Clarification A320 QRH Flaps/Slat Failure

Thread Starter

Join Date: Jul 2013

Location: Europe

Posts: 1

Likes: 0

Received 0 Likes

on

0 Posts

Clarification A320 QRH Flaps/Slat Failure

Hello

I just registered here and have a technical question, preparing for my A320 rating.

I am studying the A320 QRH and have a question concerning the section

for speed increments and flaps lever position in case of jammed flaps/slats.

How do I correctly use this table ?

Is the position e.g. "1" or "2" the position of the flap lever for the expected

landing configuration (=normally "3") or the relevant position of the lift device

when the failure happened ?

Example: I fly in Config 1 during approach (Slats out) and when moving

the lever to position "2", my slats become locked by WTB.

Landing configuration would be "Flaps3", so I go to the line with "Flaps3"

and select in the column right of it "1<=Slats<=3" and find a speed increment

of 10 kts ?

PS: How can slats be more than "3" according the table, they have only

3 mechanical positions.....

Any help appreciated....

I just registered here and have a technical question, preparing for my A320 rating.

I am studying the A320 QRH and have a question concerning the section

for speed increments and flaps lever position in case of jammed flaps/slats.

How do I correctly use this table ?

Is the position e.g. "1" or "2" the position of the flap lever for the expected

landing configuration (=normally "3") or the relevant position of the lift device

when the failure happened ?

Example: I fly in Config 1 during approach (Slats out) and when moving

the lever to position "2", my slats become locked by WTB.

Landing configuration would be "Flaps3", so I go to the line with "Flaps3"

and select in the column right of it "1<=Slats<=3" and find a speed increment

of 10 kts ?

PS: How can slats be more than "3" according the table, they have only

3 mechanical positions.....

Any help appreciated....

Join Date: Jun 2007

Location: Wanderlust

Posts: 3,403

Likes: 0

Received 0 Likes

on

0 Posts

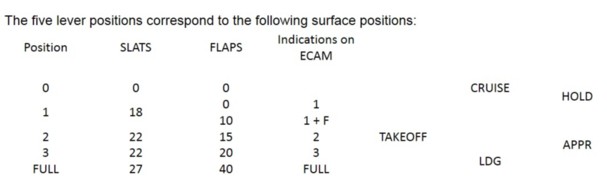

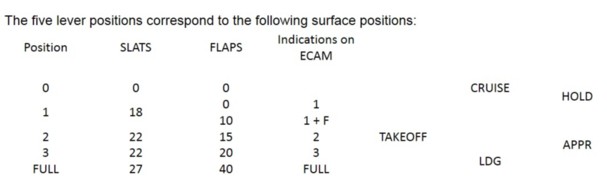

BitHigh

You have to understand the slat flap system. The three positions of slat are 1, 2&3 and full. In approach when you select flap1 only slat moves to one and when you select flap3 only flap moves to three. You will notice in the table slat 2 position is missing. That is because it treated as three. What is given under the title FAILURE is the position of the lift device when failure occurred. In this case 1≤slats≤3 is correct, flap lever for landing is3 and

ΔVref is 10kts is correct.

You have to understand the slat flap system. The three positions of slat are 1, 2&3 and full. In approach when you select flap1 only slat moves to one and when you select flap3 only flap moves to three. You will notice in the table slat 2 position is missing. That is because it treated as three. What is given under the title FAILURE is the position of the lift device when failure occurred. In this case 1≤slats≤3 is correct, flap lever for landing is3 and

ΔVref is 10kts is correct.

Whilst I admire your keenness in trying to prepare for your training, over the years I have found that it can be very counter productive. You can get completely the wrong idea if your not careful and it can be difficult to correct this down the line. Better to just do the course when it comes when everything will be explained in a timely manner and you will avoid getting any preconceived ideas.

Join Date: Jun 2002

Location: Vega Constellation

Posts: 286

Likes: 0

Received 0 Likes

on

0 Posts

The slats are actuated by hydraulics (G&B) and move to their required position along tracks, so as to follow a predesigned curve while extending.

The mechanical transfer is done through a rack and pinion mechanism along some of the slat tracks.

I can imagine that under the worst set of circumstances (end-travel sensor failed, hydraulic valve block damage, etc) the slats could be pushed outwards beyond the last extended position, resulting in the position sensor >3 and some crooked slat position.

That would be a bad day, since with less slats, most pilots can guess what the aircraft behavior can be, but with more slats (and by how much?) , flow separation, aircraft behavior, and low speed characteristics would definitely be situations with unsure outcomes.

Could it be what the table presented tries to address?

The mechanical transfer is done through a rack and pinion mechanism along some of the slat tracks.

I can imagine that under the worst set of circumstances (end-travel sensor failed, hydraulic valve block damage, etc) the slats could be pushed outwards beyond the last extended position, resulting in the position sensor >3 and some crooked slat position.

That would be a bad day, since with less slats, most pilots can guess what the aircraft behavior can be, but with more slats (and by how much?) , flow separation, aircraft behavior, and low speed characteristics would definitely be situations with unsure outcomes.

Could it be what the table presented tries to address?

Last edited by Jetdriver; 31st Jul 2013 at 14:09.

Join Date: Jun 2002

Location: Vega Constellation

Posts: 286

Likes: 0

Received 0 Likes

on

0 Posts

Oh, and there is nothing wrong in getting a head start on your studies/ course, etc.

Some people just like to learn only what comes from the instructor. With regret, in my last 20 years as a professional pilot, I have seen ground or flight instructors with questionable knowledge, although it is not the norm, either not knowing their material, or making up stuff that is imposiible to verify.

Perparing for a type rating and reading ahead while enable you to ask relevant questions.

Keep going.

Some people just like to learn only what comes from the instructor. With regret, in my last 20 years as a professional pilot, I have seen ground or flight instructors with questionable knowledge, although it is not the norm, either not knowing their material, or making up stuff that is imposiible to verify.

Perparing for a type rating and reading ahead while enable you to ask relevant questions.

Keep going.

Join Date: Oct 2009

Location: UK

Posts: 1,270

Likes: 0

Received 0 Likes

on

0 Posts

Hi Flexpwr,

Nothing as complicated as that.

The different 3 Slat positions are illogically given 4 numbers which correspond to the Flap Handle Positions.

This is very confusing for someone using logic.

I can imagine that under the worst set of circumstances (end-travel sensor failed, hydraulic valve block damage, etc) the slats could be pushed outwards beyond the last extended position, resulting in the position sensor >3 and some crooked slat position.

Could it be what the table presented tries to address?

Could it be what the table presented tries to address?

The different 3 Slat positions are illogically given 4 numbers which correspond to the Flap Handle Positions.

This is very confusing for someone using logic.

Join Date: Jun 2002

Location: Vega Constellation

Posts: 286

Likes: 0

Received 0 Likes

on

0 Posts

Rudderrat,

I know your reputation and expertise. Your explanation, although not logical as you said, is acceptable.

Yet I cannot imagine the designers at Airbus would provide Slat/Flap settings or positions that could not be encountered. That does not make sense at all. I know you mentionned to forget any logic, but it is ingrained in aviators to make sense of what they see.

If it is actually the case as you mentioned, why not write down procedures for one wheel spinning backwards after rollout, or flying an ILS inverted?

Maybe I am just naive (and I will admit I have been on more than one occasion), but if your explanation about the slat position holds true, do you not think that someone at Airbus should look into writing down procedures sticking to real life?

No disrespect, but I don't buy the flap handle position thing. Unless it is a gross error from Airbus.

As a logical mind (as you mentioned, although I may not fit the picture here), I expect -demand- to have an explanation or at least a reason for a design, a procedure, or a method of operation. This is why I dug deep into the maintenance manual to try to find an improbable situation whereas slats could be more than 27 degrees. And there is such a scenario. It might be as improbable as winning the lottery, but cannot be ruled out entirely.

I know your reputation and expertise. Your explanation, although not logical as you said, is acceptable.

Yet I cannot imagine the designers at Airbus would provide Slat/Flap settings or positions that could not be encountered. That does not make sense at all. I know you mentionned to forget any logic, but it is ingrained in aviators to make sense of what they see.

If it is actually the case as you mentioned, why not write down procedures for one wheel spinning backwards after rollout, or flying an ILS inverted?

Maybe I am just naive (and I will admit I have been on more than one occasion), but if your explanation about the slat position holds true, do you not think that someone at Airbus should look into writing down procedures sticking to real life?

No disrespect, but I don't buy the flap handle position thing. Unless it is a gross error from Airbus.

As a logical mind (as you mentioned, although I may not fit the picture here), I expect -demand- to have an explanation or at least a reason for a design, a procedure, or a method of operation. This is why I dug deep into the maintenance manual to try to find an improbable situation whereas slats could be more than 27 degrees. And there is such a scenario. It might be as improbable as winning the lottery, but cannot be ruled out entirely.

Join Date: Oct 2009

Location: UK

Posts: 1,270

Likes: 0

Received 0 Likes

on

0 Posts

Hi Flexpwr,

Please see FCOM Aircraft Systems,27 Flight Controls, 30 Flaps & Slats, 20 Controls & Indications, - Pedestal:

Flap Handle Position 2 & 3; Slats = 22°

Flap Handle Position Full; .. Slats = 27° ( >3 in QRH table).

No disrespect, but I don't buy the flap handle position thing. Unless it is a gross error from Airbus.

Flap Handle Position 2 & 3; Slats = 22°

Flap Handle Position Full; .. Slats = 27° ( >3 in QRH table).

Last edited by rudderrudderrat; 4th Aug 2013 at 14:20. Reason: table inserted

Only half a speed-brake

BitHigh

Question answered 100% by villas and r.r.r.

Indeed I know nothing about your background; still it is worthwhile to consider Fly3's comment. The conversion course is demanding and requires a lot of free memory storage to begin with as well as eagerness to listen and learn until the very end. In fact I believe the most important stuff arrives at the later stages when the philosophy of handling abnormals would be explained.

Repeatedly, the trainee gets a little burned out and overloaded towards the end. That's when the overall outcome of the course becomes less then optimal. Most likely to happen with pilots who start studying early and hard on their own, with no expert guidance in how to read the books and see interactions among the systems. Such dedicated people even could get an incorrect grasp of some information which then need to be sorted out, forgotten, and re-learned again, thus making the course harder on themselves.

I see you are actually using a A319 QRH. In case your provider does train to A320 standard, you may be required to undo some bits of knowledge if you go too deep on your own. (180 turn geometry, speedbrake autoretraction, autoland configurations ...).

My recommendation for pre-study would be:

1] Airbus Flight Deck Briefing for Pilots

While not part of the training package these days, the best start to get acquainted with the aircraft, even before one listens to stories and advice from friends already rated. Nice illustrations and fun to read too!

2] CBT chapter Introduction (each system), maybe some systems' Description (Fire prot, Eng, Fuel)

3] Avoid trying to crack the nut on autoflight from books. Would take weeks and not get you any far at all. It is best and easily learned when showed on the MFTD / APT by an instructor, only then pick up the details and reinforce knowledge from the FCOM.

For the training itself, obtain your personal, paper copy of Flight Crew Training Manual. The information there is not available from FCOM, it is pretty much all the instructor should explain verbally. If he omits or you forget, you know where to find it. If the instructor shares his wisdom beyond what's printed, write it down into it. For the first year of opeartion, this could easily become your most valuable resource.

On the other hand, I would suggest the FCOM to be used in the electronic format from day one in order to become proficient as early as possible. The true value of such skill will become obvious once line training starts.

Question answered 100% by villas and r.r.r.

Indeed I know nothing about your background; still it is worthwhile to consider Fly3's comment. The conversion course is demanding and requires a lot of free memory storage to begin with as well as eagerness to listen and learn until the very end. In fact I believe the most important stuff arrives at the later stages when the philosophy of handling abnormals would be explained.

Repeatedly, the trainee gets a little burned out and overloaded towards the end. That's when the overall outcome of the course becomes less then optimal. Most likely to happen with pilots who start studying early and hard on their own, with no expert guidance in how to read the books and see interactions among the systems. Such dedicated people even could get an incorrect grasp of some information which then need to be sorted out, forgotten, and re-learned again, thus making the course harder on themselves.

I see you are actually using a A319 QRH. In case your provider does train to A320 standard, you may be required to undo some bits of knowledge if you go too deep on your own. (180 turn geometry, speedbrake autoretraction, autoland configurations ...).

My recommendation for pre-study would be:

1] Airbus Flight Deck Briefing for Pilots

While not part of the training package these days, the best start to get acquainted with the aircraft, even before one listens to stories and advice from friends already rated. Nice illustrations and fun to read too!

2] CBT chapter Introduction (each system), maybe some systems' Description (Fire prot, Eng, Fuel)

3] Avoid trying to crack the nut on autoflight from books. Would take weeks and not get you any far at all. It is best and easily learned when showed on the MFTD / APT by an instructor, only then pick up the details and reinforce knowledge from the FCOM.

For the training itself, obtain your personal, paper copy of Flight Crew Training Manual. The information there is not available from FCOM, it is pretty much all the instructor should explain verbally. If he omits or you forget, you know where to find it. If the instructor shares his wisdom beyond what's printed, write it down into it. For the first year of opeartion, this could easily become your most valuable resource.

On the other hand, I would suggest the FCOM to be used in the electronic format from day one in order to become proficient as early as possible. The true value of such skill will become obvious once line training starts.

Last edited by FlightDetent; 4th Aug 2013 at 15:21.

Join Date: Jun 2002

Location: Vega Constellation

Posts: 286

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Rudderrat, I can read your table, and there is nothing wrong with it.

I was referring to the table in the first post showing the possibility of slats more than 3 when the flap handle (or config) is in FULL.

I was referring to the table in the first post showing the possibility of slats more than 3 when the flap handle (or config) is in FULL.

Last edited by FLEXPWR; 6th Aug 2013 at 07:02.

Join Date: May 2000

Location: Glorious West Sussex

Age: 76

Posts: 1,020

Likes: 0

Received 0 Likes

on

0 Posts

FLEXPWR

The SLATS>3 position is not necessarily a fault, it happens on every normal CONF FULL landing.... SLATS FULL.

That line on the table will cope with a SLAT FAULT/LOCK occurring during a go-around from a CONF FULL approach, when the handle is moved to FLAP 3 but the SLATS remain at FULL or some intermediate position >3.

You would then land with...

FLAP LEVER 3

FLAPS = 3

SLATS >3

The SLATS>3 position is not necessarily a fault, it happens on every normal CONF FULL landing.... SLATS FULL.

That line on the table will cope with a SLAT FAULT/LOCK occurring during a go-around from a CONF FULL approach, when the handle is moved to FLAP 3 but the SLATS remain at FULL or some intermediate position >3.

You would then land with...

FLAP LEVER 3

FLAPS = 3

SLATS >3