Lyman,

Your quote:

From the drawing, I note a build up of the LPT vanes platform at the area that makes contact first with IPT should it drift aftward. The portion of the IPT that makes contact with this strengthened area is the blade root circle. This in anticipation of wheel release, the design is meant to remove the airfoils in just such an emergency as this explosive burst.

As the design consideration, it demonstrates an improvement in concept, an anticipated mitigation. I suggest that it worked; as bad as this incident appears, if IPT retains its blades any longer than apparent here, the a/ c may have been lost.

No, No, No, that is what you don't want to have happen. What you want to have happen is the turbine blades to stay with the disc which is holding them so that if the disc becomes liberated and if and when it moves back, those turbine blades clash with the turbine nozzle airfoils behind slowing the disc acceleration before it gets to a burst situation. What would then happen would be a bunch of ground up airfoil pieces exiting through the LPT and out the exhaust pipe, but the disc would slow down and remain intact. That is what happened on several older model Trent engines where blade to nozzle contacted prevented disc bursts.

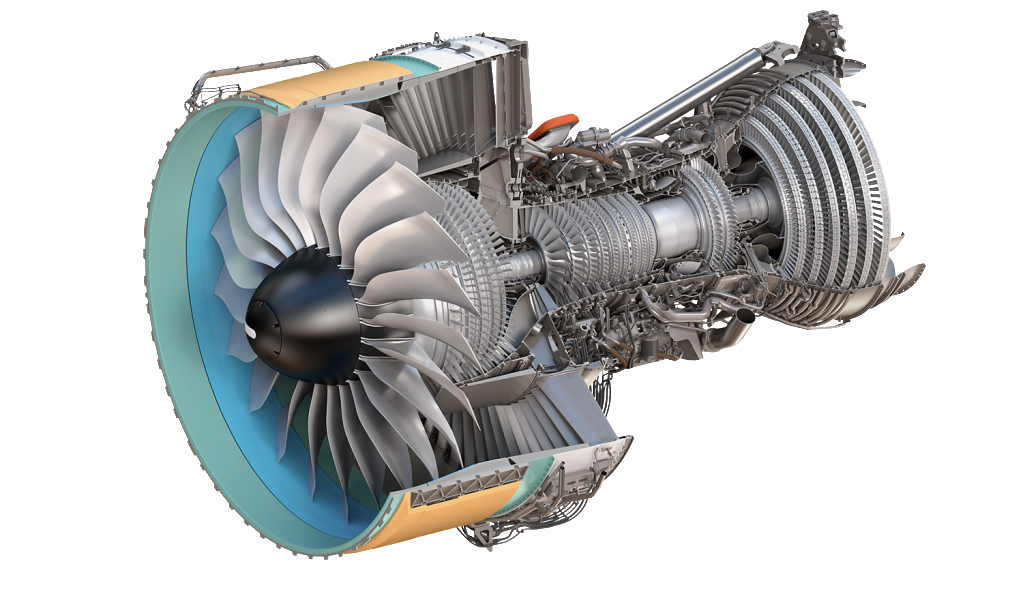

In the case of the Trent 900, when the disc became free, overspeed initiated and when it move back, the contact with the stage 1 LPT nozzle occurred at the disc rim rubbing out the turbine blade retainers thereby creating the potential for the blades to come out and making no airfoil to airfoil contact slowing the disc speed. Remember, there was little damage to the LPT other than the stage 1 LPT nozzle with most of the remnants, disc sections included, exiting radially, not good. I will look again at the photos in the ATSB reports to be sure of this scenario as I am doing it at the moment from recall. In the meantime, look at the GP7200 engine cutaway below.

You will note that if the stage 2 HPT disc (similar position to the IPT disc) became liberated for one reason or another, if it would move back, the turbine blades would clash with the stage 1 LPT nozzle slowing the disc speed. It is an important design feature to inhibit runaway disc speed.

lomapaseo,

All I can say about the intensity of the fire from the burning oil is what the ATSB said in their Interim-factual report:

The investigation has found that the intermediate pressure (IP) turbine disc failed as a result of an overspeed condition, liberating sections of the IP turbine disc that then penetrated the engine case and wing structure. The disc failure was initiated by a manufacturing defect in an oil feed pipe that resulted in a wall thickness reduction in an area that is machined to receive a coarse filter. That section of the oil feed pipe sustained a fatigue crack during engine operations that lead to an internal engine oil fire that weakened the IP turbine disc. In turn, a circumferential fracture was induced around the disc, allowing it to separate from the IP turbine shaft. The unrestrained disc accelerated to critical burst speed. This lead to the No 2 engine failure and subsequent significant penetration damage to the airframe structure and systems.

I do think there is some merit in what you suggest, the disc stayed centered for a short period of time during the acceleration.