Bell 206 Main Drive Shaft failure

The only failure I'm personally aware of was a K-Flex failure and the pilot felt a klunk which put his eyes on the panel and he saw the needle splits. He caught the overspeed which he said was quick but slower than a high side gov failure.

FWIW: I don't have a RR manual handy, but I don't recall any specific overspeed inspection for the 250 series engines. Usually if the engine exceeds any RPM limits it doesn't stop and "self-inspects" by throwing a wheel loose. However, I believe the loss of a main driveshaft falls under the "sudden stoppage" special inspection which has several levels based on component damage with the 1st levels being inspections only, ending with an overhaul requirement if the engine or xsmn mounts are deformed/broken.

FWIW: I don't have a RR manual handy, but I don't recall any specific overspeed inspection for the 250 series engines. Usually if the engine exceeds any RPM limits it doesn't stop and "self-inspects" by throwing a wheel loose. However, I believe the loss of a main driveshaft falls under the "sudden stoppage" special inspection which has several levels based on component damage with the 1st levels being inspections only, ending with an overhaul requirement if the engine or xsmn mounts are deformed/broken.

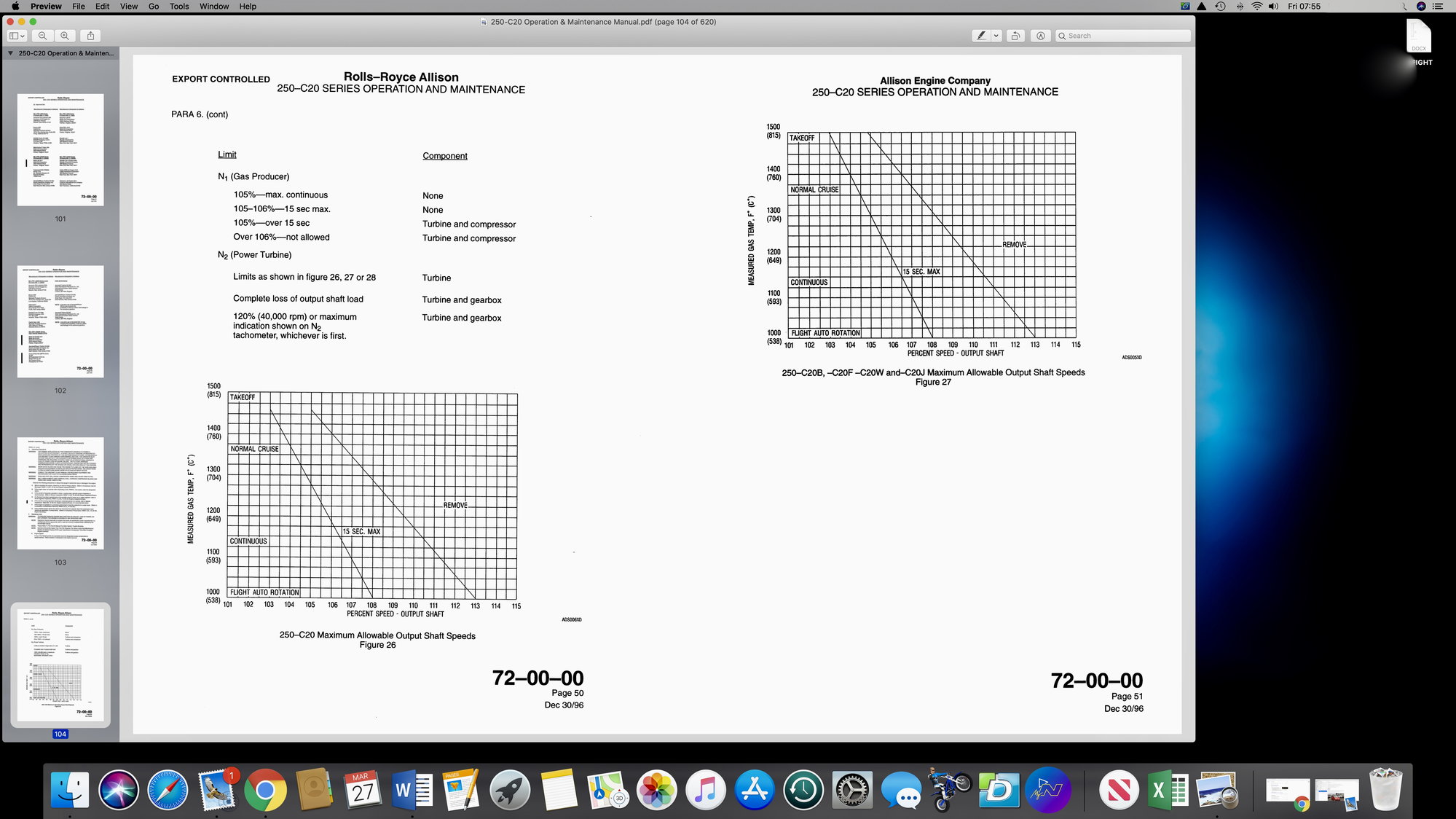

This is an old manual unamended and not up to date (on my computer) and shows what must be sent for overhaul if you exceed limitations.

I'm not aware of ovrspeed limits but i had a high side governor failure on a RR250 on a S-76 and the aircraft was not pulled off line, other than fixing the problem, governor drive shaft sheared.

Ha. And here I logged in to edit my previous post. Appreciate the correction. That's what I get for thinking without verifying. But after looking in an old C30 M&O, I still noted there is no Overspeed Inspection as I stated. Just the speed limit go/no-go table similar to what you posted. However, considering the T/R drive system is still intact and "loaded" on the engine after a IDS fails, I would not consider this a "Complete loss of output shaft load" as stated in our mutual speed limit tables. Perhaps performing the Sudden Stoppage/Engagement inspection (drive system component malfunction) and a quick call to RR Tech support would be in order before simply "sending it off for overhaul and contacting your bank manager." At least that's what my mechanic told me in the mirror this morning.

megan sez,

Er don't think so - the "shaft" you are thinking of is actually a bolted connection within the gearbox between 2 gears. And yes not only could it happen - it did!!

Not letting BS get in the way of a good story?

The S-76, irrespective of type of engine, whether it be RR250, Turbomeca or PT6 can have the same problem as the Bell 206 family if the input drive shaft from the number one engine to main gear box fails.

Not letting BS get in the way of a good story?

Here is the moment for you to shine RVDT and inform we mere plebs what the particular item is called and what it's function is besides transferring power from the engine to the main rotor shaft. I acknowledge I did err in saying "engine to main gear box", but that was to avoid having to explain the drivetrain layout, call it semantics.

megan,

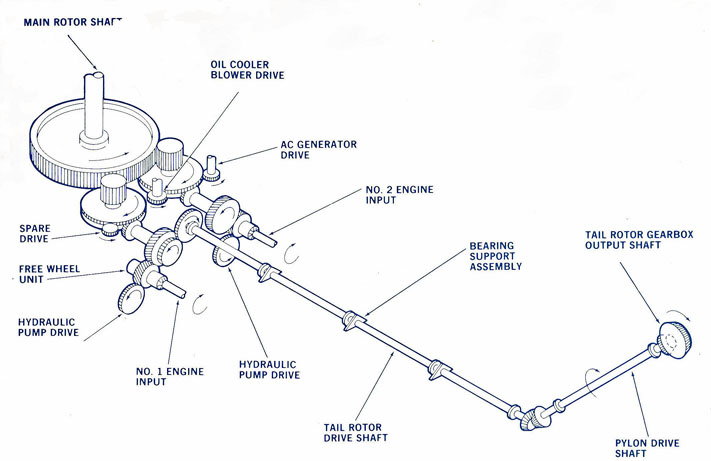

The convo here was about the drive shaft external to the main gearbox failing. If one of these failed on the 76 of which there are 2 the TR drive would remain intact.

The failure was inside the main gearbox and was a bolted coupling between 2 gears.

To quote from 2016 which you must have read because you commented on it.

All the gears and shafts and freewheels in your diagram are inside and part of the MGB except for the TRDS in the diagram.

Semantics? Maybe, but for me the devil is always in the details!

The convo here was about the drive shaft external to the main gearbox failing. If one of these failed on the 76 of which there are 2 the TR drive would remain intact.

The failure was inside the main gearbox and was a bolted coupling between 2 gears.

To quote from 2016 which you must have read because you commented on it.

Nick Lappos 2nd Nov 2001, 18:09

The procedure is based on an actual failure that occurred about 15 years ago, where the input gear attachment bolts lost torque and the separation that you describe actually occurred.

The gear was redesigned, and no repeat failure occurred. The flight crew noted the problem as noise and rumbling, a momentary upspeed of #1 engine, a swing to the left (extra tail thrust)

and then back to normal, with very low #1 torque and high #2 torque.

After a bit of discussion, the crew left well enough alone, and flew home without shutting down #1 (what a good pair of guys! If it works, leave it alone!).

When they landed, they noted that the failure, in that the tail rotor was not connected to the main rotor.

We id'd the problem and fixed it asap, of course, and no repeat has occurred. We inspect all boxes on overhaul for signs of lost torque on that gear to see if any recurrence is creeping back,

and everything is fine now.

For Nr Fairy

The above is not like a more common failure that NR fairy notes, where the engine shaft going to the transmission can fail, and N2/Np can go up while torque goes down. In that case, you have an

engine power loss, but a healthy rotor drive train otherwise. That can be confusing because the engine rpm on the triple tach goes up, but the rotor goes down. The rotor is your closest friend,

so it is wise to make it happy first, of course. Crews can get confused when those needles, always stuck together before, start to disagree.

Also, I am surprised that any A's are flogging around with disconnected electric overspeed systems. They were a pain in the early days (1979) but should be healthy now. The normal governor

will catch these failures we describe, I think, so it is not essential to the failures on this thread, but the electric overspeed is helpful for internal engine failures where the power section can unbutton

from the compressor, the internal engine overspeed can get very high and engine rupture is possible.

There are other clues to Nr - noise and vibration - pretty obvious but unless you have experienced it before it may be a little bit of a surprise as to what the strange noise is.

We used to do touchdown autos in the old days with the RRPM obscured for the student - surprising how close you can keep it to correct as you are attuned to the noise and vibration.

When DECU are involved which talk to each other to maintain constant N1 on both engines, when there are vastly different loads placed on each engine due to the MGB gear failure, then the discussion gets interesting.

I think you might mean NG or N2.

The procedure is based on an actual failure that occurred about 15 years ago, where the input gear attachment bolts lost torque and the separation that you describe actually occurred.

The gear was redesigned, and no repeat failure occurred. The flight crew noted the problem as noise and rumbling, a momentary upspeed of #1 engine, a swing to the left (extra tail thrust)

and then back to normal, with very low #1 torque and high #2 torque.

After a bit of discussion, the crew left well enough alone, and flew home without shutting down #1 (what a good pair of guys! If it works, leave it alone!).

When they landed, they noted that the failure, in that the tail rotor was not connected to the main rotor.

We id'd the problem and fixed it asap, of course, and no repeat has occurred. We inspect all boxes on overhaul for signs of lost torque on that gear to see if any recurrence is creeping back,

and everything is fine now.

For Nr Fairy

The above is not like a more common failure that NR fairy notes, where the engine shaft going to the transmission can fail, and N2/Np can go up while torque goes down. In that case, you have an

engine power loss, but a healthy rotor drive train otherwise. That can be confusing because the engine rpm on the triple tach goes up, but the rotor goes down. The rotor is your closest friend,

so it is wise to make it happy first, of course. Crews can get confused when those needles, always stuck together before, start to disagree.

Also, I am surprised that any A's are flogging around with disconnected electric overspeed systems. They were a pain in the early days (1979) but should be healthy now. The normal governor

will catch these failures we describe, I think, so it is not essential to the failures on this thread, but the electric overspeed is helpful for internal engine failures where the power section can unbutton

from the compressor, the internal engine overspeed can get very high and engine rupture is possible.

There are other clues to Nr - noise and vibration - pretty obvious but unless you have experienced it before it may be a little bit of a surprise as to what the strange noise is.

We used to do touchdown autos in the old days with the RRPM obscured for the student - surprising how close you can keep it to correct as you are attuned to the noise and vibration.

When DECU are involved which talk to each other to maintain constant N1 on both engines, when there are vastly different loads placed on each engine due to the MGB gear failure, then the discussion gets interesting.

I think you might mean NG or N2.

Semantics? Maybe, but for me the devil is always in the details!

RVDT, you need to reread the OP''s post, the devil is in the detail as you say.

The devil is in the detail, we're talking about a failure mode where power to the main rotor is reduced to zero but still leaves the tail rotor powered. The fact that the 76 failure mode occurs in the gearbox rather than external is moot. The OP asks "is there something unusual about the 206 setup", the answer is no, the 76, for one, has an identical failure mode.

it also says the engine must remain in operation to provide power to the tail rotor and that loss of control may occur if the engine is shut down.

My understanding is that conventional wisdom drives the TR from the MRGB - is this manual talking about a drive shaft failure between mrgb and the rotor system itself? Or is there something unusual about the 206 setup?

My understanding is that conventional wisdom drives the TR from the MRGB - is this manual talking about a drive shaft failure between mrgb and the rotor system itself? Or is there something unusual about the 206 setup?