Boeing Crew Oxygen systems with two bottles

Thread Starter

Join Date: Apr 2003

Location: Sutton

Posts: 564

Likes: 0

Received 0 Likes

on

0 Posts

Boeing Crew Oxygen systems with two bottles

Our 787s have two crew O2 bottles and one pressure readout on the status page. I assume all Boeings have the same logic so are these two independent O2 systems (one for the LHS and one for the RHS) or are they joined as one. There is only one over pressure bursting disk (which suggests they are linked) but I have no access to schematics. This follows on from a training debate we were having asking was it possible to loose all crew oxygen at once or is their some safety protection if say the pipe from one bottle breaks.Also no one knew if you did loose all pressure would the status page show zero (/ nothing or dashed lines). What Would a transducer failure show?

Answers to any of these questions would be much appreciated. Thanks

Answers to any of these questions would be much appreciated. Thanks

Join Date: Jul 2005

Location: Here and there....currently here.

Posts: 217

Likes: 0

Received 7 Likes

on

3 Posts

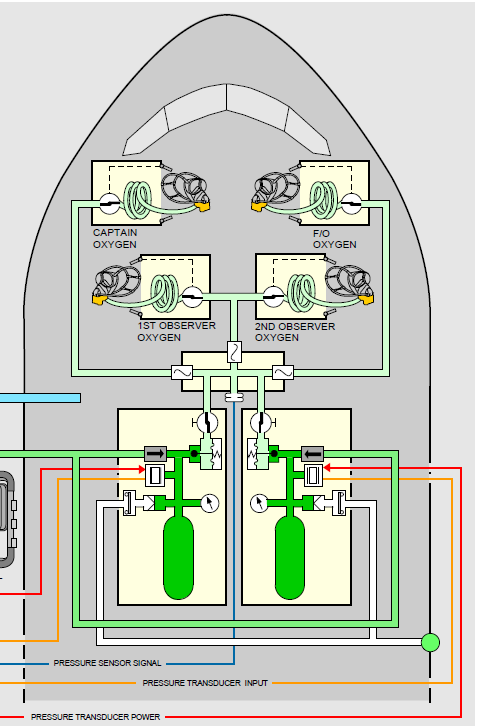

B787 - two cylinders supply what is effectively one system for the Flight Deck. There are 3 fuses (the ~ in a box) to prevent loss of all pressure due to leak in flight deck pipe circuit on one side branch. However.........

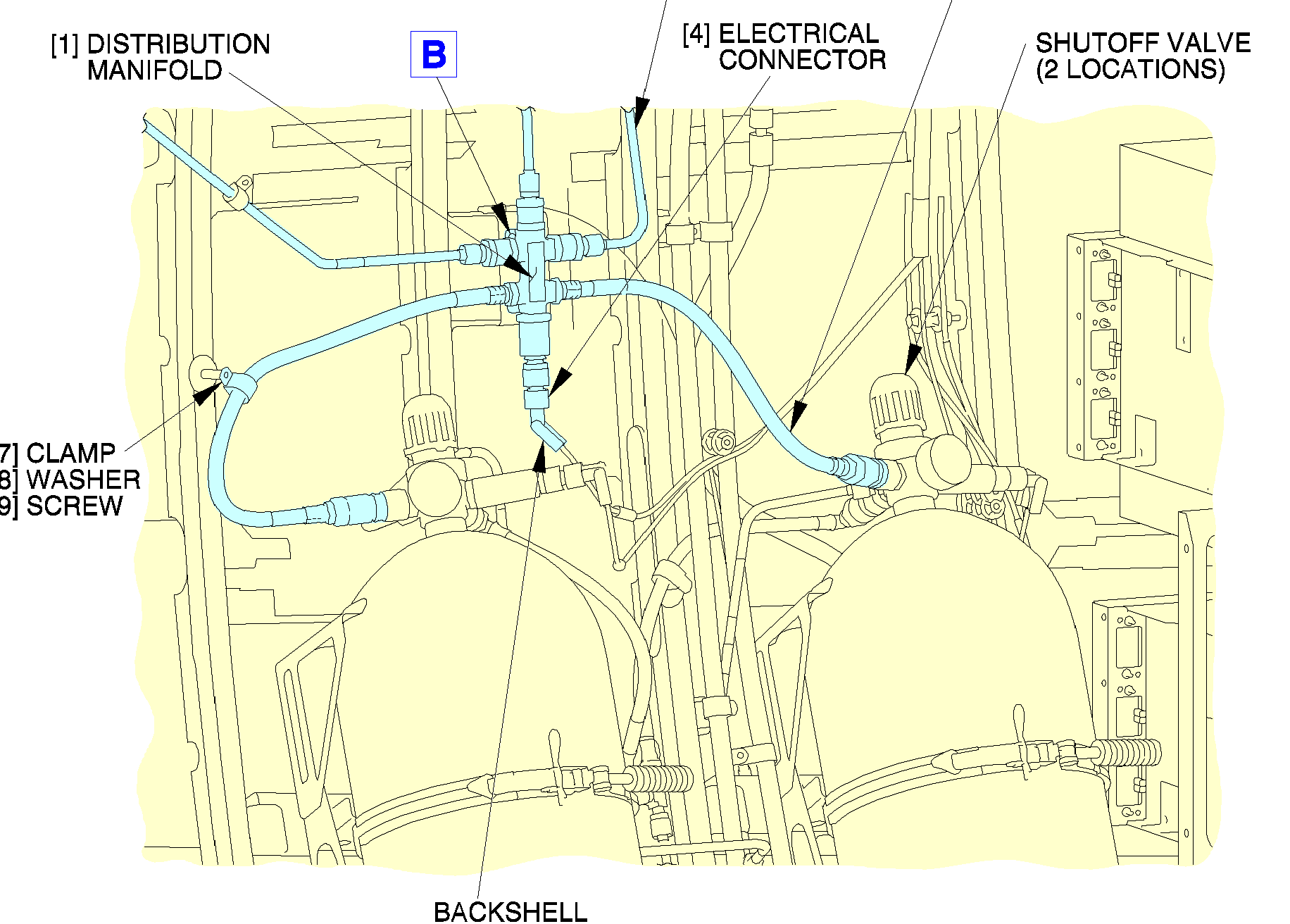

It is possible I guess that if a fracture were to occur in the pipework between either cyclinder head shut off valve and 3 way distribution manifold, it could be a problem! I'm guessing that there could be Non Return Valve at each point where the supply from the cyclinder connects to the distribution manifold to prevent flow from one cylinder to the other, and the regulator assembly on the cylinder head can detect excess flow and close off ?

My tech notes don't give any further info. I'll have a look in the AMM later if I get a chance.

If a PX Transducer fails, I think the display will go blank with a status message for you guys and associated fault code for us Engineering types.

Join Date: Jul 2005

Location: Here and there....currently here.

Posts: 217

Likes: 0

Received 7 Likes

on

3 Posts

Had a look in the AMM, but there was no mention of any design or device to prevent cross flow leakage in event of pipework failure on one side prior to the distribution manifold. I guess Boeing did a design analysis and looked at previous failures and found the design was robust enough? I'm a line engineer and in my experience the faults I have dealt with have always been in the flight deck circuit. A hangar engineer may have some experience of cylinder installation area faults?

Our 787s have two crew O2 bottles and one pressure readout on the status page. I assume all Boeings have the same logic so are these two independent O2 systems (one for the LHS and one for the RHS) or are they joined as one. There is only one over pressure bursting disk (which suggests they are linked) but I have no access to schematics. This follows on from a training debate we were having asking was it possible to loose all crew oxygen at once or is their some safety protection if say the pipe from one bottle breaks.Also no one knew if you did loose all pressure would the status page show zero (/ nothing or dashed lines). What Would a transducer failure show?

Answers to any of these questions would be much appreciated. Thanks

Answers to any of these questions would be much appreciated. Thanks

All the aircraft that I've worked on which includes all the Boeing wide-body types have NRVs in the plumbing to stop the leakage from any bottle being fed by other bottles in the system.

One thing of note of Boeing Oxygen systems [and I cannot remember if the 787 still uses the same one on the crew bottles] is that the pressure transducer fitted to each bottle in the oxygen system are an incredibly simple unit that are basically a bourdon tube with a wiper arm that moves across a wound wire resistor. Having changed many of them in the past [they do fail] it was amusing to note the compatible aircraft, which were basically every Boeing type back to the Boeing 707!!

Last edited by MAC 40612; 25th Nov 2023 at 13:05.

Join Date: Dec 1998

Location: .

Posts: 2,997

Likes: 0

Received 0 Likes

on

0 Posts

Not all Boeings have the same logic. For example, the Boeing 777 only has one crew oxygen bottle. If you lose all pressure the status page shows zero [I've seen it] and you're also into a whole world of pain as it is a bottle change, as if the Bottle [and this goes for both crew and passenger bottles, if the passenger system has bottles] goes below the stated minimum pressure the bottles have to be replaced [not just recharged] This is why the stated minimum dispatch pressure from main base is often higher than the allowable minimum pressure, to give a bit of leeway in case the system does have a slight leak and it drops lower at an overseas station. This is all stated from a UK perspective where we have charging points on the aircraft and are allowed to charge oxygen many Countries do not allow on board charging and when the system gets low, a bottle change is required [That is the case with FAA registered aircraft for example]

All the aircraft that I've worked on which includes all the Boeing wide-body types have NRVs in the plumbing to stop the leakage from any bottle being fed by other bottles in the system.

One thing of note of Boeing Oxygen systems [and I cannot remember if the 787 still uses the same one on the crew bottles] is that the pressure transducer fitted to each bottle in the oxygen system are an incredibly simple unit that are basically a bourdon tube with a wiper arm that moves across a wound wire resistor. Having changed many of them in the past [they do fail] it was amusing to note the compatible aircraft, which were basically every Boeing type back to the Boeing 707!!

All the aircraft that I've worked on which includes all the Boeing wide-body types have NRVs in the plumbing to stop the leakage from any bottle being fed by other bottles in the system.

One thing of note of Boeing Oxygen systems [and I cannot remember if the 787 still uses the same one on the crew bottles] is that the pressure transducer fitted to each bottle in the oxygen system are an incredibly simple unit that are basically a bourdon tube with a wiper arm that moves across a wound wire resistor. Having changed many of them in the past [they do fail] it was amusing to note the compatible aircraft, which were basically every Boeing type back to the Boeing 707!!

I've definitely seen two O2 bottles on 777s too.

Join Date: Jul 2005

Location: Here and there....currently here.

Posts: 217

Likes: 0

Received 7 Likes

on

3 Posts

It must be an option. I work on various airlines' 787 and some have 1, some have 2 O2 cylinders. Can even vary across same airline but with different variant -8/9/10.