Is Bell testing a multi-fenestron?

Join Date: Feb 2003

Location: Somerset

Posts: 282

Likes: 0

Received 0 Likes

on

0 Posts

It's a proof of concept demonstrator

So let's not read too much in to it, frankly we'll done Bell forgetting some real size flight hardware to this stage. I suspect the 4 motor choice is a combination of redundancy, noise, weight, heat dissipation and response reasons. I know other manufacturers are looking at electric tail control but this is the first I have heard using more than 1 rotor, a very elegant solution in my opinion as the motor is likely to be the weak link in the chain reliability wise, cabling, generators and control systems have aircraft qualification already. Would be very interesting to see how it handles in crosswords above the minimum spec point (17kts). BTW what is the normal low speed envelope for the 429?

DM🐀

DM🐀

That doesn’t account for any eventual complexity required to certify the system. Keep in mind there are zero fly by wire civil certified helicopters in existence. Adding an FBW system like this would have flight critical software, redundancy requirements all along the routing of the tail boom and a requirement for no “common mode” failures. That generally means 4 identical fans and motors would not be easily qualified with in flight critical applications because they were not designed for such a purpose.

I bet it is heavier than the system it replaces by a large margin... increases susceptibility to common mode critical failures like software, lightning or EMI.... and substantially less efficient from a pure energy transfer perspective... lots of physics to combat to prove me wrong here.

im glad Bell is investing some money in commercial space though. This seems like a real project as opposed to the FCX1 thing they showed a few years ago... so that’s nice.

I bet it is heavier than the system it replaces by a large margin... increases susceptibility to common mode critical failures like software, lightning or EMI.... and substantially less efficient from a pure energy transfer perspective... lots of physics to combat to prove me wrong here.

im glad Bell is investing some money in commercial space though. This seems like a real project as opposed to the FCX1 thing they showed a few years ago... so that’s nice.

Join Date: Apr 2009

Location: Australia

Age: 59

Posts: 12

Likes: 0

Received 0 Likes

on

0 Posts

Four layers of redundancy with four electric motors. Considerable weight saving at the rear, C of G moving forward. More streamlined than current options. Large reduction in maintenance requirements, current systems are complex and heavy.

10-15% Power saving that is now available for lift rather than yaw control.

Well worth more investment and testing.

10-15% Power saving that is now available for lift rather than yaw control.

Well worth more investment and testing.

Baby steps

I think of the Bell EDAT as a baby step for their Nexus air taxi. How will you ever FAA certify something like an all electric quad tilt rotor aircraft when you canít certify an electric tail rotor on a conventional helicopter?

Last edited by CTR; 23rd Feb 2020 at 20:58. Reason: Grammar

Join Date: Sep 2007

Location: USA

Posts: 601

Likes: 0

Received 0 Likes

on

0 Posts

dangermouse -

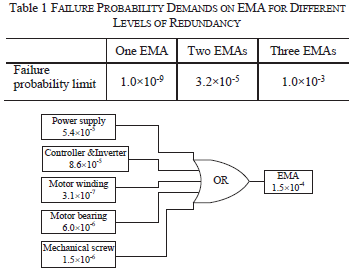

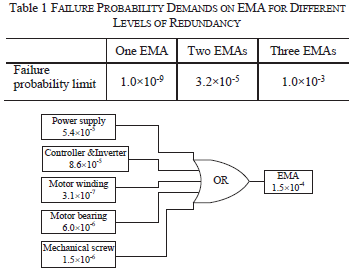

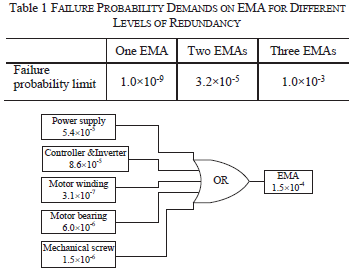

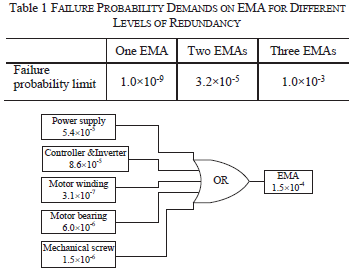

Your comment regarding the number of motors and reliability/failure rates is correct. Below is a typical fault tree for an electro-mechanical flight control actuation system. The threshold for primary flight control applications (like a helicopter tail rotor) is 1x10^-9 failures/flight hour. As you can see the least reliable parts of the system are the motor power electronics and controllers. A system like this would probably require 3 or more independent and isolated power/control circuits, and fault tolerant multi-phase motors. Fixed pitch blades are less efficient, but eliminate the need for very high reliability (and complex) actuators.

Your comment regarding the number of motors and reliability/failure rates is correct. Below is a typical fault tree for an electro-mechanical flight control actuation system. The threshold for primary flight control applications (like a helicopter tail rotor) is 1x10^-9 failures/flight hour. As you can see the least reliable parts of the system are the motor power electronics and controllers. A system like this would probably require 3 or more independent and isolated power/control circuits, and fault tolerant multi-phase motors. Fixed pitch blades are less efficient, but eliminate the need for very high reliability (and complex) actuators.

dangermouse -

Your comment regarding the number of motors and reliability/failure rates is correct. Below is a typical fault tree for an electro-mechanical flight control actuation system. The threshold for primary flight control applications (like a helicopter tail rotor) is 1x10^-9 failures/flight hour. As you can see the least reliable parts of the system are the motor power electronics and controllers. A system like this would probably require 3 or more independent and isolated power/control circuits, and fault tolerant multi-phase motors. Fixed pitch blades are less efficient, but eliminate the need for very high reliability (and complex) actuators.

Your comment regarding the number of motors and reliability/failure rates is correct. Below is a typical fault tree for an electro-mechanical flight control actuation system. The threshold for primary flight control applications (like a helicopter tail rotor) is 1x10^-9 failures/flight hour. As you can see the least reliable parts of the system are the motor power electronics and controllers. A system like this would probably require 3 or more independent and isolated power/control circuits, and fault tolerant multi-phase motors. Fixed pitch blades are less efficient, but eliminate the need for very high reliability (and complex) actuators.

AND [4 of each] ...

But that does not address common mode software or firmware failures.

The math is not that simple

Dangermouse and Riff Raff, the math is not that simple, or the whole requirements story.

First, loss of tail rotor control on most FAA certified helicopters is not classified as catastrophic, requiring 1E-9 probability of failure. Loss of tail rotor control is typically classified as hazardous, requiring only 1E-7 probability of failure. For Part 29 certification, the cyclic and collective controls however a catastrophic classification is correct.

Second, the Bell 429 is a Part 27 certified helicopter. For Part 27 certification flight controls a FEMCA is not required. However it is required under Part 29. I admit for new and novel technologies this is a gray area.

Third, the analysis you are providing as a reference is for a screw EMA actuator. You can delete the screws from the probability analysis. Additionally bearing failures are easily mitigated by use of redundant bearings or bushings, along with a sensor to detect primary bearing failure. So the probability of a dual simultaneous bearing failure is not even worth considering. Finally, main reason screw actuators are not used in aircraft primary flight controls is the difficulty in mitigating the common mode jam failure of a single screw. Configure two or three actuators in parallel, one actuator jams the assembly. Configure two or three actuators in series you end up with a very long actuator.

This is a big reason the Bell EDAT makes sense. In the event of one jammed fan, the remaining fans performance are not impacted.

First, loss of tail rotor control on most FAA certified helicopters is not classified as catastrophic, requiring 1E-9 probability of failure. Loss of tail rotor control is typically classified as hazardous, requiring only 1E-7 probability of failure. For Part 29 certification, the cyclic and collective controls however a catastrophic classification is correct.

Second, the Bell 429 is a Part 27 certified helicopter. For Part 27 certification flight controls a FEMCA is not required. However it is required under Part 29. I admit for new and novel technologies this is a gray area.

Third, the analysis you are providing as a reference is for a screw EMA actuator. You can delete the screws from the probability analysis. Additionally bearing failures are easily mitigated by use of redundant bearings or bushings, along with a sensor to detect primary bearing failure. So the probability of a dual simultaneous bearing failure is not even worth considering. Finally, main reason screw actuators are not used in aircraft primary flight controls is the difficulty in mitigating the common mode jam failure of a single screw. Configure two or three actuators in parallel, one actuator jams the assembly. Configure two or three actuators in series you end up with a very long actuator.

This is a big reason the Bell EDAT makes sense. In the event of one jammed fan, the remaining fans performance are not impacted.

Last edited by CTR; 23rd Feb 2020 at 22:36. Reason: Spelling

Dangermouse and Riff Raff, the math is not that simple, or the whole requirements story.

First, loss of tail rotor control on most FAA certified helicopters is not classified as catastrophic, requiring 1E-9 probability of failure. Loss of tail rotor control is typically classified as hazardous, requiring only 1E-7 probability of failure. For Part 29 certification, the cyclic and collective controls however a catastrophic classification is correct.

Second, the Bell 429 is a Part 27 certified helicopter. For Part 27 certification flight controls a FEMCA is not required. However it is required under Part 29. I admit for new and novel technologies this is a gray area.

Third, the analysis you are providing as a reference is for a screw EMA actuator. You can delete the screws from the probability analysis. Additionally bearing failures are easily mitigated by use of redundant bearings or bushings, along with a sensor to detect primary bearing failure. So the probability of a dual simultaneous bearing failure is not even worth considering. Finally, main reason screw actuators are not used in aircraft primary flight controls is the difficulty in mitigating the common mode jam failure of a single screw. Configure two or three actuators in parallel, one actuator jams the assembly. Configure two or three actuators in series you end up with a very long actuator.

This is a big reason the Bell EDAT makes sense. In the event of one jammed fan, the remaining fans performance are not impacted.

First, loss of tail rotor control on most FAA certified helicopters is not classified as catastrophic, requiring 1E-9 probability of failure. Loss of tail rotor control is typically classified as hazardous, requiring only 1E-7 probability of failure. For Part 29 certification, the cyclic and collective controls however a catastrophic classification is correct.

Second, the Bell 429 is a Part 27 certified helicopter. For Part 27 certification flight controls a FEMCA is not required. However it is required under Part 29. I admit for new and novel technologies this is a gray area.

Third, the analysis you are providing as a reference is for a screw EMA actuator. You can delete the screws from the probability analysis. Additionally bearing failures are easily mitigated by use of redundant bearings or bushings, along with a sensor to detect primary bearing failure. So the probability of a dual simultaneous bearing failure is not even worth considering. Finally, main reason screw actuators are not used in aircraft primary flight controls is the difficulty in mitigating the common mode jam failure of a single screw. Configure two or three actuators in parallel, one actuator jams the assembly. Configure two or three actuators in series you end up with a very long actuator.

This is a big reason the Bell EDAT makes sense. In the event of one jammed fan, the remaining fans performance are not impacted.

The energy efficiency argument is tricky though... the engine>>>generator>>>distribution>>>motor is quite inefficient vs straight mechanical power transfer... losses are very small along a traditional series of bearings and gears.

cant wait to see those performance numbers.

Fully agree on all points. But as stated earlier, EDAT is a good baby step for electric distributed propulsion. Because if you canít do an electric tail rotor requiring only 1◊E-7, how will you ever do an all electric EVTOL requiring a probability of failure better than 1XE-9?

Last edited by CTR; 24th Feb 2020 at 11:20.

Fully agree on all points. But as stated earlier, EDAT is a good baby step for electric distributed propulsion. Because if you canít do an electric tail rotor requiring only 1◊E-7, how will you ever do an all electric EVTOL requiring a probability of failure better than 1XE-9?

As long as the regulatory environment continues itís profound misplaced emphasis on process over substance, EVTOLís will be only used in Kit or Experimental applications... and helicopters have a bright and vibrant future!

Join Date: Feb 2008

Location: Manitoba Canada

Age: 72

Posts: 223

Likes: 0

Received 0 Likes

on

0 Posts

I confess to being an old school helicopter guy and find the battery-electric drones swarming the sky quite irksome.

However we must give those enthusiastic drone-youth some credit .... here is a prototype battery-electric they built to carry a passenger .... they are not hindered by anything ... probably no one told them it wouldn't work so they just went ahead and did it. Filmed at an old Zeppelin hangar in Germany I think

It is an 18 minute video .... and at 15:00 flies outdoors with a lightweight dummy .

Will be interesting to see if it will actually carry a passenger , and of course battery life will likely be under 30 minutes and not very practical as far as helicopters go.

Have to give these fellows some admiration ... not only that ... they are already self-trained to fly it by remote control ... I think I am jealous .... haaaa !!! ... and I doubt they have a multi-million dollar helicopter engineering department backing them .... they are more like video-game enthusiasts.

Anyway , it gives some credence to using several small electric motors with plastic propellers like the Bell 429 experiment.

However we must give those enthusiastic drone-youth some credit .... here is a prototype battery-electric they built to carry a passenger .... they are not hindered by anything ... probably no one told them it wouldn't work so they just went ahead and did it. Filmed at an old Zeppelin hangar in Germany I think

It is an 18 minute video .... and at 15:00 flies outdoors with a lightweight dummy .

Will be interesting to see if it will actually carry a passenger , and of course battery life will likely be under 30 minutes and not very practical as far as helicopters go.

Have to give these fellows some admiration ... not only that ... they are already self-trained to fly it by remote control ... I think I am jealous .... haaaa !!! ... and I doubt they have a multi-million dollar helicopter engineering department backing them .... they are more like video-game enthusiasts.

Anyway , it gives some credence to using several small electric motors with plastic propellers like the Bell 429 experiment.

Filmed at an old Zeppelin hangar in Germany I think

Thread Starter

However as forward speed increases, the electric fan speeds can be reduced or even stopped. Therefore the electric fan load on the engines can drop below that of a conventional shaft driven tail rotor.

Another factor to be considered is the impact of reduction in main rotor speed to reduce noise. Many helicopters today have the capability of reducing rotor speed to reduce noise. This results in reduced lift capacity and engine efficiency. The ability to reduce the tail rotor speed independent of the main rotor speed may allow for additional performance benefits.

Join Date: May 2010

Location: New Zealand

Age: 52

Posts: 395

Likes: 0

Received 0 Likes

on

0 Posts

Correct. In fact when hovering the electric fans will impose a higher engine load than a conventional shaft driven tail rotor due to the lower efficiency of electrics.

However as forward speed increases, the electric fan speeds can be reduced or even stopped. Therefore the electric fan load on the engines can drop below that of a conventional shaft driven tail rotor.

Another factor to be considered is the impact of reduction in main rotor speed to reduce noise. Many helicopters today have the capability of reducing rotor speed to reduce noise. This results in reduced lift capacity and engine efficiency. The ability to reduce the tail rotor speed independent of the main rotor speed may allow for additional performance benefits.

However as forward speed increases, the electric fan speeds can be reduced or even stopped. Therefore the electric fan load on the engines can drop below that of a conventional shaft driven tail rotor.

Another factor to be considered is the impact of reduction in main rotor speed to reduce noise. Many helicopters today have the capability of reducing rotor speed to reduce noise. This results in reduced lift capacity and engine efficiency. The ability to reduce the tail rotor speed independent of the main rotor speed may allow for additional performance benefits.

For doing what a lot of helicopters actually do, would a conventional tail rotor be better? A lot of helicopters are already maxed out when lifting heavy loads close to operating limits, and pushing a bit too much TR causes spikes that the computer loves to record for you. AS350 being an example. If the electric fans will draw more power than conventional TR, then surely they would be worse in these situations? As forward speed increases the draw on the conventional TR also decreases, but they aren't near the limits at this point.

So for operations such as Fire fighting, Utility, construction, Agricultural, lifting, logging, SAR if lots of winching, etc a conventional TR would probably be better??