DRIVESHAFT FAILURE

Thread Starter

DRIVESHAFT FAILURE

As an ex military ATCO I was at a small airfield near Shawbury today when I heard ' Driveshaft failure not good'. Could someone explain what would happen if this happens on a rotary

Most likely the driveshaft from the engine to the main rotor gearbox, leading to loss of drive naturally and therefore an autorotation, but also perhaps confusingly to engine overspeed because it's not under load any more.

Just to elaborate on #3.

The different driveshafts are ET (engine to transmission), mast, and TR (tail rotor).

Twin engine helicopters can either have a single driveshaft between a combining gearbox and the main gear box (e.g. Bell 412), or a separate drive shaft from each engine to the main gear box (e.g. S76).

Single engine helicopters have a single driveshaft between the engine and the main gear box.

If you only have a single drive shaft to the main gear box, and it fails, you have 2 issues. Loss of drive to the main rotor, requiring autorotation; and if that engine/s doesn't have an electronic overspeed system it will explode (likely uncontained engine failure). Not that the engine was helping you in any way once the driveshaft failed. So you could have a fire, severed electrics, hydraulics, other damaged components etc etc

If the mast fails (the driveshaft that the main rotor connects to), you'll arrive at the scene of the accident as a passenger.

If the TR driveshaft fails, it doesn't matter how many engines you have, without drive to the tail rotor you'll be shutting down all the engines very soon and executing an autorotation.

The different driveshafts are ET (engine to transmission), mast, and TR (tail rotor).

Twin engine helicopters can either have a single driveshaft between a combining gearbox and the main gear box (e.g. Bell 412), or a separate drive shaft from each engine to the main gear box (e.g. S76).

Single engine helicopters have a single driveshaft between the engine and the main gear box.

If you only have a single drive shaft to the main gear box, and it fails, you have 2 issues. Loss of drive to the main rotor, requiring autorotation; and if that engine/s doesn't have an electronic overspeed system it will explode (likely uncontained engine failure). Not that the engine was helping you in any way once the driveshaft failed. So you could have a fire, severed electrics, hydraulics, other damaged components etc etc

If the mast fails (the driveshaft that the main rotor connects to), you'll arrive at the scene of the accident as a passenger.

If the TR driveshaft fails, it doesn't matter how many engines you have, without drive to the tail rotor you'll be shutting down all the engines very soon and executing an autorotation.

On the B206, if the engine to txmsn driveshaft fails, you still have the drive going back to the tail rotor, which will initially go berserk with the overspeed. The N1 governor should stop the N1 at 105%. Some other aircraft have an overspeed trip and will kindly shut the engine down. Not really needed, if the overspeed is caused by a faulty sensor and it isn't overspeeding at all.

Do not shut down the 206 engine for your auto, or you will lose all tail rotor control, get to the bottom with a big spin, sideways impact, stall flick spin crash burn die.

Do not shut down the 206 engine for your auto, or you will lose all tail rotor control, get to the bottom with a big spin, sideways impact, stall flick spin crash burn die.

"... the tail rotor, which will initially go berserk with the overspeed"

Why would the tail rotor overspeed if the engine to transmission shaft fails? The tail rotor is driven out of the transmission not the engine, right? As long as the MR is driving the transmission (in the absence of the engine input) won't the transmission just drive the TR at the prescribed ratio to MR %?

"Do not shut down the 206 engine for your auto, or you will lose all tail rotor control, get to the bottom with a big spin, sideways impact, stall flick spin crash burn die."

I don't understand that either. What's the difference between "shut down the 206 engine for your auto" and having an actual engine failure auto? The latter needn't spin crash burn die.

All the above is contingent on the main transmission unit driving the TR shaft as well as the MR shaft.

Why would the tail rotor overspeed if the engine to transmission shaft fails? The tail rotor is driven out of the transmission not the engine, right? As long as the MR is driving the transmission (in the absence of the engine input) won't the transmission just drive the TR at the prescribed ratio to MR %?

"Do not shut down the 206 engine for your auto, or you will lose all tail rotor control, get to the bottom with a big spin, sideways impact, stall flick spin crash burn die."

I don't understand that either. What's the difference between "shut down the 206 engine for your auto" and having an actual engine failure auto? The latter needn't spin crash burn die.

All the above is contingent on the main transmission unit driving the TR shaft as well as the MR shaft.

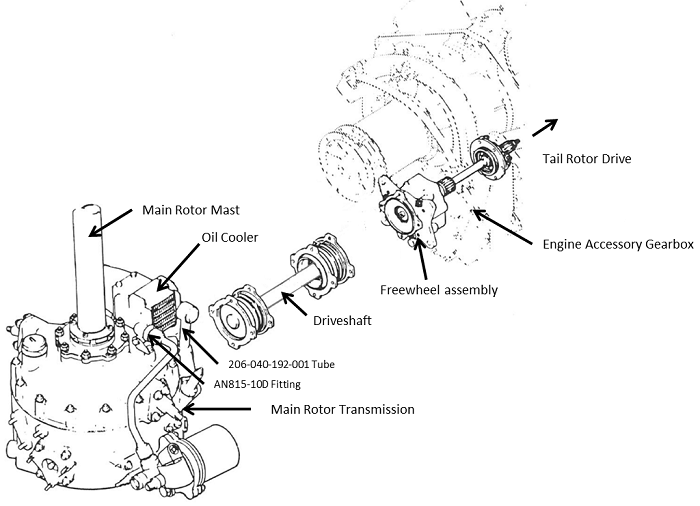

on the 206/407 the T/R driveshaft is driven by the freewheeling unit. If the driveshaft fails the xmsn will not (back) drive the T/R so the engine will be the only drive available for the tail rotor.

hahahaha - priceless!

You guys should stick to flying as your engineering knowledge is just dismal.

About 50% of what is posted so far is close to fact.

You guys should stick to flying as your engineering knowledge is just dismal.

About 50% of what is posted so far is close to fact.

Megan - the S76 tail rotor drive is geared between the two engine inputs / Free wheel units. The C++ will shut down an over speeding engine at 122.5 N1. The tail drive will not be effected.

Krypton asks:

On an engine off auto (have you ever done one? Not just having the engine at idle) you still have control of the tail rotor, unless you are in a 206 with a driveshaft failure and you have shut down the engine. Raising the lever will make the nose go left, through friction, and right pedal should keep you straight.

I seriously hope you are not a 206 pilot. If you are, you need to read the flight manual.

But then why, on a full down engine out auto, is there no torque spin on raising the collective?

I seriously hope you are not a 206 pilot. If you are, you need to read the flight manual.

No need to get snarky, Ascend Charlie.

I am not a Jetranger pilot hence the question and it was clear from the context that I was asking about the Jetranger transmission configuration so not sure why you needed to comment "unless you are in a 206". That's the point of my whole question.

When you say "Raising the lever will make the nose go left, through friction" what do you mean by "friction"? Do you mean "main rotor torque"? Or perhaps drag on the MR creating torque? Well yes I know that.

But when you say "right pedal should keep you straight" - why would pedal do anything at all if the tail rotor is not being driven?

212 Man - thanks for that diagram.

I am not a Jetranger pilot hence the question and it was clear from the context that I was asking about the Jetranger transmission configuration so not sure why you needed to comment "unless you are in a 206". That's the point of my whole question.

When you say "Raising the lever will make the nose go left, through friction" what do you mean by "friction"? Do you mean "main rotor torque"? Or perhaps drag on the MR creating torque? Well yes I know that.

But when you say "right pedal should keep you straight" - why would pedal do anything at all if the tail rotor is not being driven?

212 Man - thanks for that diagram.

The friction referred to is the friction in the main gearbox with all that stuff turning, the residual affect without any power from the engine going into it is for the gearbox to also turn in the same direction the main rotor is turning.

In the B206 the tail rotor might still be turning under power because it's driveshaft comes off the back of the engine reduction gearbox. Hence, right pedal would give you a counter-torque to the drag effect of the main gearbox turning. However, I'd be most surprised if the engine kept running after ET driveshaft failure if it was under load at the time of failure.

In the B206 the tail rotor might still be turning under power because it's driveshaft comes off the back of the engine reduction gearbox. Hence, right pedal would give you a counter-torque to the drag effect of the main gearbox turning. However, I'd be most surprised if the engine kept running after ET driveshaft failure if it was under load at the time of failure.

The friction referred to is the friction in the main gearbox with all that stuff turning, the residual affect without any power from the engine going into it is for the gearbox to also turn in the same direction the main rotor is turning.

In the B206 the tail rotor might still be turning under power because it's driveshaft comes off the back of the engine reduction gearbox. Hence, right pedal would give you a counter-torque to the drag effect of the main gearbox turning. However, I'd be most surprised if the engine kept running after ET driveshaft failure if it was under load at the time of failure.

In the B206 the tail rotor might still be turning under power because it's driveshaft comes off the back of the engine reduction gearbox. Hence, right pedal would give you a counter-torque to the drag effect of the main gearbox turning. However, I'd be most surprised if the engine kept running after ET driveshaft failure if it was under load at the time of failure.

Over fifty years ago on the Bristol Sycamore all practise EOLs were with the engine shut down. There was a cam on the collective that would open the engine to full when you raised the lever to cushion the touchdown; to avoid this the engine had to be shut down on finals when one was sure of arriving at the right place.

The droop stops held the blades clear of the boom on shutdown so in case one of them failed after landing the engine had to be started immediately before the blades slowed down to the critical stage otherwise a blade could hit the boom.

Starting the engine was already a delicate operation to avoid slamming the freewheel unit so you were using three hands and your knees..

The droop stops held the blades clear of the boom on shutdown so in case one of them failed after landing the engine had to be started immediately before the blades slowed down to the critical stage otherwise a blade could hit the boom.

Starting the engine was already a delicate operation to avoid slamming the freewheel unit so you were using three hands and your knees..

I haven't done any sort of research but I've never personally heard of a catastrophic engine failure following a short shaft failure in any Bell. YMMV

A mechanical failure of a driveshaft would most of the time NOT be related to the amount of torque on the shaft.

It could just as easily fail with little or no torque so the hellfire and brimstone regarding overspeed is meaningless.

The N1 governor should stop the N1 at 105%

Electrical overspeed governors are a whole different thing and for different reasons and certification requirements.