Peter Lemme's Blog on the JT610 accident contains a lot of good information on the 737NG AOA systems which I am going to draw on.

AOA Failure Modes

In this blog, he basically shows that any interference with the signal coming directly from the AOA sensor can be expected to create an error that varies with the indicated angle. By overlaying the left and right AOA signals, he shows that the 22 degree error between the sensors does not vary significantly until the aircraft is on the ground. Therefore we should really look elsewhere in the aircraft for the problem. Due to cross wind effects on the ground, you can understand that there might be some variation while on the ground, but there is one other difference visible in the trace while the aircraft is riding over the bumps in the taxiways, the

electrical noise level!

The trace from the left AOA forms a fat line with numerous spikes and the trace from the right AOA is smooth. This is the smoking gun that gives significant clues as to what may have happened to cause the problem.

In the course of a rather long and varied life, I have had occasion to troubleshoot misbehaving electrical circuits that carry signals, and when I see a circuit responding to vibration, I suspect either a "sneak circuit" or an intermittent circuit. In the case of JT610, other data suggests we are dealing with a sneak circuit, but when you get to the circuit board level where data is manipulated, it could also be an intermittent condition. Typically what you do to troubleshoot these problems is to put your meter/scope into the energized circuit and shake things until you see a response. In this case, we see the response, but we do not know just what got shaken. Instead, we have to infer what might be the problem by looking at the system and where it gets its signals and do a bit of mental exercise.

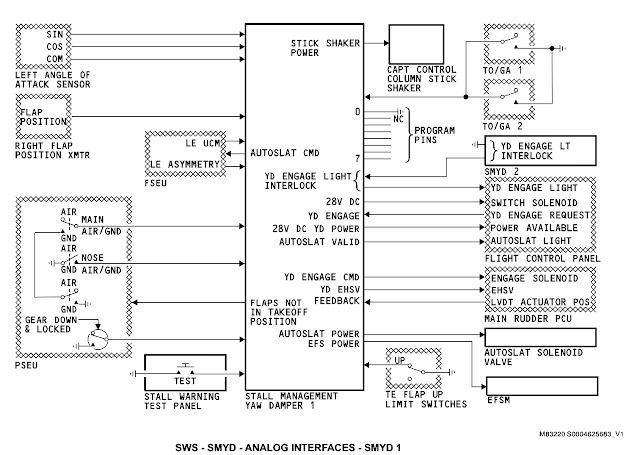

In the top left corner of the Stall Warning System-Stall Management Yaw Damper diagram, we see the signals coming in directly from the AOA resolver.

They do not go through any box to get there. If there were some sort of cross connection in those lines we would see data that varies differently from what we are observing (constant error at all angles while inflight).

This would indicate that the problem is downstream from the wires running to the SMYD. Since Boeing went to a high level of attention to ensure that there is a high level of commonality with prior 737 aircraft, and an ability to interchange between right and left AOA sensors, we should assume that it would be very difficult to mis-install one of these sensors (relatively fool proof). So lets focus our attention down stream on the SMYD box.

I do not have the schematic on this item, so I'm left to improvise by learning what I can about the topic of converting the Sine and Cosine signals inside the SMYD box. One thing I learned is that the signals likely receive conditioning by various circuit elements (amplification and filtering of noise) before being combined into a signal representing an angle.

Background-signal conditioning-resolver to digital converter

There is therefore an area inside the SMYD box that can foul up these angle signals. And what does the SMYD box do? Among other things, it activates the stick shaker!

Now what else do we know about this aircraft? Why it was nearly new! You might even say, it was still on its "shakedown" period. Supposing a loose nut, a blob of solder, or a wire fragment was floating around inside the SMYD box and eventually found the place where it could do the most damage.

Someone at Boeing who knows this system will have to look at the contents of SMYD box to have a chance at finding what failures might behave the way we have seen in the JT610 AOA data, I don't have enough info.

I think the AOA probe change is likely a red herring that can easily lead this accident investigation astray. The core problem is that the system was changed in the MAX, and with it, certain systems became critical. It is true that maintenance did not fix the problem, but given the procedures they were given, would they ever have found the problem without resorting to shotgun type trouble shooting? Does the troubleshooting ever lead to a changeout of the SMYD box?