Martin Baker to be prosecuted over death of Flt Lt. Sean Cunningham

So, I just looked up the definition of SQEP in today's MOD (MAA) MAA02: Military Aviation Authority Master Glossary Issue 6.1 :

Term: Suitably Qualified and Experienced Person

Abbreviation: SQEP

Definition: Intentionally Blank

Term: Suitably Qualified and Experienced Person

Abbreviation: SQEP

Definition: Intentionally Blank

Tucumseh:

SQEP requirements are littered throughout the RA 1000 regulations, depending on post, some more specific posts have them listed in a table, for example RA1003(1) & 1022(1) also RA 4945 has requirements for post but not utilising the descriptor SQEP:

https://www.gov.uk/government/public...egulations-gen

https://www.gov.uk/government/upload...45_Issue_2.pdf

SQEP requirements are littered throughout the RA 1000 regulations, depending on post, some more specific posts have them listed in a table, for example RA1003(1) & 1022(1) also RA 4945 has requirements for post but not utilising the descriptor SQEP:

https://www.gov.uk/government/public...egulations-gen

https://www.gov.uk/government/upload...45_Issue_2.pdf

Join Date: May 2007

Location: Banished (twice) to the pointless forest

Posts: 1,558

Likes: 0

Received 0 Likes

on

0 Posts

I think you might find the courses are even shorter than the timescales would suggest. There's a lot more team building and adventure training than in the old days. That, and all the fluffy stuff, eats into the time to learn a trade.

Engines,

Spot on!

Regardless of all other actions, despite all the failures that caused the Ejection Seat to be activated; Flt Lt Cunningham should have drifted to earth on his parachute - surprised, but unharmed.

Regards

MM

Spot on!

Regardless of all other actions, despite all the failures that caused the Ejection Seat to be activated; Flt Lt Cunningham should have drifted to earth on his parachute - surprised, but unharmed.

Regards

MM

Join Date: May 2007

Location: upstairs

Posts: 208

Likes: 0

Received 0 Likes

on

0 Posts

I suspect not but I always thought it was not fully understood by many in the MAA. The nuclear industry use it extensively and its far more than just a term meaning 'competent'. There's a generic definition here https://en.wikipedia.org/wiki/SQEP but I think it misses the full scope of the nuclear usage.

EAP

EAP

Join Date: Feb 2006

Location: Hanging off the end of a thread

Posts: 32,923

Received 2,844 Likes

on

1,215 Posts

BigGreenGilbert; He didn't "rethread" it, he cut new thread.

and example of

https://www.grainger.com/product/CLE...xed-Die-20X681

..

Last edited by NutLoose; 6th Mar 2018 at 01:26.

BGG

I apologise if I wasn't clear. I don't agree with the definition of inexperience I mentioned. (Only having managed - not just worked on - and delivered 125 projects to time, cost and performance). It was and remains ludicrous, and I'd like to think most areas of DE&S don't apply it. Nevertheless, it was a formal policy, was applied, and is still cited. I mention this because I know the local Abbeywood MP/Minister once asked Min(AF) how widely this was applied and how many staff met the criteria, but MoD wouldn't reply.

I feel it is important to define SQEP for the purposes of airworthiness delegation, and technical and financial approval delegation. (All can only be given to engineers). Again, there are mixed messages from MoD/MAA. Correctly, it requires a degree of experience and qualifications, but in parallel continues to support those who self-delegated all three delegations - leading directly to many of the deaths discussed here.

I think honesty and integrity are equally important. One can be experienced and qualified, but a fraud and incompetent. Again, see the same deaths. We're not talking about scores of people. The same names crop up in most cases.

So, I think we agree. I don't like the term as it perpetuates the policy of dumbing down.

Regarding the pubs. Many are provided in the form of 'handouts' during training and, yes, you are right, they are not maintained. (As a matter of policy, so few are). But in this context (XX177) I'm talking about basic engineering that hasn't really changed for centuries. The AP that tells you one thread showing, not the 1.5 mentioned by MoD and HSE. (Apply that, and Sean Cunningham would be alive).

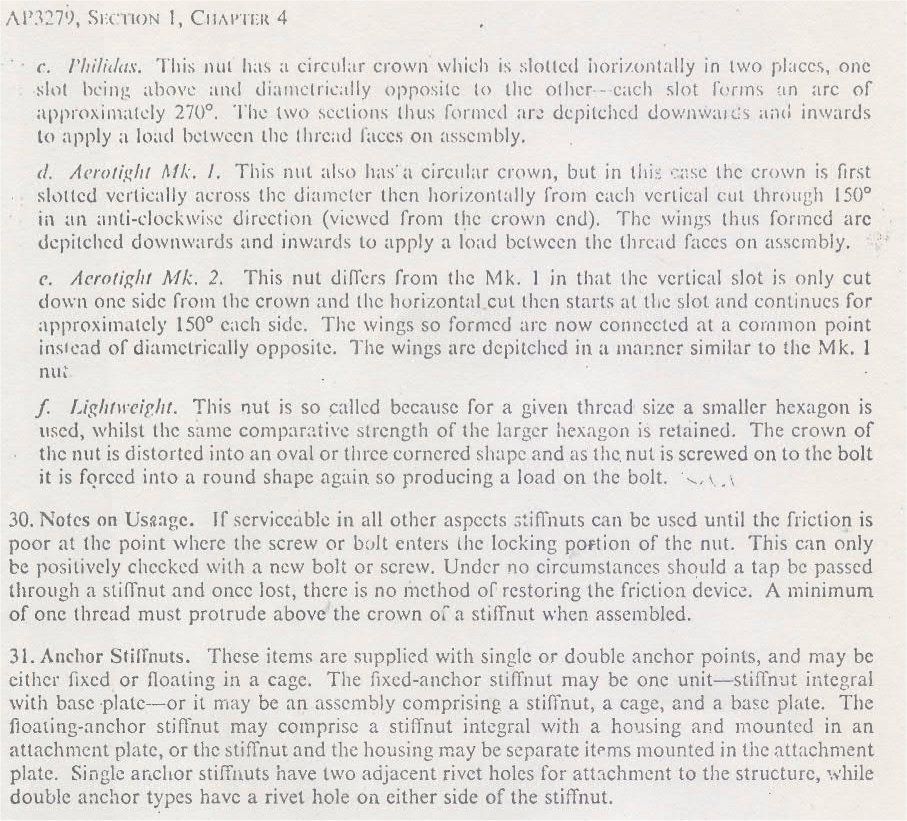

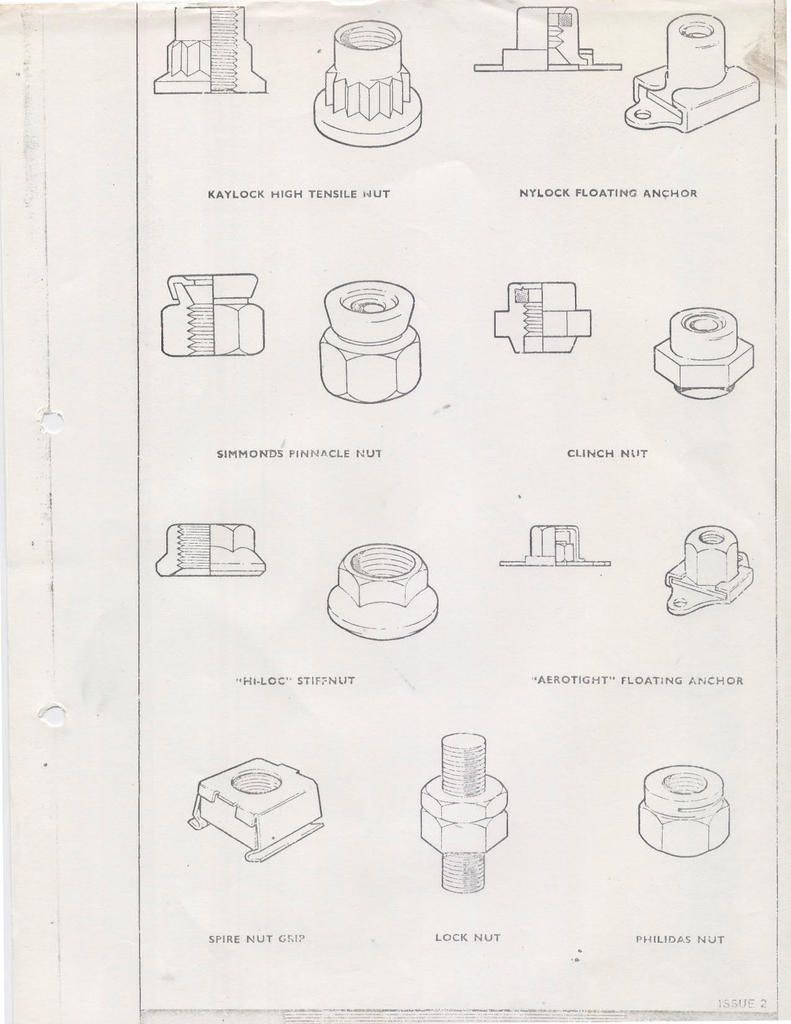

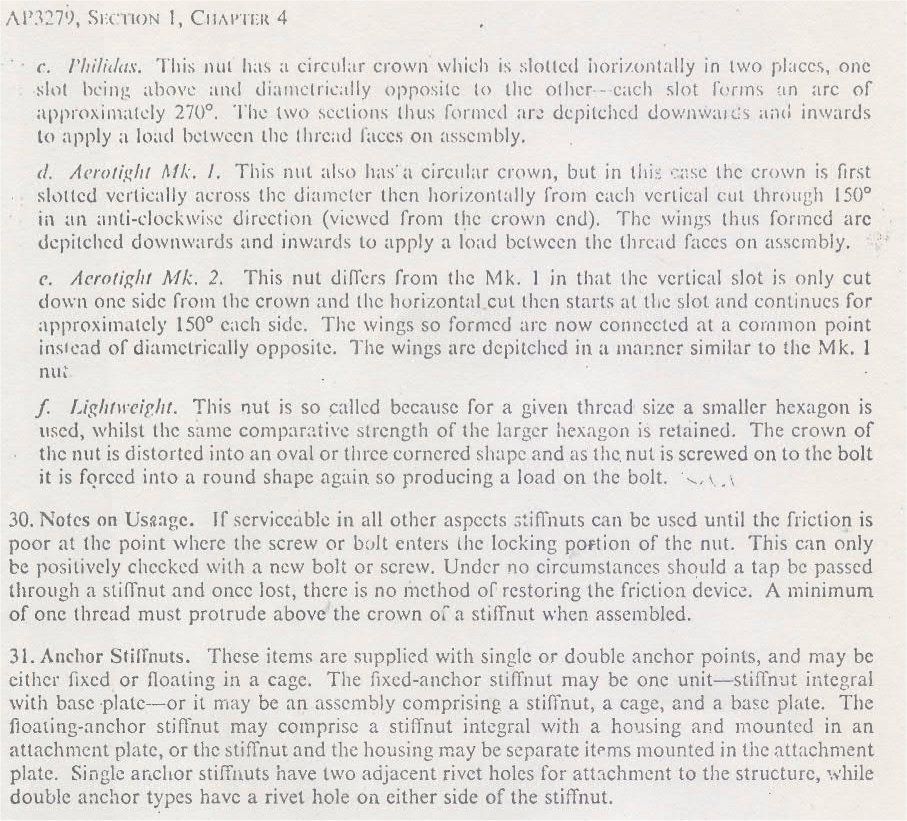

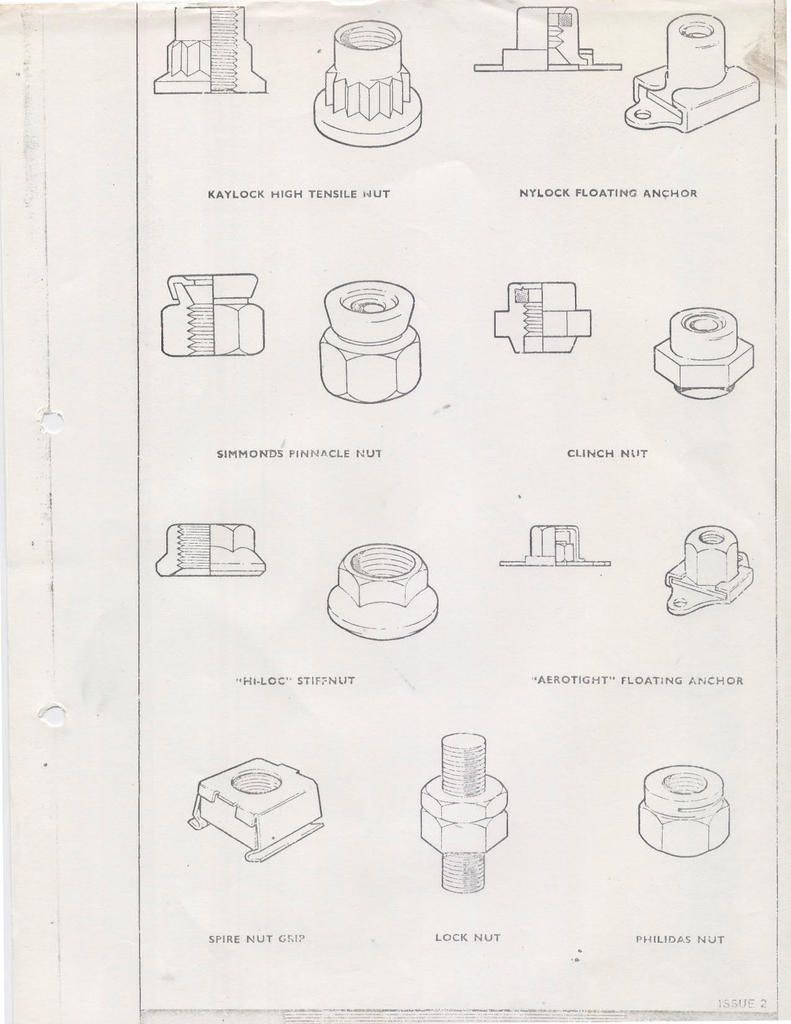

MoD has created a problem for itself by continually re-inventing the wheel. We lost our specialist Technical Authors (used to be around 600) and we now have contradictory regulations (e.g. 1.5 threads). Also, if the good book says to use a new stiffnut when loss of torque could lead to the loss of the aircraft, you really shouldn't need to spell out that this also applies to where loss of life could result, but the aircraft survive (e.g. this ejection). Note: stiffnut, not locknut, the term used by the SI. It's important to understand the difference when lives are at stake. And now that I've said this on MoD's Corporate Knowledge website, there will be a frantic re-assessment of said book and in a year's time a quiet amendment. As ever.

But, upon my first appointment as a Technical Agency (as you say, a new role, and requiring higher delegation) I was handed my personal copy of the two-volume Def Stan that anyone with airworthiness delegation should know backwards, that then sat on my desks for the rest of my career. If implemented, Sean Cunningham would be alive. (Just one of the layered defences in depth that broke down, long before he entered the aircraft). They were maintained, and our registry (sorry, showing my age) would come round and update it at each amendment. This standard was finally withdrawn in 2015, although staff had been told to stop using it many years before. It has never been replaced - D/Stan tried to update it many times, but weren't permitted. But the wise will still use it and, in fact, it still forms the basis of the Infantry's flagship programme whose aim is to reduce casualties. A noble aim, and perhaps the MAA should wander down and ask for an updated copy. Because, plainly, none of them have read it, never mind had to implement it.

I apologise if I wasn't clear. I don't agree with the definition of inexperience I mentioned. (Only having managed - not just worked on - and delivered 125 projects to time, cost and performance). It was and remains ludicrous, and I'd like to think most areas of DE&S don't apply it. Nevertheless, it was a formal policy, was applied, and is still cited. I mention this because I know the local Abbeywood MP/Minister once asked Min(AF) how widely this was applied and how many staff met the criteria, but MoD wouldn't reply.

I feel it is important to define SQEP for the purposes of airworthiness delegation, and technical and financial approval delegation. (All can only be given to engineers). Again, there are mixed messages from MoD/MAA. Correctly, it requires a degree of experience and qualifications, but in parallel continues to support those who self-delegated all three delegations - leading directly to many of the deaths discussed here.

I think honesty and integrity are equally important. One can be experienced and qualified, but a fraud and incompetent. Again, see the same deaths. We're not talking about scores of people. The same names crop up in most cases.

So, I think we agree. I don't like the term as it perpetuates the policy of dumbing down.

Regarding the pubs. Many are provided in the form of 'handouts' during training and, yes, you are right, they are not maintained. (As a matter of policy, so few are). But in this context (XX177) I'm talking about basic engineering that hasn't really changed for centuries. The AP that tells you one thread showing, not the 1.5 mentioned by MoD and HSE. (Apply that, and Sean Cunningham would be alive).

MoD has created a problem for itself by continually re-inventing the wheel. We lost our specialist Technical Authors (used to be around 600) and we now have contradictory regulations (e.g. 1.5 threads). Also, if the good book says to use a new stiffnut when loss of torque could lead to the loss of the aircraft, you really shouldn't need to spell out that this also applies to where loss of life could result, but the aircraft survive (e.g. this ejection). Note: stiffnut, not locknut, the term used by the SI. It's important to understand the difference when lives are at stake. And now that I've said this on MoD's Corporate Knowledge website, there will be a frantic re-assessment of said book and in a year's time a quiet amendment. As ever.

But, upon my first appointment as a Technical Agency (as you say, a new role, and requiring higher delegation) I was handed my personal copy of the two-volume Def Stan that anyone with airworthiness delegation should know backwards, that then sat on my desks for the rest of my career. If implemented, Sean Cunningham would be alive. (Just one of the layered defences in depth that broke down, long before he entered the aircraft). They were maintained, and our registry (sorry, showing my age) would come round and update it at each amendment. This standard was finally withdrawn in 2015, although staff had been told to stop using it many years before. It has never been replaced - D/Stan tried to update it many times, but weren't permitted. But the wise will still use it and, in fact, it still forms the basis of the Infantry's flagship programme whose aim is to reduce casualties. A noble aim, and perhaps the MAA should wander down and ask for an updated copy. Because, plainly, none of them have read it, never mind had to implement it.

Last edited by tucumseh; 6th Mar 2018 at 06:55.

Regarding the term SQEP when I was on the HEART team in 1997, the management epithet most popular at the time was 'tainted by experience'.

I found this a very curious way to do business

I found this a very curious way to do business

AA62

Yes, an oft repeated term at that time. It arose from CDPs' policy the previous year, that he did not want engineering project managers managing engineering projects. He announced 600 job cuts, just after everyone had moved from London. He was hated, and everyone I know had a little smile when Haddon-Cave dug a hole and shoved him in.

His problem was that the policy I mentioned earlier, new recruits skipping 5 grades, meant a huge disparity between staff at the same grade; so he chose to dumb down to avoid embarrassment. He should have been demanding that all staff satisfy grade minima. (Today, I'd say a mere handful in DE&S do). For example, I had two engineers of the same grade in one of my teams in 1997. One had airworthiness delegation and managed work that in other parts of MoD attracted sizeable teams. (He's still in, and one of the few). The other was minutes secy to a minor meeting, and entered data in a database. The latter was not to blame in any way, and in time became useful - but in a very narrow field, meaning he didn't meet minima. But the other was bored out of his skull, because he knew he was doing work beneath (what he considered, correctly) his paygrade. Equally, he was annoyed because the pay structure at the time favoured the inexperienced. This wasn't easy to manage, not least because Servicemen looked on aghast, as their system tends to avoid such disparity. Both OR and front line were given contact details if they had queries on any given subject, but all naturally deviated to the guy who knew how to solve the problem, even if not his job.

Yes, an oft repeated term at that time. It arose from CDPs' policy the previous year, that he did not want engineering project managers managing engineering projects. He announced 600 job cuts, just after everyone had moved from London. He was hated, and everyone I know had a little smile when Haddon-Cave dug a hole and shoved him in.

His problem was that the policy I mentioned earlier, new recruits skipping 5 grades, meant a huge disparity between staff at the same grade; so he chose to dumb down to avoid embarrassment. He should have been demanding that all staff satisfy grade minima. (Today, I'd say a mere handful in DE&S do). For example, I had two engineers of the same grade in one of my teams in 1997. One had airworthiness delegation and managed work that in other parts of MoD attracted sizeable teams. (He's still in, and one of the few). The other was minutes secy to a minor meeting, and entered data in a database. The latter was not to blame in any way, and in time became useful - but in a very narrow field, meaning he didn't meet minima. But the other was bored out of his skull, because he knew he was doing work beneath (what he considered, correctly) his paygrade. Equally, he was annoyed because the pay structure at the time favoured the inexperienced. This wasn't easy to manage, not least because Servicemen looked on aghast, as their system tends to avoid such disparity. Both OR and front line were given contact details if they had queries on any given subject, but all naturally deviated to the guy who knew how to solve the problem, even if not his job.

From the Nuclear SQEP description you have this:

Within the MAA competencies are within RA 1002:

https://www.gov.uk/government/public...petent-persons

However I think the point being made is there may be some lower down that are considered SQEP/competent and fulfil the criteria laid down, it is some of the management, both military and civilian, who don't necessarily hold that same competency or knowledge of the subject matter required of the post they hold, 'jobs for the boys' springs to mind, and are averse to being 'shown up' by their more capable subordinates, so ignore/suborn/prevaricate/hide information to cover their backsides when things go wrong, these are the ones who are at the heart of the issue.

To fill gapped posts some incumbents do not always fill the regulated requirements of experience and competency for that post, so end up not fulfilling the due diligence for the task, totally innocently in most cases, which would appear to suit the management style described above.

As has been said before, in cases like this the Accountable Manager/Duty Holder is where the buck stops and when it goes wrong they should be standing in the court to explain why it went wrong under their watch, don't see that often with regard the military to date, so these threads will no doubt continue unless they sort themselves out.

and conversely suitably means suitably, not particularly well: the Office of Nuclear Regulation takes SQEPness to be broadly equivalent to the International Atomic Energy Agency concept of 'competence'

IAEA has defined competence as “the ability to put skills and knowledge into practice in order to perform a job in an effective and efficient manner to an established standard” ONR concurs with this definition, which is widely accepted within the international nuclear community. Other factors contributing to a person’s competence include the person’s prior experience, aptitudes, attitudes, behaviours, skills and qualifications.[2]

IAEA has defined competence as “the ability to put skills and knowledge into practice in order to perform a job in an effective and efficient manner to an established standard” ONR concurs with this definition, which is widely accepted within the international nuclear community. Other factors contributing to a person’s competence include the person’s prior experience, aptitudes, attitudes, behaviours, skills and qualifications.[2]

https://www.gov.uk/government/public...petent-persons

However I think the point being made is there may be some lower down that are considered SQEP/competent and fulfil the criteria laid down, it is some of the management, both military and civilian, who don't necessarily hold that same competency or knowledge of the subject matter required of the post they hold, 'jobs for the boys' springs to mind, and are averse to being 'shown up' by their more capable subordinates, so ignore/suborn/prevaricate/hide information to cover their backsides when things go wrong, these are the ones who are at the heart of the issue.

To fill gapped posts some incumbents do not always fill the regulated requirements of experience and competency for that post, so end up not fulfilling the due diligence for the task, totally innocently in most cases, which would appear to suit the management style described above.

As has been said before, in cases like this the Accountable Manager/Duty Holder is where the buck stops and when it goes wrong they should be standing in the court to explain why it went wrong under their watch, don't see that often with regard the military to date, so these threads will no doubt continue unless they sort themselves out.

Join Date: Feb 2006

Location: Hanging off the end of a thread

Posts: 32,923

Received 2,844 Likes

on

1,215 Posts

Regarding the pubs. Many are provided in the form of 'handouts' during training and, yes, you are right, they are not maintained. (As a matter of policy, so few are). But in this context (XX177) I'm talking about basic engineering that hasn't really changed for centuries. The AP that tells you one thread showing, not the 1.5 mentioned by MoD and HSE. (Apply that, and Sean Cunningham would be alive).

MoD has created a problem for itself by continually re-inventing the wheel. We lost our specialist Technical Authors (used to be around 600) and we now have contradictory regulations (e.g. 1.5 threads). Also, if the good book says to use a new stiffnut when loss of torque could lead to the loss of the aircraft, you really shouldn't need to spell out that this also applies to where loss of life could result, but the aircraft survive (e.g. this ejection). Note: stiffnut, not locknut, the term used by the SI. It's important to understand the difference when lives are at stake. And now that I've said this on MoD's Corporate Knowledge website, there will be a frantic re-assessment of said book and in a year's time a quiet amendment. As ever.

MoD has created a problem for itself by continually re-inventing the wheel. We lost our specialist Technical Authors (used to be around 600) and we now have contradictory regulations (e.g. 1.5 threads). Also, if the good book says to use a new stiffnut when loss of torque could lead to the loss of the aircraft, you really shouldn't need to spell out that this also applies to where loss of life could result, but the aircraft survive (e.g. this ejection). Note: stiffnut, not locknut, the term used by the SI. It's important to understand the difference when lives are at stake. And now that I've said this on MoD's Corporate Knowledge website, there will be a frantic re-assessment of said book and in a year's time a quiet amendment. As ever.

The problem comes when the US started to dominate the industry and their 1 thread standard came into play, the likes of Martin Baker as a global player will have produced their goods to fit the standards of what must be their largest market. The RAF are then in a position of do you teach the 1 thread or 1 1/2 thread standard and bearing in mind that up until lately some aircraft still in service would be using the stricter tolerances, then surely that is the one to teach ( or both), if a bolt is to be tightened to 1 1/2 threads showing but is tightened to the lower figure then the potential is there for a bolt to be undertorqued.. So I can totally understand why accidents like this happen.

A stiffnut is a lock nut, they are one and the same thing, just different terminology, similarly a cotterpin is the same as a splitpin... push bikes apart.

While in the RAF I was taught and still adhere to the principal to replace all used stiffnuts, that was not always the case civilian wise as you could check it still retained a rundown torque.

note.

Advantages of the all metal lock nut are heat and wear resistance. Military and aircraft standards allow this particular style of locknut to be reused up to 15 times, given that the nut will continue to provide some minimum specified prevailing torque (United States' Military Standard 'Mil Std' MIL-N-25027).

http://mgaguru.com/mgtech/restore/rt104d.htm

Last edited by NutLoose; 6th Mar 2018 at 10:29.

My trade training notes. AP3279, AL7, Feb 1970. Para 30 is of course qualified elsewhere by the instructions when to use a new stiffnut (see previous post). A locknut is different from a stiffnut, although commonly used as a generic term. Often the difference is unimportant. Here, it is. (The one at bottom right is used in the seat).

I agree with your point that the problem is inconsistency across training and pubs. My point is that anyone using the same training I had would have followed this and the shackle would have been free to move. And the evidence, revealed in the judge's remarks, confirmed maintainers at other RAF stations stated one thread.

I agree with your point that the problem is inconsistency across training and pubs. My point is that anyone using the same training I had would have followed this and the shackle would have been free to move. And the evidence, revealed in the judge's remarks, confirmed maintainers at other RAF stations stated one thread.

Sorry, I should perhaps just clarify matters by saying all this is academic as far as the court case is concerned. The instructions issued by Martin-Baker to customers in the 1960s/70s/80s were:

‘Tighten nut until contact is made with Drogue Shackle. Do not torque. Verify that clearance exists between Drogue Shackle and the Scissor Assembly, and that the shackle can be freely rotated on the Scissor Assembly’.

Had this been followed, would Flt Lt Cunningham be alive? It may very well be that M-B didn't provide the warning in 1990, which was the basic of the HSE's sole charge. But very clearly they understood the issues and included warnings and cautions in their manuals. Their difficulty came when different customers wanted this expressed in different ways. So, just because the HSE said five other users were told in 1990, that doesn't mean MoD wasn't told in slightly different words that reflected its regs and training of the day.

‘Tighten nut until contact is made with Drogue Shackle. Do not torque. Verify that clearance exists between Drogue Shackle and the Scissor Assembly, and that the shackle can be freely rotated on the Scissor Assembly’.

Had this been followed, would Flt Lt Cunningham be alive? It may very well be that M-B didn't provide the warning in 1990, which was the basic of the HSE's sole charge. But very clearly they understood the issues and included warnings and cautions in their manuals. Their difficulty came when different customers wanted this expressed in different ways. So, just because the HSE said five other users were told in 1990, that doesn't mean MoD wasn't told in slightly different words that reflected its regs and training of the day.

RA 4266 refers to the use of self locking nuts, but as in the case of a lot of RA's it referes to the MAP-01 Chapter 6.15:

https://www.gov.uk/government/upload...tial_Issue.pdf

https://www.gov.uk/government/upload...ablemap-01.pdf

Extract from Chapter 6.15:

https://www.gov.uk/government/upload...tial_Issue.pdf

https://www.gov.uk/government/upload...ablemap-01.pdf

Extract from Chapter 6.15:

General Rules

As a general rule, the male threaded portion and nut may be removed from the assembly and re-used more than once, the nut must meet the minimum run-down torque criteria detailed in each platform Aircraft Maintenance Manual (AMM) Topic 1 on each application and must achieve a minimum of 1.5 threads protruding beyond the nut when the final locking torque is achieved. For small stiffnuts of 6mm O/D and below, the run-down torque must be greater than that which can be applied with finger pressure.

Further generic instructions on the procedures that must be used for checking aircraft self-locking fasteners is included in AP 119A-0428-1 Chap 3 paragraph 7. An entry referring to these generic procedures must be included in each AMM.

As a general rule, the male threaded portion and nut may be removed from the assembly and re-used more than once, the nut must meet the minimum run-down torque criteria detailed in each platform Aircraft Maintenance Manual (AMM) Topic 1 on each application and must achieve a minimum of 1.5 threads protruding beyond the nut when the final locking torque is achieved. For small stiffnuts of 6mm O/D and below, the run-down torque must be greater than that which can be applied with finger pressure.

Further generic instructions on the procedures that must be used for checking aircraft self-locking fasteners is included in AP 119A-0428-1 Chap 3 paragraph 7. An entry referring to these generic procedures must be included in each AMM.

Finger tight. Which hand? I'm right-handed but arthritis means my grip between thumb and forefinger is weaker. (This has many disadvantages). I do remember 'finger tight', for example when loosely assembling something so it doesn't fall apart, having partially dismantled it to gain access to another area. In any case, try tightening a philidas stiffnut finger tight. There'd be no threads protruding. The end of the bolt would be half way down inside the nut. Even 'finger tight plus half a turn', which is taught in some applications, wouldn't be enough. If by some chance you could overcome residual torque with your fingers, then the nut is scrap anyway.

But as I said, simply not applicable to a safety critical part that must be free to move. This all needs rewording.

What document does a maintainer have when working at the aircraft? Not RA4266. Nor Def Stan 00-970, as claimed by MoD & HSE. He has the AP (not written by M-B), his trade training (whatever that may be), common sense and engineering judgement.

Edited to add. After the accident, M-B issued SIL704, which said 'flush', not one or 1.5 thread pitches. As MoD (specifically the Service Inquiry/MAA according to the evidence) required this, why has RA4266 not been updated? Is this just applicable to Mk10B seats? To the RAF only? To all stiffnut applications? As the CAA promulgated this SIL, the world and his dog must now be thoroughly confused.

But as I said, simply not applicable to a safety critical part that must be free to move. This all needs rewording.

What document does a maintainer have when working at the aircraft? Not RA4266. Nor Def Stan 00-970, as claimed by MoD & HSE. He has the AP (not written by M-B), his trade training (whatever that may be), common sense and engineering judgement.

Edited to add. After the accident, M-B issued SIL704, which said 'flush', not one or 1.5 thread pitches. As MoD (specifically the Service Inquiry/MAA according to the evidence) required this, why has RA4266 not been updated? Is this just applicable to Mk10B seats? To the RAF only? To all stiffnut applications? As the CAA promulgated this SIL, the world and his dog must now be thoroughly confused.

Edited to add. After the accident, M-B issued SIL704, which said 'flush', not one or 1.5 thread pitches. As MoD (specifically the Service Inquiry/MAA according to the evidence) required this, why has RA4266 not been updated? Is this just applicable to Mk10B seats? To the RAF only? To all stiffnut applications? As the CAA promulgated this SIL, the world and his dog must now be thoroughly confused.

Will changing the rules and regulations again, make any difference, is there a will from those at the top to admit the erosion of safety/airworthiness has been happening, if they did, do they have the will and knowledge to make those changes, or will more accidents/loss of life have to occur, and more importantly someone in the military management to actually be held culpable and dealt with appropriately to get the message through.

Join Date: Dec 2006

Location: UK

Posts: 799

Likes: 0

Received 0 Likes

on

0 Posts

Perhaps I can help a little to clarify matters here.

Whenever any maintenance was carried out on RN aircraft, the supervisor for that work was required to ensure that the person carrying it out had the required qualifications, training and publications available to do the job. Units and departments also took care to ensure that any work on a safety critical item was carried out by an experienced tradesman. One of the basic requirements of any tradesman, as well as supervisors, was to understand the way in which the system they were working worked. If required to dismantle and reassemble a drogue shackle, they would have been required to understand that shackle's function, how it operated, and the key checks to be carried out after reassembly. These 'competences' were checked on a regular basis for all ratings, using a rolling 'performance check' system that was mandated on all FAA squadrons and departments. In essence, the RN pursued a 'competency based' system backed up by active local quality assurance.

Due to their particularly hazardous nature, any work on ejection seats was specifically authorised to a few personnel who had also done a special 'seat safety course'. If at all possible, work on ejection seats at first line was avoided by returning the seat to the bay and replacing it with a serviced item. One of the main reasons the RN did this was because we knew that, having dispensed with a specialist Weapons trade, the 'Weapons Electrical' ratings we had were less experienced than their forbears. hence the special precautions that were taken. Now contrast that approach with what the SI established happened on the RAFAT, where inexperienced tradesmen, with no authorised training, worked in pairs on the aircraft, supervising each others' work, using handy pre-printed forms.

Sorry if I'm repeating myself. We can all go on as much as we like about how many threads should have been showing, what sort of nut was used, and what APs were being used, and who issued what warnings. The core issues with this tragic accident are (in my view) staring us in the face.

An RTI that wasn't actually required to make the seat safe was issued by the engineering authority, possibly at the behest of the operating authority - and apparently nobody involved in the process kept a single record of how that happened.

A safety critical system was being taken apart every 50 hours. By itself, that should have raised massive warning flags. However, once again, no records seeem to exist on how that risk was supposed to be managed.

The RAF failed utterly to ensure that the people carrying out this safety critical task had the experience, training or supervision required to make it safe.

The poor s*d who actually overtightened the shackle on that day had, by the time he did it, been comprehensively failed by a number of people. Not by the system - by people not doing the jobs they were given to do.

The solution to this sort of problem is not, repeat not, more regulations and more instructions. It's this - do what we're already supposed to be doing.

Best Regards as ever to all those who are doing the work for real at the coal face today,

Engines

Whenever any maintenance was carried out on RN aircraft, the supervisor for that work was required to ensure that the person carrying it out had the required qualifications, training and publications available to do the job. Units and departments also took care to ensure that any work on a safety critical item was carried out by an experienced tradesman. One of the basic requirements of any tradesman, as well as supervisors, was to understand the way in which the system they were working worked. If required to dismantle and reassemble a drogue shackle, they would have been required to understand that shackle's function, how it operated, and the key checks to be carried out after reassembly. These 'competences' were checked on a regular basis for all ratings, using a rolling 'performance check' system that was mandated on all FAA squadrons and departments. In essence, the RN pursued a 'competency based' system backed up by active local quality assurance.

Due to their particularly hazardous nature, any work on ejection seats was specifically authorised to a few personnel who had also done a special 'seat safety course'. If at all possible, work on ejection seats at first line was avoided by returning the seat to the bay and replacing it with a serviced item. One of the main reasons the RN did this was because we knew that, having dispensed with a specialist Weapons trade, the 'Weapons Electrical' ratings we had were less experienced than their forbears. hence the special precautions that were taken. Now contrast that approach with what the SI established happened on the RAFAT, where inexperienced tradesmen, with no authorised training, worked in pairs on the aircraft, supervising each others' work, using handy pre-printed forms.

Sorry if I'm repeating myself. We can all go on as much as we like about how many threads should have been showing, what sort of nut was used, and what APs were being used, and who issued what warnings. The core issues with this tragic accident are (in my view) staring us in the face.

An RTI that wasn't actually required to make the seat safe was issued by the engineering authority, possibly at the behest of the operating authority - and apparently nobody involved in the process kept a single record of how that happened.

A safety critical system was being taken apart every 50 hours. By itself, that should have raised massive warning flags. However, once again, no records seeem to exist on how that risk was supposed to be managed.

The RAF failed utterly to ensure that the people carrying out this safety critical task had the experience, training or supervision required to make it safe.

The poor s*d who actually overtightened the shackle on that day had, by the time he did it, been comprehensively failed by a number of people. Not by the system - by people not doing the jobs they were given to do.

The solution to this sort of problem is not, repeat not, more regulations and more instructions. It's this - do what we're already supposed to be doing.

Best Regards as ever to all those who are doing the work for real at the coal face today,

Engines

Join Date: May 2007

Location: upstairs

Posts: 208

Likes: 0

Received 0 Likes

on

0 Posts

Tuc,

a SIL is a MBA 'instruction' to all their non-MOD customers. Where contracted to do so, a DO will redraft the SIL into the MOD's required format. The same happens for export customers but where there is no contract, the operator receives the SIL anyway.

Where a civil operated ex-military type has a live ejection seat, the CAA can require compliance with the SIL before the will allow a Permit To Fly to be issued. In line with usual civil practice, I believe the CAA would treat the SIL as approved data requiring operator compliance without being "promulgated" by the regulator. If its really important from an airworthiness perspective, they can designate the content as an Airworthiness Directive.

Unlike the UK MOD approach, 'approved data' is issued mostly by the Type Designer.

EAP

a SIL is a MBA 'instruction' to all their non-MOD customers. Where contracted to do so, a DO will redraft the SIL into the MOD's required format. The same happens for export customers but where there is no contract, the operator receives the SIL anyway.

Where a civil operated ex-military type has a live ejection seat, the CAA can require compliance with the SIL before the will allow a Permit To Fly to be issued. In line with usual civil practice, I believe the CAA would treat the SIL as approved data requiring operator compliance without being "promulgated" by the regulator. If its really important from an airworthiness perspective, they can designate the content as an Airworthiness Directive.

Unlike the UK MOD approach, 'approved data' is issued mostly by the Type Designer.

EAP

EAP

I tried to keep it succinct. On 16 November 2011, MoD promulgated SIL704 by means of Urgent Technical Instruction/Hawk/34. On 17 November 2011, the Civil Aviation Authority reflected it in Emergency Mandatory Permit Directive (EMPD 2011-008-E), which notified users other than the MoD. Two years later, SIL704A was issued - same again.

I tried to keep it succinct. On 16 November 2011, MoD promulgated SIL704 by means of Urgent Technical Instruction/Hawk/34. On 17 November 2011, the Civil Aviation Authority reflected it in Emergency Mandatory Permit Directive (EMPD 2011-008-E), which notified users other than the MoD. Two years later, SIL704A was issued - same again.

OMS and dragartist mention that the head of EA was a Wg Cdr stacker with no input to eng matters, these were raised to the Gp Capt. So, when the Gp Capt retired and was replaced by a CS with no eng LOD/LOA and no apparent interest, finance came first, higher level signatures were referred a Gp Capt in another PT. Then the Sqn Ldr head of AAES was posted and eventually replaced by another CS with no seat or indeed aircraft experience. Follow that up with the retirement of our PDS Officer, with his duties, LTC etc, handed over to the DOs. Add the distractions: preparing the case for seat maintenance remaining with the MoD rather than accepting a bid from MBA; constant efficiency and money saving drives and fending off the Army's bid to manage all explosive items, one can see where we are heading. I am not trying to justify anything, just adding to the plot.

Engines remarks that in his area a seat would be removed for any detailed work and swapped with a S item; surely that is the only way to do it. How on earth were RAFAT 1st line allowed to carry out a detailed RTI in situ.

Engines really hits the mark regarding knowledge and understanding of a safety critical system. A FJ sqn facing a summer of display detachments elected to 'train' an airframe snco to carry out Independent Checks on AAES, rather than send a wpns snco with the det. I have nothing against riggers, but a local training course would not imbue the individual with the depth of understanding needed to take on the responsibility of AAES Independent Checks. Our argument was dismissed. But on the same visit my faith in snco armourers was shaken. In discussion about independents with a wpns snco he ventured that to 'make sure it's done properly' he disconnects the PEC and reconnects it himself. He would not accept that by doing so he would invalidate the signatures of both the tradesman and the supervisor as well as his own. I could weep.

Phew, I've got that off my chest, it has been festering for a while. Now I can go back to working my way through the fascinating Pilots' Brevet thread.

Engines remarks that in his area a seat would be removed for any detailed work and swapped with a S item; surely that is the only way to do it. How on earth were RAFAT 1st line allowed to carry out a detailed RTI in situ.

Engines really hits the mark regarding knowledge and understanding of a safety critical system. A FJ sqn facing a summer of display detachments elected to 'train' an airframe snco to carry out Independent Checks on AAES, rather than send a wpns snco with the det. I have nothing against riggers, but a local training course would not imbue the individual with the depth of understanding needed to take on the responsibility of AAES Independent Checks. Our argument was dismissed. But on the same visit my faith in snco armourers was shaken. In discussion about independents with a wpns snco he ventured that to 'make sure it's done properly' he disconnects the PEC and reconnects it himself. He would not accept that by doing so he would invalidate the signatures of both the tradesman and the supervisor as well as his own. I could weep.

Phew, I've got that off my chest, it has been festering for a while. Now I can go back to working my way through the fascinating Pilots' Brevet thread.