Grooved Runway determination

Thread Starter

Join Date: Aug 1998

Location: australia

Posts: 320

Likes: 0

Received 0 Likes

on

0 Posts

Grooved Runway determination

Hi All,

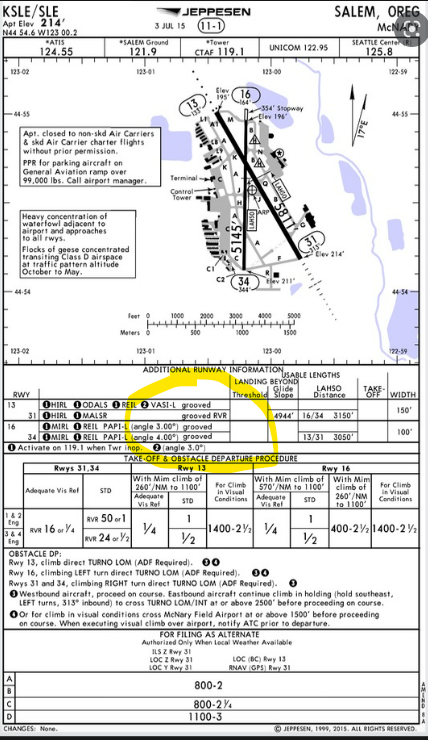

I am wondering based on the Jeppesen 10-9/10-9A charts how to ultimately determine if a runway surface is grooved or not.

I am aware that in some countries IE: USA that there is certainty on the runway surface.

However, in certain areas of Western Europe at major aerodromes, it remains unclear if these runways are grooved or not?

I understand some state aeronautical information providers have varying qualities of information they supply Jeppesen, but ultimately what is a technique/way to determine the surface status of a runway when unsure.

Thanks.

I am wondering based on the Jeppesen 10-9/10-9A charts how to ultimately determine if a runway surface is grooved or not.

I am aware that in some countries IE: USA that there is certainty on the runway surface.

However, in certain areas of Western Europe at major aerodromes, it remains unclear if these runways are grooved or not?

I understand some state aeronautical information providers have varying qualities of information they supply Jeppesen, but ultimately what is a technique/way to determine the surface status of a runway when unsure.

Thanks.

Check the national AIP for the airfield in question, aerodromes section. The individual aerodrome entry will give you the information, if it does not state anything then it is not grooved. This is where all the chart providers source their information from. But it will not make a difference to your performance calculations so it does not really matter.

MM

MM

Moderator

But it will not make a difference to your performance calculations so it does not really matter.

I think I would take issue with this thought. The idea behind grooving is to drain water from what otherwise would be a flooded runway surface. Wet and flooded runways probably need to be viewed quite differently from the point of performance calculations ?

There are several useful threads in PPRuNe, eg wet vs contaminated runway - PPRuNe Forums Take particular note of OverRun's comments. He is an airports design engineer specialist. Unfortunately, you won't be able to quiz him at all as he died several years ago, much to PPRuNe's dismay as we lost an extremely competent and knowledgeable engineer.

I think I would take issue with this thought. The idea behind grooving is to drain water from what otherwise would be a flooded runway surface. Wet and flooded runways probably need to be viewed quite differently from the point of performance calculations ?

There are several useful threads in PPRuNe, eg wet vs contaminated runway - PPRuNe Forums Take particular note of OverRun's comments. He is an airports design engineer specialist. Unfortunately, you won't be able to quiz him at all as he died several years ago, much to PPRuNe's dismay as we lost an extremely competent and knowledgeable engineer.

Join Date: Jun 2007

Location: Wanderlust

Posts: 3,404

Likes: 0

Received 0 Likes

on

0 Posts

I think I would take issue with this thought. The idea behind grooving is to drain water from what otherwise would be a flooded runway surface. Wet and flooded runways probably need to be viewed quite differently from the point of performance calculations ?

Last edited by vilas; 6th Oct 2022 at 01:44.

Thinking that additional knowledge doesn't matter - grooved or not - has no effect on published landing distance, seriously misjudges the pilots responsibilities in operations.

Heed the advice of the master of the dark art of performance, JT #3.

Landing distance is a conservative calculation of expected performance, which involves many assumptions that pilots should be aware of, but not always referenced as such (AMC CS 25.1592).

Wet performance is based on a single calculation; this has to accommodate a wide range of runway states defined as RCC 5; frost, snow, slush, and wet ranging from damp to 3mm of standing water. All of which involve varying degrees of uncertainty in measuring, interpreting and reporting. Thus the assumed accuracy of landing distance is highly variable.

Furthermore, there is a wide range of runway surfaces - material and texture, which can have a significant effect on braking performance. Grooved or not, porous texture or smooth concrete, can significantly challenge the assumptions and margins in the published performance. Then there is tyre tread condition.

Add to this the reality of operations; blocked grooves, rubber, dirt, wind ‘dammed’ water drainage.

A further (oft hidden) assumption is that the pilot will adjust operations according the conditions (i.e.what is meant by the assured ‘safe’ landing required by the pre-landing check, EU OPS).

https://www.icao.int/EURNAT/Other%20...hp%20PPT06.pdf

25.1591-1592 relevant amendment

https://www.easa.europa.eu/en/downloads/134260/en

N.B. Check for FAA differences; requirements vs advisory.

Heed the advice of the master of the dark art of performance, JT #3.

Landing distance is a conservative calculation of expected performance, which involves many assumptions that pilots should be aware of, but not always referenced as such (AMC CS 25.1592).

Wet performance is based on a single calculation; this has to accommodate a wide range of runway states defined as RCC 5; frost, snow, slush, and wet ranging from damp to 3mm of standing water. All of which involve varying degrees of uncertainty in measuring, interpreting and reporting. Thus the assumed accuracy of landing distance is highly variable.

Furthermore, there is a wide range of runway surfaces - material and texture, which can have a significant effect on braking performance. Grooved or not, porous texture or smooth concrete, can significantly challenge the assumptions and margins in the published performance. Then there is tyre tread condition.

Add to this the reality of operations; blocked grooves, rubber, dirt, wind ‘dammed’ water drainage.

A further (oft hidden) assumption is that the pilot will adjust operations according the conditions (i.e.what is meant by the assured ‘safe’ landing required by the pre-landing check, EU OPS).

https://www.icao.int/EURNAT/Other%20...hp%20PPT06.pdf

25.1591-1592 relevant amendment

https://www.easa.europa.eu/en/downloads/134260/en

N.B. Check for FAA differences; requirements vs advisory.

Join Date: Jun 2007

Location: Wanderlust

Posts: 3,404

Likes: 0

Received 0 Likes

on

0 Posts

Thinking that additional knowledge doesn't matter - grooved or not - has no effect on published landing distance, seriously misjudges the pilots responsibilities in operations.

Heed the advice of the master of the dark art of performance, JT #3.

Landing distance is a conservative calculation of expected performance, which involves many assumptions that pilots should be aware of, but not always referenced as such (AMC CS 25.1592).

Wet performance is based on a single calculation; this has to accommodate a wide range of runway states defined as RCC 5; frost, snow, slush, and wet ranging from damp to 3mm of standing water. All of which involve varying degrees of uncertainty in measuring, interpreting and reporting. Thus the assumed accuracy of landing distance is highly variable.

Furthermore, there is a wide range of runway surfaces - material and texture, which can have a significant effect on braking performance. Grooved or not, porous texture or smooth concrete, can significantly challenge the assumptions and margins in the published performance. Then there is tyre tread condition.

Add to this the reality of operations; blocked grooves, rubber, dirt, wind ‘dammed’ water drainage.

A further (oft hidden) assumption is that the pilot will adjust operations according the conditions (i.e.what is meant by the assured ‘safe’ landing required by the pre-landing check, EU OPS).

https://www.icao.int/EURNAT/Other%20...hp%20PPT06.pdf

25.1591-1592 relevant amendment

https://www.easa.europa.eu/en/downloads/134260/en

N.B. Check for FAA differences; requirements vs advisory.

Heed the advice of the master of the dark art of performance, JT #3.

Landing distance is a conservative calculation of expected performance, which involves many assumptions that pilots should be aware of, but not always referenced as such (AMC CS 25.1592).

Wet performance is based on a single calculation; this has to accommodate a wide range of runway states defined as RCC 5; frost, snow, slush, and wet ranging from damp to 3mm of standing water. All of which involve varying degrees of uncertainty in measuring, interpreting and reporting. Thus the assumed accuracy of landing distance is highly variable.

Furthermore, there is a wide range of runway surfaces - material and texture, which can have a significant effect on braking performance. Grooved or not, porous texture or smooth concrete, can significantly challenge the assumptions and margins in the published performance. Then there is tyre tread condition.

Add to this the reality of operations; blocked grooves, rubber, dirt, wind ‘dammed’ water drainage.

A further (oft hidden) assumption is that the pilot will adjust operations according the conditions (i.e.what is meant by the assured ‘safe’ landing required by the pre-landing check, EU OPS).

https://www.icao.int/EURNAT/Other%20...hp%20PPT06.pdf

25.1591-1592 relevant amendment

https://www.easa.europa.eu/en/downloads/134260/en

N.B. Check for FAA differences; requirements vs advisory.