Fuel Injection Systems

Fuel Injection Systems

While it seems there has been some movement on the technology from in fuel injection with the new FADEC systems that continental and Lycoming are introducing. As we all know the typical fuel injection system is a crude at best setup......being a constant flow type.

Now the new FADEC systems introduce sequential injection where the fuel is squirted in only when the valve is open...or there abouts. But even that technology is 30 years old.

With most of the major automotive manufacturers adopting the direct injection method where the fuel is injected directly into the cylinder under enormous pressure, something like 26,000 psi. The engineers tell me it gains small but significant fuel economy gains.

Surely this principle would work in the aero engine context?

Any engineers want to comment?

Now the new FADEC systems introduce sequential injection where the fuel is squirted in only when the valve is open...or there abouts. But even that technology is 30 years old.

With most of the major automotive manufacturers adopting the direct injection method where the fuel is injected directly into the cylinder under enormous pressure, something like 26,000 psi. The engineers tell me it gains small but significant fuel economy gains.

Surely this principle would work in the aero engine context?

Any engineers want to comment?

So what is it?

Small gain or significant gain?

Why introduce more complexity to the systems?

What's used now is simple and reliable why change for the sake of change?

Oh wait, "change" is where it's at these days isn't it.

Small gain or significant gain?

Why introduce more complexity to the systems?

What's used now is simple and reliable why change for the sake of change?

Oh wait, "change" is where it's at these days isn't it.

Grandpa Aerotart

nomorecatering as it currently stands I can run my IO550b at 49lph with just gamijectors and an EDM700 and a modicum of thought.

The system you're talking about might add 20k to the cost of the engine to save what...1 or 2 lph?

Non Diesel GA FADEC has thus far been a big flop because it costs LOTS and delivers **** all...diesel has been a bigger flop for the same reasons.

There are reasons why aircraft engine technology has only crept forward in baby steps in the last 65 years - and most of those baby steps have been metallurgical rather than technological - it has to do with 1/. economies of scale and 2/. the current technology is bloody good.

How many car engines pull several hundred HP continuously?

The system you're talking about might add 20k to the cost of the engine to save what...1 or 2 lph?

Non Diesel GA FADEC has thus far been a big flop because it costs LOTS and delivers **** all...diesel has been a bigger flop for the same reasons.

There are reasons why aircraft engine technology has only crept forward in baby steps in the last 65 years - and most of those baby steps have been metallurgical rather than technological - it has to do with 1/. economies of scale and 2/. the current technology is bloody good.

How many car engines pull several hundred HP continuously?

How many car engines pull several hundred HP continuously?

How many aeroplane piston engines can spin to 8,000rpm?

Not really a valid comparison ....

I think it is, many innovations found in automotive applications were tried and abandoned in aviation decades ago as too complex and delivering too little.

I bet any car engine that is asked to deliver similar performance for the same duration will end up just as costly.

Comparisons with boat engines are probably more valid anyway.

I bet any car engine that is asked to deliver similar performance for the same duration will end up just as costly.

Comparisons with boat engines are probably more valid anyway.

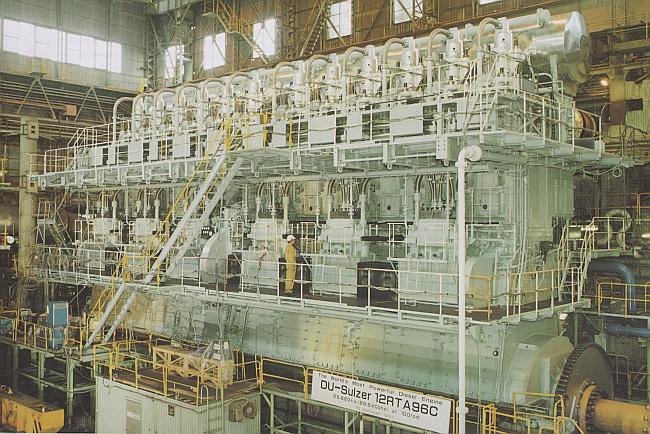

Okay, here's a 1500hp boat engine.

Nizpro Marine - The Engine - VZR-60, Quad Turbocharged V8 Engine, Ski Race Boat Engines, Competition Engines, Force Boats F21, Race Boat Setups

Only good for 30 hours at that power, but if you backed the power off and use a larger engine, etc, it'd still make far more than any dinosaur aero engine.

Nizpro Marine - The Engine - VZR-60, Quad Turbocharged V8 Engine, Ski Race Boat Engines, Competition Engines, Force Boats F21, Race Boat Setups

Only good for 30 hours at that power, but if you backed the power off and use a larger engine, etc, it'd still make far more than any dinosaur aero engine.

FADEC for GA engines

I recently removed the FADEC system from my Lycoming 360 engine in my RV7. You would think that with most, if not all, cars running FADEC that it would be easy to transfer that technology to aircraft engines, but apparently this is not the case. My engine (when run on a dyno) simply would not perform as advertised between 1600 - 2100 RPM. It was missing and surging in that area and after several suggested "fixes" by the manufacturer of the system (Aerosance), I removed the system and replaced it with a more convential injection system (Performance Airflow) and a CDI ignition system (Plasma III) which is proven technology.

It is not true to say that the FADEC system is/was a lot more expensive, there was only $2800 USD difference between the two systems, however one is a mature system and one is very much experimental. In any case the FADEC system has been withdrawn from sale on Lycoming engines. I believe that it is still available on some Continentals

It is not true to say that the FADEC system is/was a lot more expensive, there was only $2800 USD difference between the two systems, however one is a mature system and one is very much experimental. In any case the FADEC system has been withdrawn from sale on Lycoming engines. I believe that it is still available on some Continentals

Join Date: Apr 2007

Location: australia

Posts: 1,044

Likes: 0

Received 0 Likes

on

0 Posts

MMM its very simple, auto engines do not repeat do not work in aircraft. look around do your recreach and you will find that this is so true. 1st a prop will not work at 8000 rpm which now will require a gearbox that will have to take that rpm down to around the 2500 rpm level and increase the toque on that gearbox will now make it extrmely heavy. VW engines that are used are already quite light being air cooled. the main problem with diesels is the vibration and that the impluse from the firing is not smooth this now causes vibration threw the whole of the engine and back into the airframe. look at how light a gas turbine gear box is, high rpm but light loads and next to no vibration. and at the end of it all if the engine stops you cant just walk to the shops can you when the electrics stop doing there little things that they do. the cheapest part of running an aeroplane is the fuel !

Not at all likely any time soon.

An engine is an engine is an engine and controlling any of them isn't all that different. Sadly, the FADEC stuff that's on the market is either really old technology or really bad technology compared to what's available in the automotive sector. The Aerosance system is both of these.

The only reason that FADEC hasn't hit aero engines in a big way is to do with production volumes. Most controllers in the automotive sector are made in the millions p.a. In the aero engine sector, you'd be lucky to move 1000 p.a. even if you didn't have the onerous certification burdens of each type/installation. At these volumes the return-on-investment and uncertain market penetration scupper even the best laid plans.

Don't hold your breath for something meaningful from either TCM or Lycoming for more than a few years to come.

BTW, back to the original question re: direct injection. The benefits that the automotive sector are looking for with this (low load fuel consumption reduction) are not relevant for aero engines. There are some advantages to be had (improved knock resistance, for example), but I'm not sure whether the added complexity is a price worth paying (yet). Controlling carbon fouling of the injector on an air-cooled cylinder head could be a complete engineering nightmare too...

The only reason that FADEC hasn't hit aero engines in a big way is to do with production volumes. Most controllers in the automotive sector are made in the millions p.a. In the aero engine sector, you'd be lucky to move 1000 p.a. even if you didn't have the onerous certification burdens of each type/installation. At these volumes the return-on-investment and uncertain market penetration scupper even the best laid plans.

Don't hold your breath for something meaningful from either TCM or Lycoming for more than a few years to come.

BTW, back to the original question re: direct injection. The benefits that the automotive sector are looking for with this (low load fuel consumption reduction) are not relevant for aero engines. There are some advantages to be had (improved knock resistance, for example), but I'm not sure whether the added complexity is a price worth paying (yet). Controlling carbon fouling of the injector on an air-cooled cylinder head could be a complete engineering nightmare too...

CC, what % power are we talking here? 65%? If so, that's about 240-245g/kWh, which is probably as good as you'll get from an SI engine

Join Date: Apr 2007

Location: BackofBourke

Posts: 346

Likes: 0

Received 0 Likes

on

0 Posts

The demand fuel injection system has served us well.

As a wise pilot once said to me, imagine starting your car, warming up, running just under redline for 3 minutes, then 5,000 rpm (80%) power for 10 minutes. Then drive at 65% power (around 140 km/h) for 3 hours and then coast home.

Imagine doing that 6 days a week and you gain more respect for the long stroke air cooled aircraft engine, designed long before computers. He was, as always, quite correct.

As a wise pilot once said to me, imagine starting your car, warming up, running just under redline for 3 minutes, then 5,000 rpm (80%) power for 10 minutes. Then drive at 65% power (around 140 km/h) for 3 hours and then coast home.

Imagine doing that 6 days a week and you gain more respect for the long stroke air cooled aircraft engine, designed long before computers. He was, as always, quite correct.

As a wise pilot once said to me, imagine starting your car, warming up, running just under redline for 3 minutes, then 5,000 rpm (80%) power for 10 minutes. Then drive at 65% power (around 140 km/h) for 3 hours and then coast home

Can a piston aeroplane engine run for years with hardly any maintenance at all?

Can it make up around 100hp/litre without any trouble?

Can it start first time every time no matter what the temperature just by turning the key?

Join Date: Jul 2007

Location: in the classroom of life

Age: 55

Posts: 6,864

Likes: 0

Received 1 Like

on

1 Post

Gooday 18-W

This one does some of those things....... but geeez the maint. costs are not unlike a turbo Conty or Lyc.

HRCC TTT Day 09

training day, the pax now knows why we lap a lot quicker than he does in his roadie!

J

This one does some of those things....... but geeez the maint. costs are not unlike a turbo Conty or Lyc.

HRCC TTT Day 09

training day, the pax now knows why we lap a lot quicker than he does in his roadie!

J

Join Date: Apr 2007

Location: BackofBourke

Posts: 346

Likes: 0

Received 0 Likes

on

0 Posts

18 Wheeler

Doesn't make the air cooled piston engine and demand fuel injection any less impressive, even today.

A pointless comparison, as they are built to do two utterly different things.

Join Date: Feb 2006

Location: AMONGST BRIGALOW SUCKERS

Posts: 330

Likes: 0

Received 2 Likes

on

2 Posts

18 wheeler, I disagree. I think that is a very good comparison.

Find a car that has a petrol burning engine capable of producing 300hp maximum. (doesn't matter how many cylinders or engine capacity)

Drive as fast as you need to make that engine use 70-80% continuously of the 300HP. After one hour, see how much fuel you have used. I'm sure you will find that no less than 50 litres have been burned....comparable to our 300hp "dinosaur" aircraft engine.

I wonder if this car engine would still be performing well after 1700 hours of such driving, even with 100 hourly service intervals

Find a car that has a petrol burning engine capable of producing 300hp maximum. (doesn't matter how many cylinders or engine capacity)

Drive as fast as you need to make that engine use 70-80% continuously of the 300HP. After one hour, see how much fuel you have used. I'm sure you will find that no less than 50 litres have been burned....comparable to our 300hp "dinosaur" aircraft engine.

I wonder if this car engine would still be performing well after 1700 hours of such driving, even with 100 hourly service intervals