling twin rotor heads. We believe it may be possible to achieve a degree of redundancy here, or at any rate 'damage tolerance'. On the other hand it may be simpler to have some other method of cancelling main rotor torque to use in an emergency (bleed gas jet, rudder surface •••••• )

Jim

Geoffers,

I will have to challenge your maths on Chinook gearboxes.

I will happily accept there are three gear

boxes that if failed will end in tears...those being the Forward, Aft, and Combining gear boxes.

The Nose Boxes....Engine Gear box to some....will cause a loss of engine power and depending upon which end of the drive shaft that connects the Nose Box to the Combining Transmission should fail....it could cause some interesting damage....but a Nose box failure in itself is not that critical.

I have experienced two Nose Box failures and am still here. Those failures were treated as a single engine failure. Both were benign events mechanically although one was a bit sporty due to the phase of flight we were in at the time.

I know of only one person who survived a main gear box failure and that was the survivor of the 234 Crash in the UK.

To put it into perspective....I know of no one that survived a spindle failure on 61's.

I will have to challenge your maths on Chinook gearboxes.

I will happily accept there are three gear

boxes that if failed will end in tears...those being the Forward, Aft, and Combining gear boxes.

The Nose Boxes....Engine Gear box to some....will cause a loss of engine power and depending upon which end of the drive shaft that connects the Nose Box to the Combining Transmission should fail....it could cause some interesting damage....but a Nose box failure in itself is not that critical.

I have experienced two Nose Box failures and am still here. Those failures were treated as a single engine failure. Both were benign events mechanically although one was a bit sporty due to the phase of flight we were in at the time.

I know of only one person who survived a main gear box failure and that was the survivor of the 234 Crash in the UK.

To put it into perspective....I know of no one that survived a spindle failure on 61's.

Join Date: Aug 2001

Location: Cornwall

Age: 75

Posts: 1,307

Likes: 0

Received 0 Likes

on

0 Posts

Gearbox designs

JimL

Thanks Jim, the last paragraph is prophetic (re the sync shafts in the 234) and my bleat was just a regurgitation of a long-standing gripe about the introduction into service of that particular aircraft which IMHO had just too many suspect design features, not least the gearboxes and the sync shaft.

I haven't met a Chinook pilot yet that didn't sing the praises of this amazingly capable 'war-machine' but I was never a fan of its presence in the civvy world. The trip from chip light to catastrophic failure seemed just a bit to quick for my liking.

SAS

It's been a long time since I discussed this design in detail, maybe 25 years, and at that time I believe we could not be assured that the angle gearbox would fail in a benign way. If you are telling me that now we different then I'll take your word. Unfortunately if any of the three remaining gearboxes seize then the machine will eat itself and kill all on board. The two that survived the accident in the NS are the exceptions that prove the rule I believe. Lady luck was with those two on that day that's for sure.

G.

Thanks Jim, the last paragraph is prophetic (re the sync shafts in the 234) and my bleat was just a regurgitation of a long-standing gripe about the introduction into service of that particular aircraft which IMHO had just too many suspect design features, not least the gearboxes and the sync shaft.

I haven't met a Chinook pilot yet that didn't sing the praises of this amazingly capable 'war-machine' but I was never a fan of its presence in the civvy world. The trip from chip light to catastrophic failure seemed just a bit to quick for my liking.

SAS

It's been a long time since I discussed this design in detail, maybe 25 years, and at that time I believe we could not be assured that the angle gearbox would fail in a benign way. If you are telling me that now we different then I'll take your word. Unfortunately if any of the three remaining gearboxes seize then the machine will eat itself and kill all on board. The two that survived the accident in the NS are the exceptions that prove the rule I believe. Lady luck was with those two on that day that's for sure.

G.

The Chinook as every new design helicopter has its problems when first fielded.

The Chinook was no different and at one time the early "A" models had as many road miles on them as they did air miles due to being flown out to the field and towed back during their introduction during the 11th Air Assault days at Fort Benning, Georgia.

We moved on through some other problems that were solved in time and now we see the Chinook as the work horse it is and will be seeing them doing the deal well towards the end of this Century.

There was a great deal of politics and resistance to introduction of the 234 on the North Sea. Alan Bristow did not want to invest such amounts of money in so few aircraft with what appeared to be a limited use.

It is interesting to note every single one of the 234's flown on the North Sea are still earning their keep daily with Columbia Helicopters hauling heavy external loads, logging, and fire fighting, all which are much harder on the aircraft than carrying passengers offshore.

But then....Columbia geared up to sustain the aircraft and drew from the vast amount of experienced Chinook people from the US Army as well as their BV-107 experience.

You are right.....I loved flying the Chinook and did so in the worst of situations and the old girls always brought me home. They gave me a few white hairs sometimes but that gives me stories to tell!

The Chinook was no different and at one time the early "A" models had as many road miles on them as they did air miles due to being flown out to the field and towed back during their introduction during the 11th Air Assault days at Fort Benning, Georgia.

We moved on through some other problems that were solved in time and now we see the Chinook as the work horse it is and will be seeing them doing the deal well towards the end of this Century.

There was a great deal of politics and resistance to introduction of the 234 on the North Sea. Alan Bristow did not want to invest such amounts of money in so few aircraft with what appeared to be a limited use.

It is interesting to note every single one of the 234's flown on the North Sea are still earning their keep daily with Columbia Helicopters hauling heavy external loads, logging, and fire fighting, all which are much harder on the aircraft than carrying passengers offshore.

But then....Columbia geared up to sustain the aircraft and drew from the vast amount of experienced Chinook people from the US Army as well as their BV-107 experience.

You are right.....I loved flying the Chinook and did so in the worst of situations and the old girls always brought me home. They gave me a few white hairs sometimes but that gives me stories to tell!

I seem to remember that a KLM S61 had a spindle failure resulting in the loss of a blade with everyone surviving. Happened shortly after touchdown on a rig!!!!!!!!!!!!!

In flight however would have a been a different story.

Just being picky!!!!

In flight however would have a been a different story.

Just being picky!!!!

Join Date: Sep 1998

Location: at the edge

Posts: 154

Likes: 0

Received 0 Likes

on

0 Posts

Not quite all of them Sas. Probably 4 out of 6 (1 crash, 1 ditch).

Bristow actually ordered 5x BV234 if you remember then cancelled. Although there were many reasons for the cancellation, there was a genuine concern regarding transmission failure and its likely catastrophic effects with the then Engineering Director and Operations Director.

A letter or memo expressing the concern was written, can't remember who the recipients were, we are talking 1979-80 era, just before the announcement of the AS332L order. I once had a copy but its long since gone.

Bristow actually ordered 5x BV234 if you remember then cancelled. Although there were many reasons for the cancellation, there was a genuine concern regarding transmission failure and its likely catastrophic effects with the then Engineering Director and Operations Director.

A letter or memo expressing the concern was written, can't remember who the recipients were, we are talking 1979-80 era, just before the announcement of the AS332L order. I once had a copy but its long since gone.

Helicopter Services in Norway had two within six months or so.....in flight with no survivors....timing is of the essence.

Join Date: Aug 2001

Location: Cornwall

Age: 75

Posts: 1,307

Likes: 0

Received 0 Likes

on

0 Posts

Transmission issues

the 234 story

SAS - There was a lot of talk at the time about the CAA being put under pressure by both the oil company and the operator as well as the manufacturer. I remember being at a 234 presentation (I was at BCALH at the time) at which they showed a video of a large model in a test tank demonstrating wonderful integral bouyancy capabilities but also demonstrating that every passing wave struck the (stationary) blade out front. I asked the Boeing bod about blade strikes after ditching and he quickly glossed over the subject. I later found out that any such blade strike is likely to result in a sync-shaft failure quickly followed by disintegration of the fuselage as the blades enmeshed above it. "So much for bouyancy" I thought. I later met the CAA Test Pilot and asked him about that and he changed the subject. Maybe he had the same thoughts as me?

G

SAS - There was a lot of talk at the time about the CAA being put under pressure by both the oil company and the operator as well as the manufacturer. I remember being at a 234 presentation (I was at BCALH at the time) at which they showed a video of a large model in a test tank demonstrating wonderful integral bouyancy capabilities but also demonstrating that every passing wave struck the (stationary) blade out front. I asked the Boeing bod about blade strikes after ditching and he quickly glossed over the subject. I later found out that any such blade strike is likely to result in a sync-shaft failure quickly followed by disintegration of the fuselage as the blades enmeshed above it. "So much for bouyancy" I thought. I later met the CAA Test Pilot and asked him about that and he changed the subject. Maybe he had the same thoughts as me?

G

Geoffers,

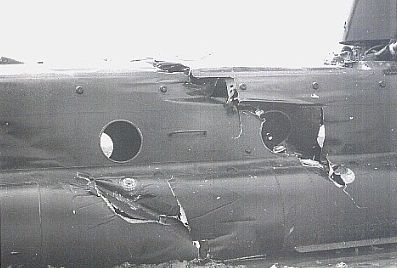

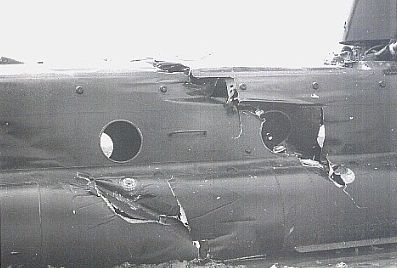

I cannot speak to the presentation you saw but I do know that synch shaft is actually a lot stronger than imagined as related to blade strikes. Lord knows we chopped down enough trees, power poles, PSP revetments and the like. The blades suffered but I do not know of an event that caused the airframe to tear itself apart unless it was the forward blades sweeping down through the synch shaft area and as far as half way into the cabin.

Usually that occurred after the aircraft sat down on top of an underslung load after having an engine failure and not being able to clear the load before touching down.

I am aware of one event where a ground taxi accident wound up with the forward blades chopping a twelve inch or more wooden power pole into a fence post and the only damage was to the blades and the Flight Engineer's under wear as he was stood against the thing directing the pilot. The blades cut through the pole about a foot above his head (he was a very tall rascal).

I do know she makes a fine boat and in fact I had a radio call sign one time of "Shrimp Boat" while instructing at the "other CFS".

This aircraft had an engine failure and landed on the underslung load....one fatality....guy was standing up when it all went wrong.

The end result of an unplanned EOL after running the aircraft out of fuel.

I cannot speak to the presentation you saw but I do know that synch shaft is actually a lot stronger than imagined as related to blade strikes. Lord knows we chopped down enough trees, power poles, PSP revetments and the like. The blades suffered but I do not know of an event that caused the airframe to tear itself apart unless it was the forward blades sweeping down through the synch shaft area and as far as half way into the cabin.

Usually that occurred after the aircraft sat down on top of an underslung load after having an engine failure and not being able to clear the load before touching down.

I am aware of one event where a ground taxi accident wound up with the forward blades chopping a twelve inch or more wooden power pole into a fence post and the only damage was to the blades and the Flight Engineer's under wear as he was stood against the thing directing the pilot. The blades cut through the pole about a foot above his head (he was a very tall rascal).

I do know she makes a fine boat and in fact I had a radio call sign one time of "Shrimp Boat" while instructing at the "other CFS".

This aircraft had an engine failure and landed on the underslung load....one fatality....guy was standing up when it all went wrong.

The end result of an unplanned EOL after running the aircraft out of fuel.

Last edited by SASless; 1st Apr 2009 at 17:44.

Join Date: Aug 2001

Location: Cornwall

Age: 75

Posts: 1,307

Likes: 0

Received 0 Likes

on

0 Posts

Transmission Design

SAS

I once gave a presentation at which I explained why we had chosen the MD902 for the London HEMS role. Afterwards the EC(F) rep cornered me and asked why I thought the NOTAR a better bet than the fenestron. I explained that in the crowded streets of London the fenestron still represented a theoretical threat and the NOTAR did not. Why should I take that (small) risk? He didn't answer but disappeared into the audience with a large 'thought' bubble over his head.

In the end it's all about risk management and I don't believe we should take one extra risk if we don't have to.

G.

I once gave a presentation at which I explained why we had chosen the MD902 for the London HEMS role. Afterwards the EC(F) rep cornered me and asked why I thought the NOTAR a better bet than the fenestron. I explained that in the crowded streets of London the fenestron still represented a theoretical threat and the NOTAR did not. Why should I take that (small) risk? He didn't answer but disappeared into the audience with a large 'thought' bubble over his head.

In the end it's all about risk management and I don't believe we should take one extra risk if we don't have to.

G.

Join Date: Nov 2005

Location: Monkeys ride bikes, ever seen one fix a puncture??

Posts: 356

Likes: 0

Received 0 Likes

on

0 Posts

One small point springs to mind, with regard to an earlier post regarding the crew of the Cougar cab noting abnormal indications, but no visible or audible signs such as vapour trails, smoke, flames or noises.

This, when coupled with a difference of opinions we used to have at the CAA HUMS users and North Sea operators gatherings, "Should HUMS data be displayed instantaneously in the cockpit?" JimL you will probably recall this, there was opposition to the displays because it was felt that the systems back then were not mature or reliable enough to provide definative data.. e.g. would a pilot ditch due to a displayed warning only? The general feeling back then from NS crews (About 5/6 years ago) was a resounding "no".. However, with modern aircraft such as S-92, where the old methods such as "noisy gearbox" etc MAY not be so evident to the crew, and given that HUMS and FDR data collection is now much more reliable and comprehensive, do we have a case for perhaps reviewing attitudes towards the onboard information and indications available to the crew? I concede that this fault most probably would not have been detectable via the HUMS / FDR but thats not to say that as in the case of the Dauphin main ring gear back in 2004, monitoring could be extended to cover new failure modes.

The arguments on here about commercial gains taking priority over safety remind me of a statement I once heard Eric Clark from Shell make..

"If you think flight safety is expensive, wait until you kill somebody"

This, when coupled with a difference of opinions we used to have at the CAA HUMS users and North Sea operators gatherings, "Should HUMS data be displayed instantaneously in the cockpit?" JimL you will probably recall this, there was opposition to the displays because it was felt that the systems back then were not mature or reliable enough to provide definative data.. e.g. would a pilot ditch due to a displayed warning only? The general feeling back then from NS crews (About 5/6 years ago) was a resounding "no".. However, with modern aircraft such as S-92, where the old methods such as "noisy gearbox" etc MAY not be so evident to the crew, and given that HUMS and FDR data collection is now much more reliable and comprehensive, do we have a case for perhaps reviewing attitudes towards the onboard information and indications available to the crew? I concede that this fault most probably would not have been detectable via the HUMS / FDR but thats not to say that as in the case of the Dauphin main ring gear back in 2004, monitoring could be extended to cover new failure modes.

The arguments on here about commercial gains taking priority over safety remind me of a statement I once heard Eric Clark from Shell make..

"If you think flight safety is expensive, wait until you kill somebody"

Geoffers,

Just a thought but as long as we are thrashing all sorts of ideas around the place....how many critical gearboxes on the 332/225/92/365/76 aircraft?

I submit they have more than one each!

Would Main Rotor blades on these aircraft have a chance of impacting waves in Sea States Five or Six?

Just a thought but as long as we are thrashing all sorts of ideas around the place....how many critical gearboxes on the 332/225/92/365/76 aircraft?

I submit they have more than one each!

Would Main Rotor blades on these aircraft have a chance of impacting waves in Sea States Five or Six?

Join Date: Aug 2001

Location: Cornwall

Age: 75

Posts: 1,307

Likes: 0

Received 0 Likes

on

0 Posts

Transmission Design

SAS

Regret I can't agree. If any of the three critical gearboxes on the 234 seize then you exit stage left in a hundred bits but if the tail or intermediate gearboxes fail on a single rotor machine you have a fighting chance of making it to the surface. We have seen examples of both of these failure modes in the NS.

As far as the blades hitting the water is concerned a single rotor machine with the pitching centre around the position of the rotor they are a lot less likely to hit the water in equal sea states. The problem for the 234 is that a sudden stop is likely to do for the sync shaft and then it eats itself. A sudden stop on a single rotor is likely to turn it upside down - which is why we have HUET.

G.

Regret I can't agree. If any of the three critical gearboxes on the 234 seize then you exit stage left in a hundred bits but if the tail or intermediate gearboxes fail on a single rotor machine you have a fighting chance of making it to the surface. We have seen examples of both of these failure modes in the NS.

As far as the blades hitting the water is concerned a single rotor machine with the pitching centre around the position of the rotor they are a lot less likely to hit the water in equal sea states. The problem for the 234 is that a sudden stop is likely to do for the sync shaft and then it eats itself. A sudden stop on a single rotor is likely to turn it upside down - which is why we have HUET.

G.

Fly3Test,

good point, and quite topical as the CAA ahve recently released a Research Paper that looks at the possibility of in cockpit warning of impending blade failure.

good point, and quite topical as the CAA ahve recently released a Research Paper that looks at the possibility of in cockpit warning of impending blade failure.

212man and Fly3,

Data for the viability of HUMS crew alerts to have assisted decision making of the Cougar crew should be available from 212's event and the Australian event (yes I know they have different causes, though same result). This information eventually should be released in any AAIB level of thoroughness report. If HUMS gave valuable/actionable data which could have been used to avoid or mitigate those events in the future it will be reported in many technical papers.

Does anyone know if any information has been published or is going to be released soon?

The Sultan

Data for the viability of HUMS crew alerts to have assisted decision making of the Cougar crew should be available from 212's event and the Australian event (yes I know they have different causes, though same result). This information eventually should be released in any AAIB level of thoroughness report. If HUMS gave valuable/actionable data which could have been used to avoid or mitigate those events in the future it will be reported in many technical papers.

Does anyone know if any information has been published or is going to be released soon?

The Sultan

Join Date: Sep 1998

Location: at the edge

Posts: 154

Likes: 0

Received 0 Likes

on

0 Posts

In these days of MFDs and minaturisation, surely a couple of small cameras (one on the pylon facing forward and one on the cowling facing backwards, even one on each sponson facing towards the rotorhead) would be easily achievable.

If I can have sat nav and TV in my car, it must be possible to play a camera image onto an MFD.

No argument about fire etc, it would all be visible from the cockpit at the flick of a switch.

As for HUMS alerts to the crew.....that is a very complicated subject. The risk of the wrong reaction to a spurious warning (it could just be a malfunctioning sensor) is a major concern. Personally, I wouldn't like to have it but I would like a camera.

If I can have sat nav and TV in my car, it must be possible to play a camera image onto an MFD.

No argument about fire etc, it would all be visible from the cockpit at the flick of a switch.

As for HUMS alerts to the crew.....that is a very complicated subject. The risk of the wrong reaction to a spurious warning (it could just be a malfunctioning sensor) is a major concern. Personally, I wouldn't like to have it but I would like a camera.

Join Date: Feb 2005

Location: not where I want to be

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

If I can have sat nav and TV in my car, it must be possible to play a camera image onto an MFD.

)

)