tdracer

The PW4000 112, GE90 etc have low examples of fan blade release, as is the case for the CFM-56-7's. These have larger chord blades in general compared to earlier fan designs, which may be helping in the path of the liberated part.

general comment not related to tdr...

. Was queried on. my post #113 on the wording I used, and it needs clarification, and that is related to your observation so here goes...

I commented on the release dynamics, noting the radial accelerations. This is more correctly stated as centripetal acceleration but has the same meaning, well at least in my limited language skills.

The fan disk transfers torque to the blade root, to counter the aerodynamic drag of the blade. The blade root transfers loads to the disk and VV through the fir tree root fittings for radial, in-plane loads. the root also absorbs the out-of-plane bending loads and also torsional loads. The blade has inertial and aerodynamic moments, and these all come to play in a failure. On the release of the blade it is free to depart the scene, and follows Nootin's 1st, translating outwards and along the tangent of the in-plane path, for a poofteenth of a second, until the tip contacts the inner wall of the annulus/rub strip, whereupon drag forces slow down the outer end of the blade, and inertia starts a rotation out of the radial alignment of the blade as built. The blade tip is a light structure, (designers are smart... ). the tip hitting anything including ice will deform, hitting the engine annulus is going to collapse the blade structure and leave a witness mark. That impact slows down the blade's outer end... at the same time, drag is moving the blade rearwards, and it approaches the following blade. Coincidentally, the lift force twists the blade out-of-plane, and the pitching moment gets a say on it's alignment, and it will start rotating LE downwards. About now, it gets the kick in the pants from the following blade, and gets pushed forward for a short while, while damaging the following blade LE at part span. rotating around its length, the blade develops Flettner style lift and gets carried forward for a short period of time.

Does the blade need to hit the intake lip to sever it? Probably not.... my guess... the out-of-balance of losing 1 1/2 blades on one arc of the fan is going to be quite impressive. Happy snaps will show if contact occurred, but I'm thinking

Arby's... that the light structure will fail under high oscillatory loads. Maybe...

Then again, the blade may work like a chainsaw and chew its way through the structure, but, I doubt that is the case.

Sunil K. Sinha and Sreekanth Dorbala wrote an interesting paper on "Dynamic Loads in the Fan Containment Structure

of a Turbofan Engine"

J. Aerospace Engineering July 2009, and stated in part:

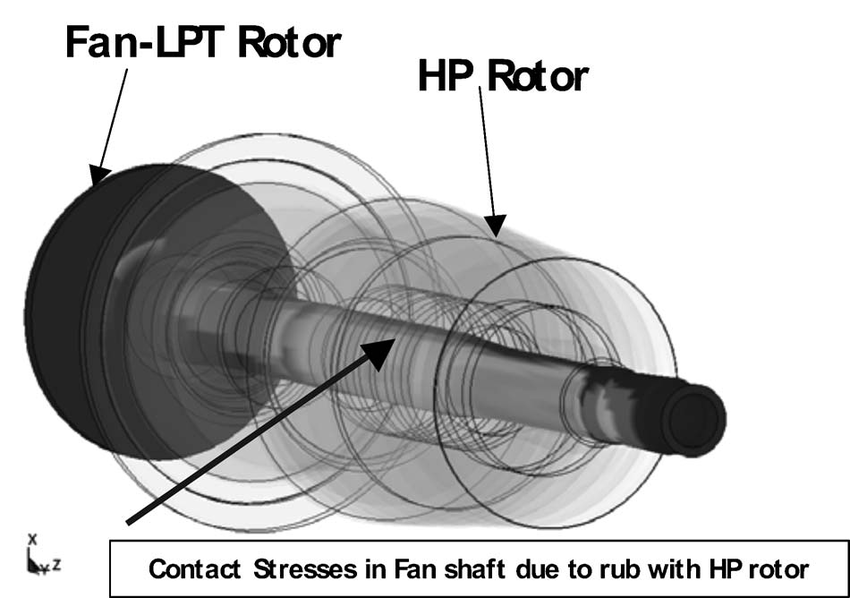

"A typical fan blade-out event involves very complex nonlinear transient dynamics with large deflection of the release blade and rigid body rotation of the trailing blade as well as progressive failure and fragmentation of various components. Due to the nature of the impact type loading, the solution to the problem should also address dependence of the material behavior such as yield strength as a function of strain rates. In short, the transient dynamic analysis of a fan blade-out event highlights the complexity of the numerical technique, which includes all the nonlinearities of structural dynamics: plastic behavior of the materials, large displacements, and contact interaction between structural elements. In this paper, we present the results of a LS-DYNA simulation of a FBO event on a full-engine analytical model, which covers both the primary as well as secondary damages."

These guys did a neat analysis,

however even using the LS-DYNA code it is a simplification of the dynamics of the release, and as far as I am aware, that remains the case to this day. The last time I looked at this was when we were doing some weird $&*T on fan blades doing a POC, and wondering where the stuff was gonna go fly. (in the end, our assumptions happened to be OK on the day, luckily, and we didn't blow up the test engine, the test cell, or the building).

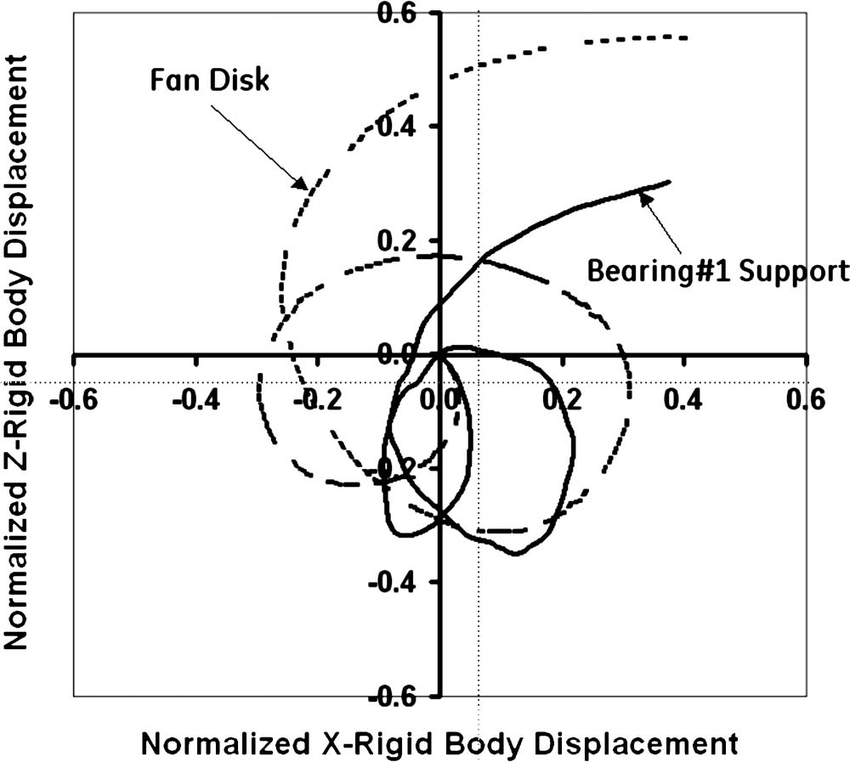

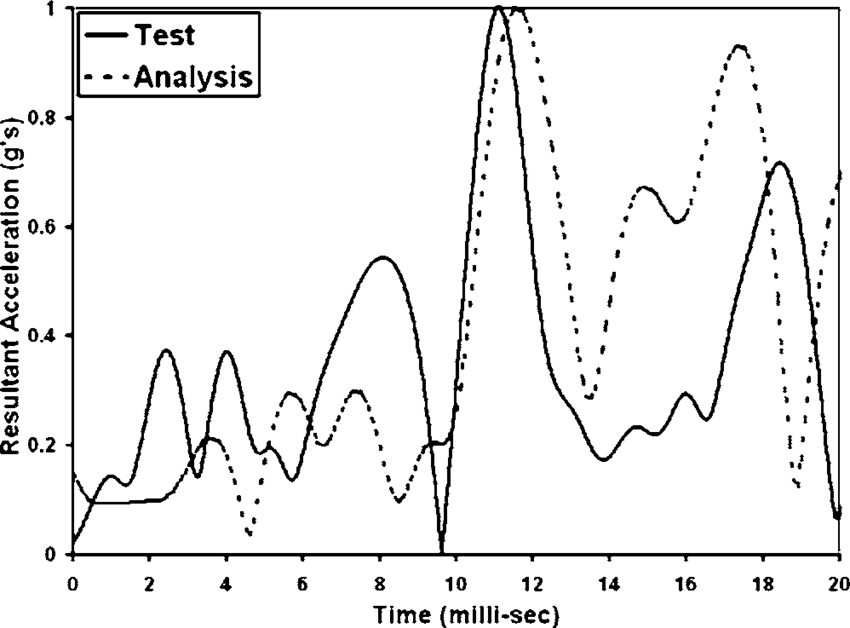

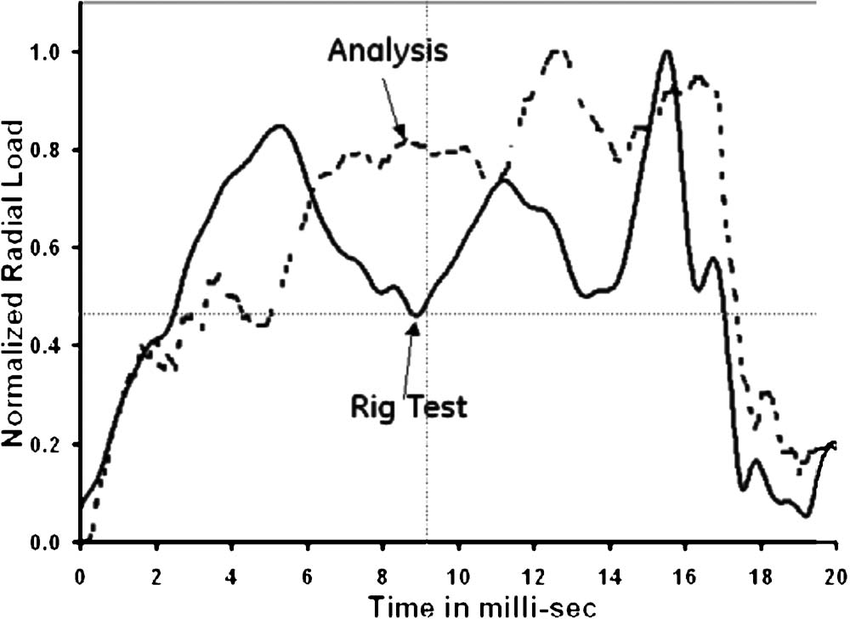

Page 264, upper right paragraph under figure 4 "Comparison of von Mises stresses between ANSYS and LS-DYNA" has comments that say in a high tech manner what is stated above in lyrical prose. The 5th happy snap below tells a story of the engine response, why it pretty much disassembles itself. the image before that with the graphs indicates what is missing in the analysis and should be considered in relation to the observation of the paragraph mentioned on page 264 of their report.

Now, it could well be that the LS-DYNA code is absolutely correct, and if so, then we can expect to see plastic deformation at one particular point of the containment ring, and then we would come up with a new trajectory for the blade parts.... how do they get from point A to entry point X. My suspicion is that there is no penetration of the containment, and that should give a hint as to what to add to the code.

Gotta say I'm a bit miffed, I quite liked the 4094 donk, I would hope the failure is from an isolated cause such as inclusions or similar rather than a design of the blade, presuming that the 112" has a common blade P/N... which is probably the case.

Zeffy, thanks for the NTSB photos, that blade root is telling a story. The future of the 4000-112 series rides on the close-ups of that picture.