AAIB BA38 B777 Initial Report Update 23 January 2008

Join Date: May 2002

Location: Canada

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

There is one thing many of you seem to be forgetting.........

The fuel was never exposed to -70 outside air temperature (SAT or Static Air Temp). The wings and fuel temperatures would have been much warmer due to the heating effect of Ram Air (TAT or Total Air Temp)

The coldest the fuel should have been during the flight is -37C.

The fuel was never exposed to -70 outside air temperature (SAT or Static Air Temp). The wings and fuel temperatures would have been much warmer due to the heating effect of Ram Air (TAT or Total Air Temp)

The coldest the fuel should have been during the flight is -37C.

That is not true of the 6 different aircraft types I have operated

(Lockheed, Boeing, Airbus) In my experience any prolonged exposure to a SAT of -60 or more has caused fuel temps well below -37C and required a modification to the flight envelope. The small Airbus models are especially affected.

Last edited by Tree; 27th Jan 2008 at 17:39.

Join Date: Jan 2008

Location: Ireland

Posts: 27

Likes: 0

Received 0 Likes

on

0 Posts

Chambudzi:

Then I stand corrected and withdraw my refutation.

RRAAMJET:

As I mentioned in my post, I am NOT an expert, I just happen to work with solvents, some of which are various types of kerosene. I certainly do not work with them at these extremely low temperatures, in fact I only mentioned it to explain my interest in this angle of speculation. Unfortunately my lack of expertise means I cannot answer your questions without resorting to speculation and guesswork.

I was flying a 747 that morning across Russia and Germany, landing in LHR at 0500am from the Far East. I have never had to decend to a lower FL in order to increase my fuel temperatue in 25 years of jet flying. That particular morning I had to go down for the last hour of cruise to FL250 before my fuel temp began to warm up. Every other jet in my vicinity that day also decended for the same reasons and some were unable to decend as low as requested. IE Qantas, Malasian and Thai Air) There was an unusually cold air mass over S Russia and Germany that day so it could well have been the cause of the 777s problems.

RRAAMJET:

A question for the kerosene expert above: does increased flow rate in cold-soaked fuel cause a greater propensity for any water particles in suspension to form ice crystals upon hitting the face of a filter or pump casing? ie: if the EEC's commanded more thrust and hence increased fuel flow, could this cause instantaneous increase in ice crystal formation?

I have had it explained to me once that a filter face can cause a multitude of microscopic points of decreased pressure perpendicular to the direction of flow, much as we all learned during fluid dynamics with a varying pipe diameter.

I have had it explained to me once that a filter face can cause a multitude of microscopic points of decreased pressure perpendicular to the direction of flow, much as we all learned during fluid dynamics with a varying pipe diameter.

Join Date: Jan 2008

Location: Minneapolis MN USA

Posts: 16

Likes: 0

Received 0 Likes

on

0 Posts

The Boeing site discussion of fuel waxing is worth a read. It leads to one question regarding the 777:

"The 777 has a fuel temperature probe located between ribs 9 and 10 of the left main tank. The probe is approximately 12.6 in from the lower wing skin and is located one rib over, approximately 40 in outboard, from the aft boost pump inlet. "

The question is how empty will this tank be when the fuel temp sensor is dry and no longer accurate?

The other part of the Boeing discussion involves the possible mixture of fuel with differing

freezing points in the same tank, and the statement that the fuel fraction with the highest freezing point will start contributing wax crystals to the liquid first. If these crystals behave anything like those in water-alcohol-gasoline mixes, they will tend to pile up like slush on the first obstruction like a filter or orifice, retarding but not entirely blocking flow.

Any informed comment available on this?

The Boeing page is:

http://www.boeing.com/commercial/aeromagazine/aero_16/polar_story.html

scroll down to section 3, "Polar Fuel Management"

"The 777 has a fuel temperature probe located between ribs 9 and 10 of the left main tank. The probe is approximately 12.6 in from the lower wing skin and is located one rib over, approximately 40 in outboard, from the aft boost pump inlet. "

The question is how empty will this tank be when the fuel temp sensor is dry and no longer accurate?

The other part of the Boeing discussion involves the possible mixture of fuel with differing

freezing points in the same tank, and the statement that the fuel fraction with the highest freezing point will start contributing wax crystals to the liquid first. If these crystals behave anything like those in water-alcohol-gasoline mixes, they will tend to pile up like slush on the first obstruction like a filter or orifice, retarding but not entirely blocking flow.

Any informed comment available on this?

The Boeing page is:

http://www.boeing.com/commercial/aeromagazine/aero_16/polar_story.html

scroll down to section 3, "Polar Fuel Management"

Registered User

Join Date: Dec 2000

Location: Romania

Age: 73

Posts: 19

Likes: 0

Received 0 Likes

on

0 Posts

Low fuel temp.

Many years ago I was flying the old IL-18. Of course it was in the winter of 1990, January to be exact. Fueled home then in Shannon than in Keflavik. Then what???? Aha so next came the beautiful sight of Greenland and in my mind came the big question does them stop or not? The type in the epoque had .3% super anti-ice liquid in fuel. Because we did not added 'I' liquid at the last two fueling stops, my hart gone small. I was flying to Gander like a ghost. Never ever from that moment on I didn't ignore the fuel temp. gauge.

Join Date: Sep 2000

Location: min rest

Posts: 424

Likes: 0

Received 0 Likes

on

0 Posts

If the crew observed themselves undershooting the touchdown aiming point so badly they would not even make the runway then they would have immediately attempted to go around.....an item on a B767 go around is to select flaps 20.....possibly this is also true on the B777....

failing to get any thrust...they elected to then landed straight ahead....Hopefully everything regarding the pressing of goaround mode and the throttle lever position for goaround...pitch attitude transiting to go around target pitch... etc will all be recorded on the tapes...and this IMHO could explain the flaps 20 position.

failing to get any thrust...they elected to then landed straight ahead....Hopefully everything regarding the pressing of goaround mode and the throttle lever position for goaround...pitch attitude transiting to go around target pitch... etc will all be recorded on the tapes...and this IMHO could explain the flaps 20 position.

Join Date: May 2000

Location: Camp X-Ray

Posts: 2,135

Likes: 0

Received 0 Likes

on

0 Posts

An unlikely scenario. If the crew saw themselves going into the undershoot they'd have tried to add more power, then more, then even more until they realised they weren't getting anything. It seems unlikely they'd have reverted to the standard call of "Go around,flap 20" call at that stage.

The AAIB do not issue statements which are untrue, they might be vague but that is because they are still unsure of the cause of the accident. One post states that they are looking at the quality of the fuel in China, I would be surprised if they didn't examine the fuel. If the crew were at fault by ignoring fuel temp warnings they would have said so, the flight was said to be uneventful, would a fuel temp warning be considered an event, I think not. This accident appears to be an engineering problem, are we going to see a pilot on TV explaining what happened, it's about time we saw a BA engineer on TV giving an explanation.

Last edited by Oldlae; 27th Jan 2008 at 22:14. Reason: Spelling

Join Date: Nov 1999

Posts: 324

Likes: 0

Received 0 Likes

on

0 Posts

A Clarification (perhaps)

Your argument seems to hinge on one premise: that the Trent-engine equivalent of the GE90's Ps3 and P3B sensors (which you refer to as "FADEC's reference port lines") could have been blocked by the icy component in cold, waxy fuel (see your post, paragraphs f, g and h).

Not quite what was said however....

.

Obviously post 79 on this thread was poorly worded so....for the purists and theoretical puritans:

.

"the FADEC's reference ports" Long-winded version

.

A FADEC has the following functions:

fuel-flow regulation (inc monitoring accelerations and decelerations)

automatic start sequence

transmitting eng data to panel insts

thrust management and protection of limits

prevention of overtemperature and overspeed

.

Few would therefore dispute that it (the FADEC) determines HP fuel input to the engine. But how would it do that (i.e. schedule the fuel supply rate to the engine) - if it has no access to LP fuel-flow data? Therefore it has "reference ports". But how does the FADEC access these?

.

Nine of Honeywell's LG-1237 Smart Pressure Transducers are used in the FADEC II (Full Authority Digital Engine Control) of the GE-90. The LG-1237's micro-controller measures air data (temps, density and pressures) for calibration, measurement and control of engine fuel flows. It also performs other measurement, control, communication, computation and self-test roles within the transducer.

.

FADEC II uses these transducers to sense pressures within the engine's core stages and those external to the core. LG1237's provide the pressure measurement feedback required for the engine's closed loop control system (aka a bootstrapping system). Internal algorithms determine the appropriate fuel flows (hence power output) and seek to optimize engine efficiency for a large number of variables. It provides a mechanism for detecting degraded performance or required maintenance that may occur as a result of normal erosion, service damage (such as bird, hail or water ingestion) or other transitory impediments such as icing within fuel, intakes or nacelles. LG1237 is

essential to the FADEC's primary function of determining (i.e. apportioning) the fuel-flow that goes to the engine and for bypassing any excess that may not be required.

.

Functional Description

A bypass valve bypasses, to the input side of the pump, a portion of the pressurized fuel flow before it reaches the flow meter. An electronic control unit is included that receives the LG1237 signal and in response thereto adjusts the bypass valve until the measured fuel flow equals the FADEC's predetermined desired (i.e. appropriate for the conditions) fuel flow stored in the electronic control unit. The FADEC controls the operation of the engine including the fuel control system. In particular, the FADEC adjusts the area of the metering valve so that the fuel flow (Wfm) exiting the metering valve is delivered in accordance with the following equation.

.

Wf=CA(ΔP)1/2

.

where C is a fuel flow constant and A is the area of the metering valve. Though not shown, a linear variable displacement transducer, (LVDT), is mounted to the metering valve to provide a feedback signal to the FADEC indicative of the position of the metering valve.

.

Summary

The objective is to provide a fuel system for delivering fuel from a fuel source to the combustor in a gas turbine engine by having a pump receiving LP fuel flows from the fuel source and producing a pressurized fuel flow that flows to a flow meter that will measure that fuel flow and generate an input signal (Wf). The FADEC's electronic control unit receives that Wf signal and in response thereto adjusts the bypass valve until the measured fuel flow (i.e. output) equals a predetermined desired fuel flow (wfm) stored in the electronic control unit. The bypass valve bypasses, to the input side of the pump, that calculated excess portion of the pressurized fuel flow before it reaches the flow meter.

.

Thus, a fuel system is provided that controls fuel flow based on a measured and calibrated fuel flow requirement. Environmental calibration inputs are derived from the FADEC's LG1237 transducers.

.

The contention is that anything stickily globular (i.e. unctuous see #3) in that LP fuel supply could prove to be a "real ball of wax" - as far as the FADEC's computational algorithms go (all other "air" pressures notwithstanding.

Join Date: Jul 2004

Location: Found in Toronto

Posts: 615

Likes: 0

Received 0 Likes

on

0 Posts

Lost in Saigon;

That is not true of the 6 different aircraft types I have operated

(Lockheed, Boeing, Airbus) In my experience any prolonged exposure to a SAT of -60 or more has caused fuel temps well below -37C and required a modification to the flight envelope. The small Airbus models are especially affected.

That is not true of the 6 different aircraft types I have operated

(Lockheed, Boeing, Airbus) In my experience any prolonged exposure to a SAT of -60 or more has caused fuel temps well below -37C and required a modification to the flight envelope. The small Airbus models are especially affected.

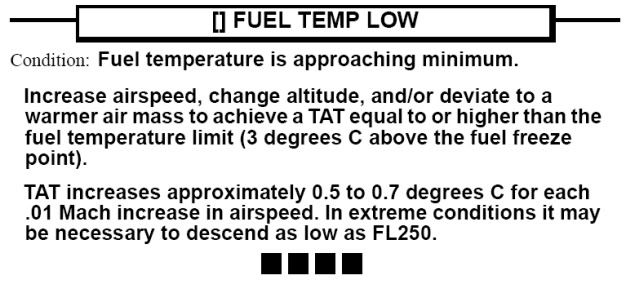

I agree that a SAT of -60C can cause fuel to temps to drop below -37C.

But in that case you will get a warning, and if you follow the proper procedure, the fuel temp will not exceed -37C.

The proper procedure is to simply increase Mach or descend until you reach a TAT of -37C or greater. The SAT will still be well below -37C, but that doesn't matter because it is the TAT that will determine the fuel temp.

Join Date: Feb 2004

Location: Australia

Posts: 1,307

Likes: 0

Received 0 Likes

on

0 Posts

"The engines may have spooled down low enough to cause the generators to trip off line...."

"ps Does anyone know whether they tried EEC ALTN or even would it have made any difference IF it had been a FADEC fault? I know that on each start attempt the EEC's (on a 737) use the other channel. Or which thread and page this was discussed?"

Few would therefore dispute that it (the FADEC) determines HP fuel input to the engine. But how would it do that (i.e. schedule the fuel supply rate to the engine) - if it has no access to LP fuel-flow data? Therefore it has "reference ports". But how does the FADEC access these?

An important point that nobody seems to have mentioned is that Jet A-1 does not definately freeze at -47C

-47C is the specified minimum for a fuel tested by method IP16/ASTM D 2386 under the conditions of test

It is determined by cooling a 25ml sample while stirring vigorously until visible wax crystals appear, then allowing the tube to warm up (while continuing stirring) until the crystals disappear, at which point the temperature is recorded as the freezeing point.

In the real world (ie in an aircraft wing), fuel is obviously stored in bulk, and is not subject to stirring (though presumable some mixing due to fuel recirculation?). The fuel would probably be subject to differential cooling, with relatively cold layers around the tank bulkheads, and a relatively warmer section in the bulk. Accordingly, the conditions in an aircraft fuel tank will be very unlike the standardised conditions of a lab test, and waxing conditions will accordingly differ.

This, in my view, will greatly add to the difficulty of the investigation if fuel waxing is suspected as a cause.

-47C is the specified minimum for a fuel tested by method IP16/ASTM D 2386 under the conditions of test

It is determined by cooling a 25ml sample while stirring vigorously until visible wax crystals appear, then allowing the tube to warm up (while continuing stirring) until the crystals disappear, at which point the temperature is recorded as the freezeing point.

In the real world (ie in an aircraft wing), fuel is obviously stored in bulk, and is not subject to stirring (though presumable some mixing due to fuel recirculation?). The fuel would probably be subject to differential cooling, with relatively cold layers around the tank bulkheads, and a relatively warmer section in the bulk. Accordingly, the conditions in an aircraft fuel tank will be very unlike the standardised conditions of a lab test, and waxing conditions will accordingly differ.

This, in my view, will greatly add to the difficulty of the investigation if fuel waxing is suspected as a cause.

Re. Unctuous posts #156 (Jan28/05:23) and #79 (Jan26/16:34)

Unctuous, you are now weakening the credibility of your hypothesis - quite unnecessarily - by being selective in your quoting of my criticism, and ignoring that from A380focal. [See both on #141 (Jan27/16:14)]

Your case is based on possible fuel blockages in components of the engine fuel system. You should now admit that your original argument in #79 contained a genuine misunderstanding of the rôles of sensors Ps3 and P3b in supplying air pressure data (NOT fuel pressure data) to the FADEC on the GE90 engine.

Quote from your #79:

f. In this theory there's no suggestion of any blockage of the main HP or LP fuel supply lines. The blockages would have been in the FADEC's reference port lines (only). As the GE engine's AD at this link says: "...simultaneous Loss of thrust control events on both engines installed on the Boeing 777 series aircraft due to common mode threats, such as certain atmospheric conditions that may result in ice in the Ps3 or P3B pressure sensing system and causing corrupted signals to the FADEC in both engines."

g. It's not just probable, but obvious therefore from the FAA's concerns, that a "corrupted signal" will cause a FADEC lockup. Why "wax" and not just ice? Water in suspension in fuel tends to stay that way, however once a fuel "waxes" it takes on an icy constituency, and a component of the mass will be water (in ice form).

(Unquote)

That a blockage in any pressure-sensing system is likely to corrupt the data received at the FADEC is bleedin' obvious, even to your most uninformed reader. Any comparison of the mechanism of rain freezing in an air-pressure sensor with waxy fuel blocking a fuel sensor, however, was plainly fatuous.

If you had known they were air-pressure sensors, you would not have attempted to make the comparison.

If and when you are prepared to admit that gaff, many of us non-engineers may be prepared to take your interesting arguments more seriously.

Your case is based on possible fuel blockages in components of the engine fuel system. You should now admit that your original argument in #79 contained a genuine misunderstanding of the rôles of sensors Ps3 and P3b in supplying air pressure data (NOT fuel pressure data) to the FADEC on the GE90 engine.

Quote from your #79:

f. In this theory there's no suggestion of any blockage of the main HP or LP fuel supply lines. The blockages would have been in the FADEC's reference port lines (only). As the GE engine's AD at this link says: "...simultaneous Loss of thrust control events on both engines installed on the Boeing 777 series aircraft due to common mode threats, such as certain atmospheric conditions that may result in ice in the Ps3 or P3B pressure sensing system and causing corrupted signals to the FADEC in both engines."

g. It's not just probable, but obvious therefore from the FAA's concerns, that a "corrupted signal" will cause a FADEC lockup. Why "wax" and not just ice? Water in suspension in fuel tends to stay that way, however once a fuel "waxes" it takes on an icy constituency, and a component of the mass will be water (in ice form).

(Unquote)

That a blockage in any pressure-sensing system is likely to corrupt the data received at the FADEC is bleedin' obvious, even to your most uninformed reader. Any comparison of the mechanism of rain freezing in an air-pressure sensor with waxy fuel blocking a fuel sensor, however, was plainly fatuous.

If you had known they were air-pressure sensors, you would not have attempted to make the comparison.

If and when you are prepared to admit that gaff, many of us non-engineers may be prepared to take your interesting arguments more seriously.

Join Date: Dec 1998

Location: England

Posts: 242

Likes: 0

Received 0 Likes

on

0 Posts

Missing the (any?) POINT here

Chris Scott

So you're saying that UNCTUOUS could read the GE AD's message (below) and yet still assume that the PS3 and P3B sense lines were fuel lines that incorporated weep holes that would release water but not fuel. Methinks you are stretching credibility more than a mite.

From the GE AD:

"Both Ps3 and P3B pressure systems incorporate weep holes that allows drainage of water in the lines that may accumulate from condensation or ingested water; however, the field events and the investigation have determined that these design features may not always be effective in eliminating water from these systems."

"GE is assessing design changes that will prevent water from freezing in these systems and causing corruption of the signals to the FADEC."

I've followed UNCTUOUS posts throughout the threads and the message that I got was simply that there is a proven capacity for the FADEC's signals to be corrupted by ice and or waxed fuel in the Fadec/EEC sensing. His #79 description of the freezing/waxing process for why and how that would happen when it did seems very credible to me.

as UNCTUOUS says in his #79

"the FADEC's reference ports (i.e. the small diameter lines of those bootstrap labyrinths that, together with various air pressure pick-offs, establish the FADEC's reference datums)....."

Obviously he's talking about what he later (#154) describes in his functional description as: <<<The FADEC's electronic control unit receives that Wf signal and in response thereto adjusts the bypass valve until the measured fuel flow (i.e. output) equals a predetermined desired fuel flow (wfm) stored in the electronic control unit.>>>

So I for one, don't see your diatribe as contributing anything to the discussion of the probabilities for BA038's very worrying simultaneous LOTC. But UNCTUOUS does seem to have his eye on the ball, notwithstanding that his expression sometimes lacks clarity. To make sure that I had a handle on his points I went back and re-read. If you don't agree with the physics of waxing and it being able to pass through filters yet still corrupt Fadecs, then point out why.

So you're saying that UNCTUOUS could read the GE AD's message (below) and yet still assume that the PS3 and P3B sense lines were fuel lines that incorporated weep holes that would release water but not fuel. Methinks you are stretching credibility more than a mite.

From the GE AD:

"Both Ps3 and P3B pressure systems incorporate weep holes that allows drainage of water in the lines that may accumulate from condensation or ingested water; however, the field events and the investigation have determined that these design features may not always be effective in eliminating water from these systems."

"GE is assessing design changes that will prevent water from freezing in these systems and causing corruption of the signals to the FADEC."

I've followed UNCTUOUS posts throughout the threads and the message that I got was simply that there is a proven capacity for the FADEC's signals to be corrupted by ice and or waxed fuel in the Fadec/EEC sensing. His #79 description of the freezing/waxing process for why and how that would happen when it did seems very credible to me.

as UNCTUOUS says in his #79

"the FADEC's reference ports (i.e. the small diameter lines of those bootstrap labyrinths that, together with various air pressure pick-offs, establish the FADEC's reference datums)....."

Obviously he's talking about what he later (#154) describes in his functional description as: <<<The FADEC's electronic control unit receives that Wf signal and in response thereto adjusts the bypass valve until the measured fuel flow (i.e. output) equals a predetermined desired fuel flow (wfm) stored in the electronic control unit.>>>

So I for one, don't see your diatribe as contributing anything to the discussion of the probabilities for BA038's very worrying simultaneous LOTC. But UNCTUOUS does seem to have his eye on the ball, notwithstanding that his expression sometimes lacks clarity. To make sure that I had a handle on his points I went back and re-read. If you don't agree with the physics of waxing and it being able to pass through filters yet still corrupt Fadecs, then point out why.

Join Date: Feb 1999

Location: land of the long BLUE cloud

Posts: 402

Likes: 0

Received 0 Likes

on

0 Posts

I am not BA, but believe Flap25 is their standard landing flap on 777.

I also understand they had had an continuous(ish) descent, and no holding LAM or elsewhere.

I also understand they had had an continuous(ish) descent, and no holding LAM or elsewhere.

Hi OVERTALK,

You are right: you have missed my point. The point is that the characteristics of rain freezing in an air-pressure sensor is irrelevant to what might happen when waxy fuel enters a fuel sensor, line, valve or filter (see my 4th paragraph). Why did Unctuous raise the subject of the freezing problem in Ps3 and P3B sensors, when it is irrelevant to possible freezing in engine fuel sensors?

That does not necessarily mean that I dismiss his and others' arguments about possible ice or waxed fuel corrupting fuel data to the FADEC/EEc in either the GE90 or Trent engines. Like you, I am following the debate with interest, as indicated in my final paragraph.

You are right: you have missed my point. The point is that the characteristics of rain freezing in an air-pressure sensor is irrelevant to what might happen when waxy fuel enters a fuel sensor, line, valve or filter (see my 4th paragraph). Why did Unctuous raise the subject of the freezing problem in Ps3 and P3B sensors, when it is irrelevant to possible freezing in engine fuel sensors?

That does not necessarily mean that I dismiss his and others' arguments about possible ice or waxed fuel corrupting fuel data to the FADEC/EEc in either the GE90 or Trent engines. Like you, I am following the debate with interest, as indicated in my final paragraph.

Join Date: Aug 2005

Location: London

Posts: 78

Likes: 0

Received 0 Likes

on

0 Posts

re recorded fuel data

Surely the reference to 'recorded fuel data' is simply a recognition of the obvious fact that a standard check with the aircraft lying on the ground after a considerable amount had leaked out anyway would have been a poor indication of how much was present at the time of the occurrence. The recorded data would presumably have included the tanks figure as well as that derived from the fuel flow measurement (totalizer in Boeing speak). If the flight was as uneventful as the AAIB hinted, there presumably weren't any fuel measurement status messages either.

Join Date: May 2002

Location: Canada

Posts: 155

Likes: 0

Received 0 Likes

on

0 Posts

I agree that a SAT of -60C can cause fuel to temps to drop below -37C.

But in that case you will get a warning, and if you follow the proper procedure, the fuel temp will not exceed -37C.

The proper procedure is to simply increase Mach or descend until you reach a TAT of -37C or greater. The SAT will still be well below -37C, but that doesn't matter because it is the TAT that will determine the fuel temp.

But in that case you will get a warning, and if you follow the proper procedure, the fuel temp will not exceed -37C.

The proper procedure is to simply increase Mach or descend until you reach a TAT of -37C or greater. The SAT will still be well below -37C, but that doesn't matter because it is the TAT that will determine the fuel temp.

I will await the FDR report to see what procedure was followed. There are instances in the high Arctic where even Jet-B+ has "gelled" or "waxed" when the surface and operating flight level temperatures were lower than -50C. The only fuel that does not "freeze" is Diesel Fuel Arctic P-50. Of course it is "unapproved" for aviation use.