Mad(Flt)Scientist

.

"20% better than book figures" relates to my ballpark guesstimate of what I could achieve in terms of stopping distance by concerted manual braking using the advocated technique but (as a qualifier) always being focused and directed at a specified turn-off. In other words, if the book said the jet needed 2800ft at the weight, I'd be taking about 0.8 times that ("around" 2240ft) with no concern at all that I'd possibly blow a tyre (never ever have BTW). Bettering that figure would obviously be possible with autobraking/antiskid. In all other respects, without supporting mensuration, the actual achievement is somewhat subjective. However I can recall that the same turn-off was also achievable with standing water on the ungrooved and heavily rubberised concrete runway during heavy rain. It wasn't just an egotistical exercise. We'd had a rash of braking and undercarriage and tyre failures being experienced dual and solo - so I'd had the hard-braking requirement written into the test schedule for myself and the other part-time UTP's to "have to" functionally check brake serviceability on every checkflight, so that solo students wouldn't be unduly hazarded by the vagaries of Dowty Rotol and BFGoodrich's very variable products. That included a check of the emergency brake for symmetrical braking on acceptance flights post major servicings (and I really hated it when engineering officer pilots in the front seat would subconsciously twist the handle and set its other function - as park brake. That was the nearest I've come to blowing a tyre, so thank goodness for reverted rubber skidding and a front-seater who understood the principle of "first up undo what you just did". That works for split flap events without flap-brakes I'd also found).

Because I didn't do ETPS I'm not sure that a 20% reduction in roll-out equates to your "claimed 20% improvement in braking effect". But no point in quibbling. There is a distinct, discernible and tangible improvement in braking effect on all airplanes that I've flown - particularly on nasty wet and snow-covered or slushy runways. I've even used it to wind up a 4 eng air display routine and once for a high-speed heavy-weight abort. Because the braking is heavy but of a more limited duration, the brake-heating seems to be no worse than usual. I've never had the thermal plugs take down a tyre afterwards for instance.

.

To achieve the claimed 20% improvement in braking effect would require increasing the mainwheel reaction force by the same amount, and having brakes capable of dealing with the increased torque.

Not sure whether this is sound logic (simple tech peasant that I am), however most a/c wheelbrakes that I've encountered in a lengthy career are [torquewise] quite capable of blowing tyres - unless it's very much later in the roll-out where brake-fade once or twice educated a fatigued and nonchalant me that I should have done the required braking much earlier (thank god for high-speed turn-offs).

.

"Assuming that the plane has just touched down, the speed will be somewhere close to stall speed."

Not a totally safe assumption in the overrun cases that we are interested in stopping. Many overruns are plonked down fast and late by pilots with an incre"mental" ref speed buffer mindset.... and some just end up "hot" for a multiplicity of reasons. It's that sort of seemingly unavoidable "lap-of-the-gods" mishandling that we are here attempting to assist in uncrunching the outcome of...

"...so that the mainwheel reaction is essentially the aircraft weight. (ignoring the nosewheel reaction component of maybe 5% for now)"

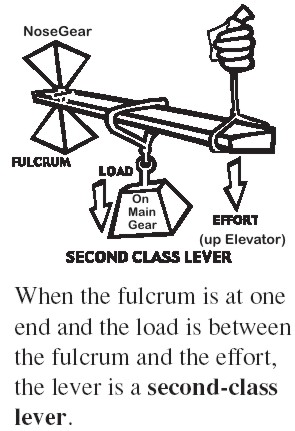

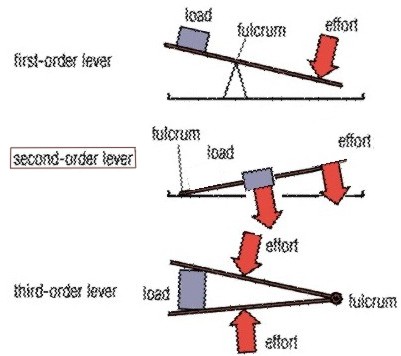

5%?? Hmm. But the only factor in play for braking effectiveness is the wheel rotational torque being imparted by the runway/tyre-tread interface. Unfortunately, on contaminated surfaces, because of the tyre's hydrodynamically lifting bow-wave at speed, tyre rotation is inhibited for a significant period after touchdown and "effective" weight-on-wheels is much less than a/c weight (thanks to efficient wings, rigger's angle and flaps). That's the nub of the argument here. Backstick uses the nose-gear's pitch-down moment as a type 2 fulcrum point to leverage an artificial weight upon the brakeable main-gear (body or wing)... and from elevator to nose-gear is a considerable moment arm (and mechanical advantage). In another sense the backstick tactic becomes a logical utilization of the effective weight shift forward caused by spoilers, auto-brake and reverse thrust. That cumulative pitch-down force becomes a dynamic fulcrum with the nose as the pivot-point.

"If the tail is about 25% of the wing area and similarly efficient, that means I have to get to about 40% of the tail stall CL, which means I'm going to need substantial amounts of elevator to get there. "....and eventually it won't much matter where the elevator is."

. I won't quibble with the figures but yes, you do eventually end up with the stick right back in the gut (as speed dissipates, that's only logical). It's a progressive process. Just like braking itself, you do it "for effect". It's when you do it that counts. Obviously at less than 50 knots there's very little efffect available (ie. minuscule). Early on and sustained is good, whereas introduced very latterly as a panicky afterthought is pathetic. That's like deciding to save fuel after the "tanks low" lights illuminate.

What does that lot mean? It means that to achieve the kinds of braking efficiency improvements talked about would require SIGNIFICANT elevator movement because it requires significant redistribution of the wheel reactions.Agreed that it's a very unpansy-like commitment to stopping, but one applied as a handling technique and never motor-moronised by rote.

It also means, if you look at the impact on nosegear reaction, that in order to achieve 20% more mainwheel download, I need to offload the nosegear by 10% - maybe more depending on geometry. Since a typical nosegear load is of this magnitude this means I am definitely risking raising the nose with this technique.

I think I'll let others here assess the validity of your %'s argument and conclusion lest I arouse

JT's ire.. The orders of magnitude in the pitch-down couples involved under reverse and heavy braking with spoilers up are such that inadvertently raising the nose is a very very minimal mishandling risk (in comparison with overrunning). The redistribution of weight towards the main-gear (in most cases a tricycle geometry) is a secondary effect of the technique that nicely enhances directional control at speed. As the AA1420 pilot found at Little Rock, light on wheels with a crosswind creates two compounding problems - stopping

and directional control.

.

Basil

Background ATPL >14.5K hrs, >half on 4eng, <half on jet trainer instruction, a lengthy helo tour in SVN, instructional (inc 4eng) since 72

Meaningful input or feedback from a manufacturer would be good. But it's rarely the equipment that gets blamed don't forget; so are they really likely to be interested? The NTSB is too busy kicking tin and are not really into the business of telling operators what to do... just what

not to do. The FAA isn't really in the pilot education business either. If you are perturbed by all the unnecessary overruns (as am I) then you may perceive it more as a pilot education and training problem. That's best dealt with by trainers who belonga operators (who always have most to lose). If insurers had a more realistic interface with the coal-face they might be interested. However it's far easier just to get the actuaries to adjust the premium tables after each statistical entry event.