Sikorsky S-92: Operations

Join Date: Sep 2007

Location: USA

Posts: 601

Likes: 0

Received 0 Likes

on

0 Posts

squib66,

I think Sikorsky has realized for a while that having a main gearbox aux. lube system is currently the only practical way to meet a 30 min. loss of lube requirement. The CH-53K main gearbox design incorporates one.

I think Sikorsky has realized for a while that having a main gearbox aux. lube system is currently the only practical way to meet a 30 min. loss of lube requirement. The CH-53K main gearbox design incorporates one.

Join Date: Dec 2003

Location: texas

Posts: 117

Likes: 0

Received 0 Likes

on

0 Posts

In today's enviroment, the 30 minute requirement is already becoming obsolete. Its not uncommon to be supporting rigs that are over 200 nautical miles from shore. Hopefully Sikorsky and the industry in general will be looking towards 60 minutes or more.

Join Date: Mar 2002

Location: Canada

Posts: 690

Likes: 0

Received 0 Likes

on

0 Posts

I think you will find that any future ASB on the studs would have a far more rapid compliance time.

I also hear that Sikorsky has recently had to clarify that even the Phase 3 MGBs also need the 10 hour foot inspection.

Join Date: Mar 2002

Location: Canada

Posts: 690

Likes: 0

Received 0 Likes

on

0 Posts

There have been rumours since 2009 that Sikorsky would have to fit an extra lube system to the CH-148 MHP.

There is more on the families' letter. Mr. Lebel's spokeswoman, Vanessa Schneider, said Friday that a response to the February letter was supposed to be sent to the families in June. “Because of an administrative error, it had not gone out as we had thought,” she said in an interview. Ms. Schneider would not discuss the contents of the response, even though family members have stressed that their letter is open and they want public answers.

There is more on the families' letter. Mr. Lebel's spokeswoman, Vanessa Schneider, said Friday that a response to the February letter was supposed to be sent to the families in June. “Because of an administrative error, it had not gone out as we had thought,” she said in an interview. Ms. Schneider would not discuss the contents of the response, even though family members have stressed that their letter is open and they want public answers.

Last edited by zalt; 7th Nov 2011 at 18:20.

That’s because the MM calls for a 10-hour inspection of the main gearbox mounting feet on ALL main upper housing assembly P/N’s, so clearly some confusion regarding the word ALL.

Zalt

Are you suggesting the OEM should seek approval from the FAA to increase, or even remove, any continued inspection requirements without first monitoring the latest in-service phase III housings, so as to ensure no evidence of cracking prior to seeking any amendment of the current inspection requirements?

And there was me thinking you were a champion of flight safety.

Are you suggesting the OEM should seek approval from the FAA to increase, or even remove, any continued inspection requirements without first monitoring the latest in-service phase III housings, so as to ensure no evidence of cracking prior to seeking any amendment of the current inspection requirements?

And there was me thinking you were a champion of flight safety.

Join Date: Sep 2008

Location: Croydon

Posts: 285

Likes: 0

Received 0 Likes

on

0 Posts

riff-raff

Thanks for the prompt to do some research, I'd not paid too much attention to the CH-53K.

From what I've read the auxiliary lube is for the TGB and IGB only.

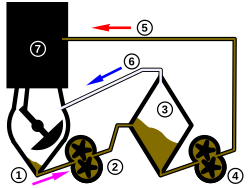

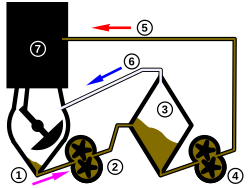

The MGB is to have a 'Redundant “Dry Sump” lube system' that allegedly gives 'significant reduction in oil leak or spray' to provide a 30 min operation capability after loss of lube. Dry sumps are used in high performance engines as seen here:

I take the description to mean two sources of oil, possibly external to the MGB, with separate pumps to give the redundancy. There is however means greater complexity and associated failure modes.

Aluminium gearbox cases are also proposed for all gearboxes, for weight, corrosion protection and greater tolerance to brittle case failure. Nice to see in acknowledged that failures from other than the oil cooler aren't extremely remote.

Some fancy new materials are also being proposed for the bearings: Triton Systems, Inc.

Thanks for the prompt to do some research, I'd not paid too much attention to the CH-53K.

From what I've read the auxiliary lube is for the TGB and IGB only.

The MGB is to have a 'Redundant “Dry Sump” lube system' that allegedly gives 'significant reduction in oil leak or spray' to provide a 30 min operation capability after loss of lube. Dry sumps are used in high performance engines as seen here:

I take the description to mean two sources of oil, possibly external to the MGB, with separate pumps to give the redundancy. There is however means greater complexity and associated failure modes.

Aluminium gearbox cases are also proposed for all gearboxes, for weight, corrosion protection and greater tolerance to brittle case failure. Nice to see in acknowledged that failures from other than the oil cooler aren't extremely remote.

Some fancy new materials are also being proposed for the bearings: Triton Systems, Inc.

Last edited by squib66; 7th Nov 2011 at 19:52.

squib:

In the Aluminum housing feature you are discussing, the US Navy seems to be moving to aluminum housings on some of their Seahawk (S-70) models in the near future as well, for the same reasons you cited.

In the Aluminum housing feature you are discussing, the US Navy seems to be moving to aluminum housings on some of their Seahawk (S-70) models in the near future as well, for the same reasons you cited.

"Only Practical Way "

Riff Raff wrote:

"I think Sikorsky has realized for a while that having a main gearbox aux. lube system is currently the only practical way to meet a 30 min. loss of lube requirement. "

Just wanted to point out that there are about 3000+ Blackhawks and Seahawks, flying around with main boxes that darn near made it to an hour during the no oil test qualification to meet the US Army 30 minute requirement.

Thanks,

John Dixson

"I think Sikorsky has realized for a while that having a main gearbox aux. lube system is currently the only practical way to meet a 30 min. loss of lube requirement. "

Just wanted to point out that there are about 3000+ Blackhawks and Seahawks, flying around with main boxes that darn near made it to an hour during the no oil test qualification to meet the US Army 30 minute requirement.

Thanks,

John Dixson

Last edited by JohnDixson; 8th Nov 2011 at 11:40. Reason: Added quotation marks

Join Date: Feb 2003

Location: Somerset

Posts: 282

Likes: 0

Received 0 Likes

on

0 Posts

only practical way pt 2

there is another way because the EH101 managed to pass the 30 minute tests without an auxiliary lube system many years ago.

Never been needed so far but fully compliant with the rules.

here is a rheotic question. Quoted above is this..

The service history therefore does not support the method of compliance that was originally accepted by the FAA at the time of the Model S-92A type certification

doesn't that mean that the FAA now recognises that the certification basis was incorrect and if that is the case why is the S92 still flying as a Category A aircraft when it patently isn't?

DM

Never been needed so far but fully compliant with the rules.

here is a rheotic question. Quoted above is this..

The service history therefore does not support the method of compliance that was originally accepted by the FAA at the time of the Model S-92A type certification

doesn't that mean that the FAA now recognises that the certification basis was incorrect and if that is the case why is the S92 still flying as a Category A aircraft when it patently isn't?

DM

Last edited by dangermouse; 8th Nov 2011 at 16:22. Reason: typo fixed

Only Practical Way

Dangermouse,

I think the operative paragraph in that article is:

"The FAA’s response reiterated its requirement that the MGB must be able to run for at least 30 minutes with a loss of lubricating oil, “unless a lubrication failure resulting in a loss of lubrication is determined to be ‘extremely remote.’”"

I'm a bit remote from the specifics of what is going on daily with the S-92 program( been retired 7 years come January ) but if the FAA didn't concur that the gearbox changes were in compliance, one would assume they would pull the certification. Ergo...

Thanks,

John Dixson

I think the operative paragraph in that article is:

"The FAA’s response reiterated its requirement that the MGB must be able to run for at least 30 minutes with a loss of lubricating oil, “unless a lubrication failure resulting in a loss of lubrication is determined to be ‘extremely remote.’”"

I'm a bit remote from the specifics of what is going on daily with the S-92 program( been retired 7 years come January ) but if the FAA didn't concur that the gearbox changes were in compliance, one would assume they would pull the certification. Ergo...

Thanks,

John Dixson

Join Date: Sep 2008

Location: Croydon

Posts: 285

Likes: 0

Received 0 Likes

on

0 Posts

John

To pull the TC the FAA would have to admit their failure plus it would be open to challenge politically because older helicopters are flying that are as bad.

Another catastrophic oil loss and that would be different.

I'd like to see the TC data sheet state the (at best) partial compliance.

Your Blackhawk claim, which AFAIK is new, that the type (the fleet size is irrelevant) made nearly an hour is interesting. If so that means the S-92, with a total oil loss is 5 or 6 times worse that the H-60. This just illustrates how big Sikorsky's S-92 design failure was.

if the FAA didn't concur that the gearbox changes were in compliance, one would assume they would pull the certification. Ergo...

Another catastrophic oil loss and that would be different.

I'd like to see the TC data sheet state the (at best) partial compliance.

Your Blackhawk claim, which AFAIK is new, that the type (the fleet size is irrelevant) made nearly an hour is interesting. If so that means the S-92, with a total oil loss is 5 or 6 times worse that the H-60. This just illustrates how big Sikorsky's S-92 design failure was.

Zalt,

Any final explanation about the Bond Aircraft that shucked its rotorhead? I might sugges Eurocopter might have a few issues to deal with as does Sikorsky.

At least we know what the problem with the 92 is....

Do we know what caused the Bond crash?

Any final explanation about the Bond Aircraft that shucked its rotorhead? I might sugges Eurocopter might have a few issues to deal with as does Sikorsky.

At least we know what the problem with the 92 is....

Do we know what caused the Bond crash?

Join Date: Mar 2002

Location: Canada

Posts: 690

Likes: 0

Received 0 Likes

on

0 Posts

I look forward to that final report, but at least Eurocopter did not only partially redo a certification test after a failure, the failure mode is not one that has caused multiple incidents months apart or that needs daily inspections for rapid cracking.

Join Date: Mar 2009

Location: St. John's, Newfoundland

Age: 54

Posts: 178

Received 0 Likes

on

0 Posts

Just wanted to point out that there are about 3000+ Blackhawks and Seahawks, flying around with main boxes that darn near made it to an hour during the no oil test qualification to meet the US Army 30 minute requirement.

The current proposed modification sounds to me like a leaf out of the S61 book i.e. aux sump and backup lube oil pump...is that what they call progress in over two and a half years since 491 and over three years since Broome?

Safe flying (with HUEBA at the ready and a suit that will hopefully keep me dry)

Max

the failure mode is not one that has caused multiple incidents months apart or that needs daily inspections for rapid cracking.

Oh...there was some rapid cracking....but it was a failure mode that when it does happen...ends the game!

The Newfoundland crash could have resulted in a very much better outcome if the aircraft had been ditched much earlier than attempted. The folks in the Bond aircraft never had that chance.

The key Zalt is we still do not know what caused the Bond Crash....it is the not knowing that is the problem. At least with daily inspections one has a something to go on rather than riding around merely hoping all is well...what ever it was that went bad.

How long has it been since the accident occurred....and still no report? No finger pointing at a cause certain?

Ya'll keep whistling as you walk by that graveyard gate!

Join Date: Sep 2007

Location: USA

Posts: 601

Likes: 0

Received 0 Likes

on

0 Posts

squib66,

As you note, the 53K aux. lube circuits are used in the MRGB, input nose GB's, and IGB/TRGB's. The aux. lube systems use a supplementary oil volume that is "misted" onto critical gear meshes and bearing using bleed air pressure from the ECS. The critical gear meshes tend to be the spiral bevels used in the nose input GB's, the IGB and the TRGB.

I believe the 53K MRGB also has switched to an aluminum housing material, since there were significant maintenance costs associated with the mag housings on the 53E's.

Lastly, the FRA MMC material you referenced from Triton is pretty neat stuff. It is used for rolling element bearing liners in mag or aluminum housings. On a big MRGB housing like the 53K's, it can probably save about 50 lbs versus carburized steel liners. But at about $300/lb, it is definitely not cheap!

riff_raff

As you note, the 53K aux. lube circuits are used in the MRGB, input nose GB's, and IGB/TRGB's. The aux. lube systems use a supplementary oil volume that is "misted" onto critical gear meshes and bearing using bleed air pressure from the ECS. The critical gear meshes tend to be the spiral bevels used in the nose input GB's, the IGB and the TRGB.

I believe the 53K MRGB also has switched to an aluminum housing material, since there were significant maintenance costs associated with the mag housings on the 53E's.

Lastly, the FRA MMC material you referenced from Triton is pretty neat stuff. It is used for rolling element bearing liners in mag or aluminum housings. On a big MRGB housing like the 53K's, it can probably save about 50 lbs versus carburized steel liners. But at about $300/lb, it is definitely not cheap!

riff_raff

Join Date: Sep 2008

Location: Croydon

Posts: 285

Likes: 0

Received 0 Likes

on

0 Posts

SASless perhaps there is greater faith in AAIB and their issuance of prompt recommendations. At least they don't do Esquire Magazine before they report. Or perhaps they expect simple static components like studs and mounting feet to be free of potentially catastrophic failure modes.

--------------------------------------------------------------------------

This incident at Scatsta has been discussed before:

Air Accidents Investigation: Sikorsky S-92A, G-IACC

The Aircraft Accident Report Form submitted by the pilot states the aircraft reached just 6ft off the ground.

Damage was reported as:

One new fact has emerged: the damage was so severe that Bristow have had to declare an extraordinary item in their accounts of a cool $0.9 million for the repair.

--------------------------------------------------------------------------

This incident at Scatsta has been discussed before:

Air Accidents Investigation: Sikorsky S-92A, G-IACC

Summary: The helicopter was ground taxied onto a parking spot and brought to a stop by the commander, who was the pilot flying. He then intended to apply the parking brake but inadvertently raised the collective control lever, which caused the helicopter to become airborne.

He [then] released the collective control lever, which was lowered by the collective trim system to the fully down position, and the helicopter landed heavily, causing damage to the landing gear and airframe.

deformation of the airframe structure in two places and a crack in one of the left main landing gear wheel rims, on which the tyre had deflated.