737NGs have cracked 'pickle forks' after finding several in the jets.

Join Date: Sep 2019

Location: USA

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

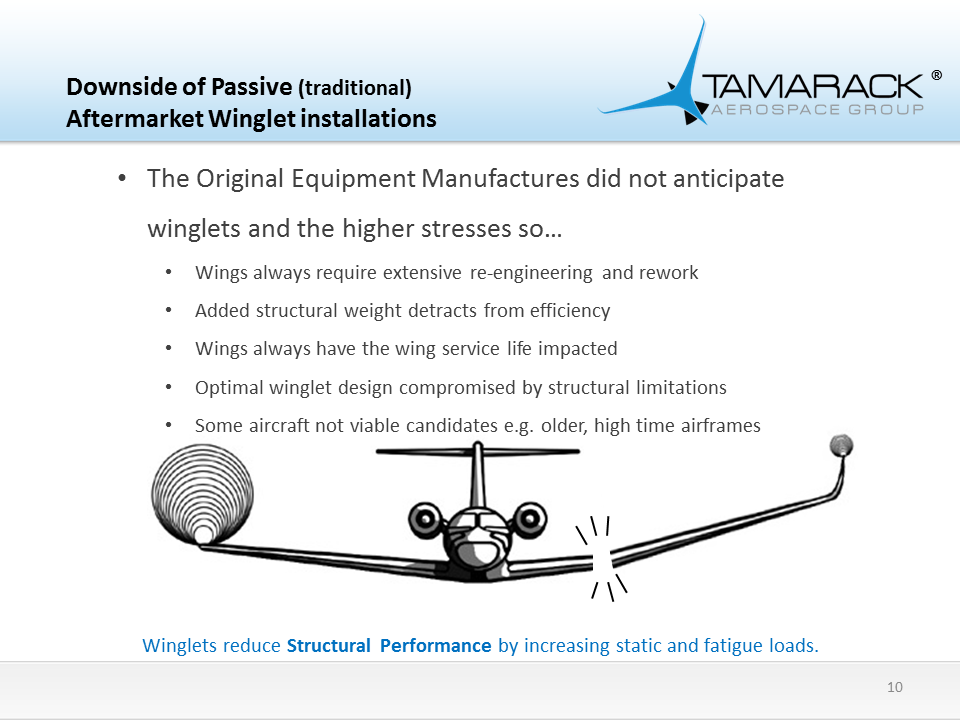

"The airframe was not designed to handle the load from the winglets...the winglets came later..."

The outer wing was modified with different structure parts before the winglets were installed on the post factory retro-fit NG aircraft.

"For example, a BBJ retrofit, accomplished according to an FAA supplemental-type certificate, involves the following tasks. (This listing does not constitute a complete work instruction package.)"

http://www.boeing.com/commercial/aer...let_story.html

The outer wing was modified with different structure parts before the winglets were installed on the post factory retro-fit NG aircraft.

"For example, a BBJ retrofit, accomplished according to an FAA supplemental-type certificate, involves the following tasks. (This listing does not constitute a complete work instruction package.)"

- Removal and replacement of the outboard upper and lower skin panels .

- Removal and replacement of rib 25, which is third from the outermost rib ).

- Installation of stiffeners across rib 25.

- Cutting of the closure rib (rib 27) and trimming of the two spars

- Installation of the new center section of rib 27 and the new winglet attach fitting

- Installation of the spar attach fittings .

- Installation of the aft-position light.

- Installation of the winglet ."

http://www.boeing.com/commercial/aer...let_story.html

Last edited by B727223Fan; 13th Oct 2019 at 04:04. Reason: More Info

Join Date: Jan 2008

Location: Herts, UK

Posts: 748

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: Feb 2019

Location: shiny side up

Posts: 431

Likes: 0

Received 0 Likes

on

0 Posts

"The airframe was not designed to handle the load from the winglets...the winglets came later..."

The outer wing was modified with different structure parts before the winglets were installed on the post factory retro-fit NG aircraft.

The outer wing was modified with different structure parts before the winglets were installed on the post factory retro-fit NG aircraft.

The rest of the wing and the pickle fork connector between the winbox and fuselage remained unchanged.

The AD applies to all N-registered 737NGs. It doesn't differentiate between passenger and cargo aircraft.

Join Date: Aug 2000

Posts: 1,499

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: Dec 2015

Location: Cape Town, ZA

Age: 62

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: Sep 2019

Location: USA

Posts: 3

Likes: 0

Received 0 Likes

on

0 Posts

The production models had even more structure modifications.

"However, during production, structural strengthening is accomplished by increasing the GAGE of spars, stringers, ribs, and panels.".

"For airplanes in production, the wings are strengthened Throughout the wingbox to accommodate the winglet loads with full use of the speed brakes to the in-flight detent position. The in-production modification meets the same design criteria as those for the retrofit. However, during production, structural strengthening is accomplished by increasing the gage of spars, stringers, ribs, and panels. Rib 27 incorporates bolt hole patterns that allow attachment of either a winglet or a standard wingtip. The winglet is installed in final assembly."

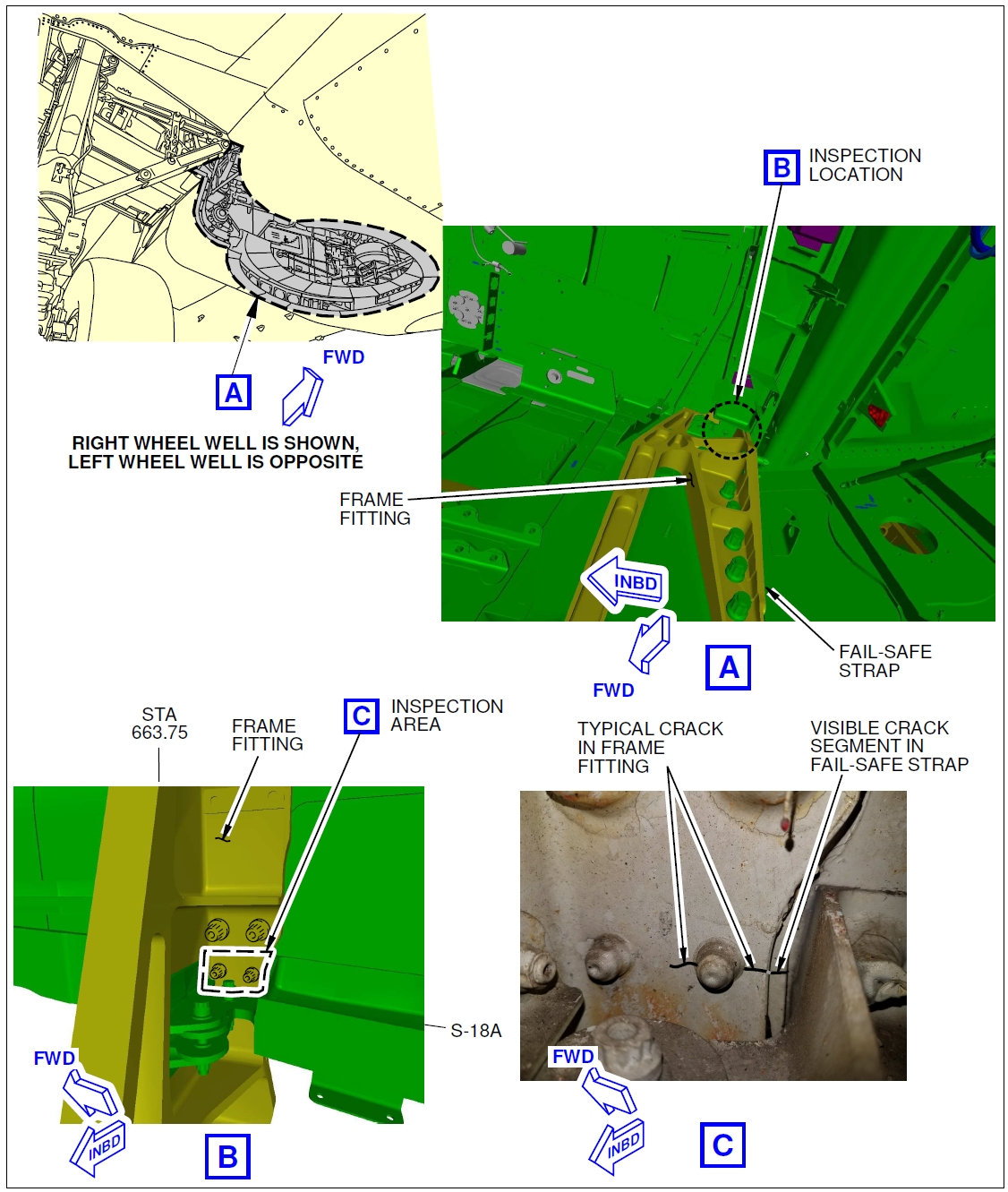

I don't think anyone here has suggested that changes were actually made to the fail safe strap / pickle fork at the wing center section on the winglet models..

In fact my posted link states that inboard wing changes were minimal or unnecessary. Maybe Boeing should re-think this position.

It is apparent that the early Generation NG aircraft were designed / produced / sold without winglets in mind.

"Structural changes.

After completing the studies of the toe angle and speed-brake angle, structural material for the mid- to outboard wingbox was still required. (Because the inboard wing had sufficient strength margins, structural changes to that area were minimal or unnecessary.) To minimize the adverse effects of the wing structural modifications on flutter, wing torsional stiffness was maximized in relation to bending stiffness."

After reading the link info [#221] it appears to me that Boeing strengthened the mid and outer wing but did not make any structure modifications to the inner wing or wing center section.

[made the outer wing stronger which had the effect of transmitting more wing loading into the wing center section that was not modified]

"However, during production, structural strengthening is accomplished by increasing the GAGE of spars, stringers, ribs, and panels.".

"For airplanes in production, the wings are strengthened Throughout the wingbox to accommodate the winglet loads with full use of the speed brakes to the in-flight detent position. The in-production modification meets the same design criteria as those for the retrofit. However, during production, structural strengthening is accomplished by increasing the gage of spars, stringers, ribs, and panels. Rib 27 incorporates bolt hole patterns that allow attachment of either a winglet or a standard wingtip. The winglet is installed in final assembly."

I don't think anyone here has suggested that changes were actually made to the fail safe strap / pickle fork at the wing center section on the winglet models..

In fact my posted link states that inboard wing changes were minimal or unnecessary. Maybe Boeing should re-think this position.

It is apparent that the early Generation NG aircraft were designed / produced / sold without winglets in mind.

"Structural changes.

After completing the studies of the toe angle and speed-brake angle, structural material for the mid- to outboard wingbox was still required. (Because the inboard wing had sufficient strength margins, structural changes to that area were minimal or unnecessary.) To minimize the adverse effects of the wing structural modifications on flutter, wing torsional stiffness was maximized in relation to bending stiffness."

After reading the link info [#221] it appears to me that Boeing strengthened the mid and outer wing but did not make any structure modifications to the inner wing or wing center section.

[made the outer wing stronger which had the effect of transmitting more wing loading into the wing center section that was not modified]

Last edited by B727223Fan; 13th Oct 2019 at 14:09. Reason: more info

After reading the link info [#221] it appears to me that Boeing strengthened the mid and outer wing but did not make any structure modifications to the inner wing or wing center section.

[made the outer wing stronger which had the effect of transmitting more wing loading into the wing center section that was not modified]

[made the outer wing stronger which had the effect of transmitting more wing loading into the wing center section that was not modified]

Join Date: Sep 2019

Location: leftcoast

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

I may be stupid, but I don't see how the wing load is greater with the winglet. The load is aircraft weight and g loading; that hasn't changed. I can see stiffening the wing tip as the winglet is increasing the local loading, but the final load carried by the wing box is constant. The wing load profile will change, but not the total load.

Uhhh look at the wing- with and without a winglet. Compare to lever arm pivoted about one side of the wingbox. Without a winglet, assume a ( hypothetical for ease of calculation ) load of say 1000 lbs 20 feet from pivot poInt= 20000 foot lbs acting on pivot point at edge of wingbox

Now with a winglet, assume a load ( due to aerodynamics in both cases ) of say 1000 lbs at 22 feet from pivot poInt = 22000 foot lbs .

This is because in simplified terms, the winglet changes the aero load ( lift) distribution a bit further outboard, thus increasing the ' lever' arm.

I have deliberately not counted extra weight of winglet, or tried to model actual aero lift numbers, etc. Simplified numbers for illustration only- not an aero engineer, etc.

For a detailed description- go to Aeropartners site.

"For airplanes in production, the wings are strengthened throughout the wingbox to accommodate the winglet loads with full use of the speed brakes to the in-flight detent position. The in-production modification meets the same design criteria as those for the retrofit. However, during production, structural strengthening is accomplished by increasing the gage of spars, stringers, ribs, and panels. Rib 27 incorporates bolt hole patterns that allow attachment of either a winglet or a standard wingtip. The winglet is installed in final assembly."

http://www.boeing.com/commercial/aer...let_story.html

http://www.boeing.com/commercial/aer...let_story.html

I may be stupid, but I don't see how the wing load is greater with the winglet. The load is aircraft weight and g loading; that hasn't changed. I can see stiffening the wing tip as the winglet is increasing the local loading, but the final load carried by the wing box is constant. The wing load profile will change, but not the total load.

It's possible that the presence/absence of winglets alters the lift distribution along the wing, and if that moves the C of P then it may well be that the proportion of the wing load carried respectively by the front/rear pickle forks changes, even if the total load remains constant.

Join Date: Mar 2019

Location: French Alps

Posts: 326

Likes: 0

Received 0 Likes

on

0 Posts

So the bending and torsional moments will change.

This might help :

https://tamarackaero.com/insights/20...se-on-winglets

This might help :

https://tamarackaero.com/insights/20...se-on-winglets

Join Date: May 2011

Location: Hampshire

Age: 76

Posts: 821

Likes: 0

Received 0 Likes

on

0 Posts

Are these "pickle forks" or fishplates related to the items that were reportedly poorly manufactured years ago?

https://www.pprune.org/archive/index.php/t-239918.html

There is an Al Jazeera you tube video, produced in 2010 on this same topic. As far as I could gather, the US Dept of Justice stepped in and halted law suits etc relating to the issues raised by a couple of whistle blowers. In the video, reference is made to 3 737NG accidents which all had one thing in common: the fuselage in each case broke into 3 parts upon impact in pretty much the same location. I was a bit baffled by the terminology used in the documentary, they refer to "failsafe cords" (or chords?)

At around 11mins in to the film, you will see evidence from Boeing that one of the most common defects with the parts as supplied from the manufacturer was "hole mislocated".

(unrelated to the safety issue, I was baffled by the process here: The parts are manufactured in California, shipped by train to Wichita where they get joined up with other parts to become fuselage sections. Which are then shipped by train to Seattle, presumably going via California??)

https://www.pprune.org/archive/index.php/t-239918.html

There is an Al Jazeera you tube video, produced in 2010 on this same topic. As far as I could gather, the US Dept of Justice stepped in and halted law suits etc relating to the issues raised by a couple of whistle blowers. In the video, reference is made to 3 737NG accidents which all had one thing in common: the fuselage in each case broke into 3 parts upon impact in pretty much the same location. I was a bit baffled by the terminology used in the documentary, they refer to "failsafe cords" (or chords?)

(unrelated to the safety issue, I was baffled by the process here: The parts are manufactured in California, shipped by train to Wichita where they get joined up with other parts to become fuselage sections. Which are then shipped by train to Seattle, presumably going via California??)

Ah, thanks. I hadn't looked at the wing as a torque generator on the center structure, but it obviously is, and moving the load outboard would increase the torque because of the changed moment arm and, consequently, increase the load carried through the pickle fork(s). I hope I've got this right now!

Join Date: Sep 2019

Location: leftcoast

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

Are these "pickle forks" or fishplates related to the items that were reportedly poorly manufactured years ago?

https://www.pprune.org/archive/index.php/t-239918.html

There is an Al Jazeera you tube video, produced in 2010 on this same topic. As far as I could gather, the US Dept of Justice stepped in and halted law suits etc relating to the issues raised by a couple of whistle blowers. In the video, reference is made to 3 737NG accidents which all had one thing in common: the fuselage in each case broke into 3 parts upon impact in pretty much the same location. I was a bit baffled by the terminology used in the documentary, they refer to "failsafe cords" (or chords?)

https://www.youtube.com/watch?v=IaWdEtANi-0

At around 11mins in to the film, you will see evidence from Boeing that one of the most common defects with the parts as supplied from the manufacturer was "hole mislocated".

(unrelated to the safety issue, I was baffled by the process here: The parts are manufactured in California, shipped by train to Wichita where they get joined up with other parts to become fuselage sections. Which are then shipped by train to Seattle, presumably going via California??)

https://www.pprune.org/archive/index.php/t-239918.html

There is an Al Jazeera you tube video, produced in 2010 on this same topic. As far as I could gather, the US Dept of Justice stepped in and halted law suits etc relating to the issues raised by a couple of whistle blowers. In the video, reference is made to 3 737NG accidents which all had one thing in common: the fuselage in each case broke into 3 parts upon impact in pretty much the same location. I was a bit baffled by the terminology used in the documentary, they refer to "failsafe cords" (or chords?)

https://www.youtube.com/watch?v=IaWdEtANi-0

At around 11mins in to the film, you will see evidence from Boeing that one of the most common defects with the parts as supplied from the manufacturer was "hole mislocated".

(unrelated to the safety issue, I was baffled by the process here: The parts are manufactured in California, shipped by train to Wichita where they get joined up with other parts to become fuselage sections. Which are then shipped by train to Seattle, presumably going via California??)

Join Date: Sep 2019

Location: leftcoast

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

Ah, thanks. I hadn't looked at the wing as a torque generator on the center structure, but it obviously is, and moving the load outboard would increase the torque because of the changed moment arm and, consequently, increase the load carried through the pickle fork(s). I hope I've got this right now!

Join Date: Aug 2015

Location: UK

Posts: 0

Likes: 0

Received 0 Likes

on

0 Posts

If I understand correctly moving centres of lift outwards also moves them backwards requiring h stab to, on average, trim slightly more nose up than without, thereby slightly increasing any tensile loads that may be imposed on the rear forks?.

Join Date: Sep 2019

Location: leftcoast

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

That is way out of my wheelhouse- need both an aero and structural engine- ear

and a senior level birdman..

and a senior level birdman..

Join Date: Mar 2019

Location: Vantaa, Finland

Posts: 0

Likes: 0

Received 0 Likes

on

0 Posts

Moving lift towards the tips increases AND wings with normal airfoil sections have AND tendency anyway. To counter AND moment one needs a downward force from horizontal tail. As far as I can see this all adds up to a compressive load on the fork.