Originally Posted by

Hi_Tech

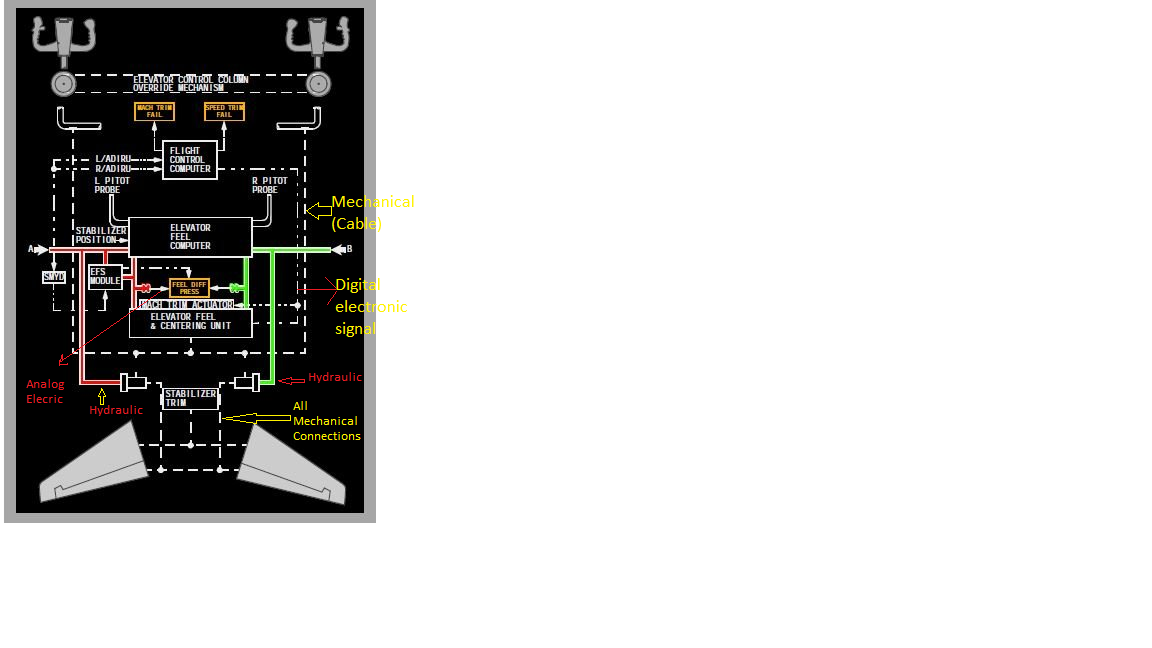

Gums: If you look at the dotted lines, they are all different. I hope the following edited fig makes sense.

UHHH Most 737 stab trim motors are electric

http://www.eaton.com/ecm/idcplg?IdcService=GET_FILE&allowInterrupt=1&RevisionSelectio nMethod=LatestReleased&Rendition=Primary&&dDocName=PCT_20101 9

Which gives a pdf file DS400-1A_B737 Stab Trim Upgrade.pdf

Eaton’s new Model 6355C Stabilizer Trim Motor features:

• Brushless three phase mo-tor design

• Low loss power bridge with IGBT switches

• Processor based motor commutation and velocity control

• Dual current limit (torque) control circuits

• Power up built-in test

• Continuous fault monitoring

• Fault storage (non-volatile memory)

• RS-232 test/maintenance interface

• Investment cast housing

• Two stage spur gear train

• Modular, bottom up assembly — two electronic sub-assemblies, motor, housing with gear train

Eaton’s Stabilizer Trim Motors

(STM) Model 6355B0001-02 and -03 have been used on Boeing’s 737-600/700/800/900 aircraft, starting with Line #1423, delivered in December 2003. The “B” model has been

superseded by Model 6355C, and replacement parts for the “B” model will be available for a limited time only — estimated at 3 years, based on usage. Parts scheduled for future obsolescence include:

• EMI FIlter Assembly

• Brushless DC Motor Assembly

• Voltage Reference

• Control Board Assemblies

• Isolated Drive Transmitter

• Isolated FET Driver