MAX’s Return Delayed by FAA Reevaluation of 737 Safety Procedures

The latest view from Boeing, 14 June, https://aviationweek.com/paris-airsh...9913b830825021

“I can’t give you a specific timeline.“

“I can’t give you a specific timeline.“

Hinged was the wrong word. The axis of rotation I suppose. Right now the H-Stabilizer rotates as though it is hinged well towards the rear. This means it is unstable in the case of failure, though I don't think this has happened but this instability means the load on the jackscrew is almost always there in one direction or another.

Join Date: Sep 2011

Location: Northern Territory Australia

Posts: 105

Likes: 0

Received 0 Likes

on

0 Posts

"Neither Boeing or FAA might be able to achieve the ideal solution, but what would the compromise be; money - politics vs sacrificing regulatory management."

Safety is our no.1 concern.

Whose safety? The integrity of the Boeing Product? The integrity of the regulatory bodies? Its sad that the rush to get the plane out initially seems to have overridden the No.1 concern It's tragic that so many lives have been lost as a result in order to do what should have been done in the first place.

So... when I hear "Safety is ....." from anyone I treat it with a bit of cynicism

Safety is our no.1 concern.

Whose safety? The integrity of the Boeing Product? The integrity of the regulatory bodies? Its sad that the rush to get the plane out initially seems to have overridden the No.1 concern It's tragic that so many lives have been lost as a result in order to do what should have been done in the first place.

So... when I hear "Safety is ....." from anyone I treat it with a bit of cynicism

Join Date: Jan 2014

Location: Norfolk

Posts: 428

Likes: 0

Received 0 Likes

on

0 Posts

"Neither Boeing or FAA might be able to achieve the ideal solution, but what would the compromise be; money - politics vs sacrificing regulatory management."

Safety is our no.1 concern.

Whose safety? The integrity of the Boeing Product? The integrity of the regulatory bodies? Its sad that the rush to get the plane out initially seems to have overridden the No.1 concern It's tragic that so many lives have been lost as a result in order to do what should have been done in the first place.

So... when I hear "Safety is ....." from anyone I treat it with a bit of cynicism

Safety is our no.1 concern.

Whose safety? The integrity of the Boeing Product? The integrity of the regulatory bodies? Its sad that the rush to get the plane out initially seems to have overridden the No.1 concern It's tragic that so many lives have been lost as a result in order to do what should have been done in the first place.

So... when I hear "Safety is ....." from anyone I treat it with a bit of cynicism

Join Date: Jun 2008

Location: Cambridge UK

Posts: 192

Likes: 0

Received 0 Likes

on

0 Posts

Last edited by Peter H; 16th Jun 2019 at 11:34. Reason: Previous link not working.

Join Date: Feb 2013

Location: Gloucestershire, UK

Posts: 34

Likes: 0

Received 0 Likes

on

0 Posts

Perhaps the FAA will no longer accept Boeing's contention that this aircraft is 'just a 737'. Could it be that the FAA has told Boeing to certify the MAX as a new type? Boeing would resist that obviously because of the cost of the certification and the re-training costs its customers would face.

I agree that the SEC should be watching this carefully but after Madoff I wouldn't trust them to watch a kettle boil.

Last edited by Turb; 15th Jun 2019 at 15:05. Reason: cold feet

Article

Here's my speculative candidates for 'deep, unacceptable issues'.

Perhaps the FAA will no longer accept Boeing's contention that this aircraft is 'just a 737'. Could it be that the FAA has told Boeing to certify the MAX as a new type? Boeing would resist that obviously because of the cost of the certification and the re-training costs its customers would face.

But an even worse issue would be if the airframe with those big engines attached is aerodynamically unstable and is therefore incapable of being certified.That sounds outrageous until you think about what we actually know about this thing - see this for example (if you haven't already done so): https://spectrum.ieee.org/aerospace/...ware-developer

I agree that the SEC should be watching this carefully but after Madoff I wouldn't trust them to watch a kettle boil.

Perhaps the FAA will no longer accept Boeing's contention that this aircraft is 'just a 737'. Could it be that the FAA has told Boeing to certify the MAX as a new type? Boeing would resist that obviously because of the cost of the certification and the re-training costs its customers would face.

But an even worse issue would be if the airframe with those big engines attached is aerodynamically unstable and is therefore incapable of being certified.That sounds outrageous until you think about what we actually know about this thing - see this for example (if you haven't already done so): https://spectrum.ieee.org/aerospace/...ware-developer

I agree that the SEC should be watching this carefully but after Madoff I wouldn't trust them to watch a kettle boil.

Join Date: Jul 2007

Location: the City by the Bay

Posts: 547

Likes: 0

Received 0 Likes

on

0 Posts

Here's my speculative candidates for 'deep, unacceptable issues'.

Perhaps the FAA will no longer accept Boeing's contention that this aircraft is 'just a 737'. Could it be that the FAA has told Boeing to certify the MAX as a new type? Boeing would resist that obviously because of the cost of the certification and the re-training costs its customers would face.

But an even worse issue would be if the airframe with those big engines attached is aerodynamically unstable and is therefore incapable of being certified.That sounds outrageous until you think about what we actually know about this thing - see this for example (if you haven't already done so): https://spectrum.ieee.org/aerospace/...ware-developer

I agree that the SEC should be watching this carefully but after Madoff I wouldn't trust them to watch a kettle boil.

Perhaps the FAA will no longer accept Boeing's contention that this aircraft is 'just a 737'. Could it be that the FAA has told Boeing to certify the MAX as a new type? Boeing would resist that obviously because of the cost of the certification and the re-training costs its customers would face.

But an even worse issue would be if the airframe with those big engines attached is aerodynamically unstable and is therefore incapable of being certified.That sounds outrageous until you think about what we actually know about this thing - see this for example (if you haven't already done so): https://spectrum.ieee.org/aerospace/...ware-developer

I agree that the SEC should be watching this carefully but after Madoff I wouldn't trust them to watch a kettle boil.

https://www.bloomberg.com/news/artic...ever-fly-again

Not unexpectedly, Ralph Nader is calling for the Max to NEVER fly again. And he may be right if the plane is inherently unstable. If they can't fix it they should junk it.

https://www.bloomberg.com/news/artic...ever-fly-again

Not unexpectedly, Ralph Nader is calling for the Max to NEVER fly again. And he may be right if the plane is inherently unstable. If they can't fix it they should junk it.

Not unexpectedly, Ralph Nader is calling for the Max to NEVER fly again. And he may be right if the plane is inherently unstable. If they can't fix it they should junk it.

Salute!

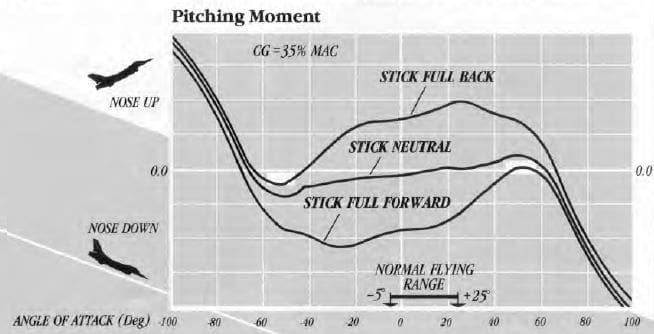

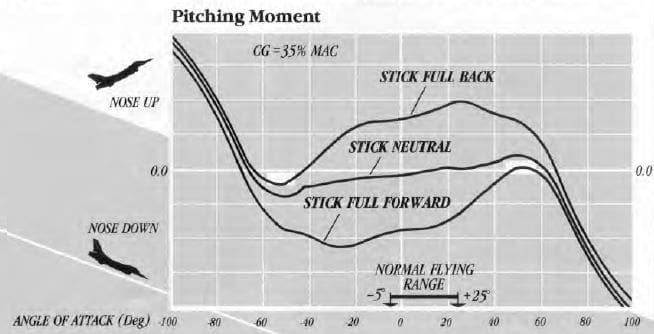

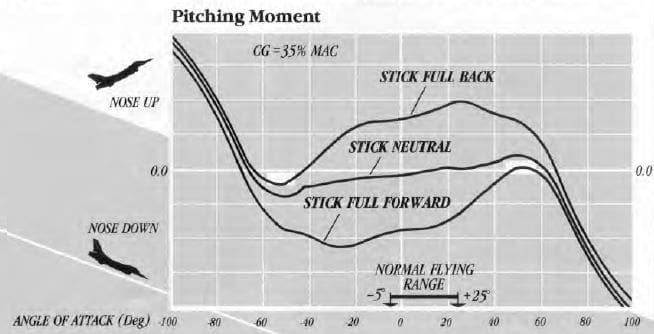

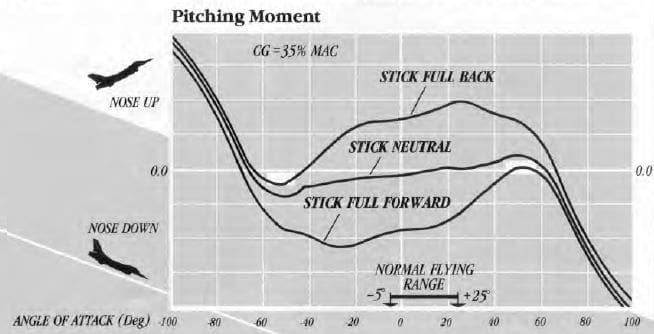

I can't help but think that someone in FAA or elsewhere ( maybe even Boeing itself) is concerned about the basic aero characteristic of the MAX that even required the MCAS. In short, the plane has a pitch moment versus AoA curve that is scary. i.e. the thing wants to increase AoA with less "control force" or control surface movement or...... at high AOA. Since Orville and I soloed back in North Carolina, what we expected was to pull back harder the higher the AoA. 'course, we were directly warping the wings and moving the canard with a lever. But if we let go of the stick or neutralized it, the nose of the flyer went down all by itself.

So I dare to show a plot from a well-known plane that illustrates an undesireable pitch moment as AoA increases. The stick neutral is a one gee command. You could get this plot by slowing down using the throttle and keeping your hand off the stick when you had trimmed for one gee ( default, BTW). The all-moving stab is progessively moving to mainain the gee, not the AoA. Somewhere about 15 degrees AoA the plane pitch moment becomes neutral, and then a degree or two higher the plane wants to raise the nose all by itself. Eeeewwwww, not good. And up there around 45 degrees you enter the falling leaf profile;

I suspect that Boeing, et al are concerned that simply using the existing stab trim mechanism to compensate for an inherent problem with the pitch moment is the "fly in the ointment".

Use of a single AoA sensor and cutting off manual electric trim to stop MCAS is a whole other thread.

Gums sends..

I can't help but think that someone in FAA or elsewhere ( maybe even Boeing itself) is concerned about the basic aero characteristic of the MAX that even required the MCAS. In short, the plane has a pitch moment versus AoA curve that is scary. i.e. the thing wants to increase AoA with less "control force" or control surface movement or...... at high AOA. Since Orville and I soloed back in North Carolina, what we expected was to pull back harder the higher the AoA. 'course, we were directly warping the wings and moving the canard with a lever. But if we let go of the stick or neutralized it, the nose of the flyer went down all by itself.

So I dare to show a plot from a well-known plane that illustrates an undesireable pitch moment as AoA increases. The stick neutral is a one gee command. You could get this plot by slowing down using the throttle and keeping your hand off the stick when you had trimmed for one gee ( default, BTW). The all-moving stab is progessively moving to mainain the gee, not the AoA. Somewhere about 15 degrees AoA the plane pitch moment becomes neutral, and then a degree or two higher the plane wants to raise the nose all by itself. Eeeewwwww, not good. And up there around 45 degrees you enter the falling leaf profile;

I suspect that Boeing, et al are concerned that simply using the existing stab trim mechanism to compensate for an inherent problem with the pitch moment is the "fly in the ointment".

Use of a single AoA sensor and cutting off manual electric trim to stop MCAS is a whole other thread.

Gums sends..

Join Date: Dec 2011

Location: Ottawa, Canada

Posts: 28

Likes: 0

Received 0 Likes

on

0 Posts

Salute!

I can't help but think that someone in FAA or elsewhere ( maybe even Boeing itself) is concerned about the basic aero characteristic of the MAX that even required the MCAS. In short, the plane has a pitch moment versus AoA curve that is scary. i.e. the thing wants to increase AoA with less "control force" or control surface movement or...... at high AOA. Since Orville and I soloed back in North Carolina, what we expected was to pull back harder the higher the AoA. 'course, we were directly warping the wings and moving the canard with a lever. But if we let go of the stick or neutralized it, the nose of the flyer went down all by itself.

So I dare to show a plot from a well-known plane that illustrates an undesireable pitch moment as AoA increases. The stick neutral is a one gee command. You could get this plot by slowing down using the throttle and keeping your hand off the stick when you had trimmed for one gee ( default, BTW). The all-moving stab is progessively moving to mainain the gee, not the AoA. Somewhere about 15 degrees AoA the plane pitch moment becomes neutral, and then a degree or two higher the plane wants to raise the nose all by itself. Eeeewwwww, not good. And up there around 45 degrees you enter the falling leaf profile;

I suspect that Boeing, et al are concerned that simply using the existing stab trim mechanism to compensate for an inherent problem with the pitch moment is the "fly in the ointment".

Use of a single AoA sensor and cutting off manual electric trim to stop MCAS is a whole other thread.

Gums sends..

I can't help but think that someone in FAA or elsewhere ( maybe even Boeing itself) is concerned about the basic aero characteristic of the MAX that even required the MCAS. In short, the plane has a pitch moment versus AoA curve that is scary. i.e. the thing wants to increase AoA with less "control force" or control surface movement or...... at high AOA. Since Orville and I soloed back in North Carolina, what we expected was to pull back harder the higher the AoA. 'course, we were directly warping the wings and moving the canard with a lever. But if we let go of the stick or neutralized it, the nose of the flyer went down all by itself.

So I dare to show a plot from a well-known plane that illustrates an undesireable pitch moment as AoA increases. The stick neutral is a one gee command. You could get this plot by slowing down using the throttle and keeping your hand off the stick when you had trimmed for one gee ( default, BTW). The all-moving stab is progessively moving to mainain the gee, not the AoA. Somewhere about 15 degrees AoA the plane pitch moment becomes neutral, and then a degree or two higher the plane wants to raise the nose all by itself. Eeeewwwww, not good. And up there around 45 degrees you enter the falling leaf profile;

I suspect that Boeing, et al are concerned that simply using the existing stab trim mechanism to compensate for an inherent problem with the pitch moment is the "fly in the ointment".

Use of a single AoA sensor and cutting off manual electric trim to stop MCAS is a whole other thread.

Gums sends..

Boeing made major changes to the B747 when they upgraded from the 100/200/300 series into the 400 series. Going from a 3 man to a 2 man crew with a full glass cockpit and EICAS was needed and enabled a 20 year old type to continue on for another 30 years. A major revision along these lines could/should have been done in the late 1980s to carry the B737 through to today.

Now Boeing would be looking at major upgrades to a 50 year old type with a 60 year old fuselage. Given the cost of bringing it up to modern standards and limited life remaining as it falls further behind more recent designs, would it be worth it ?

The A320 could do with a more modern flight deck, and if given one, could easily go another 20 years. The Comac C919 is a brand new design which will obviously be developed and improved over time.

Most of us have been in this situation with an old car, keep throwing money into it or bite the bullet and buy a new one.

Now Boeing would be looking at major upgrades to a 50 year old type with a 60 year old fuselage. Given the cost of bringing it up to modern standards and limited life remaining as it falls further behind more recent designs, would it be worth it ?

The A320 could do with a more modern flight deck, and if given one, could easily go another 20 years. The Comac C919 is a brand new design which will obviously be developed and improved over time.

Most of us have been in this situation with an old car, keep throwing money into it or bite the bullet and buy a new one.

Last edited by krismiler; 16th Jun 2019 at 07:25.

Psychophysiological entity

Today's posts have left me with a feeling of deep unease. I don't want Boeing to be brought to its knees, though I imagine there are more than a few people sharpening their swards. The whole slew of issues is desperately saddening, but with a lifetime's passionate interest in flying, electronics and mechanical systems, I don't see how the MAX will ever be anything but a compromise - at least with existing hints of corrective plans.

I suggest, without qualification, that MCAS should not have direct control of the Horizontal Stabilizer, but by definition, it has to augment control, so my very suggestion implies it has to be scrapped altogether. How one would stop the engine cowlings from flying - without dragging back a lot of the new performance, is something I don't have an answer to.

If STS is allowed to stay, then it seems logical that MCAS could be made to input safely. At the very least I'd want this previously hidden system to leave me in no doubt it had started to run, and if I pressed the warning, it would not run again until it was reset manually. Sim training for this is an obvious must.

An AoA vane comparator would be high on my list of demands. Having the logic to determine the failed side with a high probability seems doable. Even if it fails to do this, at least the crew would be alerted to make their own decision on the side to use. Not a terribly complex memory item but also not a quick iPad note.

The ground clearance issue might be corrected by a dash 10 type gear extension but I am certainly not suggesting the engines should be returned from whence they came! Someone replied to one of my posts that the wheels were displaced (rearward?) but the Y-Tube seems to show clearly the half scale model extending the (real scale) length/height by 10". It's a mechanism that has to be incredibly robust, the one in the model, a 3D print, left me a tad concerned about it coping with a thumper or two. The answer has to be some kind of leg mechanism since a bay redesign is beyond financial reach. As it is, the aircraft just looks wrong, and I have a gut feeling doing nothing is not an option.

Back to that stabilizer.

Dave's re-reply.

As I said, I have no idea why it was ever 'hinged' at the rear. No one in their right mind would do that just to make the mechanism easier to design . . . would they? IIRC, when we gave the Americans the original idea it lead to a stability that allowed supersonic flight. What happened next? Well, it seemed to be doing a great job - until one reads about the fact that when it comes to hand flying, it hasn't actually been put to the test as much as one would have imagined. Also, now and then, it's handed out some surprises which just seem to have been lost in the mists of time - unless you were involved, and then I'd imagine the memories would be rather vivid.

All of us on this forum are aware of the loading issues and desperate attempts at off-loading to crank in some ANU trim, but it seems to me that it would be a far smoother, less demanding system, if it were 'hinged' at least near the front of that vast surface. Dave's quote, little scope, sums it up perfectly, I might as well suggest moving the wings forward a bit, but an aircraft with a trailing stab would address so many issues, so there has to be a reason it's never been done.

Just supposing the powers that be deem the inability to manually trim a prime design flaw - a scenario that must be in the nightmares of more than a few senior Boeing staff. If that became reality, there is just the possibility that the airframes could be saved from total loss with hydraulic power, the designs taken from other types. The incredible irony is that the total power required to move that stab is not very great but it is just the means of conveying that power to the tail in an emergency that makes it likely to fail the crews - because of the very method retained from the old, safe, steel cable, days.

When we consider the counterintuitive design issues, there are only a few but they do sum up to being very costly if the job is to be done well. It's vital for the future of Boeing to address these problems with utterly solid remedies; a software rewrite won't come close. The whole world will be watching and I don't envy the folk under that gaze one little bit.

.

.

.

I suggest, without qualification, that MCAS should not have direct control of the Horizontal Stabilizer, but by definition, it has to augment control, so my very suggestion implies it has to be scrapped altogether. How one would stop the engine cowlings from flying - without dragging back a lot of the new performance, is something I don't have an answer to.

If STS is allowed to stay, then it seems logical that MCAS could be made to input safely. At the very least I'd want this previously hidden system to leave me in no doubt it had started to run, and if I pressed the warning, it would not run again until it was reset manually. Sim training for this is an obvious must.

An AoA vane comparator would be high on my list of demands. Having the logic to determine the failed side with a high probability seems doable. Even if it fails to do this, at least the crew would be alerted to make their own decision on the side to use. Not a terribly complex memory item but also not a quick iPad note.

The ground clearance issue might be corrected by a dash 10 type gear extension but I am certainly not suggesting the engines should be returned from whence they came! Someone replied to one of my posts that the wheels were displaced (rearward?) but the Y-Tube seems to show clearly the half scale model extending the (real scale) length/height by 10". It's a mechanism that has to be incredibly robust, the one in the model, a 3D print, left me a tad concerned about it coping with a thumper or two. The answer has to be some kind of leg mechanism since a bay redesign is beyond financial reach. As it is, the aircraft just looks wrong, and I have a gut feeling doing nothing is not an option.

Back to that stabilizer.

Dave's re-reply.

I'd be very surprised if there is/was much scope for redesigning the stab pivot and/or the jackscrew geometry in a way that would significantly reduce the aerodynamic loads on the jackscrew (and therefore on the trim wheel).

All of us on this forum are aware of the loading issues and desperate attempts at off-loading to crank in some ANU trim, but it seems to me that it would be a far smoother, less demanding system, if it were 'hinged' at least near the front of that vast surface. Dave's quote, little scope, sums it up perfectly, I might as well suggest moving the wings forward a bit, but an aircraft with a trailing stab would address so many issues, so there has to be a reason it's never been done.

Just supposing the powers that be deem the inability to manually trim a prime design flaw - a scenario that must be in the nightmares of more than a few senior Boeing staff. If that became reality, there is just the possibility that the airframes could be saved from total loss with hydraulic power, the designs taken from other types. The incredible irony is that the total power required to move that stab is not very great but it is just the means of conveying that power to the tail in an emergency that makes it likely to fail the crews - because of the very method retained from the old, safe, steel cable, days.

When we consider the counterintuitive design issues, there are only a few but they do sum up to being very costly if the job is to be done well. It's vital for the future of Boeing to address these problems with utterly solid remedies; a software rewrite won't come close. The whole world will be watching and I don't envy the folk under that gaze one little bit.

.

.

.

Last edited by Loose rivets; 16th Jun 2019 at 00:33.

Join Date: Feb 2019

Location: shiny side up

Posts: 431

Likes: 0

Received 0 Likes

on

0 Posts

Aside from the NMA program (new midsize aircraft), Boeing has the FSA program (future small aircraft)

The FSA is the replacement aircraft for the MAX.....it was not slated to come on line to replace the MAX until 2030!!!!

NOT forward thinking.

There has been some talk that Boeing will abandon the NMA for now, and move the FSA program forward.

The FSA is the replacement aircraft for the MAX.....it was not slated to come on line to replace the MAX until 2030!!!!

NOT forward thinking.

There has been some talk that Boeing will abandon the NMA for now, and move the FSA program forward.

Join Date: May 2010

Location: Boston

Age: 73

Posts: 443

Likes: 0

Received 0 Likes

on

0 Posts

Two relatively modest changes would go a long way to reducing the risk associated with manual (cable/wheel) trim.

1: Change the MAX cutout switches functions back to NG and prior to restore the option to disable -all- automatic trim inputs while allowing pilot thumb switch electric trim.

This of course would require training since they have been treated/trained as one for quite a while it seems.

2: Make the foldout handle much longer, the full diameter of the the wheel or more, greatly increasing the available torque.

I saw some suggestions along this line many many posts back.

This could be done using a ratcheting mechanism that only engaged with pilot input, otherwise it could be free wheeling. Ratchet is needed due to clearance to front.

I am sure Boeing has much better mechanical engineers than I am, (especially since I am in electronics) to work out the details.

1: Change the MAX cutout switches functions back to NG and prior to restore the option to disable -all- automatic trim inputs while allowing pilot thumb switch electric trim.

This of course would require training since they have been treated/trained as one for quite a while it seems.

2: Make the foldout handle much longer, the full diameter of the the wheel or more, greatly increasing the available torque.

I saw some suggestions along this line many many posts back.

This could be done using a ratcheting mechanism that only engaged with pilot input, otherwise it could be free wheeling. Ratchet is needed due to clearance to front.

I am sure Boeing has much better mechanical engineers than I am, (especially since I am in electronics) to work out the details.

It would be interesting to know just how much of the envelope requires MCAS type input, given that it has been said the MCAS is only required to address shortcomings at light weight and CoG at the aft limit.

Join Date: Mar 2019

Location: French Alps

Posts: 326

Likes: 0

Received 0 Likes

on

0 Posts

2: Make the foldout handle much longer, the full diameter of the the wheel or more, greatly increasing the available torque.

I saw some suggestions along this line many many posts back.

This could be done using a ratcheting mechanism that only engaged with pilot input, otherwise it could be free wheeling. Ratchet is needed due to clearance to front.

I am sure Boeing has much better mechanical engineers than I am, (especially since I am in electronics) to work out the details.

The technology, power drive and software are quite mature and inexpensive.

Psychophysiological entity

I doubt you could put anything to equal the straining arms of a frightened pilot - which seemingly fail to do the job. Those wheels were springing back on the cable tension.

No, the power has to go in the other end. Just one small motor (via clutches) is capable of driving the jackscrew. If I was filling a bin with sketches of ideas, one of them would be a second electric motor capable of at least assisting the hand cranking.

On the 1-11 I spent years with a larger wheel between finger and thumb manually trimming the T tail while hardly moving the pole. It was utterly perfect in its follower motor smoothness. - that's if you allow for the 3 degree hysteresis to give the mach trimmer some breathing space.

No, the power has to go in the other end. Just one small motor (via clutches) is capable of driving the jackscrew. If I was filling a bin with sketches of ideas, one of them would be a second electric motor capable of at least assisting the hand cranking.

On the 1-11 I spent years with a larger wheel between finger and thumb manually trimming the T tail while hardly moving the pole. It was utterly perfect in its follower motor smoothness. - that's if you allow for the 3 degree hysteresis to give the mach trimmer some breathing space.

Join Date: Mar 2019

Location: French Alps

Posts: 326

Likes: 0

Received 0 Likes

on

0 Posts

It seems the MAX has serious issues flying slow near the stall and fast with a high AoA - but fly's fine in the simulator after a short iPad differences course. The regulator will all know of the possible problems gossiped on Pprune and other places, my guess is a number of them will not take Boeing or the FAA's word on these ares of concern and require extensive flight testing to be carried out possibly with average crew. The aircraft will need to demonstrate that it is very flyable when MCAS gets deactivated intentionally or not.