Severe trim runaway E175 Republic Airways 11/6/19 Atlanta

Join Date: Jun 2001

Location: Rockytop, Tennessee, USA

Posts: 5,898

Likes: 0

Received 1 Like

on

1 Post

An update from the NTSB:

NTSB News Release

Based on preliminary findings from its ongoing investigation of an incident involving an Embraer-175 airplane, the NTSB issued 10 safety recommendations Wednesday to address safety issues identified in the investigation.

The NTSB issued six safety recommendations to the National Civil Aviation Agency of Brazil (ANAC) and four to the Federal Aviation Administration. The recommendations are designed to address areas of concern including wire chafing, application of Embraer service bulletins relating to the pitch trim switch, and potential limitations in checklist memory items for pilots to address unintended operation of the pitch trim system.

The investigation and recommendations stem from a Nov. 6, 2019, incident involving Republic Airways flight 4439, an Embraer EMB-175. The flight crew declared an emergency shortly after takeoff from Hartsfield-Jackson Atlanta International Airport, Atlanta, reporting a pitch trim-related flight control issue and difficulty controlling the airplane. There were six passengers on board the airplane. The crew returned to the airport and safely landed the plane about 15 minutes after declaring the emergency.

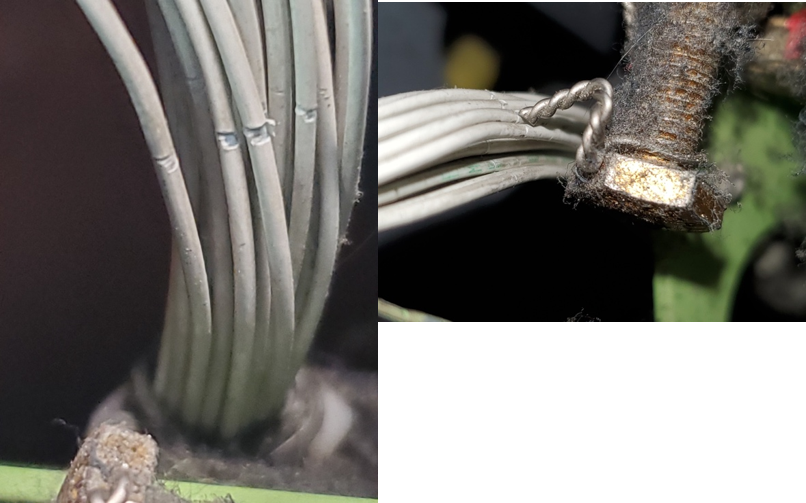

Although the cause of the incident remains under investigation, post-incident examination of the airplane revealed chafed insulation around wires connecting the horizontal stabilizer actuator control electronics to the captain’s pitch trim switch and autopilot/trim disconnect button. The chafing was caused by contact with the incorrectly untucked pigtail of the forward mechanical stop bolt safety wire.

(Wire chafing to the insulation around wires connecting the horizontal stabilizer actuator control electronics to the captain’s pitch trim switch in an Embraer-175 (left) and an incorrectly untucked pigtail (right) that caused the chafing, are seen in these photos taken Nov. 9, 2019. Photo courtesy of Republic Airways.)

When the captain’s pitch trim switch was removed from the yoke, marks were observed that indicated at some point before the incident flight, the pitch trim switch had been installed in an inverted position. Embraer previously issued three service bulletins related to pitch trim switch installation error following reports from flight crews in 2015 about flight control system difficulties. However, neither the FAA nor the ANAC required incorporation of the service bulletins. While it is not yet known if inverted switch installation was a factor in the incident, the NTSB is concerned the condition could lead to flight crew confusion, delaying appropriate recognition of and response to increased control forces.

Preliminary information from the NTSB’s investigation also suggests that unintended pitch trim operation may be masked and go undetected during certain phases of flight, such as during takeoff. Further, limitations in the checklist memory items may delay pilots in properly responding to and regaining control of the Embraer EMB-170/175/190/195 and Lineage 1000 series airplanes. The NTSB is concerned the crew’s application of the memory item(s) on the EMB-175 Pitch Trim Runaway checklist may not comprehensively address circumstances of the trim system operation in a timely manner.

Based on these preliminary findings from the ongoing investigation, the NTSB issued the 10 safety recommendations to address these safety issues.

“Issuing these 10 safety recommendations early in the investigation demonstrates the NTSB’s commitment to take action as soon as we’ve identified and verified a safety issue that needs to be addressed,” said NTSB Chairman Robert Sumwalt. “We don’t need to wait for an investigation to be completed before issuing safety recommendations. We have the responsibility to issue recommendations that when implemented by recipients, can correct safety deficiencies, prevent accidents, and save lives,” said Sumwalt.

Aviation Safety Recommendation Report 20-01 is available online.

The NTSB’s investigation of the Nov. 6, 2019, incident is ongoing and as such, no conclusions about probable cause should be drawn from the information provided in the safety recommendation report.

NTSB News Release

National Transportation Safety Board Office of Public Affairs

10 Safety Recommendations Issued Following Incident Investigation Preliminary Findings

1/29/2020Based on preliminary findings from its ongoing investigation of an incident involving an Embraer-175 airplane, the NTSB issued 10 safety recommendations Wednesday to address safety issues identified in the investigation.

The NTSB issued six safety recommendations to the National Civil Aviation Agency of Brazil (ANAC) and four to the Federal Aviation Administration. The recommendations are designed to address areas of concern including wire chafing, application of Embraer service bulletins relating to the pitch trim switch, and potential limitations in checklist memory items for pilots to address unintended operation of the pitch trim system.

The investigation and recommendations stem from a Nov. 6, 2019, incident involving Republic Airways flight 4439, an Embraer EMB-175. The flight crew declared an emergency shortly after takeoff from Hartsfield-Jackson Atlanta International Airport, Atlanta, reporting a pitch trim-related flight control issue and difficulty controlling the airplane. There were six passengers on board the airplane. The crew returned to the airport and safely landed the plane about 15 minutes after declaring the emergency.

Although the cause of the incident remains under investigation, post-incident examination of the airplane revealed chafed insulation around wires connecting the horizontal stabilizer actuator control electronics to the captain’s pitch trim switch and autopilot/trim disconnect button. The chafing was caused by contact with the incorrectly untucked pigtail of the forward mechanical stop bolt safety wire.

(Wire chafing to the insulation around wires connecting the horizontal stabilizer actuator control electronics to the captain’s pitch trim switch in an Embraer-175 (left) and an incorrectly untucked pigtail (right) that caused the chafing, are seen in these photos taken Nov. 9, 2019. Photo courtesy of Republic Airways.)

When the captain’s pitch trim switch was removed from the yoke, marks were observed that indicated at some point before the incident flight, the pitch trim switch had been installed in an inverted position. Embraer previously issued three service bulletins related to pitch trim switch installation error following reports from flight crews in 2015 about flight control system difficulties. However, neither the FAA nor the ANAC required incorporation of the service bulletins. While it is not yet known if inverted switch installation was a factor in the incident, the NTSB is concerned the condition could lead to flight crew confusion, delaying appropriate recognition of and response to increased control forces.

Preliminary information from the NTSB’s investigation also suggests that unintended pitch trim operation may be masked and go undetected during certain phases of flight, such as during takeoff. Further, limitations in the checklist memory items may delay pilots in properly responding to and regaining control of the Embraer EMB-170/175/190/195 and Lineage 1000 series airplanes. The NTSB is concerned the crew’s application of the memory item(s) on the EMB-175 Pitch Trim Runaway checklist may not comprehensively address circumstances of the trim system operation in a timely manner.

Based on these preliminary findings from the ongoing investigation, the NTSB issued the 10 safety recommendations to address these safety issues.

“Issuing these 10 safety recommendations early in the investigation demonstrates the NTSB’s commitment to take action as soon as we’ve identified and verified a safety issue that needs to be addressed,” said NTSB Chairman Robert Sumwalt. “We don’t need to wait for an investigation to be completed before issuing safety recommendations. We have the responsibility to issue recommendations that when implemented by recipients, can correct safety deficiencies, prevent accidents, and save lives,” said Sumwalt.

Aviation Safety Recommendation Report 20-01 is available online.

The NTSB’s investigation of the Nov. 6, 2019, incident is ongoing and as such, no conclusions about probable cause should be drawn from the information provided in the safety recommendation report.

Reading between the lines of the ASR, this sounds like a maintenance, rather than a manufacturing issue.

I can remember learning the hard way, many years ago, that leaving a projecting locking wire tail is not only a Cardinal Sin, but can hurt like h*ll.

I can remember learning the hard way, many years ago, that leaving a projecting locking wire tail is not only a Cardinal Sin, but can hurt like h*ll.

Join Date: Jul 2002

Location: Netherlands

Age: 71

Posts: 165

Likes: 0

Received 0 Likes

on

0 Posts

Dave Reid, so true.

It was during a DC9 training session with a few F/O's doing touch and goes, we had a massive bird strike (a duck) on the RH windscreen on short final. Just red all over, blocking the instructor's view nearly completely. Stopped and turned off the active, and the instructor, armed with a load of toilet paper, opened the RH window to lean outside and started to clean up the mess.

Did not take long before he made a scream and came back inside, bleeding like h&ll from his RH wrist.

He had hit the safety wire of the wiper's axle.

Called it quits, we saw enough blood for that day ...

...

It was during a DC9 training session with a few F/O's doing touch and goes, we had a massive bird strike (a duck) on the RH windscreen on short final. Just red all over, blocking the instructor's view nearly completely. Stopped and turned off the active, and the instructor, armed with a load of toilet paper, opened the RH window to lean outside and started to clean up the mess.

Did not take long before he made a scream and came back inside, bleeding like h&ll from his RH wrist.

He had hit the safety wire of the wiper's axle.

Called it quits, we saw enough blood for that day

...

...Join Date: Dec 2019

Location: Derry

Posts: 140

Likes: 0

Received 0 Likes

on

0 Posts

Thanks barrow

Looks very interesting even though I know less that the square root of zero about Embraer.

They clearly can have a stab that can runaway that can exceed pilot elevator capability which sounds familiar - hence the ref to banking turns to reduce lift. Banking heavily left and right to fly the plane is clearly a last ditch idea. A bit like yoyo on the 737, but it works.

The OFF buttons seem to be the equivalent of the 737 STAB OFF switches

They don't have manual trim wheels or any other fallback.

QRH

In a runway the drill seems to be that one of the two channels is malfunctioning, so....

BOTH OFF

Re-instate one at a time to find the one that works and that's all right then. Continue with good channel.

It doesn't say what to do if this doesn't work. Probably because they think the chances of both channels going at once is considered to unlikely.

Are there any Embraer pilots who can explain this one because it was clearly very difficult to control.

Cheers

R Guy

ps just seen post NO 28 which asks the same question. What next?.......

Looks very interesting even though I know less that the square root of zero about Embraer.

They clearly can have a stab that can runaway that can exceed pilot elevator capability which sounds familiar - hence the ref to banking turns to reduce lift. Banking heavily left and right to fly the plane is clearly a last ditch idea. A bit like yoyo on the 737, but it works.

The OFF buttons seem to be the equivalent of the 737 STAB OFF switches

They don't have manual trim wheels or any other fallback.

QRH

In a runway the drill seems to be that one of the two channels is malfunctioning, so....

BOTH OFF

Re-instate one at a time to find the one that works and that's all right then. Continue with good channel.

It doesn't say what to do if this doesn't work. Probably because they think the chances of both channels going at once is considered to unlikely.

Are there any Embraer pilots who can explain this one because it was clearly very difficult to control.

Cheers

R Guy

ps just seen post NO 28 which asks the same question. What next?.......

Join Date: Dec 2019

Location: Derry

Posts: 140

Likes: 0

Received 0 Likes

on

0 Posts

Are we sure it is mechanical as per the 737, or is it a wheel on the flight deck that sends electrical power to a motor which runs the STAB up and down?

I would be surprised if Airbus had anything "mechanical"!

Cheers

R Guy

Join Date: Dec 2019

Location: Derry

Posts: 140

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: Apr 2019

Location: EDSP

Posts: 334

Likes: 0

Received 0 Likes

on

0 Posts

Where is it supposed to tie against anyway?

Maybe the safety wire can be seen going to the top left in an acute angle? Doesn't make sense to me. Loop would be on the wrong side as well?

Maybe the safety wire can be seen going to the top left in an acute angle? Doesn't make sense to me. Loop would be on the wrong side as well?

Looks OK to me. The wire-locking is oriented so as to prevent the bolt from unscrewing. The other end of the wire presumably loops through something that doesn't move.

Join Date: Oct 2011

Location: NV USA

Posts: 260

Likes: 0

Received 0 Likes

on

0 Posts

I understand all ERJ aircraft at my airline got inspected immediately and none were found with this situation.

The ERJ has complete fly-by-wire elevators, ailerons are are mechanical however so you have that going for you.

?????? ????

Dude, you need to read what you have written, and then correct the statement? "...same as with the NOSE DOWN TRIM on the MAX..." Please, please, please take time to correct what you have put there so it is not misleading.

HINT:

1. an undesired nose up moment can benefit from using bank to avoid excessively high attitude and corresponding low energy state.

2. an undesirable NOSE DOWN TRIM case is compromised further by bank; loading required to raise attitude is higher than wings level case.

Now if you are suggesting inverted flying in yon B73Max, that has a limited shelf life, it is going to get quiet in about 30 seconds as the boost pumps are then above the fuel level.... as is the engine oil pickup, as is the hydraulic feed to the hyd pumps from the reservoir... possibly a good scenario for a B grade movie, hey, like AK261, but add winglets, add coke, as everything goes better with coke, and, yup lets take out the steeple of a baptist church and park the tube in the field in front of the parishioners. If Neil Williams can do it in a Zlin, then, heck let's do that in the Max.

Dunno though, I have enough fun landing a Pitts on its main gear, but at least it isn't the most entertaining single seat bipe to alight on terra firma. A glide approach from the 180 is so much fun in a Pitts, even right side up. Add a 180 roll at 20' and the fun quotient may exceed my bowel watertightness.

just sayin'

and

Hope it is useful.

.

Join Date: Dec 2019

Location: Derry

Posts: 140

Likes: 0

Received 0 Likes

on

0 Posts

Ah. So it is wheels (like 737) connected to a cable going back the rear of the plane? So far so good.

And then connected to hydraulic components. I wonder does it bypass all the electrical functions?

So it isn't mechanical like the 737 which is clockwork. But it does permit pitch control via hydraulics in the event of falling back to the Airbus equivalent of manual control.

I know you Airbus guys will be able to write dissertions on this stuff but for us Boeing guys currently keeping heads down, it is all very interesting.

These are all questions by the way to gain greater understanding.

Best wishes

R Guy

And then connected to hydraulic components. I wonder does it bypass all the electrical functions?

So it isn't mechanical like the 737 which is clockwork. But it does permit pitch control via hydraulics in the event of falling back to the Airbus equivalent of manual control.

I know you Airbus guys will be able to write dissertions on this stuff but for us Boeing guys currently keeping heads down, it is all very interesting.

These are all questions by the way to gain greater understanding.

Best wishes

R Guy

Join Date: Dec 2019

Location: Derry

Posts: 140

Likes: 0

Received 0 Likes

on

0 Posts

?????? ????

Now if you are suggesting inverted flying in yon B73Max, that has a limited shelf life, it is going to get quiet in about 30 seconds as the boost pumps are then above the fuel level.... as is the engine oil pickup, as is the hydraulic feed to the hyd pumps from the reservoir... possibly a good scenario for a B grade movie, hey, like AK261, but add winglets, add coke, as everything goes better with coke, and, yup lets take out the steeple of a baptist church and park the tube in the field in front of the parishioners. If Neil Williams can do it in a Zlin, then, heck let's do that in the Max.

just sayin'

Now if you are suggesting inverted flying in yon B73Max, that has a limited shelf life, it is going to get quiet in about 30 seconds as the boost pumps are then above the fuel level.... as is the engine oil pickup, as is the hydraulic feed to the hyd pumps from the reservoir... possibly a good scenario for a B grade movie, hey, like AK261, but add winglets, add coke, as everything goes better with coke, and, yup lets take out the steeple of a baptist church and park the tube in the field in front of the parishioners. If Neil Williams can do it in a Zlin, then, heck let's do that in the Max.

just sayin'

How's it going?

For info I was training a 737 guy on Lesson one FFS (first day on sim.). How to fly straight and level. Effect of power. That sort of boring but essential ab initial stuff.

After 3:45 of a four hour session, as was our custom, I asked if he wanted to try anything. He said 'can I have a play'. Of course - she's all yours.

Took off, turned it upside down, inverted climb out and circuit perfectly, base leg and finals inverted before rolling wings level for landing. Yes on the real thing it would have flamed out and the sim. didn't know that! But the handling was he said what he expected. He then showed me a loop and barrel roll. They have been my 737 party piece ever since.

Not on the real plane of course because the passengers get upset.

Cheers

R Guy

https://news.aviation-safety.net/201...-trim-runaway/

OK ex military pilots!

Join Date: Aug 2006

Location: Looking for the signals square at LHR

Posts: 236

Likes: 0

Received 0 Likes

on

0 Posts

Dunno though, I have enough fun landing a Pitts on its main gear, but at least it isn't the most entertaining single seat bipe to alight on terra firma. A glide approach from the 180 is so much fun in a Pitts, even right side up. Add a 180 roll at 20' and the fun quotient may exceed my bowel watertightness.

just sayin'

just sayin'

Apologies for resurrecting an old thread but I saw a YouTube video of this incident and the errors from design, regulator, pilots and maintenance are quite staggering.

How can it be OK to allow it to be possible to fit the trim switches upside down? Where was the function test after refitting it? Secondary inspection after disturbing flt control systems?

Unbelievable!

Then the pilot flying uses a system that was declared inoperable minutes before?

How can it be OK to allow it to be possible to fit the trim switches upside down? Where was the function test after refitting it? Secondary inspection after disturbing flt control systems?

Unbelievable!

Then the pilot flying uses a system that was declared inoperable minutes before?

How can it be OK to allow it to be possible to fit the trim switches upside down? Where was the function test after refitting it? Secondary inspection after disturbing flt control systems?

Unbelievable!

Then the pilot flying uses a system that was declared inoperable minutes before?

Unbelievable!

Then the pilot flying uses a system that was declared inoperable minutes before?

https://data.ntsb.gov/carol-repgen/a...ort/100540/pdf

Originally Posted by Hovis

Unbelievable!

Then the pilot flying uses a system that was declared inoperable minutes before?

Then the pilot flying uses a system that was declared inoperable minutes before?

Believe me I'm not pointing solely at the Captain here, its a mess from the beginning. I'm particularly disappointed that a function check and duplicate inspection wasn't performed by maintenance after disturbing the switch. Would it be unusual for a Captain to deligate the FO to fly the sector due to the fault on his trim switch?

Have a read of the NTSB Final report. It has many of the answers you seek.

https://data.ntsb.gov/carol-repgen/a...ort/100540/pdf

https://data.ntsb.gov/carol-repgen/a...ort/100540/pdf