Turbulence and feet per second

Join Date: Jul 2005

Location: Queensland

Posts: 686

Likes: 0

Received 0 Likes

on

0 Posts

A few inches is probably a bit of an overestimate. (male problem) The few inches of movement I was referring to is the amount the whole aft end of the aircraft moves.( NOT the movement of the stabilizer tip relative to the fuselage. Anyway just move it enough so you hear the oil canning and know you are putting a bit of pressure on those critical attach brackets which unfortunately can't be seen.

Cheers RA

Cheers RA

Join Date: Feb 2009

Location: dans un cercle dont le centre est eveywhere et circumfernce n'est nulle part

Posts: 2,606

Likes: 0

Received 0 Likes

on

0 Posts

CPA E-ATIS

Volume 15 Issue 05

May 1, 2012

CESSNA CALLS FOR INSPECTION OF LOWER SPAR CAP ON CANTILEVER WING 210’s, FAA TO FOLLOW WITH AN IMMEDIATELY ADOPTED RULE AIRWORTHINESS DIRECTIVE

Friday April 27th Cessna issued Service Letter SEL-57-01 which calls out for a visual inspection of the first 20 inches of the lower spar cap on both wings of 210s with over 5,000 hours total time in service. On aircraft with more than 10,000 hours an external visual inspection must be done before further flight and an internal visual inspection within the next 5 hours. On aircraft with between 5,000 and 10,000 hours an internal visual inspection must be done within 25 hours. On all aircraft with more than 5,000 hours this internal visual inspection must be repeated every 100 hours or 12 months whichever occurs first.

Cessna made a presentation to the FAA’s Wichita Aircraft Certification Office (ACO) on Friday April 27th during which Cessna requested that the FAA issue an airworthiness directive. Cessna’s presentation so impressed the ACO that at a meeting on Monday April 30th they decided to issue an Immediately Adopted Rule (IAR) that puts the AD in effect with no comment or input from the public or industry until after the fact. This IAR process is supposed to be used only in cases where the threat to public safety is so severe as to preclude the FAA from using its normal rulemaking procedures.

Interestingly, according to the FAA not one cracked spar cap has been found to date on aircraft operated in the US.

So what brought this all about? Look to the Land Down Under. Australia’s Civil Aviation Safety Authority (CASA) is that country’s equivalent to the US’s FAA. CASA reported to Cessna and the FAA that they had reports of 7 incidents of spar cap cracks on Cessna 210s and that this problem was “common knowledge” in that country. The FAA looked around and could find no reports of spar cap cracks in the US but did find one from Canada. Meanwhile these reports had Cessna’s attention big time and they started writing a service bulletin to deal with it.

CPA first became aware of what was in the wind when we were provided a draft of Cessna’s service bulletin late the afternoon of Friday April 27th. A call to the FAA picked up that there was going to be a meeting on Monday April 30th to decide what action to take.

This is serious business and could have a profound effect on the 210 fleet and the value of the aircraft.

As this was a shot out of the blue for us, CPA staff had to get up to speed quickly. Tom Carr was already here in Santa Maria to teach a 210 class. Phil Kirkham of Coastal Valley Aviation was involved in the class as well. I called Paul New at Tennessee Aircraft and got him on board. Paul is more knowledgeable about the spar system on the 210 than anyone else as he repairs them. So I had a top team of people available to sort this issue out.

The first thing we determined was that none of us had seen or heard of cracks in the lower spar cap on the 210. On Sunday (Monday in Australia) I spoke with three repair stations in Australia, including the largest Cessna Service Center in the country, and none of them knew anything about it. So much for the problem being common knowledge.

Second thing we discovered is that the inspection cannot be carried out with a light and a mirror as called for in the Cessna service bulletin. You can see most of the cap with a light and a mirror but not all of the cap area called out for inspection. This is particularly true for aircraft with de-ice boots and/or avionics bays in the wings. Later we found out that the people at Cessna involved in writing the service bulletin hadn’t actually gone out and looked at a real 210 in this area, they were working from drawings and memory.

And what about those 7 reports in Australia? I searched 10 years of CASA Service Difficulty Reports and could not find a single reference to this. There also were no Australian ADs, Bulletins or Advisories. So how does anyone know about these 7 aircraft. On Sunday, their Monday, I placed a call to CASA and they actually called me back. It turns out that CASA has only two confirmed reports of spar cap cracks. These reports are very recent and apparently have not made their SDR listing yet. The aircraft involved had 15,000 hours and 5,600 hours.

It is the 5,600 hour aircraft that is causing all the knee jerk reaction by government agencies and Cessna. That is way to low a time for this sort of thing to occur, though at this time extenuating circumstances have not been found. However no one from CASA has looked at this aircraft. And what about the other 5 incidents in Australia? Well it seems as if somebody has recently mentioned these aircraft to CASA and now CASA is trying to find out more. So solid, verifiable cases? Only 2, not 7. Throw in the SDR from Canada and that makes 3. So it is 3 aircraft verified, not 8.

And what happened to these aircraft with cracked spar caps? Were the cracked spar caps thrown away? Cessna hasn’t sold a lower spar cap in 6 years. The Canadian aircraft did buy a new wing from Cessna, I am told.

Apparently the FAA and Cessna became aware of these cases in Australia about 10 days ago and have been running around like chickens with their heads cut off since. There are three verified incidents, no accidents, and no cases in the US. These cantilever wing Cessna 210s have been flying for 45 years without this problem rearing its ugly head, you would think we could take more than a few days to gather data and get this right.

First of all somebody knowledgeable needs to look at the 210L in Australia that had a spar cap failure at 5,600 hours (or 5,750 hours, they don’t seem quite able to pin that down). That number is so out of line that we have to be suspicious. Was the spar cap heat treat correct when it was originally manufactured? Was the spar assembled correctly at the factory? Was the aircraft equipped with tip tanks at any time (which would have greatly increased the stress on the lower spar cap)? Was corrosion involved?

The other two verified incidents are on aircraft with over 10,000 hours each, but Cessna’s SB and the impending AD subject a much larger portion of the fleet to onerous inspections because of this one airplane that hasn’t been very well scrutinized?

And here is another little twist. Australia changed their rules a few years ago and now requires their mechanics to abide by FAA issued ADs. CASA only issues a Australian AD if the FAA chooses to pass on issuing an AD on a subject that CASA thinks an AD should be issued on. Instead of rushing off to impose rules, without public input, that will affect 210s in the US where this problem has not been seen, perhaps the FAA should say to CASA, ‘We’d like to help you, bloke, but we need more data, particularly on the low time incident.”

We don’t know yet what the Immediately Adopted Rule AD is going to say, but it really shouldn’t include the reoccurring 100 hour or 12 months inspection called for in Cessna’s new SB. That is something that does not fall any where near the requirements for bypassing public input, and so far there appears to be no engineering data to support it.

Cessna’s SEL-57-01 requires that operators report the results of the inspections, cracks or no cracks, to Cessna. If the FAA is going to impose an Immediately Adopted Rule then the reports should come to the FAA, not Cessna, so that they will be available for public scrutiny. In fairness to Cessna, the factory has always been open about sharing information CPA has requested. However on an issue this big and important it is in everyone’s best interest, including Cessna’s, that there be transparency.

So, on to the inspection. Basically inspection panels are removed on the bottom skin of the aircraft to gain access to the wing spar assembly from the wing root at station 25.52 outboard 20 inches to station 45.00. This is the area where the Huck bolts sandwich the spar cap, spar fittings and spar web together. The spar cap is a tee shaped extrusion with the vertical portion of the tee fastened between the spar fittings and web. The wing skins are lap joint riveted to the cross of the tee.

The area to be inspected is the fore and aft flanges of the spar cap and as much of the vertical flange as can be seen. First the area has to be cleaned. Depending on the conditions the aircraft has been operated in this can range from blowing out with shop air to repeatedly brushing in Varsol and then blasting shop air.

Once clean the edge and face of the flange is visually inspected for cracks. Several of us tried doing this with a light and a mirror but weren’t real happy with what we could see. It became clear if the aircraft had avionics bays and/or deice boots a light and a mirror wasn’t going to cut it. We tried various optical devices with limited success. Then I found the perfect tool at, of all places, Harbor Freight. It is called a High Resolution Digital Inspection Camera with Recorder. Item 67980. On sale for $200. This little flexible ecoscope can fit about anywhere. It takes pictures and videos. It can be hooked up to a monitor or computer. But most importantly we could see all of the spar cap including sections of the vertical. The inspection should take an hour to two hours depending on how much cleaning has to be done. So the inspection shouldn’t be particularly a problem unless of course cracks are found.

This is a developing situation so you can expect change to occur. Right now if you have a high time 210 I think I would hold off until some of this gets sorted out. At this time there is no requirement that you have the inspection done though it will be mandated shortly by an Airworthiness Directive. It going to take Cessna a bit of time to straighten out their service bulletin and then the FAA a bit more time to promulgate their Airworthiness Directive. CPA staff believes when the time comes to get the inspection, it best be done by shops that are intimatelyfamiliar with the 210 and these sorts of inspections. CPA will keep you informed.

You can read and print Cessna Service Letter SEL-57-01 here

We are posting spar pictures provided by Paul New. Links below:

Photo 1

Photo 2

Photo 3

Photo 4

Photo 5

Photo 6

Photo 7

Photo 8

Photo 9

Photo 10

Photo 11

Join Date: Feb 2009

Location: dans un cercle dont le centre est eveywhere et circumfernce n'est nulle part

Posts: 2,606

Likes: 0

Received 0 Likes

on

0 Posts

CPA E-ATIS

Volume 15 Issue 06

May 2, 2012

UPDATE ON 210 SPAR CAP ISSUE

Well, when you stir the pot things happen. An update on the 210 wing spar cap service bulletin.

-Turns out Cessna has not asked for an airworthiness directive. I was told that by someone at the factory that was not in the meeting. Cessna left the action decision solely to the FAA.

-Some felt that when I said people with high time aircraft should hold off getting an inspection until this gets sorted out, that I meant it ain’t that big a deal wait awhile. What I meant was hold off until Cessna gets their service bulletin cleaned up and with the right information in it. I expect that will take less than a week.

-The hours on the low time airplane in Australia have been confirmed at 5750 hrs not 5600.

-Two more aircraft in Australia have been verified to have had cracked spar caps. One is a 12,000 hour 210L and the other is 9,000 hour 210M owned by a CPA member.

-The FAA has told us that they are requesting further information from CASA on the 5750 hour aircraft. As they say in Australia – Good on ya, mate.

-CPA has provided Cessna and the FAA a list of areas we think the service bulletin needs to be corrected, clarified and improved.

-Paul New at Tennessee Aircraft has now done 5 inspections, Phil Kirkham at Coastal Valley had done one (actually kind of more than that as he was looking at spar caps with us all weekend). No cracks found so far. If someone feels they want the inspection right now, either one of those shops would be good places to have it done. And Yingling in Wichita can certainly go on the list.

-It's becoming clear that if the aircraft does not have boots or wing avionics bays the inspection can be done with a light and a mirror. If it has either of those a thin flexible borescope will be needed.

That’s the update as of Wednesday May 2nd.

Originally Posted by Oktas8

das uber soldat, and makeithappencaptain,

That aeroplane did not crash because the pilot went ten or twenty knots too fast in turbulence. If you have read the report behind it, perhaps you might tell us what led to the crash. (Exceeded Va by 10 or 20kts in moderate turbulence on an otherwise fine day? Ha ha.)

That aeroplane did not crash because the pilot went ten or twenty knots too fast in turbulence. If you have read the report behind it, perhaps you might tell us what led to the crash. (Exceeded Va by 10 or 20kts in moderate turbulence on an otherwise fine day? Ha ha.)

At 7000 ft 3 deg OAT, thats an IAS of 145 KIAS. Published Va for the shrike is 141 KIAS. The thing was 400 kg below MTOW so reduce that to 131 kts, making the a/c at best estimate, 14 KIAS over Va at the point of failure.

"That aeroplane did not crash because the pilot went ten or twenty knots too fast in turbulence." - The final report suggests this is exactly what happened.

So Yeh, you've lost me.

Last edited by das Uber Soldat; 3rd May 2012 at 17:52.

Join Date: Oct 2007

Location: Tjuntjuntjarra

Age: 54

Posts: 336

Likes: 0

Received 0 Likes

on

0 Posts

Two more aircraft in Australia have been verified to have had cracked spar caps. One is a 12,000 hour 210L and the other is 9,000 hour 210M owned by a CPA member.

Join Date: May 2012

Location: Wichita, Kansas

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

Cessna SEL-57-01

Please let it be noted that the notice Cessna published is a "Service Letter" not a "Service Bulletin" which I myself found rather strange because of the subject matter and importance which Cessna made this alert.

Thank you for the referral by the way. Yingling is your one stop shop for Cessna products.

Thank you for the referral by the way. Yingling is your one stop shop for Cessna products.

Join Date: May 2012

Location: Wichita, Kansas

Posts: 2

Likes: 0

Received 0 Likes

on

0 Posts

Here is an explaination from Cessna concerning the issuance of Service Bulletins and Service Letters

Q: What is the difference between a Service Bulletin and a Service Letter.

A: Service Bulletins are technical documents that provide parts, instructions and approval for incorporation of an installation, modification or repair to a specific Cessna airplane by model and unit number. They are used to announce special product inspection criteria and modifications, revised maintenance information, operational information which is intended to assist in improving aircraft safety, reliability, durability, or performance.

There are four compliance categories for service bulletins and are defined as follows:

Q: What is the difference between a Service Bulletin and a Service Letter.

A: Service Bulletins are technical documents that provide parts, instructions and approval for incorporation of an installation, modification or repair to a specific Cessna airplane by model and unit number. They are used to announce special product inspection criteria and modifications, revised maintenance information, operational information which is intended to assist in improving aircraft safety, reliability, durability, or performance.

There are four compliance categories for service bulletins and are defined as follows:

A. MANDATORY. Cessna's compliance level for a service document that must be accomplished for continued airworthiness under 14 CFR 43.13.

B. RECOMMENDED. Cessna's compliance level for a service document that modifies or changes and airplane system that are intended to improve dispatch reliability which should be accomplished within the specified time requirements.

C. DISCRETIONARY. Cessna's compliance level for a service document that modifies or changes and airplane system that is intended to improve dispatch reliability which can be accomplished at the discretion of the airplane owner.

D. OPTIONAL. Cessna's compliance level for a service document that installs, upgrades components, systems, or the airframe at the customer's request. Optional service bulletins are accomplished at the customer's expense.

Service Letters provide Information important to the maintenance and operation of airplanes. While Service letters might provide instructions on how to accomplish a task they do not provide parts and approval for the work accomplished.</STRONG>

B. RECOMMENDED. Cessna's compliance level for a service document that modifies or changes and airplane system that are intended to improve dispatch reliability which should be accomplished within the specified time requirements.

C. DISCRETIONARY. Cessna's compliance level for a service document that modifies or changes and airplane system that is intended to improve dispatch reliability which can be accomplished at the discretion of the airplane owner.

D. OPTIONAL. Cessna's compliance level for a service document that installs, upgrades components, systems, or the airframe at the customer's request. Optional service bulletins are accomplished at the customer's expense.

Join Date: Jul 2005

Location: Queensland

Posts: 686

Likes: 0

Received 0 Likes

on

0 Posts

Aileron 69

I understand you do a lot of low level often rough air flying. Referring to those two 210s,which suffered spar cap failures at similar airframe hours could you give an estimate of the percentage of each aircrafts TT spent in rough air. I realize you probably didn't operate them from new but a rough estimate might be educational for other C210 owners. I know some of the Northern Territory mail planes have around 30,000 hours and I haven't heard of spar cap problems. They have rough air but would mostly fly above it. It's just the short sector routes that would be all rough.

Cheers RA

I understand you do a lot of low level often rough air flying. Referring to those two 210s,which suffered spar cap failures at similar airframe hours could you give an estimate of the percentage of each aircrafts TT spent in rough air. I realize you probably didn't operate them from new but a rough estimate might be educational for other C210 owners. I know some of the Northern Territory mail planes have around 30,000 hours and I haven't heard of spar cap problems. They have rough air but would mostly fly above it. It's just the short sector routes that would be all rough.

Cheers RA

Join Date: Oct 2007

Location: Tjuntjuntjarra

Age: 54

Posts: 336

Likes: 0

Received 0 Likes

on

0 Posts

Gday Rutan,

Both the 210s that had spar cap cracks had long range flint tip tanks on them and probably spent at least half of their 14000 hours below 300feet in the 'rough stuff.' Its a pretty hard life for the old girls and the tip tanks dont really help.

Both the 210s that had spar cap cracks had long range flint tip tanks on them and probably spent at least half of their 14000 hours below 300feet in the 'rough stuff.' Its a pretty hard life for the old girls and the tip tanks dont really help.

Links don't work....

mhtml B39EE9F3-2420-4EFA-9500-3C893C85FAB8}mid://00000020/!x-usc:http://www.cessna.org/atis/1505/210_spar_1.JPG

B39EE9F3-2420-4EFA-9500-3C893C85FAB8}mid://00000020/!x-usc:http://www.cessna.org/atis/1505/210_spar_1.JPG

You need to delete all that rubbish in front of..... http://www.cessna.org/atis/1505/210_spar_1.JPG

mhtml

B39EE9F3-2420-4EFA-9500-3C893C85FAB8}mid://00000020/!x-usc:http://www.cessna.org/atis/1505/210_spar_1.JPG

B39EE9F3-2420-4EFA-9500-3C893C85FAB8}mid://00000020/!x-usc:http://www.cessna.org/atis/1505/210_spar_1.JPGYou need to delete all that rubbish in front of..... http://www.cessna.org/atis/1505/210_spar_1.JPG

Join Date: Jul 2005

Location: Queensland

Posts: 686

Likes: 0

Received 0 Likes

on

0 Posts

Aileron 69

Thanks mate you've cheered me up. My 210 although it has Flint tanks is only a pup at just over 10,000 hours. Also it spends most of it's time in smooth air. It would appear that what's good for me is also good for the plane. I checked with a big 210 operator in WA & NT and they have had no problems even on their 30,000 hr units. My contact said they fly high whenever they can and their fleet doesn't have tip tanks.

Cheers RA

Thanks mate you've cheered me up. My 210 although it has Flint tanks is only a pup at just over 10,000 hours. Also it spends most of it's time in smooth air. It would appear that what's good for me is also good for the plane. I checked with a big 210 operator in WA & NT and they have had no problems even on their 30,000 hr units. My contact said they fly high whenever they can and their fleet doesn't have tip tanks.

Cheers RA

Thread Starter

Join Date: Oct 2011

Location: a spinning rock

Age: 34

Posts: 29

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Captain

@Rutan, I tried your horizontal stabilizer trick on 2 different planes and it looks and sounds like the aircraft skin is just moving and warping. no grossly disturbing knife to the can sound.......

@Rutan, I tried your horizontal stabilizer trick on 2 different planes and it looks and sounds like the aircraft skin is just moving and warping. no grossly disturbing knife to the can sound.......

Join Date: Jul 2005

Location: Queensland

Posts: 686

Likes: 0

Received 0 Likes

on

0 Posts

RE C210 SPAR CAP PROBLEM

I spoke to a Cessna Pilots Assn. technical adviser this morning ( Wed 9-5-12 ) They are still seeking information regarding the supposed spar cap failure on a 210 with only 5,750 hrs I'm not sure they even have its' VH call sign. They would very much like lots of information about this aircraft. Was it ever determined what caused this apparently one off low time failure? How was it operated over its' lifetime prior to failure? Perhaps it tangled with a thunder storm or perhaps the operator had a penchant for aerobatics. Perhaps it was a manufacturing fault. This information is urgently needed to determine the direction of further action. So far in US a few hundred have now been checked and none have been found with cracks.

Anyone out there with information about any 210 spar cap failure please share it with us so appropriate action can be taken. Aileron 69 your information was appreciated.

Cheers RA

I spoke to a Cessna Pilots Assn. technical adviser this morning ( Wed 9-5-12 ) They are still seeking information regarding the supposed spar cap failure on a 210 with only 5,750 hrs I'm not sure they even have its' VH call sign. They would very much like lots of information about this aircraft. Was it ever determined what caused this apparently one off low time failure? How was it operated over its' lifetime prior to failure? Perhaps it tangled with a thunder storm or perhaps the operator had a penchant for aerobatics. Perhaps it was a manufacturing fault. This information is urgently needed to determine the direction of further action. So far in US a few hundred have now been checked and none have been found with cracks.

Anyone out there with information about any 210 spar cap failure please share it with us so appropriate action can be taken. Aileron 69 your information was appreciated.

Cheers RA

Join Date: Jul 2015

Location: NZ

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

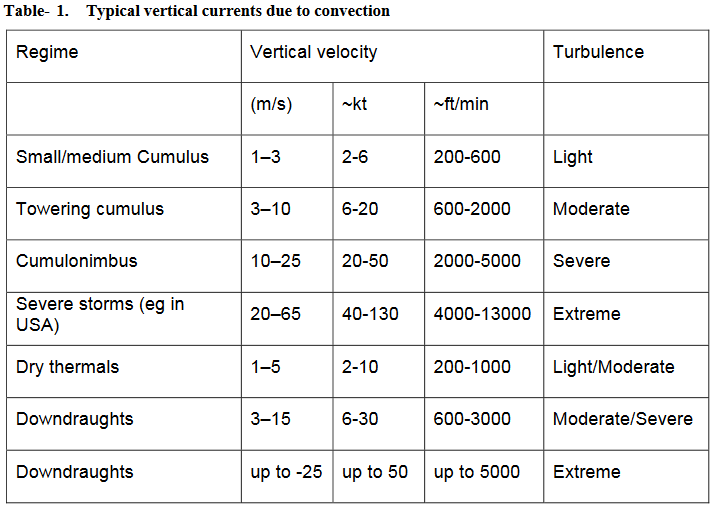

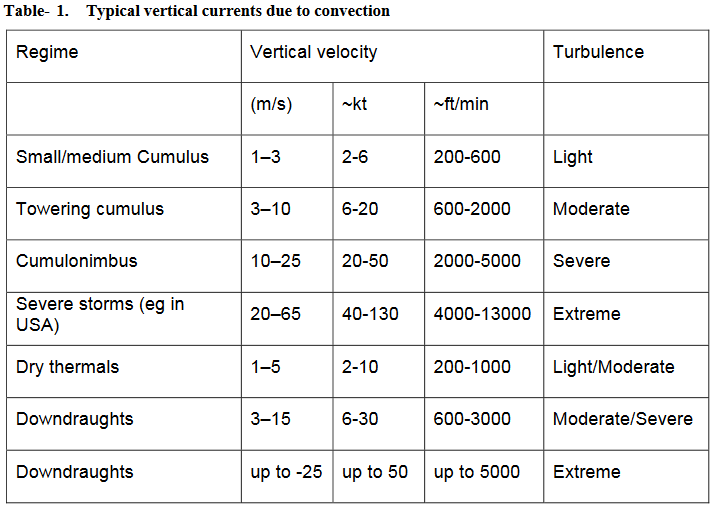

Turbulence Deffinitions

Join Date: Jul 2015

Location: NZ

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

OK I found this from the WMO Technical Regulations, Volume I - General Meteorological Standards and Recommended Practices

https://library.wmo.int/doc_num.php?explnum_id=9359

Does anyone know of any regs for instance in Aircraft Certification that lines up with this?

https://library.wmo.int/doc_num.php?explnum_id=9359

Does anyone know of any regs for instance in Aircraft Certification that lines up with this?