Aircraft without a loss of oil pressure procedure

Join Date: Oct 2010

Location: Germany

Age: 47

Posts: 402

Likes: 0

Received 0 Likes

on

0 Posts

@sns3guppy: please show me ONE video or explanation where a singleshaft turboprop continues to run in feather.

since here you have a rigid mechnanical connection between the core engine and the prop via gearbox feathering the prop will stop the whole engine. thats why in a singleshaft the feather position is linked to a fuel stop and on a splitshaft it is not.

maybe kengineer 130 can comment the possibility to keep the t56 ( also singleshaft design) runnig when the prop is feathered...

i a splitshaft you can do it, no question.

in the meantime ... be careful with claming other people lacking in turboprop operation fundamentals when you say such nonsense ( tpe331 is not a singleshaft, running it in feather is possible...)

i truly hope that some other garrett drivers can come in to comment...

beta range... uff c,mon, let it be... its the range betwenn flight idle and ground idle but above reverse. the only range which is not governor controlled and you have a direct control of blade pitch with the power lever. reverse is like alpha range governor controlled again...

some claim it indeed the range all below flight idle, but, thats not fully true.

now i know you never operated one.

ok... back to props...

"The PT6-20/27/28 types...loss of engine oil quantity, the propeller will feather.

I know, because, I've had it happen twice on BE99 aircraft.

On successive nights. "

"

seems logical to me , the pt6a has no pitch locks , but then you loose any thrust from the propeller ( you may have an enourmous torque indication due to the resistance when the core tries to drive the feathered prop)

did you shut?

since here you have a rigid mechnanical connection between the core engine and the prop via gearbox feathering the prop will stop the whole engine. thats why in a singleshaft the feather position is linked to a fuel stop and on a splitshaft it is not.

maybe kengineer 130 can comment the possibility to keep the t56 ( also singleshaft design) runnig when the prop is feathered...

i a splitshaft you can do it, no question.

in the meantime ... be careful with claming other people lacking in turboprop operation fundamentals when you say such nonsense ( tpe331 is not a singleshaft, running it in feather is possible...)

i truly hope that some other garrett drivers can come in to comment...

beta range... uff c,mon, let it be... its the range betwenn flight idle and ground idle but above reverse. the only range which is not governor controlled and you have a direct control of blade pitch with the power lever. reverse is like alpha range governor controlled again...

some claim it indeed the range all below flight idle, but, thats not fully true.

now i know you never operated one.

ok... back to props...

"The PT6-20/27/28 types...loss of engine oil quantity, the propeller will feather.

I know, because, I've had it happen twice on BE99 aircraft.

On successive nights.

"

"seems logical to me , the pt6a has no pitch locks , but then you loose any thrust from the propeller ( you may have an enourmous torque indication due to the resistance when the core tries to drive the feathered prop)

did you shut?

Join Date: Oct 2005

Location: USA

Posts: 3,218

Likes: 0

Received 0 Likes

on

0 Posts

beta range... uff c,mon, let it be... its the range betwenn flight idle and ground idle but above reverse. the only range which is not governor controlled and you have a direct control of blade pitch with the power lever. reverse is like alpha range governor controlled again...

All ranges are governed. Do you know which governors manage which range?

Show us you know something about the motor.

seems logical to me , the pt6a has no pitch locks , but then you loose any thrust from the propeller ( you may have an enourmous torque indication due to the resistance when the core tries to drive the feathered prop)

in the meantime ... be careful with claming other people lacking in turboprop operation fundamentals when you say such nonsense ( tpe331 is not a singleshaft, running it in feather is possible...)

i a splitshaft you can do it, no question.

some claim it indeed the range all below flight idle, but, thats not fully true.

now i know you never operated one.

now i know you never operated one.

You don't understand beta. If you don't understand alpha or beta operation, then you don't know anything about the engine. Your previous comments suggested that you acted as a passenger or possibly a "copilot" in a Conquest (a single pilot aircraft, incidentally), so perhaps that explains your ignorance. If you stopped at ignorance, you'd be okay, but what you are clearly here, is a troll.

Join Date: Oct 2010

Location: Germany

Age: 47

Posts: 402

Likes: 0

Received 0 Likes

on

0 Posts

and did they found the reason for the loss of oil on your pt6? can you say something more what exactly happened? the prop featherd with a still spooled up gas generator or did you closed the throttle before?

"but what you are clearly here, is a troll."

you are are right and i have my peace. truly, there is no need for such a discussion. life is too short.

you claim the garrett is not a singleshaft because it has a short driveshaft out of the reduction gearbox? ok... lets stop discussing turbine details, wikipedia says it is, honewell also- but you are nevertheless right.

maybe some other will comment.

in the meantime i have to do the same job in real life you do infront of microsoft flight simulator. so- enjoy YOUR short shaft when sitting infront of the computer hearing the garrett screaming out of the speaker.

"but what you are clearly here, is a troll."

you are are right and i have my peace. truly, there is no need for such a discussion. life is too short.

you claim the garrett is not a singleshaft because it has a short driveshaft out of the reduction gearbox? ok... lets stop discussing turbine details, wikipedia says it is, honewell also- but you are nevertheless right.

maybe some other will comment.

in the meantime i have to do the same job in real life you do infront of microsoft flight simulator. so- enjoy YOUR short shaft when sitting infront of the computer hearing the garrett screaming out of the speaker.

Last edited by aerobat77; 2nd Dec 2010 at 21:01.

Originally Posted by SNS3Guppy

...On some turboprop engines, such as the PT6, the oil pressure is sampled at the same location as the torque indication.[post #5]

Originally Posted by SNS3Guppy

...Separate pickups deliver oil pressure to cockpit indications, from the torque indications... but they come from the same location in the engine...[post #8]

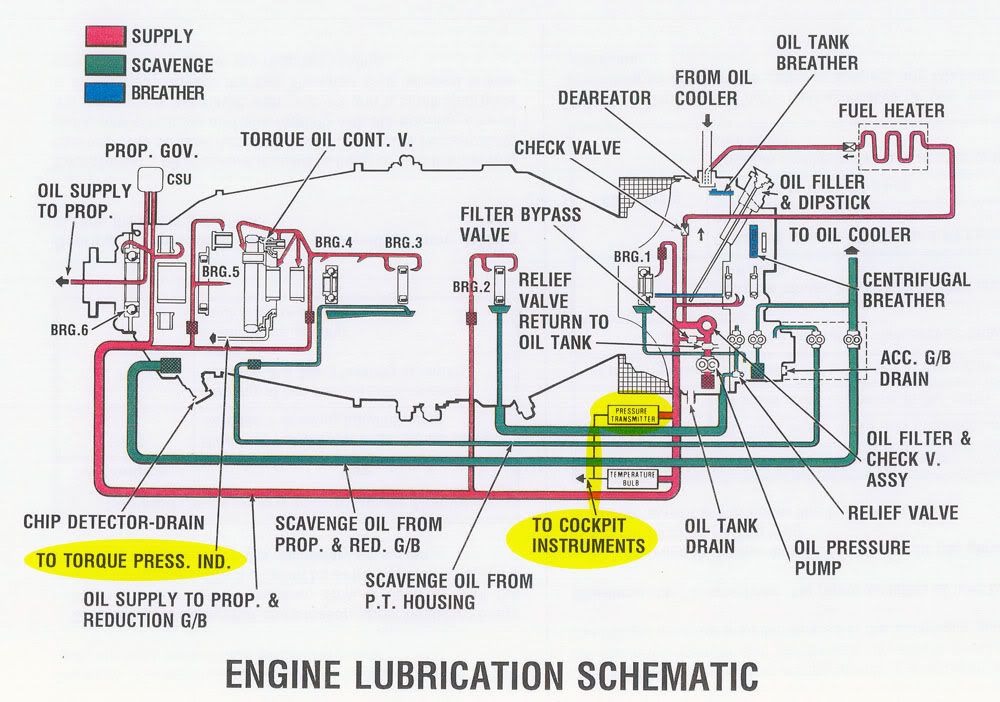

On the PT6A series of engines, engine oil pressure (displayed as "Oil Pressure" on the engine instruments) is measured by a sensor located on the aft part of the engine (the compressor section), and torque (displayed as "Torque" on the engine instruments) is measured by a sensor mounted on the reduction gearbox, which is at the forward end (the power section) of the engine.

The two sensors are approximately three feet apart and are entirely independent of each other - both mechanically and electrically.

The illustration below, published by Pratt & Whitney, illustrates the oil system in the 'small' PT6A engines (-6 to -34) and clearly shows the two different sensor systems, which I have highlighted in yellow.

SNS3Guppy, you are becoming awfully combative and bumptious in your posts - maybe you might want to tone it down a notch, OK? Most of us come here to gather and exchange information, not to participate in the text equivalent of a bar fight.

PT6A Engine Oil Principles

Originally Posted by 411A

...The PT6-20/27/28 types...[in case of] loss of engine oil quantity, the propeller will feather. I know, because, I've had it happen twice on BE99 aircraft.

The reason for this is that propeller blade angle on the small PT6A engines is controlled by a propeller governor that uses oil under pressure to move the propeller blades out of the feather position, and the force created by that oil under pressure is opposed by springs and counterweights within/on the propeller hub that act to move the propeller towards the feather position. In any case of loss of supply of oil to the propeller governor, the propeller will feather. By way of example, autofeather systems on PT6A engines operate by dumping oil from the propeller hub.

I have only experienced one complete loss of oil quantity while operating a PT6A powered aircraft. The loss of oil quantity was almost instantaneous, and so was the feathering of the propeller. By the time I turned my head to look out the window to try and determine what had happened to the engine, the propeller had feathered.

Michael

Join Date: Oct 2005

Location: USA

Posts: 3,218

Likes: 0

Received 0 Likes

on

0 Posts

"but what you are clearly here, is a troll."

you are are right and i have my peace. truly, there is no need for such a discussion. life is too short.

you are are right and i have my peace. truly, there is no need for such a discussion. life is too short.

Most of us come here to gather and exchange information, not to participate in the text equivalent of a bar fight.

This message is hidden because aerobat77 is on your ignore list.

The two sensors are approximately three feet apart and are entirely independent of each other - both mechanically and electrically.

Reference the previous discussion on the TPE-331 and electronic control, visit TCDS E4WE, as someone recently invoked the TCDS, for this comment:

http://rgl.faa.gov/Regulatory_and_Guidance_Library/rgMakeModel.nsf/0/2c8af3bbc45fc47186256d96005eb743/$FILE/E4we.pdf

"The -10A, -10B, -10N, and -12B engines are equipped with an integrated fuel control system consisting of an engine driven hydromechanical control and an aircraft mounted EEC which is energized by the aircraft electrical system. This system may be operated in either an Automatic Mode in which both control components are active, or in a Manual Mode with the EEC de-activated."

The point of the thread, of course, is oil quantity in an engine, and operating procedures thereof. The point of introducing the TPE-331 (which I do not presently fly) was as an example of an incident I had experienced regarding an engine with no oil, and the effects thereof. I believe the original poster was more interested in turbojet or turbofan operations. I have had turbofan powerplants run very low on oil, but to date haven't had to shut one down as a result . A couple of years ago we prepared to shut down a JT9D that reached the 1 gallon oil reading, and would have shut it down if it had reached the .5 gallon limit per the checklist. We were close to the destination, and continued to use it until landing, without incident.

Many aircraft and powerplant installations do not utilize oil quantity cockpit indications. This isn't the end of the world. In the event of an oil loss, other signs and symptoms exist which must be addressed, and procedures will be found to cover these eventualities.

Join Date: Oct 2010

Location: Germany

Age: 47

Posts: 402

Likes: 0

Received 0 Likes

on

0 Posts

TPE331 TCDS

"TYPE: Single-shaft engine with two-stage centrifugal compressor, three-stage axial turbine, and singular annular combustion chamber"

thanks brian- of course the 331 IS a singleshaft like ( nearly) everybody knows...

@V1....ooops: you,re are pretty right and i can confirm this also for the large versions of the pt6a. we had some time ago a TQ sensor fault and it clearly is located on the reduction gearbox. ( PT6A-41)

the feather of the prop with a complete oil loss seems very logical since the PT6a does not have mechanical pitch locks on the prop . the -41 definitly will feather e.g on a normal shutdown with the prop lever full forward.

the clue then is : shut down in any case... with a feathered prop you will have no use even when the engine still delivers power, and you highly risk to toast the turbine in the next minute...

one interesting point is what happens in singleshaft turbines which have mechanical pitch locks on the prop. ( but NTS may in this situation also initiate an autofeather as a result )

"TYPE: Single-shaft engine with two-stage centrifugal compressor, three-stage axial turbine, and singular annular combustion chamber"

thanks brian- of course the 331 IS a singleshaft like ( nearly) everybody knows...

@V1....ooops: you,re are pretty right and i can confirm this also for the large versions of the pt6a. we had some time ago a TQ sensor fault and it clearly is located on the reduction gearbox. ( PT6A-41)

the feather of the prop with a complete oil loss seems very logical since the PT6a does not have mechanical pitch locks on the prop . the -41 definitly will feather e.g on a normal shutdown with the prop lever full forward.

the clue then is : shut down in any case... with a feathered prop you will have no use even when the engine still delivers power, and you highly risk to toast the turbine in the next minute...

one interesting point is what happens in singleshaft turbines which have mechanical pitch locks on the prop. ( but NTS may in this situation also initiate an autofeather as a result )

Thread Starter

Whilst the argument over semantics is perhaps more fun than rolling around in broken glass, the question I posed still remains - Simplistically, there is always a red light in the cockpit that tells you when the oil pressure in your engine is low. Pretty much every other red light on the annunciator panel has a checklist procedure for that red light, so why does a low oil pressure light not rate one from the different engine makers and/or aircraft makers?

It's been established that there is a very good chance that rather bad things will happen if you do nothing, so why is this important action not rated as important enough to even get a mention in the QRH's & so on?

As I've mentioned if I saw the oil pressure starting to fade I would without hesitation pull the S&F on a Garrett but I know of others that would dig around trying to find a solution in the QRH, only to dig themselves a deeper hole. There's large numbers of lesser failures that all get a mention, but not loss of oil.

Why?

It's been established that there is a very good chance that rather bad things will happen if you do nothing, so why is this important action not rated as important enough to even get a mention in the QRH's & so on?

As I've mentioned if I saw the oil pressure starting to fade I would without hesitation pull the S&F on a Garrett but I know of others that would dig around trying to find a solution in the QRH, only to dig themselves a deeper hole. There's large numbers of lesser failures that all get a mention, but not loss of oil.

Why?

Join Date: Oct 2005

Location: USA

Posts: 3,218

Likes: 0

Received 0 Likes

on

0 Posts

Whilst the argument over semantics is perhaps more fun than rolling around in broken glass, the question I posed still remains - Simplistically, there is always a red light in the cockpit that tells you when the oil pressure in your engine is low. Pretty much every other red light on the annunciator panel has a checklist procedure for that red light, so why does a low oil pressure light not rate one from the different engine makers and/or aircraft makers?

Which manufacturers are you aware of that don't have a procedure for loss of oil pressure?

Certainly if there is no cockpit indication available of oil quantity, then having a procedure to deal with low oil quantity (oil loss) is somewhat redundant. Dealing with the effects of loss of oil, however, where such indications are available (and generally more readily apparent), is always appropriate, and one generally has ample procedure available for this.

Again, loss of oil is not the same as loss of oil pressure.

As I've mentioned if I saw the oil pressure starting to fade I would without hesitation pull the S&F on a Garrett but I know of others that would dig around trying to find a solution in the QRH, only to dig themselves a deeper hole. There's large numbers of lesser failures that all get a mention, but not loss of oil.

Furthermore, upon pitching up, there was again a surge in both oil pressure and torque, until the last of the oil was gone (the bit that was pumped as a result of the pitch change). Shutting the engine down wasn't really an issue with a power loss in a burning canyon at 150'. The increase in oil pressure and torque lasted for about three seconds and it was gone again, this time with no significant torque indication, where previously I'd had about fifteen percent.

You do seem to be confusing loss of oil with loss of oil pressure, though perhaps you're suggesting that without an oil quantity indication, then one will look to a loss of pressure as indicative of being out of oil (often not the case, as a pump failure, sensor failure, or gauge failure, as well as a bypass failure in the open position, thermostat or thermovern failure open, and other types of malfunctions, can cause a loss in oil pressure, as can high temperatures).

Are you suggesting the aircraft you fly has no procedure for loss of oil pressure? In your initial post you posed a different conundrum, namely that the aircraft you flew had no procedure for loss of engine oil.

Surely procedures are in place for dealing with the effects of the loss of engine oil, are they not?

Thread Starter

Semantic argument, then ...

Surely procedures are in place for dealing with the effects of the loss of engine oil, are they not?

Surely procedures are in place for dealing with the effects of the loss of engine oil, are they not?

Why?

Join Date: Feb 2008

Location: Wingham NSW Australia

Age: 83

Posts: 1,343

Likes: 0

Received 0 Likes

on

0 Posts

Loss of Oil Quantity - Effects

Guppy, You have not been reluctant to "put down" aerobat77 as being a troll. Whilst you may well have reason to feel as you do about aerobat77 I have to question some of the assertions you have made. You write "loss of oil does not necessarily mean a loss in pressure, nor does a decrease in quantity (loss of oil) show up as an increase in temperature". I accept that loss of some oil does not necessarily result in a loss of pressure, but a total loss of oil must result in a loss of oil pressure. Also, loss of oil quantity can most certainly show up as an increase in oil temperature, just as loss of coolant will result in an increase in coolant temperature in liquid cooled engines. Not everyone will understand that an important part of the work oil does is to carry heat away from the engine. With reduced quantity the oil is circulated quicker and a temperature increase will take place accompanied by a drop in indicated pressure. I also note that you choose to not respond to my comments regarding reduction gearbox lubrication on C130 and P3/Electra aircraft. None of us are infallible sir.

Join Date: Oct 2010

Location: Germany

Age: 47

Posts: 402

Likes: 0

Received 0 Likes

on

0 Posts

There was no procedure for dealing with either loss of oil quantity or pressure. Metro 3 type, Garrett TPE-331 engine.

i cannot say much about the metro but i will look when at home , i think i have still some documents from the C441 time, also equipped with garretts.

my current cheyenne gives procedures for low oil pressure ( i wrote it above).

but for an oil leak - i think its hard to determine a procedure you can deal with. how dou you want do deal with an oilleak inflight? just wait until pressure drops below redline and then here we go with single engine procedures...

@old fella: thanks , but beyond that i would be exited to know where i was fundamentally wrong with my statements ...

and no, something is wrong here- just let me quote some original statements from guppy for clarification :

"EGT and RPM responded proportionately to power lever movement "

the garrett responds with RPM changes due to POWER lever moments inflight?

"TPE-331 is not a "single shaft"

no?

i wrote this :

what we can say: it is technically IMPOSSIBLE to keep a tpe331 running with the prop feathered- instead of a pt6 where stopping the prop will not stop the core

that is the reply from guppy :

This is not true.

i truly always thought that the garrets incorporate a SHUT and feather (S&F) emergency position, not just feather without shutting down...

ok, nevermind... but now- he says simulatany this :

"I've not only used airframes with TPE-331's, but am a check airman in one of them"

the conquest II was my first job and i have not sooo much time on it, but hey-to all real garrett drivers.... what do you think about this? , something smells...

after this discussion he tries to defend his reputation to death and finally calls me a troll and assests i have no idea about anything... well, ok, i respekt his estimation, thats all

i cannot say much about the metro but i will look when at home , i think i have still some documents from the C441 time, also equipped with garretts.

my current cheyenne gives procedures for low oil pressure ( i wrote it above).

but for an oil leak - i think its hard to determine a procedure you can deal with. how dou you want do deal with an oilleak inflight? just wait until pressure drops below redline and then here we go with single engine procedures...

@old fella: thanks , but beyond that i would be exited to know where i was fundamentally wrong with my statements ...

and no, something is wrong here- just let me quote some original statements from guppy for clarification :

"EGT and RPM responded proportionately to power lever movement "

the garrett responds with RPM changes due to POWER lever moments inflight?

"TPE-331 is not a "single shaft"

no?

i wrote this :

what we can say: it is technically IMPOSSIBLE to keep a tpe331 running with the prop feathered- instead of a pt6 where stopping the prop will not stop the core

that is the reply from guppy :

This is not true.

i truly always thought that the garrets incorporate a SHUT and feather (S&F) emergency position, not just feather without shutting down...

ok, nevermind... but now- he says simulatany this :

"I've not only used airframes with TPE-331's, but am a check airman in one of them"

the conquest II was my first job and i have not sooo much time on it, but hey-to all real garrett drivers.... what do you think about this? , something smells...

after this discussion he tries to defend his reputation to death and finally calls me a troll and assests i have no idea about anything... well, ok, i respekt his estimation, thats all

Originally Posted by SNS3Guppy

...That really depends on the motor and on the installation. that is not the case for the entire series. [referring to the torque sensor and oil pressure sensor being at opposite ends of the PT6A series of engines]

I have this morning spoken to Pratt & Whitney engineering in Montréal and they confirm that every PT6A engine has two entirely different systems for sensing torque and oil pressure, and they are at opposite ends of the engine.

Note that we are speaking about engines (prime movers), not motors.

Michael

Join Date: Sep 2006

Location: West Coast Canada

Age: 71

Posts: 69

Likes: 0

Received 0 Likes

on

0 Posts

18 Wheeler

As the OP of this topic these comments are directed to you.

You have certainly started a lively discussion here with thread drift that is unbelievable - to the point of some members slagging each other in a rather rude way.

Next time you post you might want to be more specific as it took until page 3 for you to post the real question that you wanted.

Which appears to be: There was no procedure for dealing with either loss of oil quantity or pressure. Metro 3 type, Garrett TPE-331 engine.

Why?

Had you posted that question in the first page then the answer would have been a lot easier to give you.

The short answer to your question lies in the original certification of the aircraft - in this case SFAR 41. This was a number of exemptions for this type of aircraft to be operated in commercial service without having to be built and certified to "Big" airplane standards.

Ed Swearengen was the original designer and everything about the San Antonio Sewer Pipe was done on the cheap. I would suspect that the flight manual meets the minimum standard for the type but probably not much more.

Back in the day this aircraft was built the authorities still believed in a "Common Sense" approach to flying aircraft - nowadays they not only have to make it "Fool Proof" but have to make it "Damn Fool Proof" as well. Thus newer aircraft have a lot more in the flight manuals.

So the real reason is - because that is how the flight manual was approved in the first place.

Google SFAR 41 and Wiki for the Metro 3 and read.

Regards,

Mx

As the OP of this topic these comments are directed to you.

You have certainly started a lively discussion here with thread drift that is unbelievable - to the point of some members slagging each other in a rather rude way.

Next time you post you might want to be more specific as it took until page 3 for you to post the real question that you wanted.

Which appears to be: There was no procedure for dealing with either loss of oil quantity or pressure. Metro 3 type, Garrett TPE-331 engine.

Why?

Had you posted that question in the first page then the answer would have been a lot easier to give you.

The short answer to your question lies in the original certification of the aircraft - in this case SFAR 41. This was a number of exemptions for this type of aircraft to be operated in commercial service without having to be built and certified to "Big" airplane standards.

Ed Swearengen was the original designer and everything about the San Antonio Sewer Pipe was done on the cheap. I would suspect that the flight manual meets the minimum standard for the type but probably not much more.

Back in the day this aircraft was built the authorities still believed in a "Common Sense" approach to flying aircraft - nowadays they not only have to make it "Fool Proof" but have to make it "Damn Fool Proof" as well. Thus newer aircraft have a lot more in the flight manuals.

So the real reason is - because that is how the flight manual was approved in the first place.

Google SFAR 41 and Wiki for the Metro 3 and read.

Regards,

Mx

Join Date: Oct 2005

Location: USA

Posts: 3,218

Likes: 0

Received 0 Likes

on

0 Posts

I accept that loss of some oil does not necessarily result in a loss of pressure, but a total loss of oil must result in a loss of oil pressure. Also, loss of oil quantity can most certainly show up as an increase in oil temperature, just as loss of coolant will result in an increase in coolant temperature in liquid cooled engines.

I can tell you that I've experienced both; complete oil loss, as well as complete coolant loss. Lose the coolant, all of it, from an engine block, and you generally won't see a coolant temperature rise, but a fall...because there is no coolant passing the temperature probe to indicate a rise. Likewise, I've seen oil temperature drop to zero and remain the same with oil loss. Both are possible, and both do happen. Furthermore, if one waits until one is seeing an oil temperature increase, depending on the nature of the problem, the system, probe placement and condition, etc, then it may be far too late to worry about the loss; one may have other issues with which to content.

I accept that loss of some oil does not necessarily result in a loss of pressure, but a total loss of oil must result in a loss of oil pressure.

Further, there was no core lock or seizure resulting from that loss, and the manufacturer indicated that the engine could be expected to continue running for a half hour without oil.

The indication of oil loss wasn't quantity, as it didn't exist. The indication of pressure loss wasn't the oil pressure gauge, which continued to read oil pressure. It was the loss of torque.

Guppy, You have not been reluctant to "put down" aerobat77 as being a troll.

I also note that you choose to not respond to my comments regarding reduction gearbox lubrication on C130 and P3/Electra aircraft.

The reduction gear box on both, however, is most certainly lubricated using engine oil (MIL-L-7808) which is supplied from the same oil tank as the engine.

For the past 25 years or so, the USAF has used different fluids, under approval. H-83282 H-87257 are also in use: these fluids are newer specs for H5606. All three are hydrocarbon-based hydraulic fluid, the latter two are synthetic base. I operated A models and can tell you with absolute certainty that the sumps were separate, pressurized, and utilized H-5606.

http://rgl.faa.gov/Regulatory_and_Gu...FILE/A39CE.pdf

You'll note, specifically, per the TCDS (A39CE), the propeller oil called out. You'll note that this isn't a 30 year old revision, either, but a current TCDS, with current specifications. Therefore, while one might cite the age of the airplane and suggest that once upon a time 5606 was used, the fact is that it's still called out, and still in use, in a separate lubrication and supply system to the engine oil. The propeller is a separate assembly, mechanically and physically attached, made by a different manufacturer, using a separate, dedicated pressurized sump and separate pump and lubrication/actuation system.

Propeller Oil

(1) Hamilton Standard, propeller - MIL-H-5606B

(2) Aero Products, Propeller -Penola Aviation Instrument Oil, Government No. 1191X, Manufactured by ESSO Standard Oil Company, Type P-Q Rust Preventative No. 107, Government No. 6603X, manufactured by American Oil Company or Government No. 3106 or 3106X manufactured by Humble Oil and Refining Company, FSN 9150-473-9849

Would that be the specification to which you're referring that doesn't use 5606 for operation of the Hamilton Standard Hydromatic propeller installation on the T56 in the C-130? The one that calls for H5606? Now, given that the same specification calls out Mil-7808 for the engine oil, and given that one really shouldn't mix H5606 and Mil-7808, why do you suppose the manufacturer (and FAA) call for two different fluids for the engine and propeller, if indeed they share a common sump and lubrication system? They do not.

The Oil quantity, Oil temperature, Engine Oil Pressure, Reduction Gearbox Oil Pressure and Oil Cooler Flap position were all provided with indicators as well as a "Eng Oil Low Quantity" annunciator which could be triggered by any of the four engines.

Inappropriate engine in-flight engine shutdowns for oil propeller oil quantity indications are a known issue in the airplane, and I've seen and shut down the motors for actual hydraulic issues involving incorrect propeller overservice action, and failure to secure the lid on the pressurized sump (the ham standard assembly on the T56 uses an atmospheric, and pressurized sump...neither of which are not part of the engine lubrication system).

Guppy, is this the NTSB report for your engine failure?

None of us are infallible sir.

Join Date: Sep 2006

Location: West Coast Canada

Age: 71

Posts: 69

Likes: 0

Received 0 Likes

on

0 Posts

And this link is why you have a maintenance department to ask about these types of questions. Asking a good qualified and up to date maintenance "person" can do a lot to help understand what problems might be there for your consideration. Asking an armchair expert on a forum can get you some pretty interesting and totally wrong information in the process - not that that is such a bad thing but you really have to sort through all the chaff to get to the wheat!!! And just so everyone knows I do believe in "Free Speech" - everyone has the right to spout off whatever nonsense floats their boat. I also believe in making sure that someone I am about to take information from - that might possibly put my or someones elses' life in danger - is in fact actually in the know.

In almost 40 years in the maintenance industry I can count on one hand the number of pilots that have asked me to dump my pot of knowledge in their lap so they could understand what was really happening with the aircraft they were flying. In fact I have actually had chief and training pilots come to me and tell me to dumb it down a bit for the flight crews because they were starting to snag the airplane as a result of actually knowing that something needed to be looked at. - Oh well " I was looking for a job when I found this one!!" was the usual result of that request and my P(inCorrect) reply being less than desired by management.

Engines - Transport Canada

Continuing to run this engine with an oil pressure downward trend would have resulted in another event for us all to armchair quarterback!!!

Remember the old saw about learning from the mistakes of others as you don't have enough time to learn them all yourself. One of those mistakes is taking bad advice from someone - VERIFY EVERYTHING!!! - (Except of course stuff from me because I always tell the truth)

Regards,

Mx

In almost 40 years in the maintenance industry I can count on one hand the number of pilots that have asked me to dump my pot of knowledge in their lap so they could understand what was really happening with the aircraft they were flying. In fact I have actually had chief and training pilots come to me and tell me to dumb it down a bit for the flight crews because they were starting to snag the airplane as a result of actually knowing that something needed to be looked at. - Oh well " I was looking for a job when I found this one!!" was the usual result of that request and my P(inCorrect) reply being less than desired by management.

Engines - Transport Canada

Continuing to run this engine with an oil pressure downward trend would have resulted in another event for us all to armchair quarterback!!!

Remember the old saw about learning from the mistakes of others as you don't have enough time to learn them all yourself. One of those mistakes is taking bad advice from someone - VERIFY EVERYTHING!!! - (Except of course stuff from me because I always tell the truth)

Regards,

Mx