Originally Posted by

MechEngr

I have never seen a tapered groove for a snap ring. .

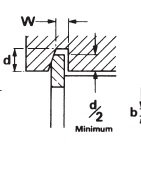

They're not common, but there are beveled snap ring applications out there. As I recall they were used mainly where the retained part was submerged in oil, fuel, or other lubricants. I don't know if this specific installation uses them but if you have access to MIL-SPEC cross-reference tables for TCM parts we can put this topic to rest. TCM P/N: 62104 retaining ring. The applicable spec will be MS16625 internal ring, basic or MS16631 internal ring, beveled.

Originally Posted by

EXDAC

Is there any suggestion that the groove/register is not rectangular section?

Don't know. As noted above if a beveled ring is used in this installation the groove will have a 15 deg taper to match the ring, i.e., the bottom of the groove will be narrower than the top. Just a guess as to why the ring didn't seat. Regardless, if the minimum ear gap wasn't checked by the installer doesn't matter what the groove profile is.