Boeing at X-Roads?

Another important factor might have been the joint strike fighter competition. Boeing had great hopes that it could win this huge business with MD's help.

Join Date: Jul 2013

Location: Within AM radio broadcast range of downtown Chicago

Age: 71

Posts: 852

Received 0 Likes

on

0 Posts

The Peace Dividend, Ah Yes . . . so-called

A few objections to factoring into the discussion on this thread the assertions in the 1997 article linked into the thread by pattern-etc. (I don't mean folks shouldn't read it and consider it - instead for the reasons to follow, it's much more static noise than signal.)

1. It is abundantly clear today that "Clinton's DoD" was extremely short-sighted, and even blind in many respects, in formulating a strategically forecast scenario of a so-called "peace dividend", first of all, and then advising consolidation. (I'm taking the assertions in the article, with regard to the meeting and what was said to the contractors, at face value - a huge leap of faith - only because by now the article isn't either a rumour or news story; further, whether the meeting and its advisories in fact caused the consolidation decisions . . . but hey, this isn't scholarly research, a/k/a pendamatic or something.)

Technological advances were going to happen, if for no other reason people (in one category) and cultures (in another) seek better lives and security, and more prosperity. And systems of government and economic systems as well were going to come into conflict. To think, let alone act upon, the notion that the apparent end of the Cold War would mean a massive downshift in the needs, the imperatives, of national security and national defense strategies globally, can best be called naive. (By globally, I mean only the spherically shaped object you see in a classroom "globe" - they're about the size of an ordinary basketball, and have absolutely nothing to do with "globalists", "globalization" or various half-insane conspiracy theories about how things Really Work. Global is an adjective which refers to things of a given nature being true, being the case, all over the world.)

Perhaps some will say "but Ike and his Farewell!!. . . M-I-C." Yes, there is a complex formed by the Armed Forces and the major defense production entities. This isn't a history pro-seminar so folks can derive for themselves what Ike meant; imo his MIC segment (and address overall) very obviously was not meant to be taken at literal face value, rather than as a prompt, or rubric, for thinking on a symbolic and hence strategic level. But in any event, what actually occurred was a rise of technological advance, and continued competition between systems of countries, polities, economies, regions, cultures. "And/or" between all of those; "both/and" between them too, as suits the reader. Point here is, the article proceeds from the weak and in fact wrong-headed buy-in to the so-called Peace Dividend.

2. How do we know it really is wrong-headed? Look at what happened in fact. Technological advance factually has occurred rapidly enough so that the punditry class is exhausting itself reciting the letters "A" and "I" endlessly and breathlessly, and of course we're racing the PRC and its ruling Party. Perhaps folks might have a look at the Congressional Commission on the Strategic Posture of the United States - its Final Report - and ask, looking back to the dinner meeting supposedly reported upon in the article, were even just a large measure of the strategic developments noted in the Report unforeseeable? IMO the strategic developments were almost entirely foreseeable. And look at what Peace Dividend thinking did to, oh I don't know, one of the most prominent if not the most prominent world-wide symbols of the Cold War era. That is, the obscenely grossly over-costly Space Launch System, compared to Falcon space launch vehicles from SpaceX. By the way, from a free markets, free people, free enterprise system business organization. Same analysis for information technology, telecommunications, space applications.

3. Northrup Grumman didn't get bought up, as anybody should know. In fact, per Defense News, the top five U.S. defense contractors for 2023 are LockheedMartin (63.3); RTX (39.6); NorthrupGrumman (32.4); Boeing (30.8); and Gen Dynamics (30.4) [figures are billiions of defense dollars].

4. Cynicism about corporate affairs, especially transactions, appears too easily to spread insidiously and lead to overbroad conclusions and analysis. There obviously were massive consolidations, and without getting into specific case studies, this SLF/attorney is not asserting that none of them were driven by greed. Still, Boeing is a separate case - too big, too sordid, too tragic. And that's why I've gone all polemic-pedantic here, because the linked article isn't really healthy for this discussion, I mean, imo.

1. It is abundantly clear today that "Clinton's DoD" was extremely short-sighted, and even blind in many respects, in formulating a strategically forecast scenario of a so-called "peace dividend", first of all, and then advising consolidation. (I'm taking the assertions in the article, with regard to the meeting and what was said to the contractors, at face value - a huge leap of faith - only because by now the article isn't either a rumour or news story; further, whether the meeting and its advisories in fact caused the consolidation decisions . . . but hey, this isn't scholarly research, a/k/a pendamatic or something.)

Technological advances were going to happen, if for no other reason people (in one category) and cultures (in another) seek better lives and security, and more prosperity. And systems of government and economic systems as well were going to come into conflict. To think, let alone act upon, the notion that the apparent end of the Cold War would mean a massive downshift in the needs, the imperatives, of national security and national defense strategies globally, can best be called naive. (By globally, I mean only the spherically shaped object you see in a classroom "globe" - they're about the size of an ordinary basketball, and have absolutely nothing to do with "globalists", "globalization" or various half-insane conspiracy theories about how things Really Work. Global is an adjective which refers to things of a given nature being true, being the case, all over the world.)

Perhaps some will say "but Ike and his Farewell!!. . . M-I-C." Yes, there is a complex formed by the Armed Forces and the major defense production entities. This isn't a history pro-seminar so folks can derive for themselves what Ike meant; imo his MIC segment (and address overall) very obviously was not meant to be taken at literal face value, rather than as a prompt, or rubric, for thinking on a symbolic and hence strategic level. But in any event, what actually occurred was a rise of technological advance, and continued competition between systems of countries, polities, economies, regions, cultures. "And/or" between all of those; "both/and" between them too, as suits the reader. Point here is, the article proceeds from the weak and in fact wrong-headed buy-in to the so-called Peace Dividend.

2. How do we know it really is wrong-headed? Look at what happened in fact. Technological advance factually has occurred rapidly enough so that the punditry class is exhausting itself reciting the letters "A" and "I" endlessly and breathlessly, and of course we're racing the PRC and its ruling Party. Perhaps folks might have a look at the Congressional Commission on the Strategic Posture of the United States - its Final Report - and ask, looking back to the dinner meeting supposedly reported upon in the article, were even just a large measure of the strategic developments noted in the Report unforeseeable? IMO the strategic developments were almost entirely foreseeable. And look at what Peace Dividend thinking did to, oh I don't know, one of the most prominent if not the most prominent world-wide symbols of the Cold War era. That is, the obscenely grossly over-costly Space Launch System, compared to Falcon space launch vehicles from SpaceX. By the way, from a free markets, free people, free enterprise system business organization. Same analysis for information technology, telecommunications, space applications.

3. Northrup Grumman didn't get bought up, as anybody should know. In fact, per Defense News, the top five U.S. defense contractors for 2023 are LockheedMartin (63.3); RTX (39.6); NorthrupGrumman (32.4); Boeing (30.8); and Gen Dynamics (30.4) [figures are billiions of defense dollars].

4. Cynicism about corporate affairs, especially transactions, appears too easily to spread insidiously and lead to overbroad conclusions and analysis. There obviously were massive consolidations, and without getting into specific case studies, this SLF/attorney is not asserting that none of them were driven by greed. Still, Boeing is a separate case - too big, too sordid, too tragic. And that's why I've gone all polemic-pedantic here, because the linked article isn't really healthy for this discussion, I mean, imo.

Last edited by WillowRun 6-3; 28th Jan 2024 at 08:09.

I'm only aware of the first extension by Congress. Was there another one (or two)? I think at this point we would have to be on Extension #3.

I feel like wings could be stretched or un-stretched to a couple different sizes depending on the airframe, but certification might be onerous. Then again, given Boeing's reluctance to publicize changes that should cause more involved certification, maybe they could have different size wings without telling anyone.

The 737 is dead ended unless someone can figure out a way to mount the next engines, which will presumably have even larger fans, above the wings. Horizontal stab probably won't like that though. If it were possible to have longer gear and an actual gear bay with a door, that would have happened by the time of the NG. Basically I think the 737 is obsolescent and EoL soon. All hail Airbus and tiny overhead bins.

I feel like wings could be stretched or un-stretched to a couple different sizes depending on the airframe, but certification might be onerous. Then again, given Boeing's reluctance to publicize changes that should cause more involved certification, maybe they could have different size wings without telling anyone.

The 737 is dead ended unless someone can figure out a way to mount the next engines, which will presumably have even larger fans, above the wings. Horizontal stab probably won't like that though. If it were possible to have longer gear and an actual gear bay with a door, that would have happened by the time of the NG. Basically I think the 737 is obsolescent and EoL soon. All hail Airbus and tiny overhead bins.

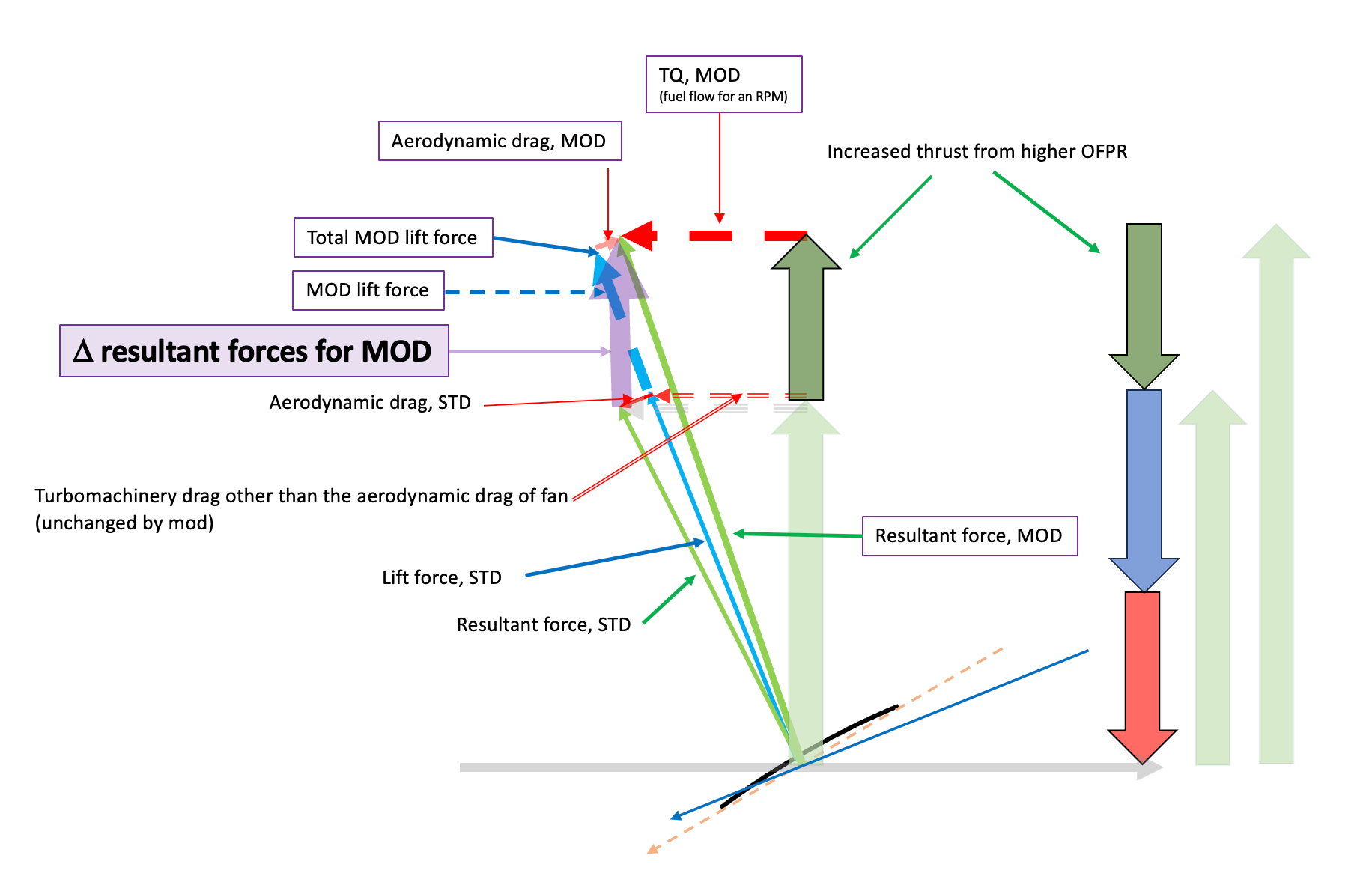

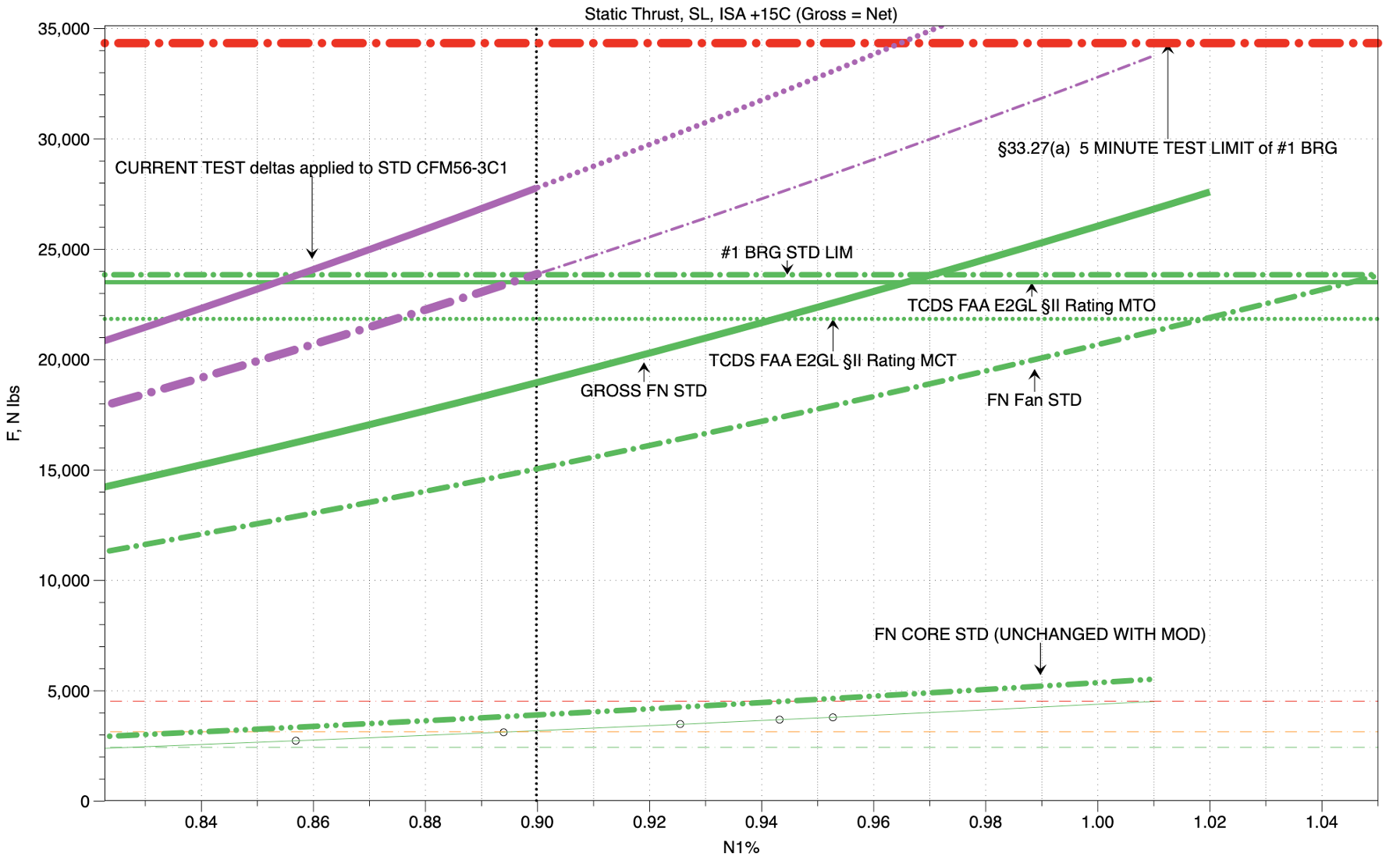

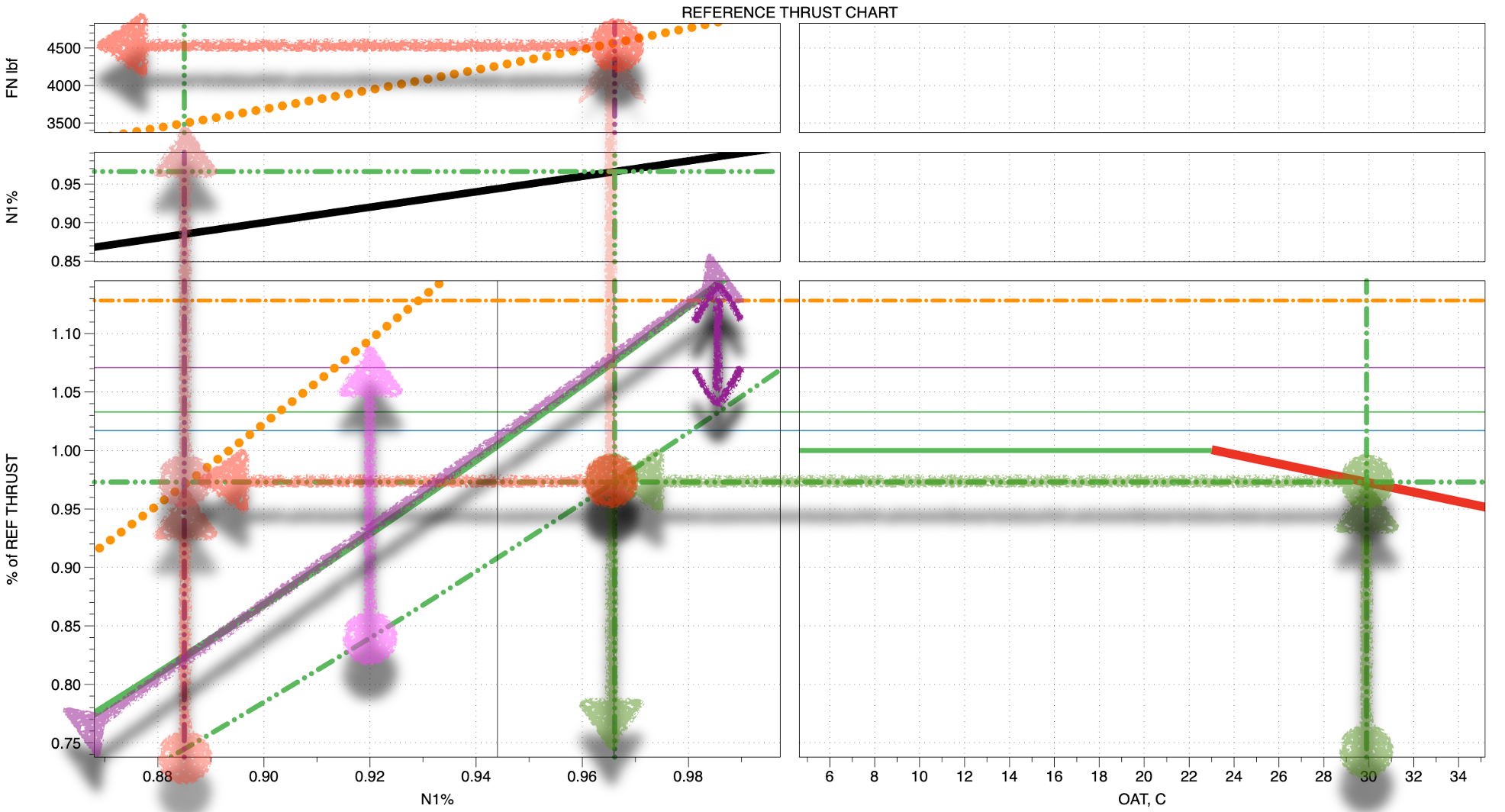

I've been flying a modified turbofan engine for a while, demonstrated it to the OEM, and the change in the performance of the fan only modification is:

For equal N1%, 44% more thrust at sea level, ISA+18C (550' PA) for 1% lower fuel flow, and 20C lower EGT(T5).

At cruise altitude, the effect is a bit better, I have demonstrated 53% higher Net thrust, for slightly lower fuel flows. The aircraft in this case is also around 5,000' higher than the normal MCT limit case for the relatively high speed that it was demo'd at. The outcome there was an instantaneous SAR that was 36% higher than the standard aircraft.

On this engine, we can in fact run it at higher total thrust, however, that is an oddity, the fan bearing and fan frame happen to also have been installed in higher rated engines, so we can bump up the thrust. As they are my engines, I run them instead at the normal rating. For a thrust level that is equivalent to rated thrust, with a target of 97.5% N1, the standard engine has a FF of 1730 and an EGT of 883C. The modified engine is videoed in a demo that we did for the OEM giving more thrust, at 88.5%, a FF of 1230 and an EGT of 793C. That EGT has a known (thanks, OEM) over-read of 26C, so the actual EGT at the DEEC is 767C. We use this video as it was also taken by the observer of the OEM. (It has an easter egg in it as well)

None of this should be possible, there are constraints that exist in turbo machinery that are taken to be absolute. I happened to find a way around some of those.

A similar effect is employed on the work on propellers that some of you may be aware that we have been doing for many years, trying to resolve the materials problem which is really really difficult. We resolved that, but having already shown in a test cell that a JT15D could get around 30% more thrust within the same fuel flows and EGT, and RPM limits, I've spent my time resolving the design and materials issues to do this trick and to demonstrate it. My company is starting a JV on a major T/prop transport prop, and we are also doing the turbo fan as an STC. The mod is a field modification to the engine "on the wing", it takes my engineers around 1-hour to mod an engine, bigger is easier (don't have to grease their shoulders to fit into tight places). This mod is not applicable to F-110's or 407's etc; we are only applicable to BPR of 2.3 and above, the bigger the better outcome so far which follows the math.

So, to the position that the B737 is the end of the road, I think that should be the case for other reasons, but the uprating of the existing engines could be done, without altering the fan diameter but it needs the fan bearing to be upgraded in most cases, and the fan frame to be re rated. For the STCs that we are working on at present, we are not intending to increase the TO thrust, we are just dropping the fuel flows commensurate with the RPM operating at about 10% lower than your standard values, and EGT follows obediently. A current discussion with the regulator is whether we are obliged to give a time limit for the TO and GA thrust cases, as they occur at lower RPM, fuel flow, EGT and stress than the normal MCT level. A potential benefit is we are able to have more than 30% greater climb thrust at all altitudes, and maintain TO thrust rating up to around 9000'PA at ISA +15C. The initial STCs are intended to be minimum operational change, and as the outcome is about 1/3rd better fuel reduction than the standard engines being produced today, we are aiming at making a difference early rather than gaining 100% optimisation. On the demonstrator, we are able to climb over 5000' higher than the planning case, and to operate up to MMO instead of LRC at those altitudes. Clarkson would be impressed.

We have just arranged 2 CFM56 engines to run in a calibrated test cell in the next couple of months, and a loaner jet to do the aircraft integration STC. Some are much easier than others... We are completely privately funded at present, we are prepared to do specific types as JVs with some parties, but not so many.

For the airlines, they don't have to take advantage of an STC that will reduce their fuel burns by around 1/3rd, but they may need to assess how their competitiveness goes with their neighbours. For the first few STCs, airlines are welcome as JV partners, they can make some cash flow from their competitors, that seems fair.

What will the CFM56, a 6 BPR engine achieve? It is an extension from what we have already tested, but what the mod achieves is shown below, and that suggests that it will give a better outcome than we achieve at a BPR of 2.7.

In every case we have run, the fan vibration reduces, steady strains naturally reduce, we are running at lower N1 and that also reduces N2, (fuel, EGT etc).

For info, you can PM me, or you can follow the YouTube site.

Gross thust total, Gross fan, Gross Core, and Net changes...

Spoiler

What happens to the engine...

Spoiler

CFM estimates

Spoiler

TFE731 actual outcomes

Spoiler

Last edited by fdr; 28th Jan 2024 at 07:08.

Join Date: Jul 2013

Location: Within AM radio broadcast range of downtown Chicago

Age: 71

Posts: 852

Received 0 Likes

on

0 Posts

Multiple news outlets reporting that Boeing has withdrawn its request for an exemption for the 737 MAX 7 relating to engine anti-icing system limitations.

If I was FAA, I’d deny the request. Too many exemptions. Gaming the system.

Here's the background from Flight Global:

https://www.flightglobal.com/airfram...156098.article

You need to sign up, but it's free.

https://www.flightglobal.com/airfram...156098.article

You need to sign up, but it's free.

The AWST article, free to read for a few more days:

https://aviationweek.com/air-transpo...rther-delaying

more...

In addition, EICAS is still waiting in the wings.

Then there's this. If MAX 10 is certificated in 2026, is 2029 really an appropriate time frame for these safety features?

https://airinsight.com/boeing-max-7-and-10-certification-deadline-gets-a-waiver/

But things will be okay in the C-suite if 2023 was any indication:

https://aviationweek.com/air-transpo...rther-delaying

Boeing is withdrawing its request for a time-limited exemption (TLE) covering the current engine inlet de-icing system that, if granted, would have allowed the 737-7 to be certified with a known noncompliance under current regulatory standards. The decision likely pushes FAA certification of the smallest MAX variant into at least 2025.

Boeing is expected to reveal more details about the 737-7 and its new certification timeline during its Jan. 31 annual earnings presentation for 2023. In November 2023, Boeing had asked the FAA for another 18 months to conclude development and certification of a new EAI system that complies with current standards. Before the latest decisions, certification of the -7 was expected for the beginning of 2024. If Boeing moves at its own expected speed, the aircraft can now be certified in the middle of 2025 at the earliest

Then there's this. If MAX 10 is certificated in 2026, is 2029 really an appropriate time frame for these safety features?

https://airinsight.com/boeing-max-7-and-10-certification-deadline-gets-a-waiver/

Safety enhancements

While the waiver gives Boeing and the FAA more time to certify the two MAX models without the time pressure and need to include the engine indicating and crew alerting system (EICAS), the airframer still has some modifications to do on all MAX models. That’s because Congress included a condition that was set out in an amendment by Democratic Senator Maria Cantwell. Her November amendment calls for the retrofit to all MAX types of two systems to enhance systems no later than three years after the MAX 10 is certified.

The Omnibus Bill states on page 1926: “Beginning on the date that is 3 years after the date on which the Administrator issues a type certificate for the Boeing 737-10, no person may operate a Boeing 737 MAX aircraft unless (A) the type design for the aircraft includes safety enhancements approved by the Administrator; and (B) the aircraft was ‘‘(i) produced in conformance with such type design; or ‘‘(ii) altered in accordance with such 22 type design.” The two systems required under the Cantwell amendment include “(i) a synthetic enhanced angle-of-attack system; and ‘‘(ii) means to shut off stall warning and overspeed alerts.” The former system has been made compulsory on the MAX 10 by the European regulatory agency EASA in its conditions for the re-certification of the MAX set out in 2020. The stall warning and overspeed alert system is also on the MAX 10.

While the waiver gives Boeing and the FAA more time to certify the two MAX models without the time pressure and need to include the engine indicating and crew alerting system (EICAS), the airframer still has some modifications to do on all MAX models. That’s because Congress included a condition that was set out in an amendment by Democratic Senator Maria Cantwell. Her November amendment calls for the retrofit to all MAX types of two systems to enhance systems no later than three years after the MAX 10 is certified.

The Omnibus Bill states on page 1926: “Beginning on the date that is 3 years after the date on which the Administrator issues a type certificate for the Boeing 737-10, no person may operate a Boeing 737 MAX aircraft unless (A) the type design for the aircraft includes safety enhancements approved by the Administrator; and (B) the aircraft was ‘‘(i) produced in conformance with such type design; or ‘‘(ii) altered in accordance with such 22 type design.” The two systems required under the Cantwell amendment include “(i) a synthetic enhanced angle-of-attack system; and ‘‘(ii) means to shut off stall warning and overspeed alerts.” The former system has been made compulsory on the MAX 10 by the European regulatory agency EASA in its conditions for the re-certification of the MAX set out in 2020. The stall warning and overspeed alert system is also on the MAX 10.

Nevertheless, Calhoun did all right. He received $22.5 million in total compensation last year, 154 times the $145,000 salary of the median Boeing employee. In Friday’s filing, despite the necessity of that $7 million cut, the board expressed continued confidence in Calhoun’s leadership. Last month, it granted him shares — not contingent on company performance and worth $15 million at today’s price — that will vest in installments over the next three years.

Last edited by remi; 30th Jan 2024 at 11:41.

And a very pertinent comment to the AWST article:

”PALADIN

Tue, 01/30/2024 - 14:00

You absolutely nailed it Jens. It looks like it's up to the share holders to fix this. The big lesson for the nation is that the company that is too big to fail could take down hundreds of suppliers with it. Europe has spread risk world wide which makes Airbus semi immune to individual failures. U.S. government consolidation actions and lack of domestic competition helped create this blind Cyclops. Replacing accountants at the top, with engineers and purging the DEI culture, replaced with competency, are the only rational steps forward.”

”PALADIN

Tue, 01/30/2024 - 14:00

You absolutely nailed it Jens. It looks like it's up to the share holders to fix this. The big lesson for the nation is that the company that is too big to fail could take down hundreds of suppliers with it. Europe has spread risk world wide which makes Airbus semi immune to individual failures. U.S. government consolidation actions and lack of domestic competition helped create this blind Cyclops. Replacing accountants at the top, with engineers and purging the DEI culture, replaced with competency, are the only rational steps forward.”

Join Date: Jul 2013

Location: Within AM radio broadcast range of downtown Chicago

Age: 71

Posts: 852

Received 0 Likes

on

0 Posts

I realize it's old news. But reading again that specific avionics or subsystem components were expressly iterated in Congressional legislation . . . Now, because of what has happened with the MAX variant - I mean the excursion taken by part of the fuselage separate from the rest of the aircraft. - as well as additional manufacturing problems that have been revealed (fastener holes, shims, for instance), I have a question.

Are there previous instances of Congress writing into law that certification cannot be granted unless specifically iterated avionics or subsystem components have been included? If so, what were they, and when?

Are there previous instances of Congress writing into law that certification cannot be granted unless specifically iterated avionics or subsystem components have been included? If so, what were they, and when?

I realize it's old news. But reading again that specific avionics or subsystem components were expressly iterated in Congressional legislation . . . Now, because of what has happened with the MAX variant - I mean the excursion taken by part of the fuselage separate from the rest of the aircraft. - as well as additional manufacturing problems that have been revealed (fastener holes, shims, for instance), I have a question.

Are there previous instances of Congress writing into law that certification cannot be granted unless specifically iterated avionics or subsystem components have been included? If so, what were they, and when?

Are there previous instances of Congress writing into law that certification cannot be granted unless specifically iterated avionics or subsystem components have been included? If so, what were they, and when?

I'm sure that over the years countless such changes for specific regularly situations have been made. Low profile of course.

Boeing was the company that designed the and built the first 777 in about 4 years. Maybe it is time to say if you can build an entirely new wide body intercontinental airliner in 4 years it shouldn’t take the same amount of time to fix 737 systems that are not compliant with modern safety standards.

I think it is time to say enough. Boeing get your Shyte together. You have 2 years to get every new or in service MAX up to standard or they will be grounded. Maybe it will incentivize Boeing to invest in engineers instead of accountants and lobbyists.

I think it is time to say enough. Boeing get your Shyte together. You have 2 years to get every new or in service MAX up to standard or they will be grounded. Maybe it will incentivize Boeing to invest in engineers instead of accountants and lobbyists.

Join Date: Jul 2013

Location: Within AM radio broadcast range of downtown Chicago

Age: 71

Posts: 852

Received 0 Likes

on

0 Posts

What I asked is whether any other specific items of avionics or subsystems have been identified in legislation. If the instances are so many as to warrant referring to them as "countless", let's see some examples.

The closest comparative situation I could cite would be the "Special Conditions" included in the certification of the 787, with regard (for example) to the lithium-ion batteries. But of course those Special Conditions were authorized by the FAR (afaik) and in any event not specifically introduced to the certification process by Congressional legislation identifying them by name.

Boeing was the company that designed the and built the first 777 in about 4 years. Maybe it is time to say if you can build an entirely new wide body intercontinental airliner in 4 years it shouldn’t take the same amount of time to fix 737 systems that are not compliant with modern safety standards.

It takes time to get it right - I'd far rather see Boeing take a rational (slower) approach and get it right. Rushing something just to get it certified is what gave us MCAS...

I doubt that any additional time would have uncovered MCAS until an AoA sensor got the vane clipped off. More telling was that the subcontractor that was building the sensors which Boeing and Lion Air used had not been using a sufficient QA/QC process to ensure that miscalibration could never occur, added on the oddity that there was no post-installation confirmation step required of the maintainers to ensure the calibration on the plane was correct - a quality escape of itself. I never heard if the FAA shut down that company for a full investigation of all their work and procedures as they should have done.

That was the early warning the FAA should have taken, that subcontractors and repair work weren't properly managed.

That was the early warning the FAA should have taken, that subcontractors and repair work weren't properly managed.

A longer, more thorough review and vetting of the design may have pointed out the flaw in using a single sensor. The problem with MCAS was that in the rush to get things certified, no one considered the impact of a cascade of warnings and faults associated with a bad AoA sensor - overwhelming the flight crew and resulting in them failing to appreciate what was happening with the stab trim.

That's not quite true. The 777 was certified 4 years after the program was launched. But work on what would become the 777 started years before that - with major design efforts being made while the 747-400 was still in development.

It takes time to get it right - I'd far rather see Boeing take a rational (slower) approach and get it right. Rushing something just to get it certified is what gave us MCAS...

It takes time to get it right - I'd far rather see Boeing take a rational (slower) approach and get it right. Rushing something just to get it certified is what gave us MCAS...

I hear what you are saying but ultimately it is Boeing’s choice as to how much resources they want to assign to fix the identified system problems. The resources assigned will largely drive the timeline. The problem is the fairly massive upfront cost of an all hands on deck, let’s make this right ! approach would impair short term profitability which impact C suite bonuses, so we know that will never happen.

I know I am massively naive but wouldn’t it be nice if Boeing for once under promised and over delivered.

What’s the motivation for the dogged continuance of the 737?

Southwest’s reported demands for no extra simulator sessions are part of the story.

What of the grandfathered standards of the 70’s does the design still exploit? Do the smaller doors = more passenger seating for example?

Highly likely a new design today will lose that edge, even when you put aside the design and testing costs.

Southwest’s reported demands for no extra simulator sessions are part of the story.

What of the grandfathered standards of the 70’s does the design still exploit? Do the smaller doors = more passenger seating for example?

Highly likely a new design today will lose that edge, even when you put aside the design and testing costs.

A longer, more thorough review and vetting of the design may have pointed out the flaw in using a single sensor. The problem with MCAS was that in the rush to get things certified, no one considered the impact of a cascade of warnings and faults associated with a bad AoA sensor - overwhelming the flight crew and resulting in them failing to appreciate what was happening with the stab trim.

The problem wasn't in using a single sensor. The problem was that the system reporting that single sensor was unable to validate it. Had the SMYD system been properly designed the AoA sensor would have been invalidated, causing the back-up sensor to be used and no false stall warning issued. The Lion Air miscalibration was also not identified as a potential problem - if it had been then an on-aircraft verification would be required. The Ethiopian sudden move to 70 degrees should have seen that sensor taken out of the loop; a better design would have had a vane stop at 60 degrees AoA so that 70 would have indicated out-of-range. Again, 30+ years and no one noticed.

---

I find odd the calls for a massive new redesign effort for an entirely new airframe with hundreds of thousands to millions of fundamental decisions to be made by the same group that is having trouble with the thousands of new decisions they need to make about an existing product.

In IBM, when IBM meant something, they used to have a group called the Black Team. This was a core of independent reviewers with significant experience that was given the freedom to go where they wanted and investigate what they wanted. A bit like the Spanish Inquisition, but less physical torture. They questioned fundamental assumptions, examined processes, and ran roughshod over the unprepared. In the initial rise of Microsoft, Bill Gates performed that function with the OS and the applications teams. It requires people who are smart enough to do the entire design job, but simply don't have the hours to do so. The clear mission isn't to tear people to bits, but to make the product as perfect as possible. Passing an audit was seen as a positive accomplishment.

This process made IBM an industrial giant and a feared competitor. It took the US Government to cripple them enough to allow Microsoft to take their place.