Qantas 744 Depressurisation

Let me get this clear, an oxy cylinder pressurised to, say 150 bar is secured by ONE tiny looking clamp. It also looks like the clamp is locked by some quick-locking device? This on a platform that vibrates and are subject to G-forces in all directions.

Not good enough on any ship I was on.

Per

Not good enough on any ship I was on.

Per

Please read post #186 again about possible damage repairs around where the missing bottle mount was.

Apparently nobody understands well enough to comment, so perhaps the originator should comment further.

Join Date: Mar 2008

Location: Canada

Posts: 13

Likes: 0

Received 0 Likes

on

0 Posts

One idea for a failure mechanism.

Lets assume for the moment that the regulator did suddenly fail while the oxygen tank was standing upright. Perhaps due to a one-in-a-million reason (bad threading, damage during the last inspection, corrosion, grease contamination, whatever).

The regulator flies upwards, and the oxygen tank tries to go downwards. The escaping gas from the tank would put a rather huge load on the bottom support bracket. Athough we don't have any really clear photos yet, it appears that the bottom support bracket for the oxygen tank is directly attached to the longitudinal ribs on the fuselage (see the photos of the tanks sitting on the bottom brackets and also the closeup photos of the adjacent bottom support bracket some posts back).

If the tank's bottom support bracket is directly attached to the fuselage, the huge downward force from the tank may have bent the bottom support bracket sufficiently to split open a seam in the fuselage. Perhaps that skinny little band clamp was strong enough to hold the oxygen tank vertical, but I suspect it would not have prevented the tank from putting a large vertical downwards force on the lower support bracket.

If that did cause a split in the hull, escaping pressure from the interior would have rapidly enlarged the split and thus the oxygen tank was perhaps propelled and/or sucked out of the opening. Any thoughts on this as possibly being the breach initiation mechanism?

Engineering school was a long time ago, but depending on the design and attachment of the bottom support bracket, a unexpectedly large load on the bracket could have put a very great stress on some part of the fuselage.

Anybody in a position to get a better photo of how the bottom support bracket is actually attached to the airplane?

speedbump

Lets assume for the moment that the regulator did suddenly fail while the oxygen tank was standing upright. Perhaps due to a one-in-a-million reason (bad threading, damage during the last inspection, corrosion, grease contamination, whatever).

The regulator flies upwards, and the oxygen tank tries to go downwards. The escaping gas from the tank would put a rather huge load on the bottom support bracket. Athough we don't have any really clear photos yet, it appears that the bottom support bracket for the oxygen tank is directly attached to the longitudinal ribs on the fuselage (see the photos of the tanks sitting on the bottom brackets and also the closeup photos of the adjacent bottom support bracket some posts back).

If the tank's bottom support bracket is directly attached to the fuselage, the huge downward force from the tank may have bent the bottom support bracket sufficiently to split open a seam in the fuselage. Perhaps that skinny little band clamp was strong enough to hold the oxygen tank vertical, but I suspect it would not have prevented the tank from putting a large vertical downwards force on the lower support bracket.

If that did cause a split in the hull, escaping pressure from the interior would have rapidly enlarged the split and thus the oxygen tank was perhaps propelled and/or sucked out of the opening. Any thoughts on this as possibly being the breach initiation mechanism?

Engineering school was a long time ago, but depending on the design and attachment of the bottom support bracket, a unexpectedly large load on the bracket could have put a very great stress on some part of the fuselage.

Anybody in a position to get a better photo of how the bottom support bracket is actually attached to the airplane?

speedbump

Join Date: Sep 2001

Location: 38N

Posts: 356

Likes: 0

Received 0 Likes

on

0 Posts

Interesting to note in CPTN's post #823 upper photo that the two adjacent O2 cylinders are significantly different in appearance and somewhat different in fixturing:

Even with allowance for perspective in the photo, it would seem the cylinder on the left is taller and newer than the one on the right. It is differently marked, a different shade of green, and possibly has some differences in the pipe attachments and fixings.

The cylinder mounting arrangement is clearly designed to optimize quick & easy installation & removal, consistent with the requirements described for certain cases where cylinders must be physically removed for charging. The clamp in contact with the bottle appears to be a standard stainless-type aircraft clamp material with a cam-over lever handle for latching. One might expect the handle to be safety-wired in place when closed, but no visual confirmation can be seen of any such safety tie-down, so it is either not present or is very hard to casually inspect for security.

For the bottle on the right, one can see that the hook side of the clamp (on the left side of the right bottle, as seen) engages the opposing loop side in a skewed manner, as compared to the bottle seen on the left in this image. This suggests that either a spring mechanism may be present for tensioning in the back, out of view, or that the clamp metal itself imposes enough spring tension to average out variations in mating angle between the sides. It also suggests that there might exist some clamps that are less secure in their grip than others - especially after years of use.

One might surmise that the bottle on the right is possibly one of the older metal-type O2 cylinders, and the one on the left a newer composite model.

One wonders if these types are considered to be interchangeable in general usage, despite minor differences in size and significant differences in weight?

One also wonders what kind of engineering analysis was done, and when, to determine the suitability of the original holder-bracket design and associated structures and fittings for use with the newer bottle style?

Even with allowance for perspective in the photo, it would seem the cylinder on the left is taller and newer than the one on the right. It is differently marked, a different shade of green, and possibly has some differences in the pipe attachments and fixings.

The cylinder mounting arrangement is clearly designed to optimize quick & easy installation & removal, consistent with the requirements described for certain cases where cylinders must be physically removed for charging. The clamp in contact with the bottle appears to be a standard stainless-type aircraft clamp material with a cam-over lever handle for latching. One might expect the handle to be safety-wired in place when closed, but no visual confirmation can be seen of any such safety tie-down, so it is either not present or is very hard to casually inspect for security.

For the bottle on the right, one can see that the hook side of the clamp (on the left side of the right bottle, as seen) engages the opposing loop side in a skewed manner, as compared to the bottle seen on the left in this image. This suggests that either a spring mechanism may be present for tensioning in the back, out of view, or that the clamp metal itself imposes enough spring tension to average out variations in mating angle between the sides. It also suggests that there might exist some clamps that are less secure in their grip than others - especially after years of use.

One might surmise that the bottle on the right is possibly one of the older metal-type O2 cylinders, and the one on the left a newer composite model.

One wonders if these types are considered to be interchangeable in general usage, despite minor differences in size and significant differences in weight?

One also wonders what kind of engineering analysis was done, and when, to determine the suitability of the original holder-bracket design and associated structures and fittings for use with the newer bottle style?

Join Date: Feb 2006

Location: sussex,england

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

What would happen if the fuselage failed at an area near the oxygen bottle lower support bracket causing a twisting motion to the regulator assembly enough to snap it off .Was the bottle a steel one or composite type ? Food for thought...............................

Join Date: Apr 2008

Location: YMMM FIR

Posts: 15

Likes: 0

Received 0 Likes

on

0 Posts

No probs Ancient,

I've got a novel idea that might help crew. Some PAX should not be so complacent and maybe pay a little extra attention to the pilots or cabin crew pre-flight briefing and read that laminated thingie in the pocket in front of them. A wealth of info on that plastic thingameebob

I've got a novel idea that might help crew. Some PAX should not be so complacent and maybe pay a little extra attention to the pilots or cabin crew pre-flight briefing and read that laminated thingie in the pocket in front of them. A wealth of info on that plastic thingameebob

Join Date: Feb 2004

Location: Australia

Posts: 1,307

Likes: 0

Received 0 Likes

on

0 Posts

The cylinder mounting arrangement is clearly designed to optimize quick & easy installation & removal, consistent with the requirements described for certain cases where cylinders must be physically removed for charging. The clamp in contact with the bottle appears to be a standard stainless-type aircraft clamp material with a cam-over lever handle for latching. One might expect the handle to be safety-wired in place when closed, but no visual confirmation can be seen of any such safety tie-down, so it is either not present or is very hard to casually inspect for security.

One might surmise that the bottle on the right is possibly one of the older metal-type O2 cylinders, and the one on the left a newer composite model.

Gentlemen, don't confuse the term "regulator" with "valve". The regulator is separate from the bottle on a T-piece attached to the right (aft) side of the bottle. The shutoff "valve" is on top of the bottle (normally wound fully open). However, looking at the pictures of the damage, the regulator, thermal compensator, pressure sensor/transducer and bottle valve (as well as the bottle) are completely missing. Only half the electrical plug for the pressure sensor remains.

Note that, without the spring clamp, the bottle will still be held in place with the rather rigid stainless pipework attached to both sides of the neck of the bottle. The pipework will flex to a degree, but when I changed a bottle last week, I found that the bottle had to be in a precise position to get the nuts on both pipes to thread properly.

Join Date: Nov 2006

Location: Asia

Posts: 183

Likes: 0

Received 0 Likes

on

0 Posts

Attn. Pacplyer re. 781

Yes, it's possible that Li grease + O2 in fair concentration could give you a fire.

There seems to be a drift towards the idea that the tank 'pushed' its way through the hull by jet propulsion, having ignominiously lost its valve. This really doesn't wash: the forces involved are not high enough, and are broadly downwards rather than outwards. However, the failure / loss of the valve is very likely to compromise the rest of the tank's structure. It would be strange if it didn't. We are then looking at sudden explosive failure a very short time after the loss of the valve, as a result of the considerable pressure that remains inside the tank blowing out the damaged tank structure. The resulting explosion would account for the observed damage to the a/c: a sudden, violent force outwards, powerful enough not just to hole the skin nearby but also to fracture neighbouring structural elements.

Yes, it's possible that Li grease + O2 in fair concentration could give you a fire.

There seems to be a drift towards the idea that the tank 'pushed' its way through the hull by jet propulsion, having ignominiously lost its valve. This really doesn't wash: the forces involved are not high enough, and are broadly downwards rather than outwards. However, the failure / loss of the valve is very likely to compromise the rest of the tank's structure. It would be strange if it didn't. We are then looking at sudden explosive failure a very short time after the loss of the valve, as a result of the considerable pressure that remains inside the tank blowing out the damaged tank structure. The resulting explosion would account for the observed damage to the a/c: a sudden, violent force outwards, powerful enough not just to hole the skin nearby but also to fracture neighbouring structural elements.

I agree with you. What makes the thrust of the bottle less likely a cause of the lattice work side-wall failure is the fact that this "rocket" is only potentially dangerous because of it's mass; and only if that mass can get time/space to accelerate the bottle into something with enough kinetic energy going to punch a whole through the side. Sitting in it's bracket venting isn't going to do it. If something else first knocked the valve off the bottle (or it fell) and then that cylinder, was free out of the bracket and looped around and hit...... man, sounds so problematical.... but I guess, if the tank threading was offset it might be possible.

And none of this really explains why people in business class reported that the floor buckled up (if that's true)..... does it?

Right now I'm in the camp that the popped-cork happened after and as a result of a seperate explosion or repair failure of some sort. But... I'm leaning toward complete cylinder disintegration as a primary cause for the first time in history because of those green smears at the R-2 door post. What we need to see is a picture of the fragments or get a report about what they are comprised of: fiberglass, bottle metal, bottle neck or just attached hardware?

Here's a fun exercise:

Could someone analyze the green tank color at the R2 doorpost for a color wavelength signature of that particular shade of green and see if it even comes close to the tank color vs. the green zinc chromate sprayed everywhere?) Note: we are just readers not safety experts. Don't quote anything in this thread in your newspaper.

What we need around here is more acurate press reports!

Last edited by pacplyer; 1st Aug 2008 at 02:19. Reason: expansion of idea

Join Date: Feb 2004

Location: Australia

Posts: 1,307

Likes: 0

Received 0 Likes

on

0 Posts

Quote:

The team have confirmed that the aircrafts three Instrument Landing Systems (ILS) and the anti-skid system were not available for the arrival and landing at Manila.

Was this merely more holes in the cheese, or is there a logical explanation?

The team have confirmed that the aircrafts three Instrument Landing Systems (ILS) and the anti-skid system were not available for the arrival and landing at Manila.

Was this merely more holes in the cheese, or is there a logical explanation?

Finding shrapnel damage in an aircraft this complex is not going to be easy. Somehow, I don't think this aircraft is going anywhere in a hurry

Let me get this clear, an oxy cylinder pressurised to, say 150 bar is secured by ONE tiny looking clamp. It also looks like the clamp is locked by some quick-locking device? This on a platform that vibrates and are subject to G-forces in all directions.

Not good enough on any ship I was on.

Not good enough on any ship I was on.

Join Date: Jul 2008

Location: Australia

Age: 64

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

As a way of visual perspective this is what happens to a motor vehicle when an industrial oxygen cylinder of about the same physical dimensions as the aircraft units has a catastrophic failure in a confined space. It occured in a suburb of Newcastle, NSW, Australia in about December 2005.

The owner was in the flats at the back asleep and was uninjured as the failure occured at night.

Notice the lack of glass in the buildings windows and the absence of a rear door on the building, now just an opening.

There was no fire, just a massive release of stored gaseous energy.

Two pictures of the damage and one of a similar specified vehicle for perspective.

The owner was in the flats at the back asleep and was uninjured as the failure occured at night.

Notice the lack of glass in the buildings windows and the absence of a rear door on the building, now just an opening.

There was no fire, just a massive release of stored gaseous energy.

Two pictures of the damage and one of a similar specified vehicle for perspective.

No expert here, just SLF with an interest in aviation, flying since the sixties.

But a thought - and perhaps some LAMEs can comment.

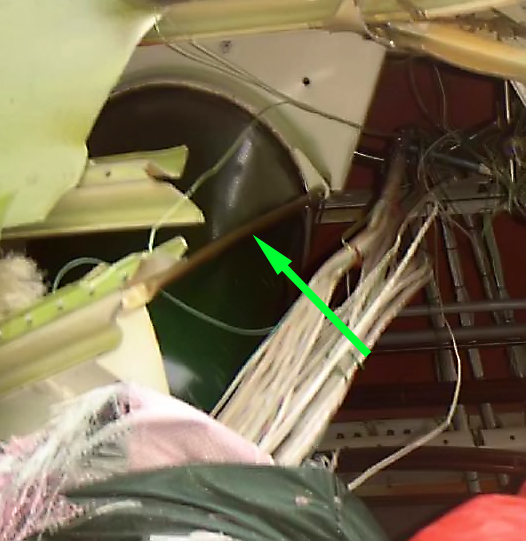

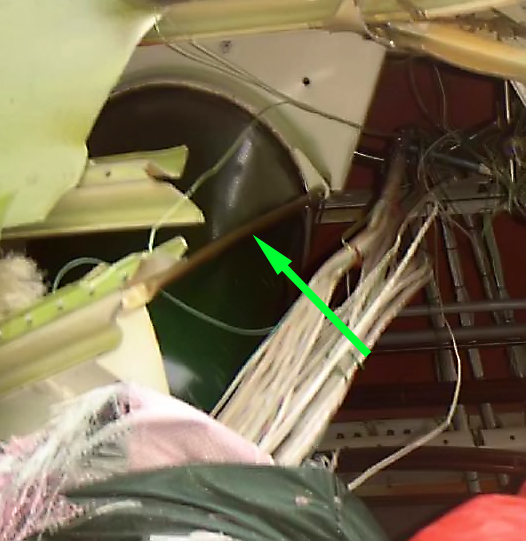

There seems to be two stays running from the top cradle of the oxygen cylinders back to the stringers, as shown in this pic:

If the cylinder ruptured, might not these pull back on the stringer (against the pressure differential pushing the hull out) causing it to separate from the skin and perhaps opening up a fracture in the hull?

Just a thought ......

But a thought - and perhaps some LAMEs can comment.

There seems to be two stays running from the top cradle of the oxygen cylinders back to the stringers, as shown in this pic:

If the cylinder ruptured, might not these pull back on the stringer (against the pressure differential pushing the hull out) causing it to separate from the skin and perhaps opening up a fracture in the hull?

Just a thought ......

Last edited by triton140; 1st Aug 2008 at 01:43.

Join Date: Sep 2007

Location: Switzerland

Age: 70

Posts: 62

Likes: 0

Received 0 Likes

on

0 Posts

Hi,

The clamping system for retain those bottles is very safe and it's nothing like vibrations or G forces who will open them (the handle have a insignifiant weight).The only way to them open is to applicate a great force on the handle.Of course if they broke .. the bottle will be free .. but this apply for any type of retainer.

I tell this by my experience with such retainers.

One remarkable thing in those photos is the car just aside is pratically intact ....

Seem's to indicate the blow destructions are dependent of the bottle position in the car ....

Cheers.

Let me get this clear, an oxy cylinder pressurised to, say 150 bar is secured by ONE tiny looking clamp. It also looks like the clamp is locked by some quick-locking device? This on a platform that vibrates and are subject to G-forces in all directions.

I tell this by my experience with such retainers.

Two pictures of the damage and one of a similar specified vehicle for perspective.

Seem's to indicate the blow destructions are dependent of the bottle position in the car ....

Cheers.

Last edited by NotPilotAtALL; 1st Aug 2008 at 01:56.

Can anyone seriously look at those photos of a Hilux ute, where a cylinder rupture in the rear load area, only contained by a fibreglass canopy, has utterly demolished the cabin area as well, and still feel a need to explain what direction the Qantas cylinder was facing, etc, when it failed?

The cylinder failed.

Some of it, including the valve, went upwards and was found in and around the door in the passenger cabin.

The escaping gas (not a rocketing near intact cylinder) blew a hole in the aircraft fuselage.

There was no fire. The oxygen was all gone, dissipated in a fraction of a second, long before any fire had a chance to get started.

Have another look. Gas, not cylinder fragments, did the damage.

Mechanical engineer.

No aircraft industry experience, but a healthy respect for compressed gases.

The cylinder failed.

Some of it, including the valve, went upwards and was found in and around the door in the passenger cabin.

The escaping gas (not a rocketing near intact cylinder) blew a hole in the aircraft fuselage.

There was no fire. The oxygen was all gone, dissipated in a fraction of a second, long before any fire had a chance to get started.

Have another look. Gas, not cylinder fragments, did the damage.

Mechanical engineer.

No aircraft industry experience, but a healthy respect for compressed gases.

Join Date: Nov 2006

Location: Asia

Posts: 183

Likes: 0

Received 0 Likes

on

0 Posts

Inspector Clouseau (aka: nonsense) has solved the case!

Gee Mr nonsense,

Was this a pressurized pick up truck? Structured to fly at 45,000 feet and handle over 9.2 internal differential before it failed?

Complete with a plumbed in aviation oxygen system with a known history of leaking at a bottle pressure of [up to] 1800 psi? Sitting next to unknown pallets of god-knows-what being shipped in huge pallet positions?

The Toyota picture may be appropriate to outline the destructive force possible with bottle structural failure, O.K. But your conclusions if stated non-hypothetically, are poor and without reasonable foundation.

Is that what you meant to do? Solve the investigation with proof from Toyota?

(I agree, however, that the "rocketeer theory" sounds unlikely. The problem is that your "cylinder failure theory" is statistically unheard of in reported jet aviation history of over fifty years. We can't find one case of this ever happening in millions of flight hours.)

Sometimes though, even Peter Sellers is right for the wrong reasons.....

.

Was this a pressurized pick up truck? Structured to fly at 45,000 feet and handle over 9.2 internal differential before it failed?

Complete with a plumbed in aviation oxygen system with a known history of leaking at a bottle pressure of [up to] 1800 psi? Sitting next to unknown pallets of god-knows-what being shipped in huge pallet positions?

The Toyota picture may be appropriate to outline the destructive force possible with bottle structural failure, O.K. But your conclusions if stated non-hypothetically, are poor and without reasonable foundation.

Is that what you meant to do? Solve the investigation with proof from Toyota?

(I agree, however, that the "rocketeer theory" sounds unlikely. The problem is that your "cylinder failure theory" is statistically unheard of in reported jet aviation history of over fifty years. We can't find one case of this ever happening in millions of flight hours.)

Sometimes though, even Peter Sellers is right for the wrong reasons.....

.

Last edited by pacplyer; 1st Aug 2008 at 05:15. Reason: better sarcasm

Join Date: Jul 2003

Location: Australia

Posts: 157

Likes: 0

Received 0 Likes

on

0 Posts

If it is confirmed that the bottle caused the incident or was a result of an incident which ruptured the oxy bottle presenting missile type debris inside an aircraft, we have a serious problem and one that is going to present itself as a headache for commercial aircraft designers, on all continents.

How many other unexplained hull losses over the years could have been caused by just such an event?

Was this the real cause of the TWA disaster, a bottle projecting itself into the centre fuel tank?

The list is endless, are we as passengers playing Russian Roulette and flying around on time bombs?

Is the only answer to a safer aircraft can be unpressurized stowage and the use of oxygen generators?

How many other unexplained hull losses over the years could have been caused by just such an event?

Was this the real cause of the TWA disaster, a bottle projecting itself into the centre fuel tank?

The list is endless, are we as passengers playing Russian Roulette and flying around on time bombs?

Is the only answer to a safer aircraft can be unpressurized stowage and the use of oxygen generators?

Join Date: Jul 2004

Location: Sydney, Australia

Posts: 13

Likes: 0

Received 0 Likes

on

0 Posts

Interesting point, Vortsa - particularly the TWA accident.

As tech crew I'm not overly concerned given the number of miles flown vs accident/incident rates, however as you say, it's a headache for designers, not to mention what happens to existing a/c already in service.

[EDIT: Also the issue regarding O2 generators is covered in this thread too - quite a few pages back but I recall it was a very good point]

Cheers, Chardster

As tech crew I'm not overly concerned given the number of miles flown vs accident/incident rates, however as you say, it's a headache for designers, not to mention what happens to existing a/c already in service.

[EDIT: Also the issue regarding O2 generators is covered in this thread too - quite a few pages back but I recall it was a very good point]

Cheers, Chardster

Join Date: Oct 2003

Location: Canberra Australia

Posts: 1,300

Likes: 0

Received 0 Likes

on

0 Posts

Missing factors.

We don't yet know the oxygen pressure in the bottles before the event. Top pressure is believed to be 1800 psi and a recharge reportably required if 1300 psi or less. Ultimate design strength another unknown yet. Charge pressure could have been anywhere between 1300 and 1800 psi..

Other unknown yet in this thread is the metallurgy of the bottle material.

Oxygen under pressure is a powerful oxident. An internal bottle scratch/blemish/flaw in manufacture may be all that is necessary as a crack starter particularly if there is any propensity for "stress corrosion cracking". A crack in steel under stress will grow at the tip of the crack as hydrogen ions migrate to the crack tip resulting in corrosion slowly extending the crack.

Every square inch of the bottle will have a force on it of up to 1800 pnds. If the valve in the neck of the bottle breaks away leaving a 3 square inch hole then the immediate thrust to propell the bottle will be say 3 X 1500 = 4,500 pnds.

Recall the MythBusters playing around with a bottle of compressed air. When the valve departed, the bottle went through a solid brick wall at high speed..

Another unknown is the life of the bottle and the number of pressure change cycles it will have experienced.. Could fatigue of the bottle material be a factor?

We don't yet know the oxygen pressure in the bottles before the event. Top pressure is believed to be 1800 psi and a recharge reportably required if 1300 psi or less. Ultimate design strength another unknown yet. Charge pressure could have been anywhere between 1300 and 1800 psi..

Other unknown yet in this thread is the metallurgy of the bottle material.

Oxygen under pressure is a powerful oxident. An internal bottle scratch/blemish/flaw in manufacture may be all that is necessary as a crack starter particularly if there is any propensity for "stress corrosion cracking". A crack in steel under stress will grow at the tip of the crack as hydrogen ions migrate to the crack tip resulting in corrosion slowly extending the crack.

Every square inch of the bottle will have a force on it of up to 1800 pnds. If the valve in the neck of the bottle breaks away leaving a 3 square inch hole then the immediate thrust to propell the bottle will be say 3 X 1500 = 4,500 pnds.

Recall the MythBusters playing around with a bottle of compressed air. When the valve departed, the bottle went through a solid brick wall at high speed..

Another unknown is the life of the bottle and the number of pressure change cycles it will have experienced.. Could fatigue of the bottle material be a factor?

The clamping system for retain those bottles is very safe and it's nothing like vibrations or G forces who will open them

Join Date: Jun 2006

Location: Wellington, New Zealand

Age: 43

Posts: 51

Likes: 0

Received 0 Likes

on

0 Posts

"Was this a pressurized pick up truck? Structured to fly at 45,000 feet and handle over 9.2 internal differential before it failed?"

No, but it was a modern car, which has to pass modern safety standards, made of steel, not thin aluminum alloy. I'm sure if you sealed it up properly, took care of the windows, it would be able to stand much higher pressure than a 747.

"The problem is that your "cylinder failure theory" is statistically unheard of in reported jet aviation history of over fifty years."

Stats are great, but they are also just that. They don't mean rare things can't happen, they just make them rare. Many accidents are caused by things that haven't happened before.

Besides, I don't think nonsense meant to imply that the bottle exploded on it's own, just that if it did rupture, the orientation might not have mattered compared to the bottle rocket theory. Then there's the possibility that it was a bit of both.

No, but it was a modern car, which has to pass modern safety standards, made of steel, not thin aluminum alloy. I'm sure if you sealed it up properly, took care of the windows, it would be able to stand much higher pressure than a 747.

"The problem is that your "cylinder failure theory" is statistically unheard of in reported jet aviation history of over fifty years."

Stats are great, but they are also just that. They don't mean rare things can't happen, they just make them rare. Many accidents are caused by things that haven't happened before.

Besides, I don't think nonsense meant to imply that the bottle exploded on it's own, just that if it did rupture, the orientation might not have mattered compared to the bottle rocket theory. Then there's the possibility that it was a bit of both.