Ethiopian airliner down in Africa

Join Date: Dec 2015

Location: Cape Town, ZA

Age: 62

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

Cows getting bigger

If you change the scale in the matrix from linear to exponential, and divide by a standard of 1 in 10^9 flight hours, that might be a starting approximation. The introduction of MCAS seems to have produced an additional risk of the order of 10^2, or 100 times what might be expected from a new and untested system. The mitigating factors noted in the emergency AD may have been assumed to reduce the risk by a factor of 10^4, but probably did not by a factor 10^2, under real world conditions and with actual pilots.

Some safety management thoughts. Below is a very basic and generic risk management matrix, something many of us will be familiar with and probably far more basic that the management system Boeing use.

Introduction of MCAS without additional mitigations increased the overall risk associated with an unsatisfactory trim runaway event. Boeing should have number crunched this one and it would be very interesting to see the numbers.

Join Date: Apr 2005

Location: Australia

Posts: 1,414

Likes: 0

Received 0 Likes

on

0 Posts

Apologies if a similar posting has already been made among the over 4000 posts on the subject. Extract from the Boeing 737-200 Pilot Training Manual February 1982 page 04.80.31. Edited for brevity. Runaway and Manual Stabiliser - Recovery from Severe Out-of-Trim:

. "In an extreme nose-up out-of-trim condition, requiring almost full forward control column, decelerate, extend the flaps and/or reduce thrust to a minimum practical setting consistent with flight conditions until elevator control is established. Do not decrease airspeed below the minimum maneuvering speed for the flap configuration. A bank of 30 degrees or more will relieve some force on the control column

. This, combined with flap extension and reduced speed should permit easier manual trimming.If other methods fail to relieve the elevator load and control column force, use the "roller coaster" technique. If nose-up trim is required, raise the nose well above the horizon with elevator control. Then slowly relax the control column pressure and manually trim nose-up. Allow the nose to drop below the horizon while trimming. Repeat this sequence until the airplane is trim.

If nose-down trim is required, slowing down and extending the flaps will account for a large degree of nose-up pitch. If this does not allow manual trimming then the reverse "roller coaster" can be performed to permit manual trimming."

Boeing "Airliner" magazine published in May 1961 discussed the above subject as it applied to the Boeing 707 by stating: "To trim the stabilizer manually while holding a high stick force on control column. As the airplane changes altitude, crank in the desired trim change. Correct airplane attitude after a few seconds with elevators. Relax stick force again and crank in more trim. Repeat this procedure as necessary until proper 'trim' position of stabilizer is established."

We learned all about these maneuvers in the 1950-60s. Yet, for some inexplicable reason, Boeing manuals have since deleted what was then - and still is - vital handling information for flight crews. Finally, author D.P.Davies comprehensively covers the subject of large trim changes, failure cases and Mach number effect on stabilizers, at pages 38 to 42 in his fine book "Handling the Big Jets," A good case for current airline pilots to buy his book as it is still the best on the market,

IMHO, perhaps if the crews of the ill-fated Boeing 737-800MAX aircraft were familiar with this advice, current as far back as in 1982 and further back still to Boeing 707 types, they could have applied the roller coaster method to gain manual stabiliser control sooner; rather than be caught out by the stabiliser reaching full forward before attempting to trim manually.

. "In an extreme nose-up out-of-trim condition, requiring almost full forward control column, decelerate, extend the flaps and/or reduce thrust to a minimum practical setting consistent with flight conditions until elevator control is established. Do not decrease airspeed below the minimum maneuvering speed for the flap configuration. A bank of 30 degrees or more will relieve some force on the control column

. This, combined with flap extension and reduced speed should permit easier manual trimming.If other methods fail to relieve the elevator load and control column force, use the "roller coaster" technique. If nose-up trim is required, raise the nose well above the horizon with elevator control. Then slowly relax the control column pressure and manually trim nose-up. Allow the nose to drop below the horizon while trimming. Repeat this sequence until the airplane is trim.

If nose-down trim is required, slowing down and extending the flaps will account for a large degree of nose-up pitch. If this does not allow manual trimming then the reverse "roller coaster" can be performed to permit manual trimming."

Boeing "Airliner" magazine published in May 1961 discussed the above subject as it applied to the Boeing 707 by stating: "To trim the stabilizer manually while holding a high stick force on control column. As the airplane changes altitude, crank in the desired trim change. Correct airplane attitude after a few seconds with elevators. Relax stick force again and crank in more trim. Repeat this procedure as necessary until proper 'trim' position of stabilizer is established."

We learned all about these maneuvers in the 1950-60s. Yet, for some inexplicable reason, Boeing manuals have since deleted what was then - and still is - vital handling information for flight crews. Finally, author D.P.Davies comprehensively covers the subject of large trim changes, failure cases and Mach number effect on stabilizers, at pages 38 to 42 in his fine book "Handling the Big Jets," A good case for current airline pilots to buy his book as it is still the best on the market,

IMHO, perhaps if the crews of the ill-fated Boeing 737-800MAX aircraft were familiar with this advice, current as far back as in 1982 and further back still to Boeing 707 types, they could have applied the roller coaster method to gain manual stabiliser control sooner; rather than be caught out by the stabiliser reaching full forward before attempting to trim manually.

Last edited by A37575; 19th Apr 2019 at 12:54.

Join Date: Dec 2006

Location: Florida and wherever my laptop is

Posts: 1,350

Likes: 0

Received 0 Likes

on

0 Posts

Is that a obviously yes or a obviously no answer Capn Bloggs?

Keeping in mind, no other breed of the 737 would have put a nose down input to the stabiliser.

As a side, a run away stabiliser you would expect after a input was made and a stop of input expected, but did not happen. That is not what happened in these two cases as no nose down input should have happened (it was not an over run, but more like a 1958 red Plymouth Fury event)

Keeping in mind, no other breed of the 737 would have put a nose down input to the stabiliser.

As a side, a run away stabiliser you would expect after a input was made and a stop of input expected, but did not happen. That is not what happened in these two cases as no nose down input should have happened (it was not an over run, but more like a 1958 red Plymouth Fury event)

This highlights a problem in training which is almost certain with the limitations on time spent and a tick box approach. It would seem that there is a requirement for complex failures that do not fit in simple 'trigger an NNC' by rote responses, but which require some thought and it should be the analytical approach to some failures that is taught rather than only a limited set of [ -simple failure- -> by-rote-unthinking-response] exercises that require no understanding of what is being done.

Roller Coaster

Apologies if a similar posting has already been made among the over 4000 posts on the subject. Extract from the Boeing 737-200 Pilot Training Manual February 1982 page 04.80.31. Edited for brevity. Runaway and Manual Stabiliser - Recovery from Severe Out-of-Trim:

. "In an extreme nose-up out-of-trim condition, requiring almost full forward control column, decelerate, extend the flaps and/or reduce thrust to a minimum practical setting consistent with flight conditions until elevator control is established. Do not decrease airspeed below the minimum maneuvering speed for the flap configuration. A bank of 30 degrees or more will relieve some force on the control column

. This, combined with flap extension and reduced speed should permit easier manual trimming.If other methods fail to relieve the elevator load and control column force, use the "roller coaster" technique. If nose-up trim is required, raise the nose well above the horizon with elevator control. Then slowly relax the control column pressure and manually trim nose-up. Allow the nose to drop below the horizon while trimming. Repeat this sequence until the airplane is trim.

If nose-down trim is required, slowing down and extending the flaps will account for a large degree of nose-up pitch. If this does not allow manual trimming then the reverse "roller coaster" can be performed to permit manual trimming."

Boeing "Airliner" magazine published in May 1961 discussed the above subject as it applied to the Boeing 707 by stating: "To trim the stabilizer manually while holding a high stick force on control column. As the airplane changes altitude, crank in the desired trim change. Correct airplane attitude after a few seconds with elevators. Relax stick force again and crank in more trim. Repeat this procedure as necessary until proper 'trim' position of stabilizer is established."

We learned all about these maneuvers in the 1950-60s. Yet, for some inexplicable reason, Boeing manuals have since deleted what was then - and still is - vital handling information for flight crews. Finally, author D.P.Davies comprehensively covers the subject of large trim changes, failure cases and Mach number effect on stabilizers, at pages 38 to 42 in his fine book "Handling the Big Jets," A good case for current airline pilots to buy his book as it is still the best on the market,

IMHO, perhaps if the crews of the ill-fated Boeing 737-800MAX aircraft were familiar with this advice, current as far back as in 1982 and further back still to Boeing 707 types, they could have applied the roller coaster method to gain manual stabiliser control sooner; rather than be caught out by the stabiliser reaching full forward before attempting to trim manually.

. "In an extreme nose-up out-of-trim condition, requiring almost full forward control column, decelerate, extend the flaps and/or reduce thrust to a minimum practical setting consistent with flight conditions until elevator control is established. Do not decrease airspeed below the minimum maneuvering speed for the flap configuration. A bank of 30 degrees or more will relieve some force on the control column

. This, combined with flap extension and reduced speed should permit easier manual trimming.If other methods fail to relieve the elevator load and control column force, use the "roller coaster" technique. If nose-up trim is required, raise the nose well above the horizon with elevator control. Then slowly relax the control column pressure and manually trim nose-up. Allow the nose to drop below the horizon while trimming. Repeat this sequence until the airplane is trim.

If nose-down trim is required, slowing down and extending the flaps will account for a large degree of nose-up pitch. If this does not allow manual trimming then the reverse "roller coaster" can be performed to permit manual trimming."

Boeing "Airliner" magazine published in May 1961 discussed the above subject as it applied to the Boeing 707 by stating: "To trim the stabilizer manually while holding a high stick force on control column. As the airplane changes altitude, crank in the desired trim change. Correct airplane attitude after a few seconds with elevators. Relax stick force again and crank in more trim. Repeat this procedure as necessary until proper 'trim' position of stabilizer is established."

We learned all about these maneuvers in the 1950-60s. Yet, for some inexplicable reason, Boeing manuals have since deleted what was then - and still is - vital handling information for flight crews. Finally, author D.P.Davies comprehensively covers the subject of large trim changes, failure cases and Mach number effect on stabilizers, at pages 38 to 42 in his fine book "Handling the Big Jets," A good case for current airline pilots to buy his book as it is still the best on the market,

IMHO, perhaps if the crews of the ill-fated Boeing 737-800MAX aircraft were familiar with this advice, current as far back as in 1982 and further back still to Boeing 707 types, they could have applied the roller coaster method to gain manual stabiliser control sooner; rather than be caught out by the stabiliser reaching full forward before attempting to trim manually.

If you relaxed pull at treetop height you would be in the deck before you could trim.

Join Date: Apr 2019

Location: Switzerland

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

34 years aircraft maintenance.

Good post L39 - but MCAS is far from a stall protection (system). MCAS is a system that supplies an a feel to the control column, and the aircraft can fly perfectly without it.

But without MCAS the 737 MAX could not meet the certification requirements for Grandfather rights. Without the Grandfather rights the 737 MAX requires more certification and pilots will require extra training - this would make the MAX less desirable/competitive.

So the task was to incorporate a new system without calling it "new" and retain Grandfather rights. It seems to me that the priority was the "extra training" being minimal between the MAX and other 737's (you heavily touched training in your reply) and the result was a few hours of slides on an iPad that included nothing on the new system.

...

Good post L39 - but MCAS is far from a stall protection (system). MCAS is a system that supplies an a feel to the control column, and the aircraft can fly perfectly without it.

But without MCAS the 737 MAX could not meet the certification requirements for Grandfather rights. Without the Grandfather rights the 737 MAX requires more certification and pilots will require extra training - this would make the MAX less desirable/competitive.

So the task was to incorporate a new system without calling it "new" and retain Grandfather rights. It seems to me that the priority was the "extra training" being minimal between the MAX and other 737's (you heavily touched training in your reply) and the result was a few hours of slides on an iPad that included nothing on the new system.

...

Thanks for your replies.

Join Date: Jul 2011

Location: Canada

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Fly the damn airplane...

34 years aircraft maintenance.

Good post L39 - but MCAS is far from a stall protection (system). MCAS is a system that supplies an a feel to the control column, and the aircraft can fly perfectly without it.

But without MCAS the 737 MAX could not meet the certification requirements for Grandfather rights. Without the Grandfather rights the 737 MAX requires more certification and pilots will require extra training - this would make the MAX less desirable/competitive.

Good post L39 - but MCAS is far from a stall protection (system). MCAS is a system that supplies an a feel to the control column, and the aircraft can fly perfectly without it.

But without MCAS the 737 MAX could not meet the certification requirements for Grandfather rights. Without the Grandfather rights the 737 MAX requires more certification and pilots will require extra training - this would make the MAX less desirable/competitive.

An MCAS failure, owing to the sensor failure (birdstrike or whatever other cause), causing the nose to pitch down in manual flight with the flaps up, presents identical characteristics to the pilot as a stab trim runaway (nose down) which has been taught on this aircraft forever. I can see why Boeing did not want to complicate things by creating a separate MCAS procedure as this would cause pilots to try to differentiate between a classic stab trim runaway and an MCAS failure while the aircraft is out-of-control. And since the emergency response is identical there is nothing to be gained either by trying to diagnose the problem in the air.

Although it might be politically more correct (optics) to insist on simulator training as the Transport Minister in Canada is doing, what is one going to practice? Airspeed Unreliable, which is part of the training and type certificate already? Stab trim runaway, which is part of the training and type certificate already too?

Join Date: Oct 2011

Location: Lower Skunk Cabbageland, WA

Age: 74

Posts: 354

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: May 2010

Location: Boston

Age: 73

Posts: 443

Likes: 0

Received 0 Likes

on

0 Posts

An MCAS failure, owing to the sensor failure (birdstrike or whatever other cause), causing the nose to pitch down in manual flight with the flaps up, presents identical characteristics to the pilot as a stab trim runaway (nose down) which has been taught on this aircraft forever. I can see why Boeing did not want to complicate things by creating a separate MCAS procedure as this would cause pilots to try to differentiate between a classic stab trim runaway and an MCAS failure while the aircraft is out-of-control. And since the emergency response is identical there is nothing to be gained either by trying to diagnose the problem in the air.

A MCAS checklist could stress both the need for and safety of -fully- trimming before using the cutout switches to avoid possibility of manual trim not working due to aero loads.

Had this been included in the AD in response to Lion Air it may have helped.

In roughly the time it takes to read this post MCAS provided 2 nose down inputs to ET.

Join Date: Aug 2000

Posts: 1,500

Likes: 0

Received 0 Likes

on

0 Posts

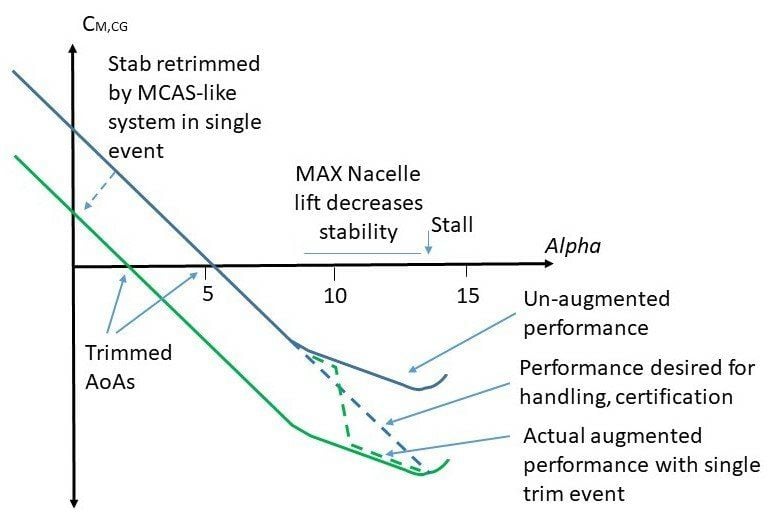

FCeng84 earlier in this thread provided a really good explanation of what MCAS is all about; it's not there to provide a "feel" but rather to provide positive stability at high angles of attack (alphas). This is FAR's, EASA and every other certification agency requirement that the aircraft not be neutrally stable (nothing happens) or negatively stable (gets worse) near the stall but instead is positively stable (gets better but lowering the alpha). It only kicks in near the stall, assuming the sensors are working properly.

An MCAS failure, owing to the sensor failure (birdstrike or whatever other cause), causing the nose to pitch down in manual flight with the flaps up, presents identical characteristics to the pilot as a stab trim runaway (nose down) which has been taught on this aircraft forever. I can see why Boeing did not want to complicate things by creating a separate MCAS procedure as this would cause pilots to try to differentiate between a classic stab trim runaway and an MCAS failure while the aircraft is out-of-control. And since the emergency response is identical there is nothing to be gained either by trying to diagnose the problem in the air.

Although it might be politically more correct (optics) to insist on simulator training as the Transport Minister in Canada is doing, what is one going to practice? Airspeed Unreliable, which is part of the training and type certificate already? Stab trim runaway, which is part of the training and type certificate already too?

An MCAS failure, owing to the sensor failure (birdstrike or whatever other cause), causing the nose to pitch down in manual flight with the flaps up, presents identical characteristics to the pilot as a stab trim runaway (nose down) which has been taught on this aircraft forever. I can see why Boeing did not want to complicate things by creating a separate MCAS procedure as this would cause pilots to try to differentiate between a classic stab trim runaway and an MCAS failure while the aircraft is out-of-control. And since the emergency response is identical there is nothing to be gained either by trying to diagnose the problem in the air.

Although it might be politically more correct (optics) to insist on simulator training as the Transport Minister in Canada is doing, what is one going to practice? Airspeed Unreliable, which is part of the training and type certificate already? Stab trim runaway, which is part of the training and type certificate already too?

Itís a different animal and doesnít bite the same way.

Join Date: Oct 2011

Location: Lower Skunk Cabbageland, WA

Age: 74

Posts: 354

Likes: 0

Received 0 Likes

on

0 Posts

Join Date: Feb 2019

Location: shiny side up

Posts: 431

Likes: 0

Received 0 Likes

on

0 Posts

Quote: Is there an indication at what AoA the bump in lift occurs?

Depends on many other factors. (All I know is what I read here.)

Depends on many other factors. (All I know is what I read here.)

I am trying to word this correctly...

Join Date: Dec 2015

Location: Cape Town, ZA

Age: 62

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

for want of more accurate values, the nacelle lift region stretches from AoA 8' to 14' (where the wing stalls)

Join Date: Dec 2015

Location: Cape Town, ZA

Age: 62

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

It is a shame that the Mentour Pilot video has been disabled, I managed to watch it and it showed what happens when the IAS disagree and runaway trim checklist are followed in the (presumed) ET MCAS case. Overall fairly similar to your scenario.

The pilots in the sim calmly and methodically followed the checklists in what I would call a demonstrating or teaching mode, certainly not stressed or surprised. Don't believer they even had a stick shaker going.

Even so they ended up in a state where manual trim inputs were physically close to impossible after electrical trim cutout due to the air speed.

My takeaway was that unless the pilot trimmed close to neutral before electrical tim cutout there was no way to manually trim.

Note that this should be possible (as shown in both lion air flights) since pilot trim cancels (for 5 seconds) MCAS trim actions.

One other observation from the video is that from the jumpseat camera point of view the trim wheel action is very obvious. I suspect it might be much less so for stressed pilots trying to make sense of the situation. This may be why the jumpseat pilot was able to save the penultimate Lion air flight.

The pilots in the sim calmly and methodically followed the checklists in what I would call a demonstrating or teaching mode, certainly not stressed or surprised. Don't believer they even had a stick shaker going.

Even so they ended up in a state where manual trim inputs were physically close to impossible after electrical trim cutout due to the air speed.

My takeaway was that unless the pilot trimmed close to neutral before electrical tim cutout there was no way to manually trim.

Note that this should be possible (as shown in both lion air flights) since pilot trim cancels (for 5 seconds) MCAS trim actions.

One other observation from the video is that from the jumpseat camera point of view the trim wheel action is very obvious. I suspect it might be much less so for stressed pilots trying to make sense of the situation. This may be why the jumpseat pilot was able to save the penultimate Lion air flight.

Edit: Skip forward to 10 mins to see the actual footage.

Join Date: Mar 2019

Location: Bavaria

Posts: 20

Likes: 0

Received 0 Likes

on

0 Posts

OK, first: I'm not a pilot, I'm a functional safety engineer, mostly working for automotive.

Second: I read this thread from the beginning and learned a lot, thanks!

But I think I can explain one tendency which went up:

Pilots blame the pilots, engineers blame the Boeing engineers.

From my point of view, the reason in both cases is the same:

Pilots know the processes and trained procedures for pilots and learned, that the crews didn't follow them completely and textbook-like but rather improvised. But they do not know the engineering process regarding safety-critical systems/hardware/software.

With the engineers it is exactly otherwise. They see a crew overwhelmed by alarms, shakers and informations caused by an engineering error. For them (sorry) the pilot is the last line of defense in case they did not do their job of everything goes wrong (multiple point fault).

Pilots follow procedures which e.g. minimize the risk to take off with a wrong configuration, They double-check and check again and have proven-in-use procedures which make sure that such things happen less than one in a million flights.

Engineers know proven-in-use processes which make sure that something like the current MCAS system effectively never happens.

Still it happened.

Boeing knows why they put all focus on how great they fix MCAS because if someone asks the right question, they are in much deeper trouble like, for example Volkswagen:

The big punishment for them was not fixing the cars but they had to implement a process that makes sure that this never happens again.

So far nobody asked Boeing how something so obvious and big could slip thru their safety process including document reviews, walk-thru, inspections, accessments and linked documents on several layers of detail. And, in addition, how this would not be found in all the classic safety/quality analysis methods (FMEDA, FMEA, FTA, DFA...).

Safety is not based on the genius of the one great programmer who is also a pilot and simulates every thin in his head (but makes a mistake after having too much pizza) but rather a strict process including a lot of people and a lot of documentation and testing.

Within this thread, pilots question the training and qualification of mainly all pilots regarding critical situations. But they are the last line of defense.

Following the same logic, one could question the qualification, independence and culture of Boeing safety engineers.

And yes, that would lead to the question if there are other functions like MCAS still hidden...

Maybe the pilots may have been able to safe a few lives, but the biggest mistakes happened years before driven by

-> Strange laws (Grandfather rights)

-> Commercial interest (no training)

-> inconsistent requirements / documentation (0,6 within risk analysis and 2.5 within SW)

-> Maybe bad safety culture if this was done on purpose and not by mistake

-> Mistakes within the impact analysis of a wrong MCAS activation

If I would be a member of the FAA or similar organization, I would not focus on MCAS and the bugfix, I would simply aks: What went wrong within the engineering process and how can you prove that no other hazards excaped thru the exact same hole in your process.

The deviation from established engineering rocesses I assume here in my opinion far exceeds the deviation between the trim runaway procedure and what actually happened.

But as mentioned: I'm not a pilot.

Second: I read this thread from the beginning and learned a lot, thanks!

But I think I can explain one tendency which went up:

Pilots blame the pilots, engineers blame the Boeing engineers.

From my point of view, the reason in both cases is the same:

Pilots know the processes and trained procedures for pilots and learned, that the crews didn't follow them completely and textbook-like but rather improvised. But they do not know the engineering process regarding safety-critical systems/hardware/software.

With the engineers it is exactly otherwise. They see a crew overwhelmed by alarms, shakers and informations caused by an engineering error. For them (sorry) the pilot is the last line of defense in case they did not do their job of everything goes wrong (multiple point fault).

Pilots follow procedures which e.g. minimize the risk to take off with a wrong configuration, They double-check and check again and have proven-in-use procedures which make sure that such things happen less than one in a million flights.

Engineers know proven-in-use processes which make sure that something like the current MCAS system effectively never happens.

Still it happened.

Boeing knows why they put all focus on how great they fix MCAS because if someone asks the right question, they are in much deeper trouble like, for example Volkswagen:

The big punishment for them was not fixing the cars but they had to implement a process that makes sure that this never happens again.

So far nobody asked Boeing how something so obvious and big could slip thru their safety process including document reviews, walk-thru, inspections, accessments and linked documents on several layers of detail. And, in addition, how this would not be found in all the classic safety/quality analysis methods (FMEDA, FMEA, FTA, DFA...).

Safety is not based on the genius of the one great programmer who is also a pilot and simulates every thin in his head (but makes a mistake after having too much pizza) but rather a strict process including a lot of people and a lot of documentation and testing.

Within this thread, pilots question the training and qualification of mainly all pilots regarding critical situations. But they are the last line of defense.

Following the same logic, one could question the qualification, independence and culture of Boeing safety engineers.

And yes, that would lead to the question if there are other functions like MCAS still hidden...

Maybe the pilots may have been able to safe a few lives, but the biggest mistakes happened years before driven by

-> Strange laws (Grandfather rights)

-> Commercial interest (no training)

-> inconsistent requirements / documentation (0,6 within risk analysis and 2.5 within SW)

-> Maybe bad safety culture if this was done on purpose and not by mistake

-> Mistakes within the impact analysis of a wrong MCAS activation

If I would be a member of the FAA or similar organization, I would not focus on MCAS and the bugfix, I would simply aks: What went wrong within the engineering process and how can you prove that no other hazards excaped thru the exact same hole in your process.

The deviation from established engineering rocesses I assume here in my opinion far exceeds the deviation between the trim runaway procedure and what actually happened.

But as mentioned: I'm not a pilot.

Join Date: Jan 2008

Location: Hotel Sheets, Downtown Plunketville

Age: 76

Posts: 0

Likes: 0

Received 0 Likes

on

0 Posts

There was a time when pilots talked about the laws of aerodynamics in a language that was clear, concise and understood by the aviation community. Now the language has changed, it is full of computer terminology. Yet despite all that talk about all sorts of wizardry with computers, the laws of aerodynamics remain unchanged. It is those that have resulted in a ten meter crater in this instance, it is that very combat between this new phenomenon and the basics of aerodynamics that we seem to put our faith and trust . I ask this question, Is the whole scenario really that much different to the VW emissions scandal.

Join Date: Jul 2011

Location: Canada

Posts: 55

Likes: 0

Received 0 Likes

on

0 Posts

Not exactly the same signs as stab trim runaway which would be trained/expected to be continuous whereas MCAS (unpatched) worked in up to 10 second bursts then stops until the next pilot trim input.

A MCAS checklist could stress both the need for and safety of -fully- trimming before using the cutout switches to avoid possibility of manual trim not working due to aero loads.

Had this been included in the AD in response to Lion Air it may have helped.

In roughly the time it takes to read this post MCAS provided 2 nose down inputs to ET.

A MCAS checklist could stress both the need for and safety of -fully- trimming before using the cutout switches to avoid possibility of manual trim not working due to aero loads.

Had this been included in the AD in response to Lion Air it may have helped.

In roughly the time it takes to read this post MCAS provided 2 nose down inputs to ET.

What does continuous mean? 5 seconds, 10 seconds, 1 minute, one hour? And let's say that the uncommanded stabilizer trim movement is caused by an intermittent short circuit somewhere (trim switch, wiring harness, etc) that produces a 5 second, 10 second, 1 minute uncommanded stabilizer trim movement? How can you tell the difference? Do you really care what the source is? Does the source affect the outcome? Do you really think that someone flying along, fat, dumb and happy and suddenly has the nose pitch down will have the presence of mind to count how long the trim is moving? I would suggest the shock value would preclude that.

As well, one does not want to get into the game of diagnosing the source of the failure (MCAS or otherwise) while the control of the aircraft is at stake. One checklist to cover all scenarios is more than adequate. Secure the malfunction, fly the airplane and land asap and save the diagnosis and troubleshooting once you're back on terra firma.

Psychophysiological entity

We keep going back to the limited electrical trimming applied by the captain. Or should it be electrical trimming achieved?

I'm really puzzled by the fuzzy inputs - just about on the centre vertical of the graph. More like noise than a specific thumb input, or even a few inputs.

I'm really puzzled by the fuzzy inputs - just about on the centre vertical of the graph. More like noise than a specific thumb input, or even a few inputs.

Join Date: Jan 2018

Location: Gold coast

Posts: 32

Likes: 0

Received 0 Likes

on

0 Posts

Hi all

just read an interesting news story about all cirrus vision jets being grounded due to faulty aoa information forcing the nose down in some instances

https://www.flyingmag.com/faa-ground...us-vision-jets

just read an interesting news story about all cirrus vision jets being grounded due to faulty aoa information forcing the nose down in some instances

https://www.flyingmag.com/faa-ground...us-vision-jets

Join Date: May 2010

Location: Boston

Age: 73

Posts: 443

Likes: 0

Received 0 Likes

on

0 Posts

The Runaway Stabilizer checklist states "Condition: Uncommanded stabilizer trim movement occurs continuously". I think we can agree that an MCAS event is "uncommanded".

What does continuous mean? 5 seconds, 10 seconds, 1 minute, one hour? And let's say that the uncommanded stabilizer trim movement is caused by an intermittent short circuit somewhere (trim switch, wiring harness, etc) that produces a 5 second, 10 second, 1 minute uncommanded stabilizer trim movement? How can you tell the difference? Do you really care what the source is? Does the source affect the outcome? Do you really think that someone flying along, fat, dumb and happy and suddenly has the nose pitch down will have the presence of mind to count how long the trim is moving? I would suggest the shock value would preclude that.

As well, one does not want to get into the game of diagnosing the source of the failure (MCAS or otherwise) while the control of the aircraft is at stake. One checklist to cover all scenarios is more than adequate. Secure the malfunction, fly the airplane and land asap and save the diagnosis and troubleshooting once you're back on terra firma.

What does continuous mean? 5 seconds, 10 seconds, 1 minute, one hour? And let's say that the uncommanded stabilizer trim movement is caused by an intermittent short circuit somewhere (trim switch, wiring harness, etc) that produces a 5 second, 10 second, 1 minute uncommanded stabilizer trim movement? How can you tell the difference? Do you really care what the source is? Does the source affect the outcome? Do you really think that someone flying along, fat, dumb and happy and suddenly has the nose pitch down will have the presence of mind to count how long the trim is moving? I would suggest the shock value would preclude that.

As well, one does not want to get into the game of diagnosing the source of the failure (MCAS or otherwise) while the control of the aircraft is at stake. One checklist to cover all scenarios is more than adequate. Secure the malfunction, fly the airplane and land asap and save the diagnosis and troubleshooting once you're back on terra firma.

My point was more about the nature of the emergency AD that could have been much clearer about uncommanded trim that stops with any pilot trim then restarts about 5 seconds later.

In that case stress importance of first fully trimming then hitting cutout.

This is hinted at in a note at the end of the procedure, I say it should have been highlighted.

Unlike 'stuck switch" uncommanded trim the MCAS case does allow for pilot electrical trim first then followed by cutout, a quick blip of the switch is all that would be needed to test if this was possible. That could be a step in the runaway trim procedure, I agree do not need a seperate MCAS checklist if that was included.

As I said before I am sure Boeing pilots/engineer could come up with a clear procedure if given the mandate to do so.