BA 787 Nosewheel collapse @ LHR

Don't we ever learn?

The BAe 146 had a problem where the downlock pin could be placed in a hole in the torque link instead of the downlock. That was fixed with a plastic bung in the wrong hole, 40 odd years ago.

I know it's not Boeing but don't Designers/Engineers learn from others?

The BAe 146 had a problem where the downlock pin could be placed in a hole in the torque link instead of the downlock. That was fixed with a plastic bung in the wrong hole, 40 odd years ago.

I know it's not Boeing but don't Designers/Engineers learn from others?

Join Date: Jan 2008

Location: Portugal

Posts: 7

Likes: 0

Received 0 Likes

on

0 Posts

Dang...

I would love to see how they repair this composite structure.

Although it was not a big damage (i'm guessing...) it still will be a hard work to do and a big check to get it out of the shop.

I would love to see how they repair this composite structure.

Although it was not a big damage (i'm guessing...) it still will be a hard work to do and a big check to get it out of the shop.

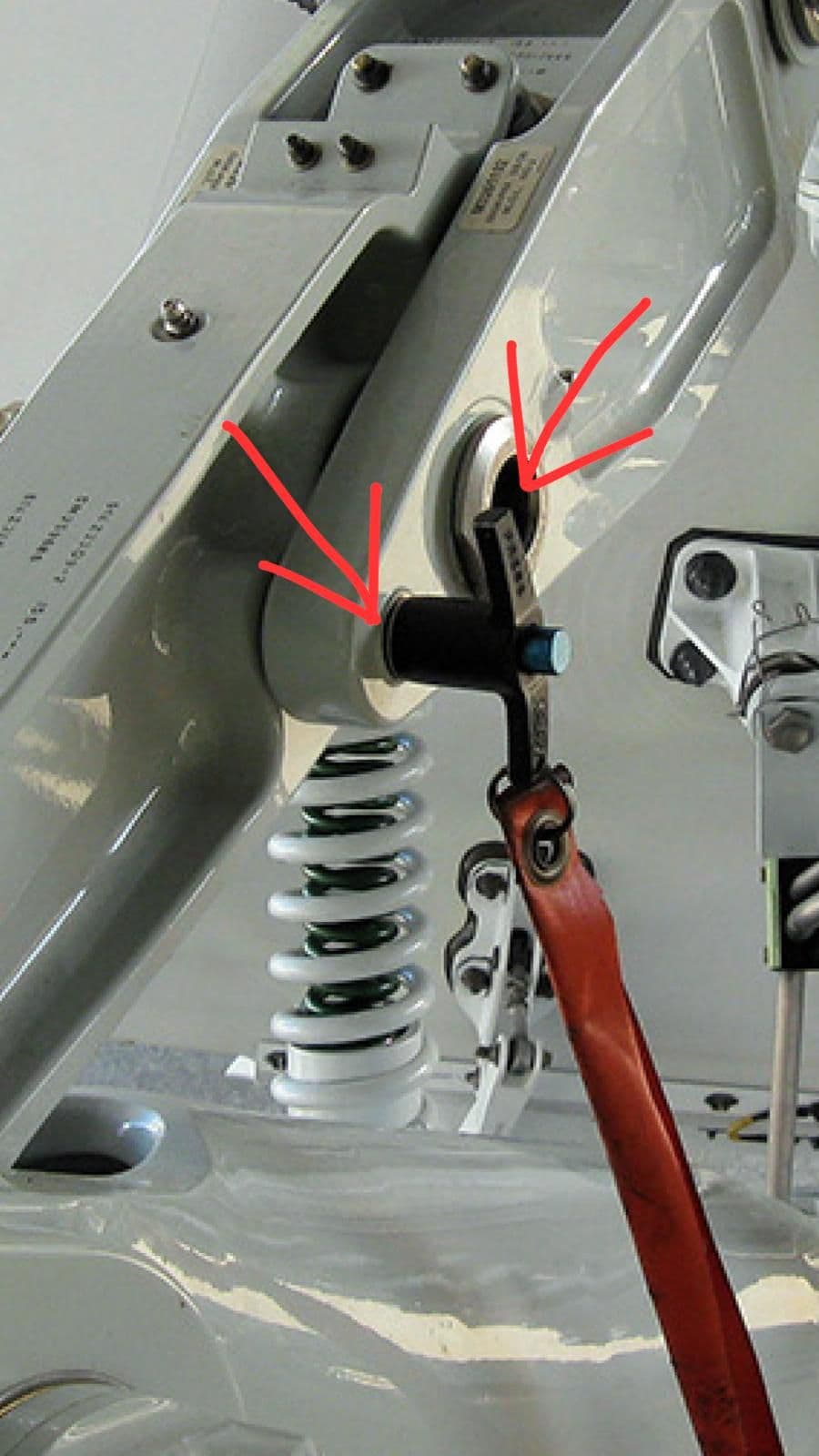

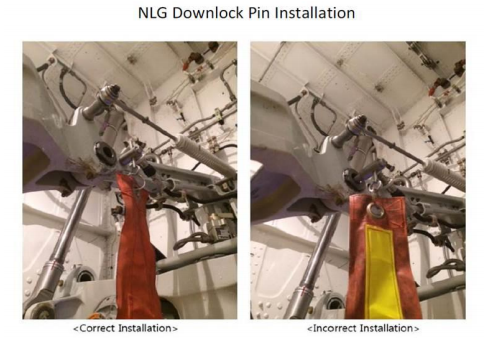

Get a photo from the other side, the diameter of the incorrect hole is smaller on the left and “takes the pin snugly”.

Here’s the relevant FAA narrative.

Narrative 1

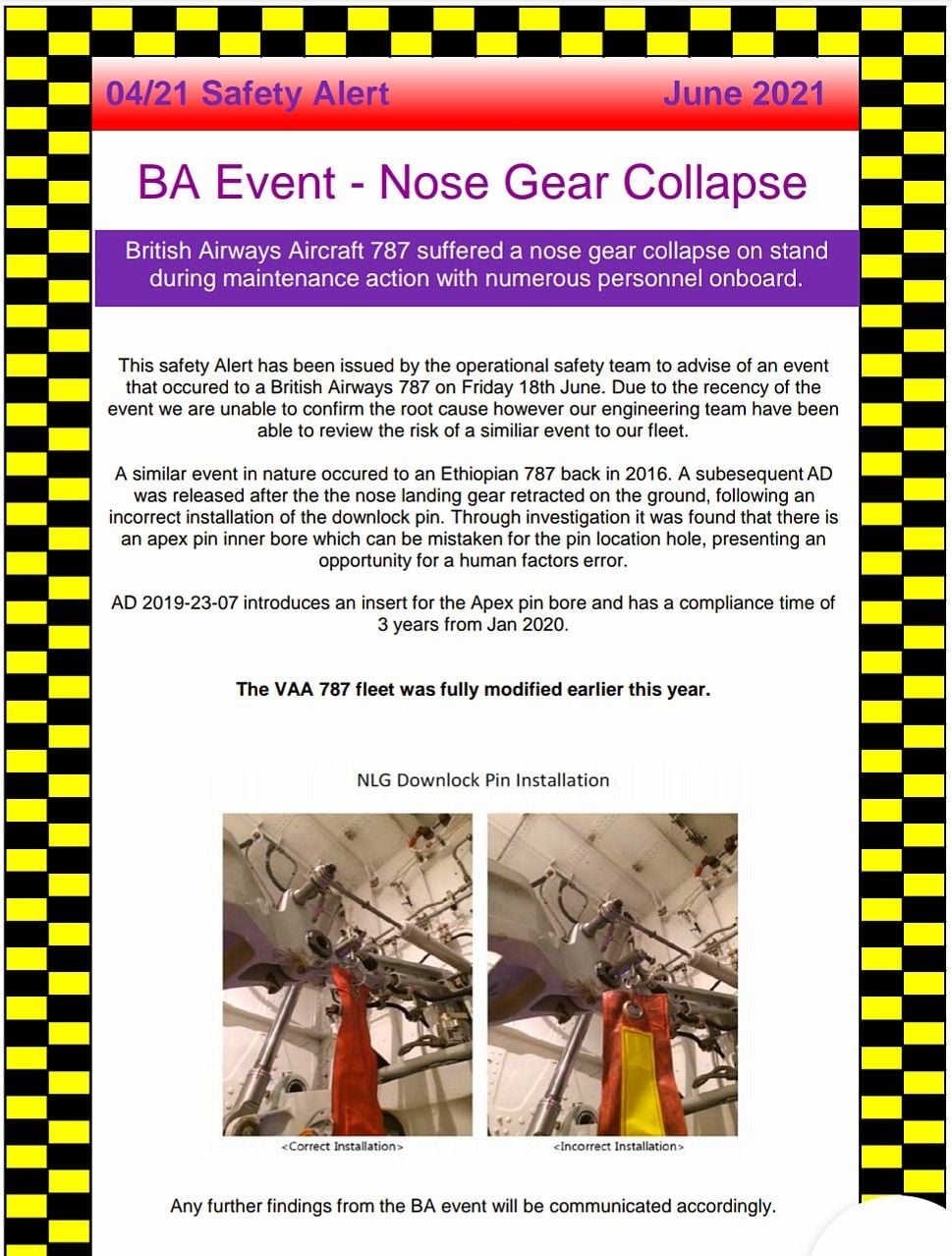

New B787 aircraft arrived for post-delivery mod. The NLG drag brace pivot link hollow bolt will accept the gear pin snuggly from LH side while the correct locking hole is 3 inches away and "unmarked." An inexperienced mechanic could accidentally place the locking pin in the wrong hole leading to gear collapse during ground testing damaging the aircraft and potentially injuring or killing persons in the vicinity of the gear.

Apply sealant or similar mitigation to the LH inside bolt hole, mark correct hole with red outline. Has previous Engineering Authorization been implemented on the fleet?

Seems like an accident waiting to happen to me. Except it has happened. Three times. I’d suggest this needs to be a mandatory urgent mod before it happens again.

Here’s the relevant FAA narrative.

Narrative 1

New B787 aircraft arrived for post-delivery mod. The NLG drag brace pivot link hollow bolt will accept the gear pin snuggly from LH side while the correct locking hole is 3 inches away and "unmarked." An inexperienced mechanic could accidentally place the locking pin in the wrong hole leading to gear collapse during ground testing damaging the aircraft and potentially injuring or killing persons in the vicinity of the gear.

Apply sealant or similar mitigation to the LH inside bolt hole, mark correct hole with red outline. Has previous Engineering Authorization been implemented on the fleet?

Seems like an accident waiting to happen to me. Except it has happened. Three times. I’d suggest this needs to be a mandatory urgent mod before it happens again.

We should probably wait before hanging a poor mechanic or ground handler out to dry until we have ascertained whether or not BA have embodied the relevant Boeing SB (as far as I'm aware, there is no corresponding EASA AD equivalent to the FAA one).

Paxing All Over The World

As someone who spent 27 years in IT and Telecommunications trying to make systems fool proof, the idea of a 21st cetury designed pin NOT having a unique notch/detent/angle/single entry point is another indication that Boeing really threw the book on the fire. Possibly on the fire of a 787 lithium battery pack

Am I missing something here? Notwithstanding that the nosegear ground lock pin was incorrectly positioned, the crew are onboard and the aircraft being made ready for departure so why would hydraulic and electrical selections be made such that the leg is unlocked and starts to retract?

Pure supposition but i would strongly suspect NLG door or gear position solenoid issue and gear function test carried out with the ensuing result . I wonder if the test passed ?

Wot spannersatcx said...it certainly didn't use to be unheard of to have rectification/maintenance being performed in parallel with pre-departure processes...just for once it probably was just as well this was a freight only service..

I think most types have at least one example of a nose gear collapse/retract and not just Boeing.

It is unnerving seeing the landing gear lever selected up as part of a maintenance check whilst firmly on the ground especially when you feel and hear the gear doors move.

It is unnerving seeing the landing gear lever selected up as part of a maintenance check whilst firmly on the ground especially when you feel and hear the gear doors move.