AN-124 Uncontained Engine Failure

Join Date: Dec 2013

Location: UK

Posts: 22

Likes: 0

Received 0 Likes

on

0 Posts

Just to add to DaveReidUK's comment. The pictures posted of the disc segment with blade roots and 2 damaged blades still attached is a fan disc (LPC) not a turbine disc.

I can't post links, but there are engine schematics for the D-18T online. It's a 3 spool engine with a single stage LPC/Fan. The IPC and HPC use dovetail blade roots, whilst the 3 turbine sections use fir-tree roots. I originally thought the disc segment was the HPT due to those fir-tree roots, but on seeing the remainder of the engine on the wing and a wider shot of the disc segment I concluded that it's part of the LPC/Fan disc. If you look at the 2 damaged blades you can see that the blades lack air cooling (HPT and IPT are cooled on this engine), whilst the blade length and chord are too large to be turbine blades. If you look at the blade nearest the camera you can see that it's fractured along the line of the snubber, again indicating this is part of the fan disc.

We won't know what caused the failure until a full metallurgical analysis is performed, which may be dependent on the missing disc fragment(s) being found.

Turbine disc failure modes are for another topic.

I can't post links, but there are engine schematics for the D-18T online. It's a 3 spool engine with a single stage LPC/Fan. The IPC and HPC use dovetail blade roots, whilst the 3 turbine sections use fir-tree roots. I originally thought the disc segment was the HPT due to those fir-tree roots, but on seeing the remainder of the engine on the wing and a wider shot of the disc segment I concluded that it's part of the LPC/Fan disc. If you look at the 2 damaged blades you can see that the blades lack air cooling (HPT and IPT are cooled on this engine), whilst the blade length and chord are too large to be turbine blades. If you look at the blade nearest the camera you can see that it's fractured along the line of the snubber, again indicating this is part of the fan disc.

We won't know what caused the failure until a full metallurgical analysis is performed, which may be dependent on the missing disc fragment(s) being found.

Turbine disc failure modes are for another topic.

Last edited by iranu; 19th Nov 2020 at 11:11. Reason: spelling

Three equal piece failures are typical only for overstress condition (speed and temperature to a smooth shaped disk. This is due to the conservation of kinematic energy (radial and tangential) before they actually fracture. Little chance of most compressor disks being equally stressed (radial and tangential) or even oversped or overtemperatured. This leave the majority of disk fractures to be split roughly in half with one of the halves splitting over a rough 1/3 section (shock waves in disk after severing the tangential force)

Agree that the assumption of only a single large section of maximum energy (1/3 not 1/2 just do the math) only needs to be considered, The pass fail criteria is then driven by subjective judgements of the FAA against the manufacturers estimates of chance impingements then to be accomodated by shielding (that actually works), separation of critical controls and redundancy (it still flies even though wounded)

The above approximates how one estimates the survivability of military jets to threats

I thought the subject event in this thread did quite well

Agree that the assumption of only a single large section of maximum energy (1/3 not 1/2 just do the math) only needs to be considered, The pass fail criteria is then driven by subjective judgements of the FAA against the manufacturers estimates of chance impingements then to be accomodated by shielding (that actually works), separation of critical controls and redundancy (it still flies even though wounded)

The above approximates how one estimates the survivability of military jets to threats

I thought the subject event in this thread did quite well

To add a bit to what Dave wrote, the 'one in twenty' Advisory Circular guidance (FAA, but EASA also accepts this method of compliance) specifies a 1/3rd disc - with infinite energy. You can't take any credit for shielding for the rotor disc fragments (also known as 'high energy debris'). Smaller bits - such as the blades and blade fragments - are 'low energy debris' and shielding credit can be taken.

There is a defined forward/aft trajectory range for both - IIRC it's +/- 3 deg for 'high energy' debris, and +/- 20 deg for 'low energy' debris (but I stand to be corrected - it's been a while since I worried this).

There is a defined forward/aft trajectory range for both - IIRC it's +/- 3 deg for 'high energy' debris, and +/- 20 deg for 'low energy' debris (but I stand to be corrected - it's been a while since I worried this).

And I forgot to add that the reason only a single 1/3rd disk section was considered was based on experience both before and after the Concorde program. Naturally if a disk breaks into three equal pieces it leaves a mathematical shortfall.for the other two segments. However the predicted generation of three equal pieces (see above) says that they will leave simultaneously so only one is expected to be aimed at the critical parts of an aircraft (critical is in the eyes of the manufacturer and the FAA)

Lessons learned have now taught us that not every 1/3 section has infinite penetration power. In fan disk failures those 20-30lb fan blade fragments tend to cover a lot more area. Thus don't expect to meet a 1/20 safety rate unless you really can shield against. those fragments. The good news is that most really large engines use Kevlar which has been shown to capture multiple blades from a fan disk fracture.

Somewhere on my hard drive I have all this stuff as it was developed for the FAA to review. In the end they went for the subjective stuff because it gave them something to hide behind

Lessons learned have now taught us that not every 1/3 section has infinite penetration power. In fan disk failures those 20-30lb fan blade fragments tend to cover a lot more area. Thus don't expect to meet a 1/20 safety rate unless you really can shield against. those fragments. The good news is that most really large engines use Kevlar which has been shown to capture multiple blades from a fan disk fracture.

Somewhere on my hard drive I have all this stuff as it was developed for the FAA to review. In the end they went for the subjective stuff because it gave them something to hide behind

Fan disc that fail are bad enough. Back, I have seen the result of a front bearing internal fire and severing of both the main shaft but also the "fail-safe" shaft releasing the entire fan disc assembly. It was the 22B version (early model) of the RB-211 and the entire assembly marched forward. Being in the Nbr. 2 position of an L-1011 it ate out the S-Duct section, dinged the top of the horizontal stabilizer box below it and came apart just before entering the rear pressure bulkhead. Portside hole in fuselage side was big enough to walk through. Severed three of the four hydraulic systems, fourth had damaged tubing but fortunately was not holed. Eventually, an AD required a system to be installed to detect the first movement of a failing front locator bearing. That essentially, due top cost, ended the 22B engine and sped the retirement of all the L-1011-1 models.

I actually witnessed a disc from a CF6-50 engine roll at very high velocity across JFK airport and end at the then Pan Am ground equipment shop. Came out of an Overseas National DC10-30 on takeoff roll. It aborted, came to a stop and I saw the best evacuation of a burning aiurcraft ever. All aboard were ONA personnel going to support Hah flights. Unfortunately, the fire totally destroyed the aircraft in spite of the efforts of the JFK PONYA firefighters.

Don't believe any protection will prevent whole discs from coming out. Aircraft survival will depend on which way it goes.

I actually witnessed a disc from a CF6-50 engine roll at very high velocity across JFK airport and end at the then Pan Am ground equipment shop. Came out of an Overseas National DC10-30 on takeoff roll. It aborted, came to a stop and I saw the best evacuation of a burning aiurcraft ever. All aboard were ONA personnel going to support Hah flights. Unfortunately, the fire totally destroyed the aircraft in spite of the efforts of the JFK PONYA firefighters.

Don't believe any protection will prevent whole discs from coming out. Aircraft survival will depend on which way it goes.

There is some very simple physics why a disc failure will result in three roughly equal fragments, with none substantially larger than 120° (the largest on your example is 130-140°). Failure originates from a single point, with a crack propagating through the entire cross-section. Once the crack is complete, the integrity of the ring is compromised, and centrifugal forces will start to bend it outwards. The maximum stress due to these forces is not at the side opposite to the initial failure, but at the two sides, roughly 1/3 the way, where two more cracks will form. Of course all this happens in less than a millisecond, and things like lost/damaged blades and speed of rotation will determine the exact outcome. Due to interaction with other components the initial pieces may or may not fracture any further, but you will always start out with three roughly similar sized fragments. This also means that only one of the three (or subsequent smaller fragments) will be on a trajectory towards the fuselage. Of course if the bearing fails, and the entire disk goes AWOL, that is a different story.

Fascintating science behind it.

and the highest energy piece may be less of a risk to penetrate a critical aircraft structure..There is less worry about 180 degree segment pieces than a 115 degree piece of disk. The smaller the angle section the lower the weight but the higher escape velocity. That works out to a highest penetration range for aircraft structures between about 100-140 degree segments (worst combination of translational velocity and weight) Of course anything really close by is going to suffer from the more numerous smaller fragments

You would need armour comparable to a battle tank to have adequate protection against these failures. The key is to prevent them from happening in the first place and designing the aircraft so that critical components and wiring won’t be damaged if they occur. If this can’t be done, then separate back up systems for the most critical systems need to be looked at.

An emergency means of shutting of the fuel supply at the tank end could be worth having.

An emergency means of shutting of the fuel supply at the tank end could be worth having.

Join Date: Nov 2005

Location: on the way to sea

Posts: 272

Likes: 0

Received 0 Likes

on

0 Posts

Just to add to DaveReidUK's comment. The pictures posted of the disc segment with blade roots and 2 damaged blades still attached is a fan disc (LPC) not a turbine disc.

I can't post links, but there are engine schematics for the D-18T online. It's a 3 spool engine with a single stage LPC/Fan. The IPC and HPC use dovetail blade roots, whilst the 3 turbine sections use fir-tree roots. I originally thought the disc segment was the HPT due to those fir-tree roots, but on seeing the remainder of the engine on the wing and a wider shot of the disc segment I concluded that it's part of the LPC/Fan disc. If you look at the 2 damaged blades you can see that the blades lack air cooling (HPT and IPT are cooled on this engine), whilst the blade length and chord are too large to be turbine blades. If you look at the blade nearest the camera you can see that it's fractured along the line of the snubber, again indicating this is part of the fan disc.

We won't know what caused the failure until a full metallurgical analysis is performed, which may be dependent on the missing disc fragment(s) being found.

Turbine disc failure modes are for another topic.

I can't post links, but there are engine schematics for the D-18T online. It's a 3 spool engine with a single stage LPC/Fan. The IPC and HPC use dovetail blade roots, whilst the 3 turbine sections use fir-tree roots. I originally thought the disc segment was the HPT due to those fir-tree roots, but on seeing the remainder of the engine on the wing and a wider shot of the disc segment I concluded that it's part of the LPC/Fan disc. If you look at the 2 damaged blades you can see that the blades lack air cooling (HPT and IPT are cooled on this engine), whilst the blade length and chord are too large to be turbine blades. If you look at the blade nearest the camera you can see that it's fractured along the line of the snubber, again indicating this is part of the fan disc.

We won't know what caused the failure until a full metallurgical analysis is performed, which may be dependent on the missing disc fragment(s) being found.

Turbine disc failure modes are for another topic.

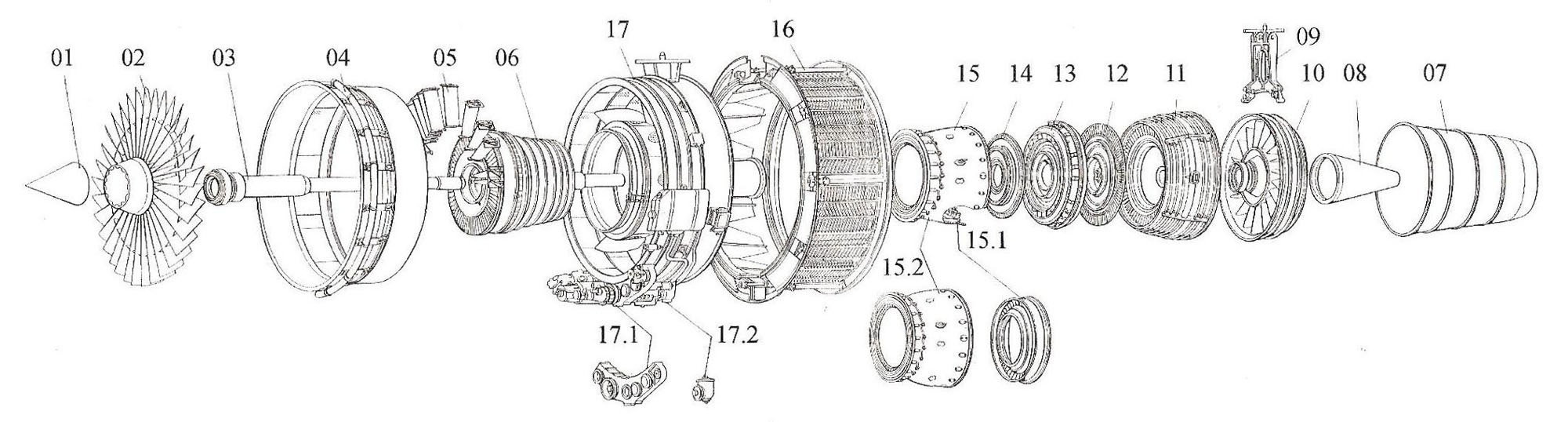

1-Cone leading edge section; 2-Fan wheel; 3-Fan shaft with bearing support; 4-Fan casing; 5-Fan straightener vane; 6-Intermediate pressure compressor; 7-Jet nozzle; 8-Exhaust cone; 9-Rear mount; 10-Rear bearing; 11-Fan turbine; 12-Intermediate pressure turbine rotor; 13-Turbine bearings casing; 14-High pressure turbine rotor; 15-Combustion chamber with hight pressure turbine; 15.1-High pressure turbine nozzle guide vanes; 15.2-Combustion chamber; 16-Thrust reverser; 17-Engine master module; 17.1-Accessory drive gear box; 17.2-Intermediate drive.

source: http://www.buran-energia.com/mriya-a...ine-consti.php

http://www.buran-energia.com/mriya-a...ngine-desc.php

Last edited by kontrolor; 28th Nov 2020 at 19:12. Reason: added caption

Join Date: Aug 2006

Location: Looking for the signals square at LHR

Posts: 236

Likes: 0

Received 0 Likes

on

0 Posts

Not for penetration, velocities below 1800 ft/s in steel and 1100 ft/s in Alum act about a 3/2 power while mass is only at a power of 1. It's more than energy that gets involved. It also involves shock waves and adiabatic shear. Fortunately Kevlar belts have a whole different mechanism going on at the engine level

Last edited by lomapaseo; 29th Nov 2020 at 09:24. Reason: typo

Join Date: Aug 2006

Location: Looking for the signals square at LHR

Posts: 236

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Lom - I imagine that if there were any means of introducing isothermal characteristics to these assemblies, it would have been done years ago.

Typically uncontained failure issues with existing engines are addressed with a combination of increased inspections and hard time life limits (cycles and/or hours) - usually enforced by AD.

Sometimes there are changes that can be reworked into existing parts (during a shop visit) such as machining an increased radius into a high stress area to improve the crack resistance.

The trick is finding the correct inspection intervals and life limits to prevent future failures. I know this was on ongoing issue with the CF6-50 turbine discs installed on older 747 Freighters. The Feds kept changing (reducing) the inspection intervals and hard time life limits, but they kept failing at the rate of one or two a year right up to the time I retired. Fortunately they never did enough damage to serious threaten continued safe flight and landing, but I suspect if the event aircraft had been carrying hundreds of passengers instead of tons of freight, it would have gotten a lot more attention.

Sometimes there are changes that can be reworked into existing parts (during a shop visit) such as machining an increased radius into a high stress area to improve the crack resistance.

The trick is finding the correct inspection intervals and life limits to prevent future failures. I know this was on ongoing issue with the CF6-50 turbine discs installed on older 747 Freighters. The Feds kept changing (reducing) the inspection intervals and hard time life limits, but they kept failing at the rate of one or two a year right up to the time I retired. Fortunately they never did enough damage to serious threaten continued safe flight and landing, but I suspect if the event aircraft had been carrying hundreds of passengers instead of tons of freight, it would have gotten a lot more attention.